Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 200BPH, 4000BPH, 500BPH, 1000BPH, 400BPH, 2000BPH, 100BPH

- Applicable Industries: Machinery Repair Shops, Food & Beverage Factory, Retail, Energy & Mining, Food Shop, Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Farms, Restaurant, Home Use, Printing Shops, Construction works , Food & Beverage Shops, Other, Advertising Company, Factory Production workshop

- Showroom Location: Egypt, Philippines

- Application: Beverage, Commodity, Machinery & Hardware, Chemical, Food

- Packaging Type: Barrel, Bottles, CANS

- Packaging Material: Metal, Plastic

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Place of Origin: Shanghai, China

- Brand Name: VKPAK

- Dimension(L*W*H): 2000*1500*1950mm

- Weight: 1000 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Filling Material: Oil, Water, Juice, Detergent

- Filling Accuracy: ±1%, ±1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 5 years

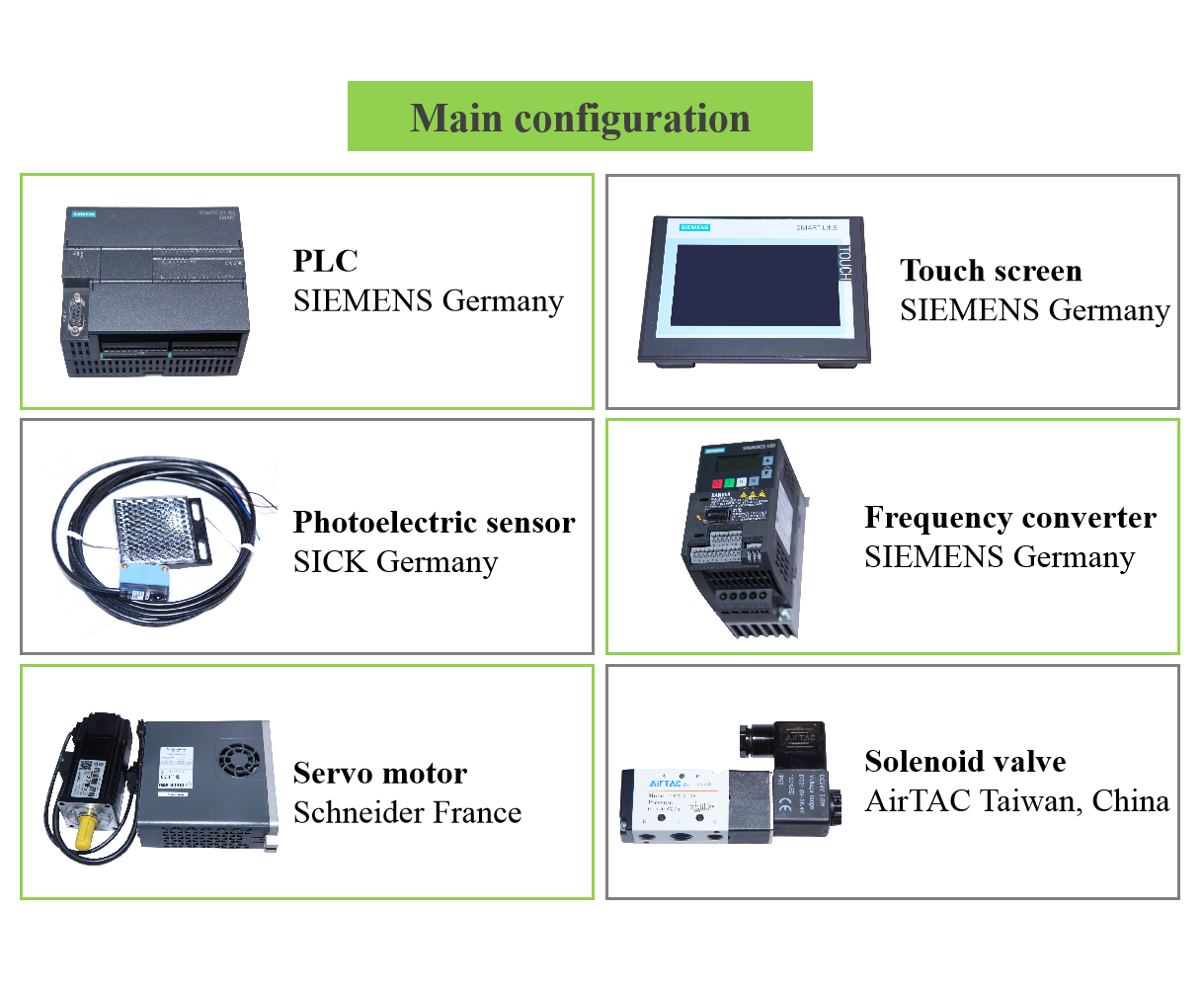

- Core Components: Pressure vessel, PLC, Pump

- Product name: 12 heads liquid filling machine

- Filling speed: 30-50 bottles/min

- Processing Types: Filling liquid into the bottle

- Operation: Touch screen control

- Material: Stainless Steel 304/316

- Filling volume: 500-5000ml, customization

- Bottle type: The bottle provided by customer

- After-sales Service: 24 hours online service, Overseas service

- Advantage: Factory price, Honest buiness

More Details

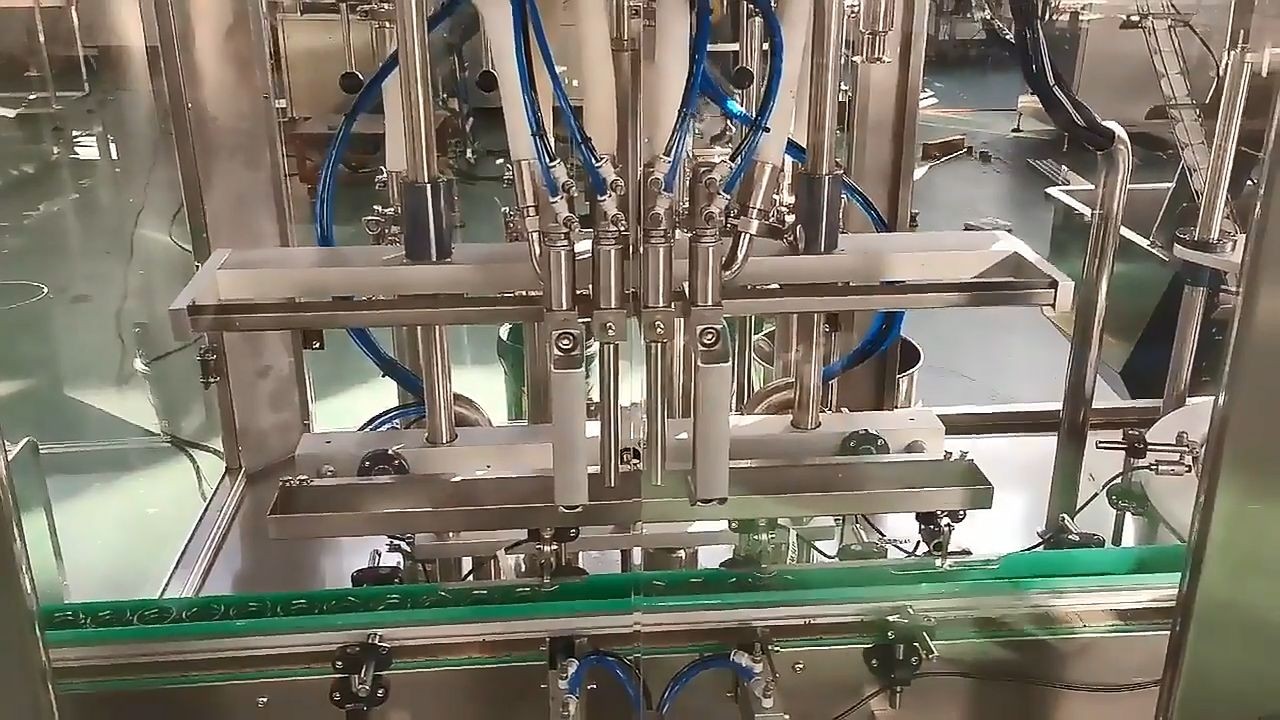

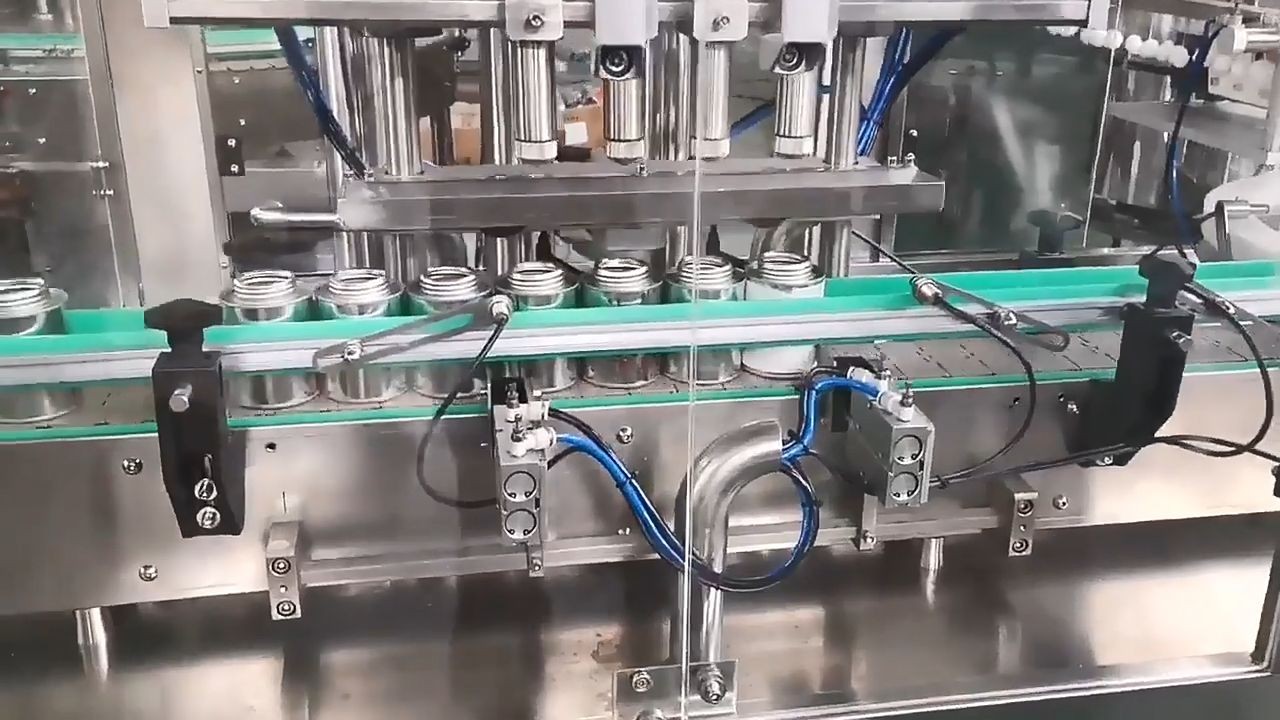

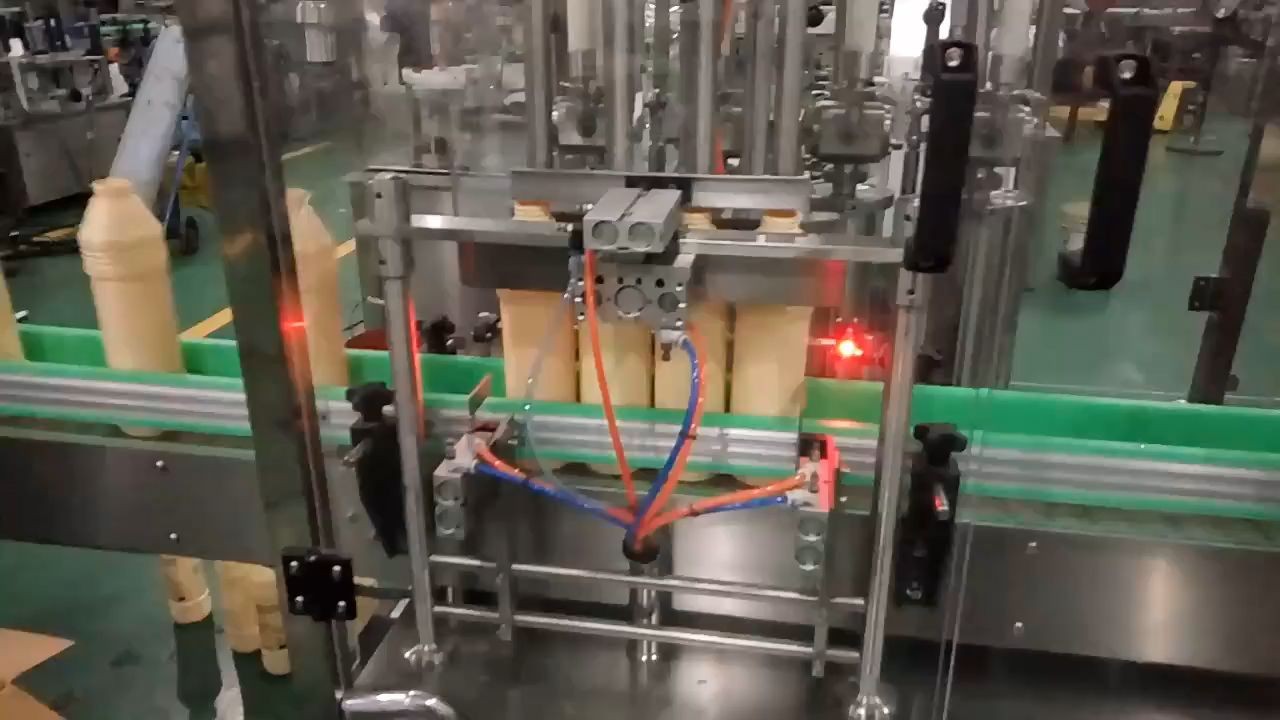

The full-automatic servo filling line adopts PLC and servo quantitative control, integrates the machine's electrical and pneumatic functions, and uses world-famous brands for electrical and pneumatic components. It has the characteristics of stable performance, high filling precision, wide application range, simple operation and convenient maintenance.

It is widely used in daily chemical, such as detergent, shampoo, lotion, hand sanitizer, pigment, white emulsion, and other viscous liquid or semi fluid.

| Technical Parameter | |

| Number of filling heads | 12 heads |

| Filling volume | 100-1000ml |

| Filling form | Multi-head heads into bottle bottom fast or slow filling |

| Filling speed | 60-120 bottles/minute (50ml bottles) |

| Filling accuracy | ±1% |

| Tank volume | 300L (with liquid level switch) |

| Air pressure | 0.6-0.7MPa |

| Total power | 3KW/AC220V/380V, 50/60Hz |

| Program control | PLC touch screen |

| Net weight | 500KG |

| Dimensions | 2000*1200*1900mm (L*W*H) |

| Materials of liquid contacting parts such as filling nozzle and chute: 316L # stainless steel and PVC pipe. | |

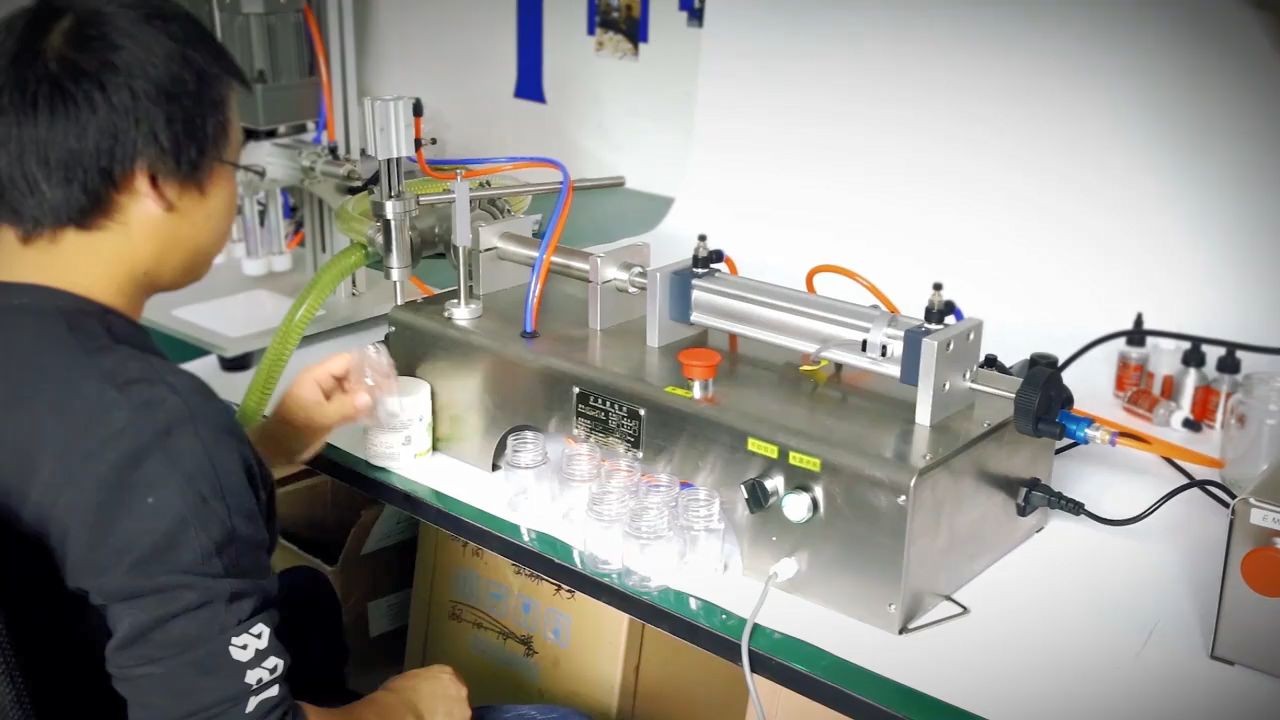

Details Images

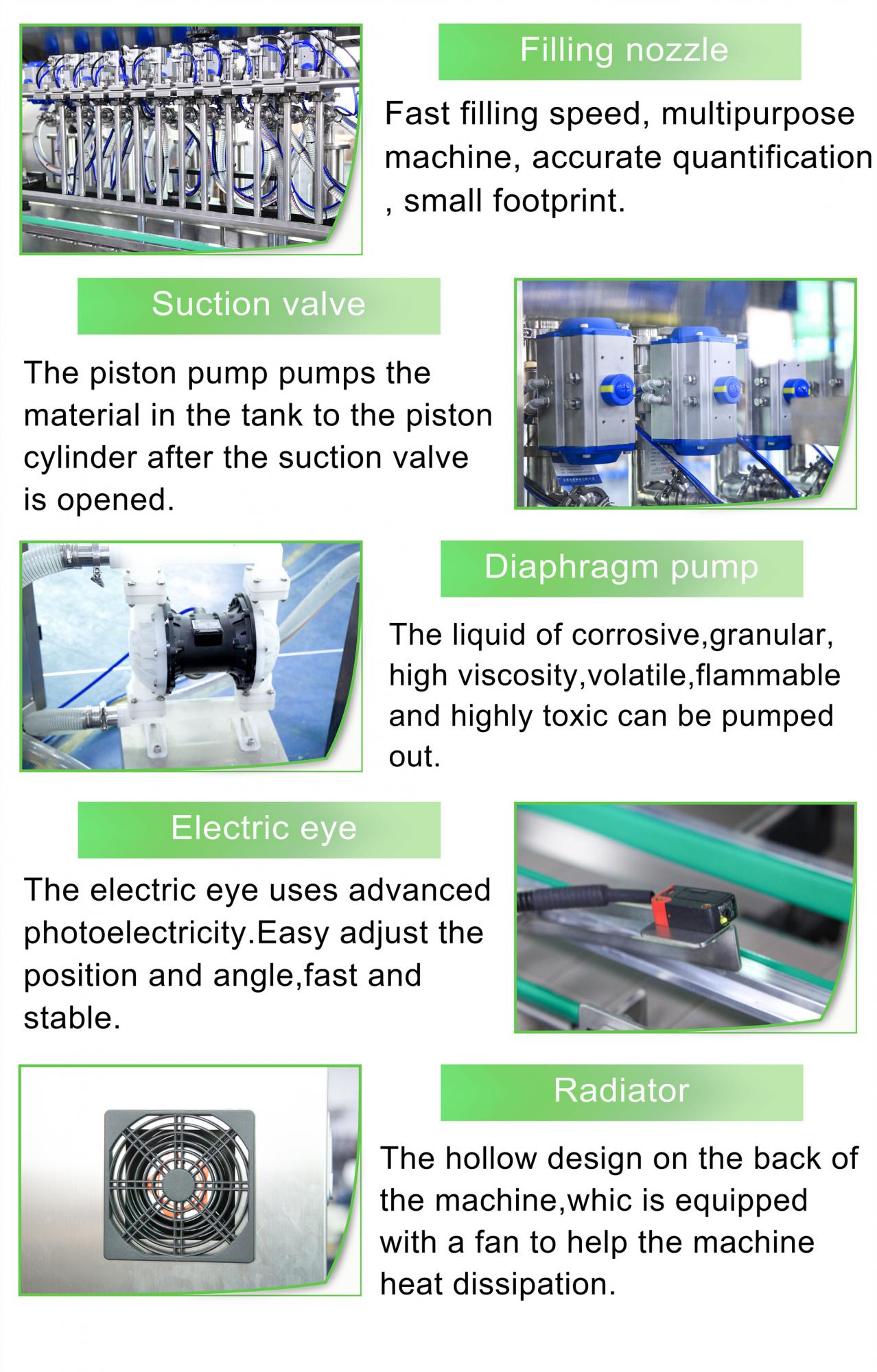

Bottle separating cylinder

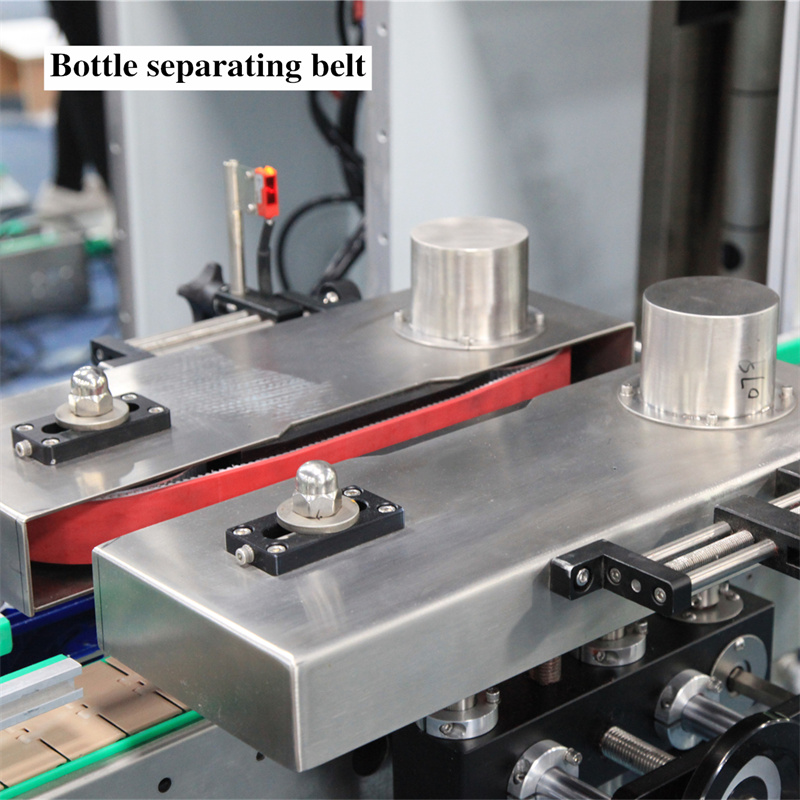

Bottle separating belt

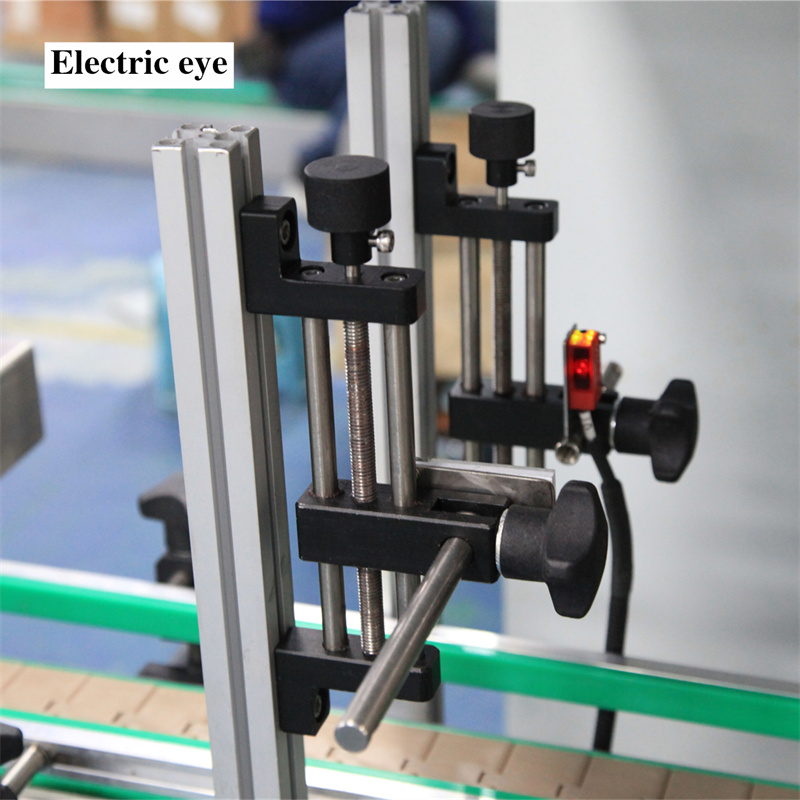

Electric eye

Feeding pump

FAQ

FAQ

Q: What industry is your product suitable for?

A: The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A: Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q: What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method.

FAQ

FAQ