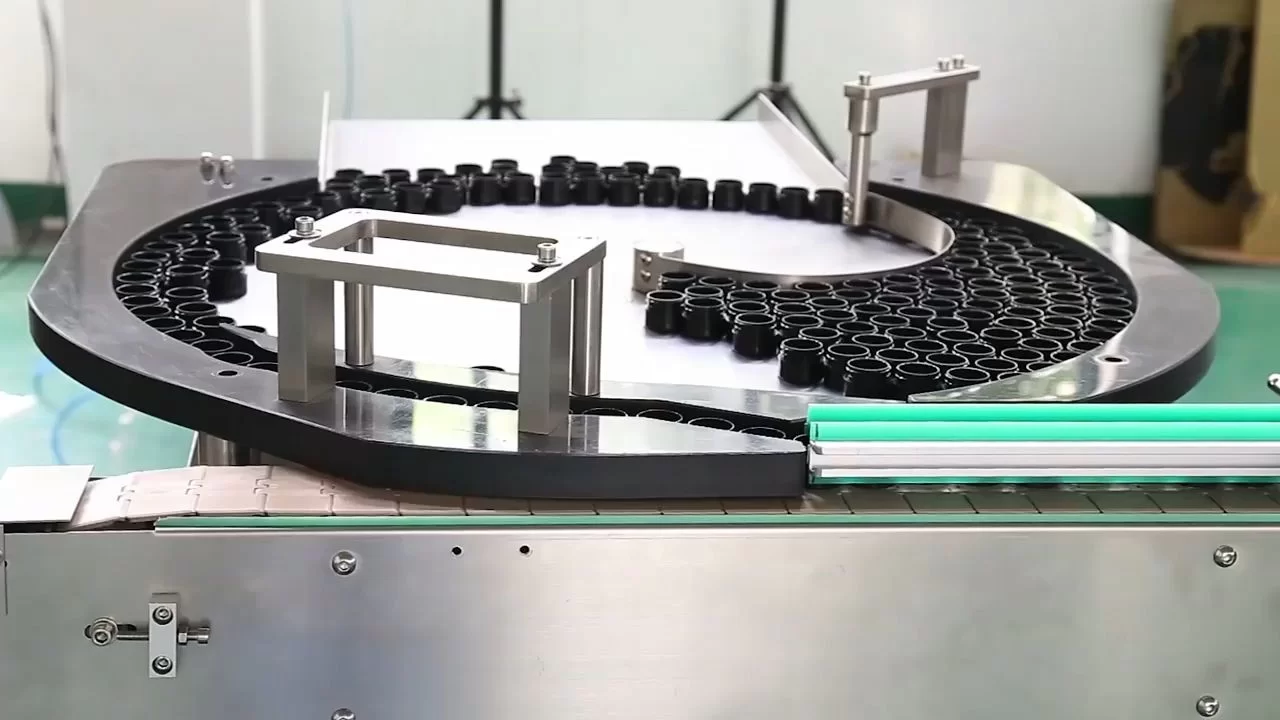

The small bottle liquid filling machine adopts piston pump volumetric metering, with high filling accuracy, stable performance, low bottle damage rate and small floor area. It adopts electromagnetic vibration capping and centrifugal capping, and integrates filling and sealing. The sugar filling and capping process can be completed by the whole machine, All parts in contact with drugs are made of 316L stainless steel or PTFE, with the functions of no bottle, no filling,variable frequency speed regulation, etc. This machine is mainly used for filling, pressing and capping of various oral liquid and syrup liquid, and is widely used in food, pharmaceutical, chemical industry and scientific research fields

1. the capacity of the Syrup filling machine is range from 80b/hour to100 bottles per hour

2. the filling volume of the machine is range from 5ml to 200ml

| Yield capacity | 80-100pcs/min | |

| Filling station | 4 | |

| Filling accuracy | ±1% | |

| Filling range | 5ml to 200ml | |

| filling tolerance | ±1% | |

| Capping station | tow | |

| Qualified cap putting | more or equal then 99% | |

| Qualified capping | more or equal then 99% | |

| Speed regulation | by inverter | |

| power supply | 380V 50Hz | |

| Power | 3.5kw | |

| outside dimension | 1410×1170×1850mm | |

Main features

1. The syrup filling machine is controlled by PLC, stable and reliable; Touch screen human-computer interface, easy to operate;

2. Syrup filling machine has high temperature and high pressure resistant food grade pipes and quick joints, which is easy to dismantle and clean.

3. The whole syrup filling machine meets the food grade requirements.

4. No bottle, no filling function, filling number counting function.

5. CIP function.

6. High measurement accuracy, filling error rate ≤ ± 1%。

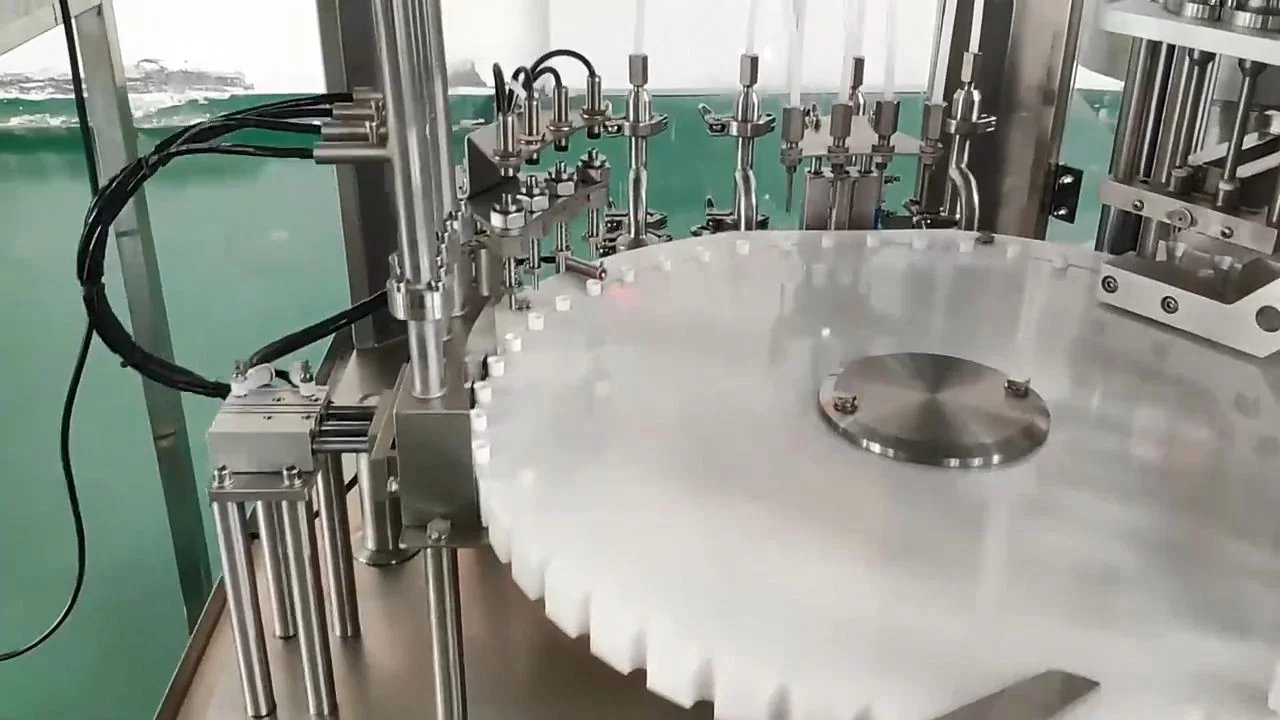

7. Piston pump filling, high filling accuracy

8. Manufactured according to the new GMP standard

The automatic 25ml small bottle liquid filling capping labeling machine is a specialized piece of equipment designed to efficiently and accurately fill, cap, and label small bottles of liquid. The machine is equipped with advanced technology that ensures precise and consistent filling, capping, and labeling, making it an ideal solution for manufacturers looking to increase productivity and efficiency.

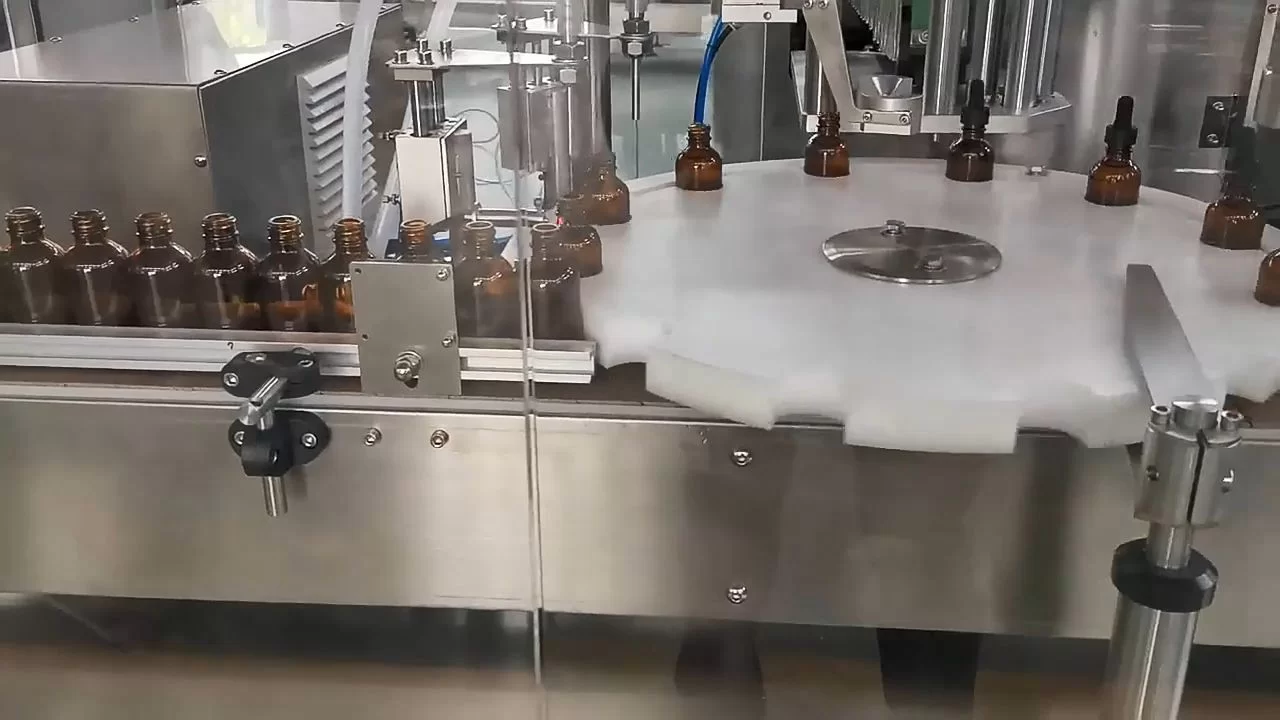

The machine is designed to handle small bottle sizes and shapes, making it versatile and suitable for different production requirements. It is equipped with a conveyor system that moves the bottles to the filling station, where the liquid is dispensed into the bottles. The filling process is highly precise and accurate, ensuring that each bottle is filled to the desired level.

The machine is also equipped with a capping mechanism that securely applies caps to the bottles. The capping mechanism is highly efficient and can cap up to six bottles simultaneously. The machine uses a pneumatic system that ensures the capping process is fast, accurate, and reliable.

The machine is also equipped with a labeling mechanism that accurately applies labels to the bottles. The labeling mechanism is highly efficient and can apply labels to multiple bottles simultaneously. The machine is designed to handle different types of labels and can be adjusted to apply labels of different sizes and shapes.

The machine is also equipped with a touch screen interface that allows the operator to control the entire production process. The interface is user-friendly and intuitive, making it easy for operators to adjust the filling speed, volume, labeling parameters, and other parameters as required.

The automatic 25ml small bottle liquid filling capping labeling machine is designed to operate at high speeds, ensuring that the production process is efficient and fast. The machine is also equipped with a cleaning system that ensures that the filling and capping stations and other parts of the machine are kept clean and free from contaminants. This helps to maintain the quality of the product and ensures that it is safe for use.

In conclusion, the automatic 25ml small bottle liquid filling capping labeling machine is a specialized machine that provides an efficient and automated process for filling, capping, and labeling small bottles of liquid. Its advanced technology ensures precise and consistent filling, capping, and labeling, making it an ideal solution for manufacturers looking to increase productivity and efficiency. Its versatility, high speed, user-friendly interface, and cleaning system make it a valuable asset in any production facility.