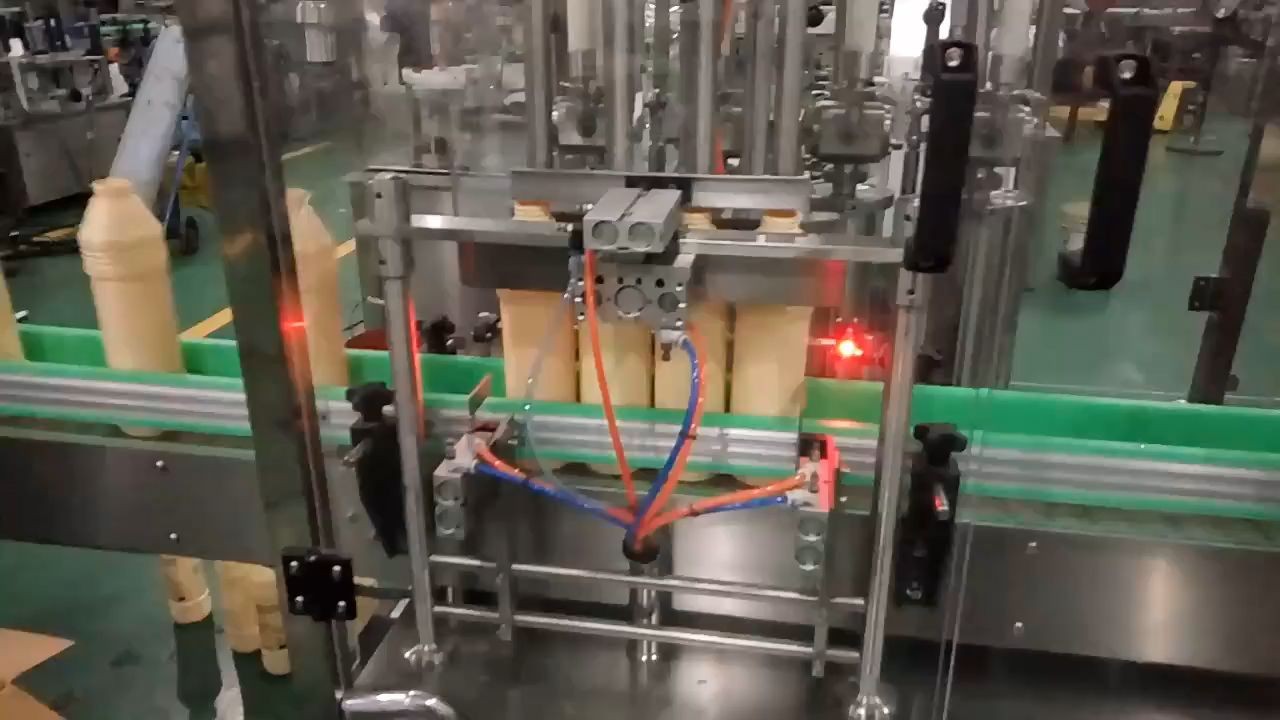

This machine adopts optical fibers to track bottle for high speed and high efficiency filling, and there is no break in the production process.

It is suitable for daily chemical liquid paste filling such as shampoo, shower gel, liquid soap and detergent.

Fully automatic operation, bottle entry, positioning, filling and bottle exit are automatically controlled by PLC, and the whole process meets GMP standards

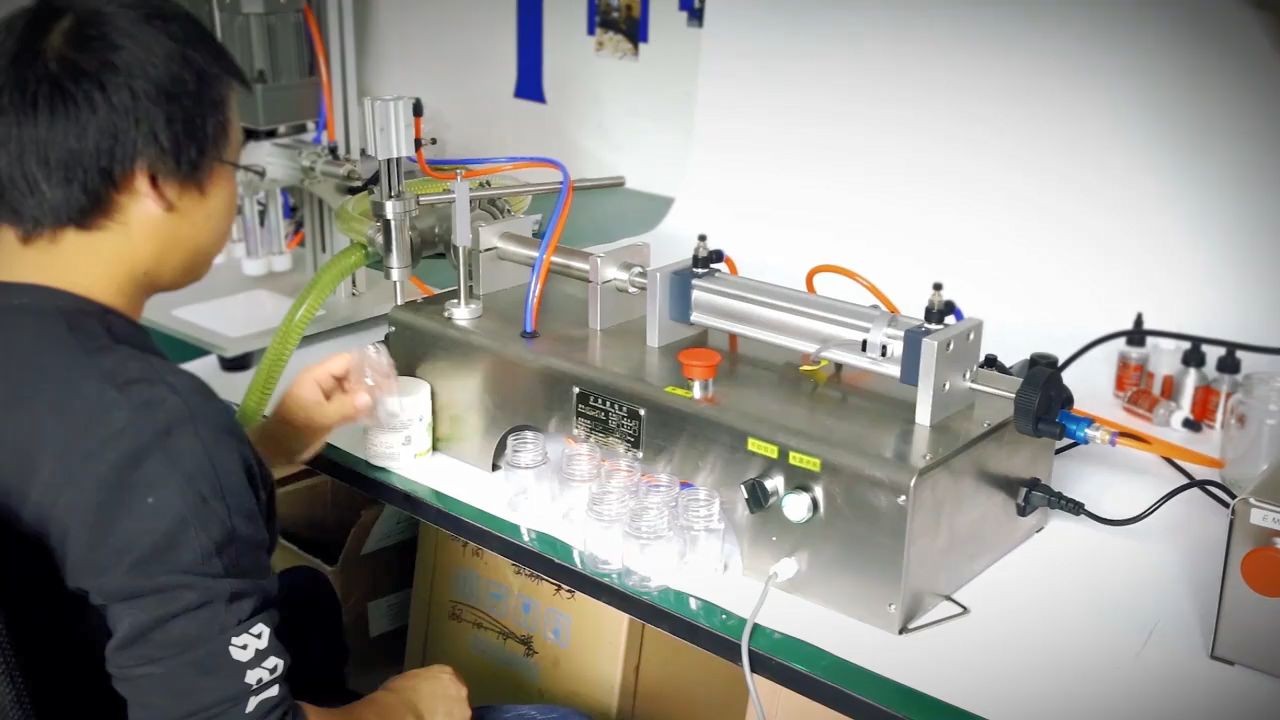

According to the characteristics of different products, we can provide piston, rotor pump, flowmeter, solenoid valve and other measurement methods.

For different types bottle of different heights and capacities, especially special-shaped bottles, it only takes 3-5min to complete the commissioning.

It solves the problems of time-consuming and laborious due to a wide variety, small number of single products and frequent machine adjustment. At the same time, it is suitable for mass production.

| Container size | 100ml to 5000m | ||||||

| Nozzles available | 2 to 4 | ||||||

| Overall dimensions | 1800mm*1300mm*2000mm | ||||||

| Air consumption | 2 to 4 | ||||||

| Electrical | 220 V 50/60hz single phase | ||||||

| Power | 3.5KW | ||||||

| Production rate | 40 to 50 Containers/Minute | ||||||

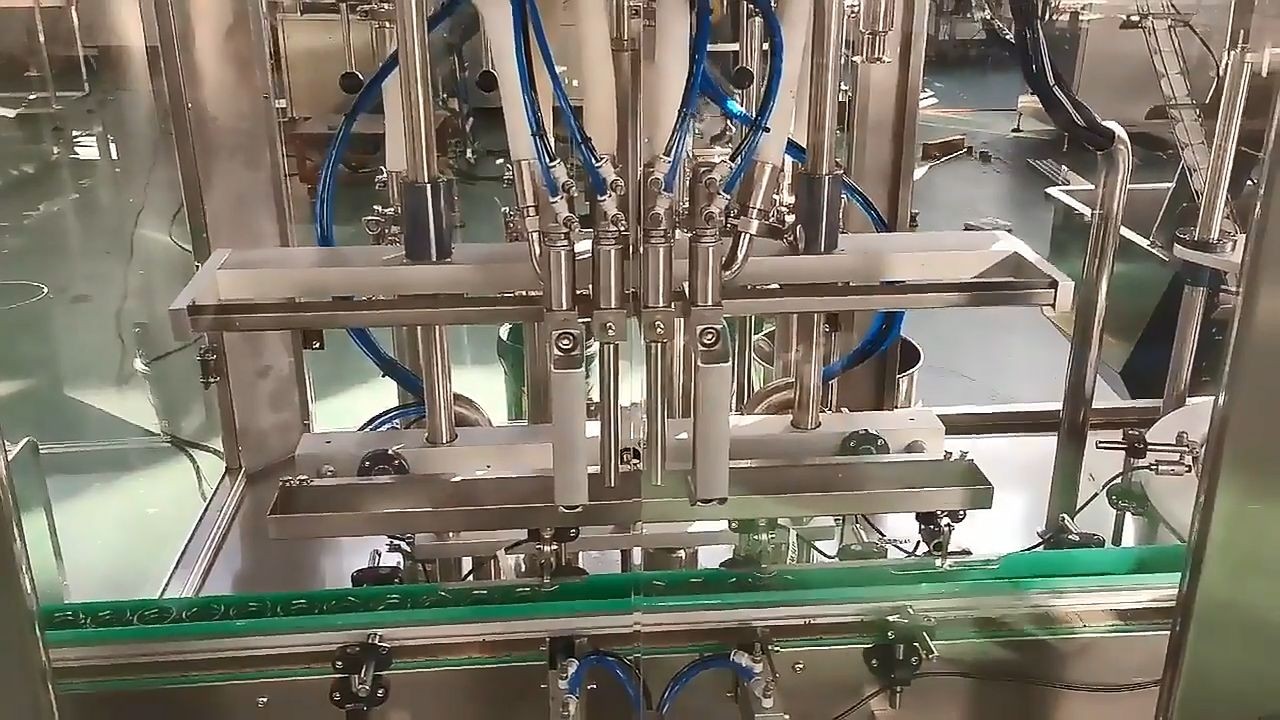

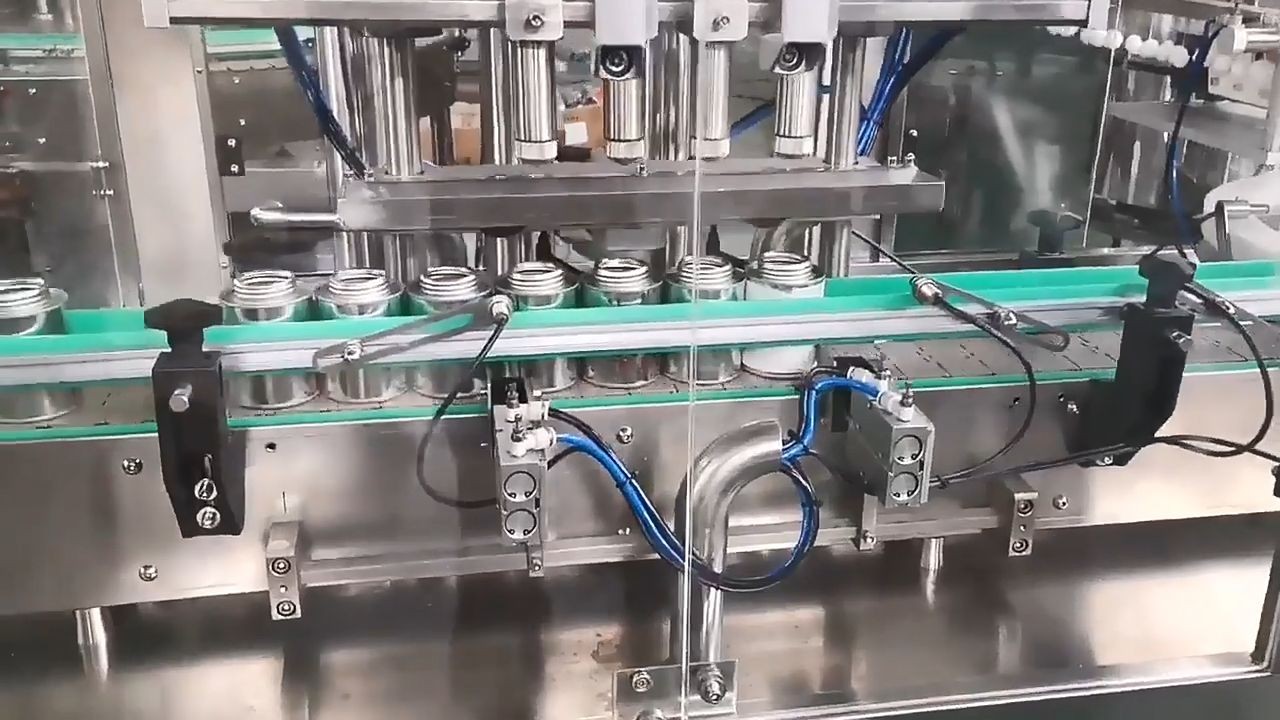

An automatic 2 heads liquid detergent filling machine is a state-of-the-art equipment that is specifically designed for filling and packaging liquid detergents, cleaning agents, and similar liquid products. The machine can fill and seal multiple bottles or containers simultaneously, ensuring a high level of efficiency and accuracy in the packaging process.

The machine is equipped with two filling heads that can dispense the liquid product into bottles or containers with a high level of accuracy, minimizing waste and ensuring that each bottle is filled to the desired level. The filling process is fully automated, allowing for a fast and efficient production process.

The liquid detergent filling machine is also equipped with a conveyor system that can transport the bottles or containers to the filling station, and then to the sealing station, where the bottles are capped or sealed. The conveyor system is designed to handle a wide range of bottle sizes and shapes, making it a versatile option for different packaging needs.

The machine is made of high-quality materials that ensure durability and longevity, even with constant use. It is also designed for easy maintenance, with easily accessible components that can be cleaned or replaced when necessary.

Overall, an automatic 2 heads liquid detergent filling machine is an excellent investment for manufacturers who want to increase their production capacity and efficiency while ensuring the highest quality of their products.