Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, customization

- Applicable Industries: Food & Beverage Factory, Retail, Energy & Mining, Engine Oil Factory, Daily Chemical Factory

- Showroom Location: Egypt, Italy, Philippines

- Application: Food, Beverage, Chemical, Machinery & Hardware

- Packaging Type: Bottles, Barrel

- Packaging Material: Plastic, Metal, Glass, Other

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220/380V, 50/60Hz

- Dimension(L*W*H): 2600*1700*1600mm

- Weight: 600 KG

- Warranty: 1-3 Years

- Key Selling Points: Easy to Operate

- Filling Material: Milk, Water, Oil

- Filling Accuracy: ≤±1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1-3 Year

- Core Components: Pump, PLC, Gear, Engine, standard

- Product name: Weighting Type Lube Oil Bottle Filling Machine

- Keywords: Lube Oil Bottle Filling Machine

- Feeling nozzle: 4, 5 or customization

- Filling volume: 5-60kg

- Feeling material: Cream, Liquid, Paste

- Bottle type: Plastic barrel bottle

- Feeling speed: 10-15pcs/min

- Filling temperature: Normal temperature or heating

- Control system: PLC Touch screen

- After sale services: Online services, after services whole life

- Marketing Type: Hot Product 2020

More Details

Wide Range of Applications

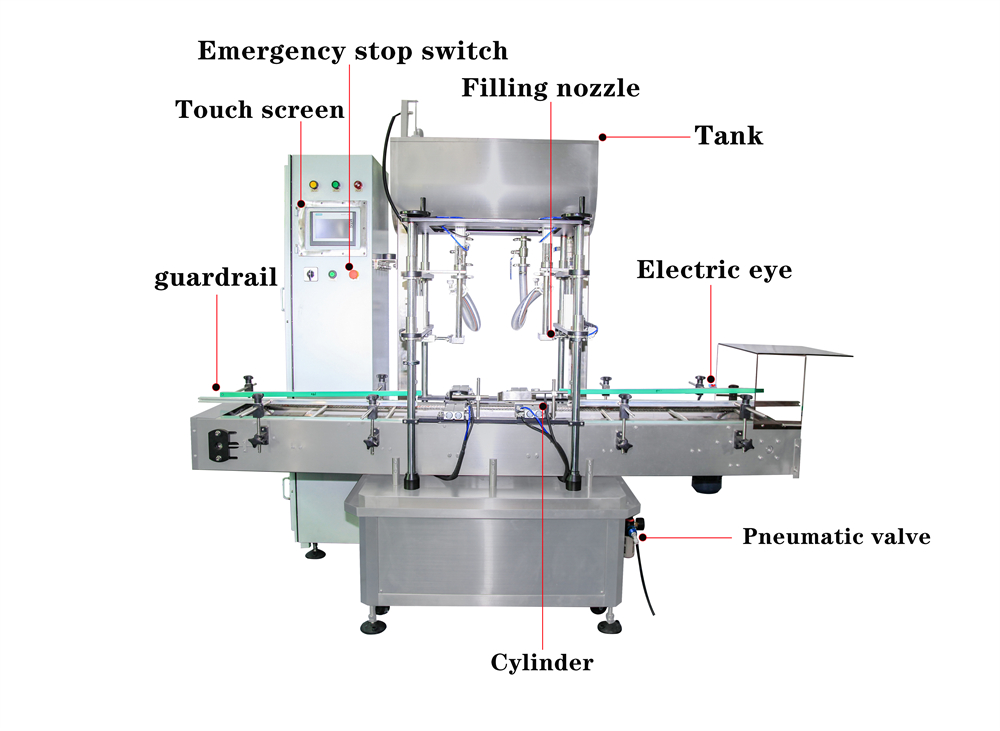

Main configuration:

1. Frame, foot and guardrail materials: aluminum profile, 304 stainless steel

2. Pneumatic components: Taiwan brand AIRTAC

3. Program controller: German brand Siemens

4. Man machine interface: German brand Siemens 7-inch color touch screen

5. Photoelectric sensor: German brand Leuze

6. Relay and air switch: French brand Schneider

7. Motor frequency converter: German brand Siemens

8. Materials of exposed parts: aluminum profile, stainless steel, anodized aluminum alloy, electroplated 45 steel and plastic parts

| Technical Parameters | |

| Filling head | 2/4/6 (customization) |

| Filling speed | 200-400 barrels/hour |

| Filling volume | 100ml-1L, 500ml-5L, 1L-10L |

| Filling form | Weighing filling |

| Filling accuracy | ±1.5% |

| Power supply | 220V 50/60Hz, 1KW |

| Air pressure | 0.6-0.8MPa |

| Net weight | 600KG |

The 20l Drum Jugs Pet Bottle Cooking Edible Oil Weigh Filling Machine is an automatic filling machine designed for accurately filling large containers such as drums, jugs, and PET bottles with cooking or edible oil. The machine uses a weigh filling system that ensures precise measurements and minimizes product waste.

The machine is equipped with an advanced control system that allows for easy operation and monitoring of the filling process. The control panel features a touch screen interface that displays real-time information on the filling process, including the weight of the container, the amount of oil filled, and any errors or alarms. The machine also includes a user-friendly menu system that allows for quick and easy adjustment of filling parameters, such as the fill weight and speed.

The filling process is carried out using a high-precision weigh scale and a fast-acting filling valve that ensures accurate and efficient filling of the container. The machine is designed to handle a variety of container sizes and shapes, including drums, jugs, and PET bottles, and can fill up to 20 liters of oil per container. The filling speed is adjustable, allowing for a range of production rates to be achieved.

The machine is made of high-quality materials and is designed for long-lasting performance and durability. It is easy to clean and maintain, with easily accessible parts that can be quickly replaced if necessary. The machine is also designed to meet international safety and hygiene standards, making it suitable for use in food processing facilities.

Overall, the 20l Drum Jugs Pet Bottle Cooking Edible Oil Weigh Filling Machine is a reliable and efficient solution for filling large containers with cooking or edible oil. Its precision weighing system, user-friendly interface, and flexible container handling capabilities make it a valuable addition to any food processing facility.