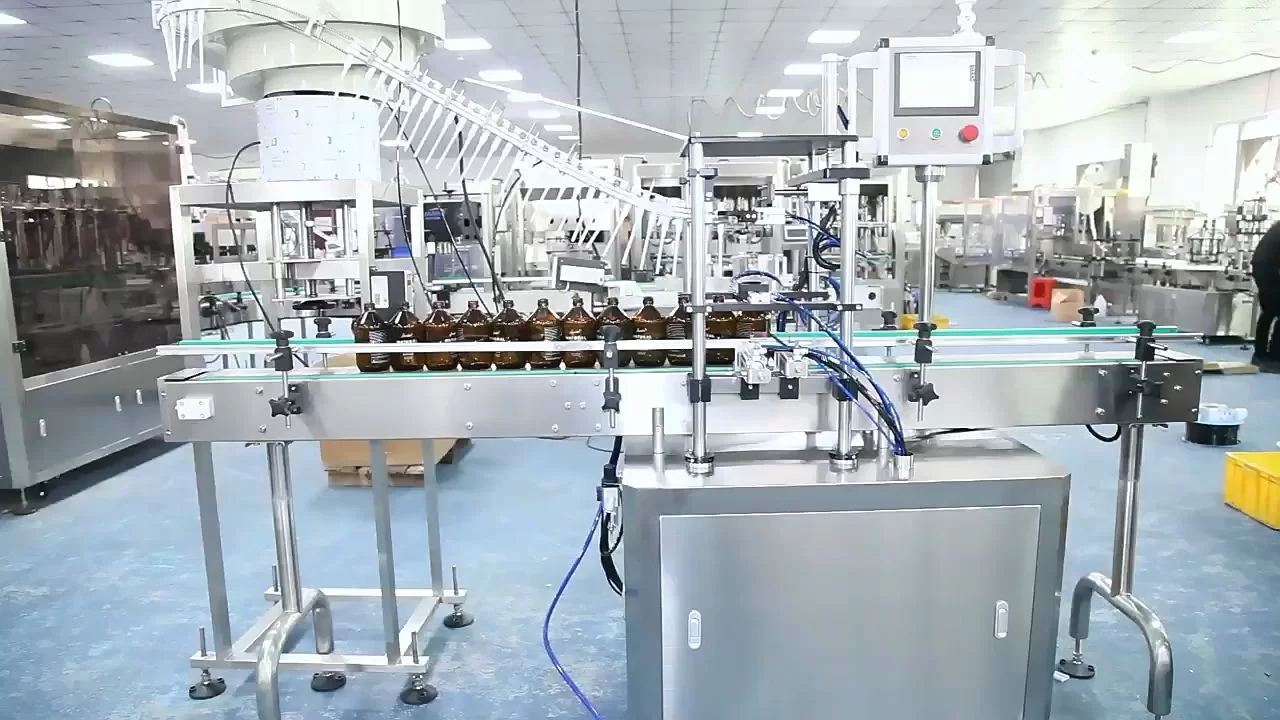

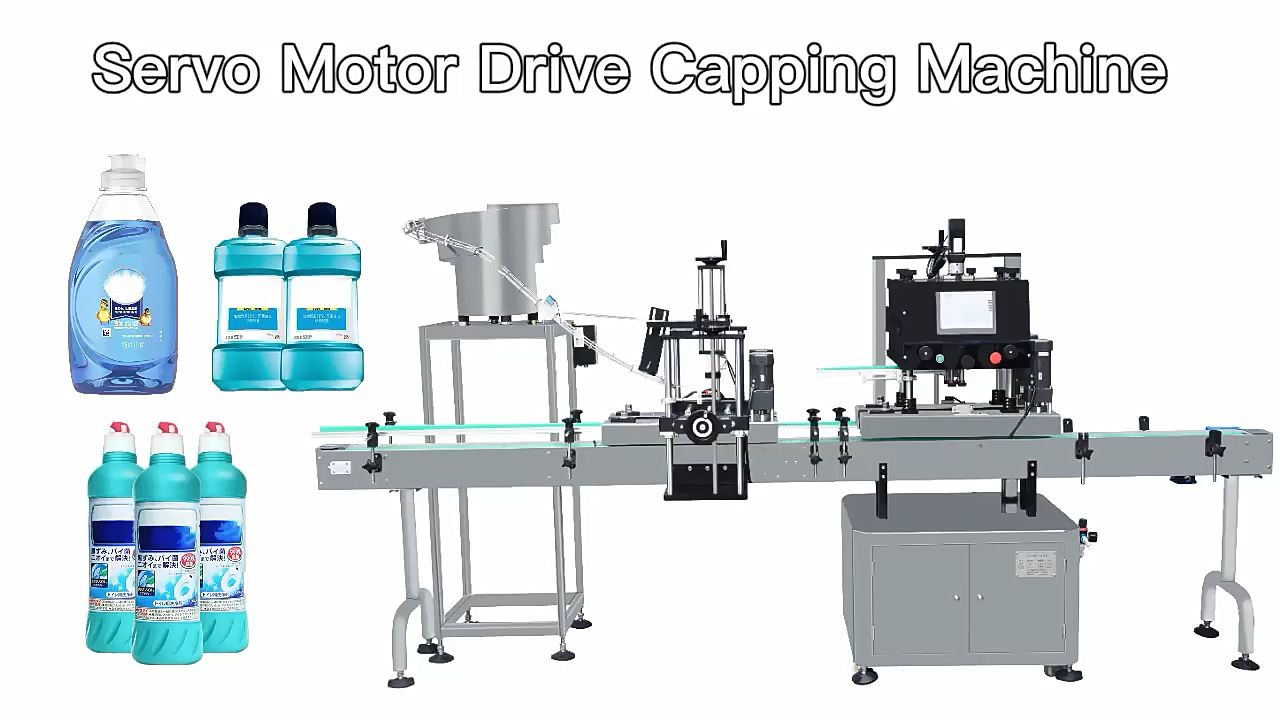

The main structure is made of durable 304 stainless steel. The machine is control by touch screen,parameter can be set on touch screen very easily. It is very flexible for different sizes of round bottles, square bottles and flat bottles by adjustment. Capping time can be set to fit different caps and different levels of tightness. It is very easy for exist line upgrade.

MAIN FEATURE

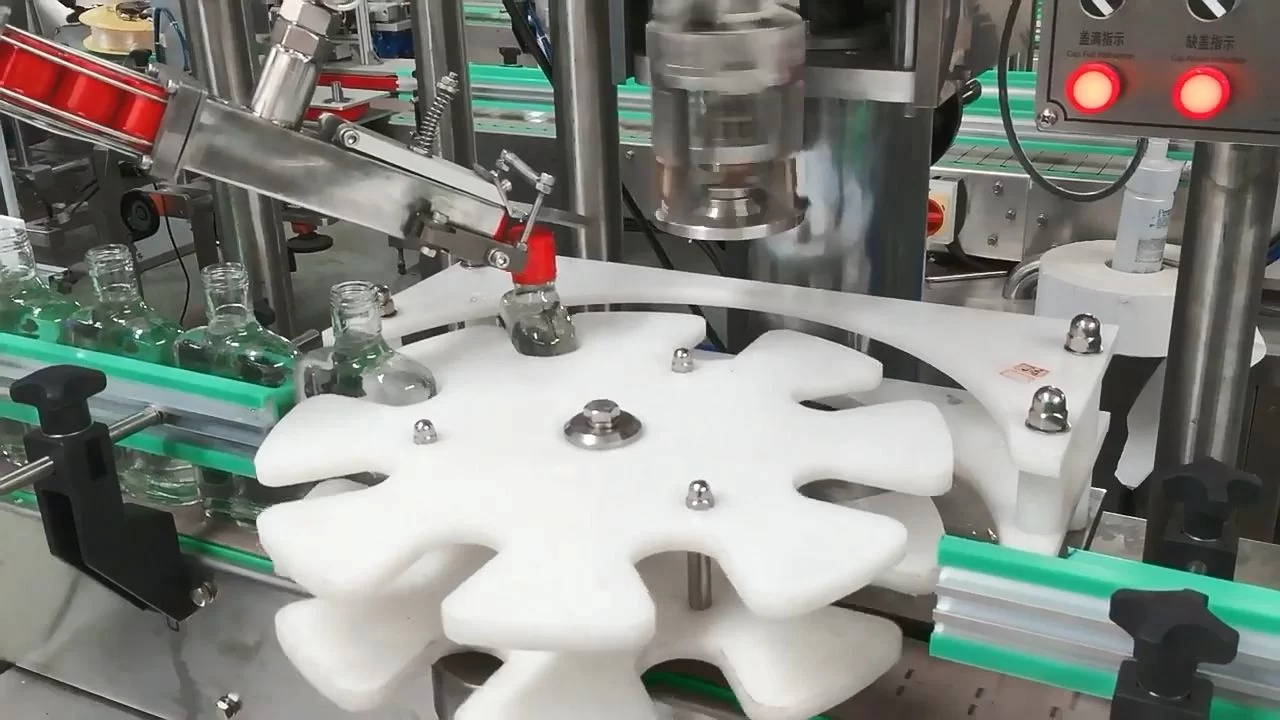

1. Automatic cap feeding system, vibrating tray.

2. No tools requirements for different size adjust for capping system.

3. Output meet the filling machine, but max 30 bottles/ min.

4. No bottle No capping.

5. Control panel with touch screen. capping programs saving.

6. Machine’s body of SS 304.

| 1 | Capping Head | 1 Heads | |

| 2 | Production Capacity | 25-35BPM | |

| 3 | Cap diameter | Up to 70MM | |

| 4 | Bottle Height | Up to 460MM | |

| 5 | Voltage/Power | 220VAC 50/60Hz 450W | |

| 5 | Driven way | Motor with 4 wheels | |

| 6 | Interface | DALTA Touch Screen | |

| 7 | Spare Parts | Capping Wheels | |

Main Component List

| No. | Descriptions | BRAND | ITEM | Remark |

| 1 | Capping Motor | JSCC | 120W | Germany Technology |

| 2 | Reducer | JSCC | Germany Technology | |

| 3 | Touch Screen | DALTA | TAIWAN | |

| 4 | PLC | DALTA | TAIWAN | |

| 5 | Pneumatic Cylinder | AIRTAC | TAIWAN | |

| 6 | Air Filter | AIRTAC | TAIWAN | |

| 7 | Main Structure | 304SS | ||

| 8 | Press Controller | AIRTAC | TAIWAN |

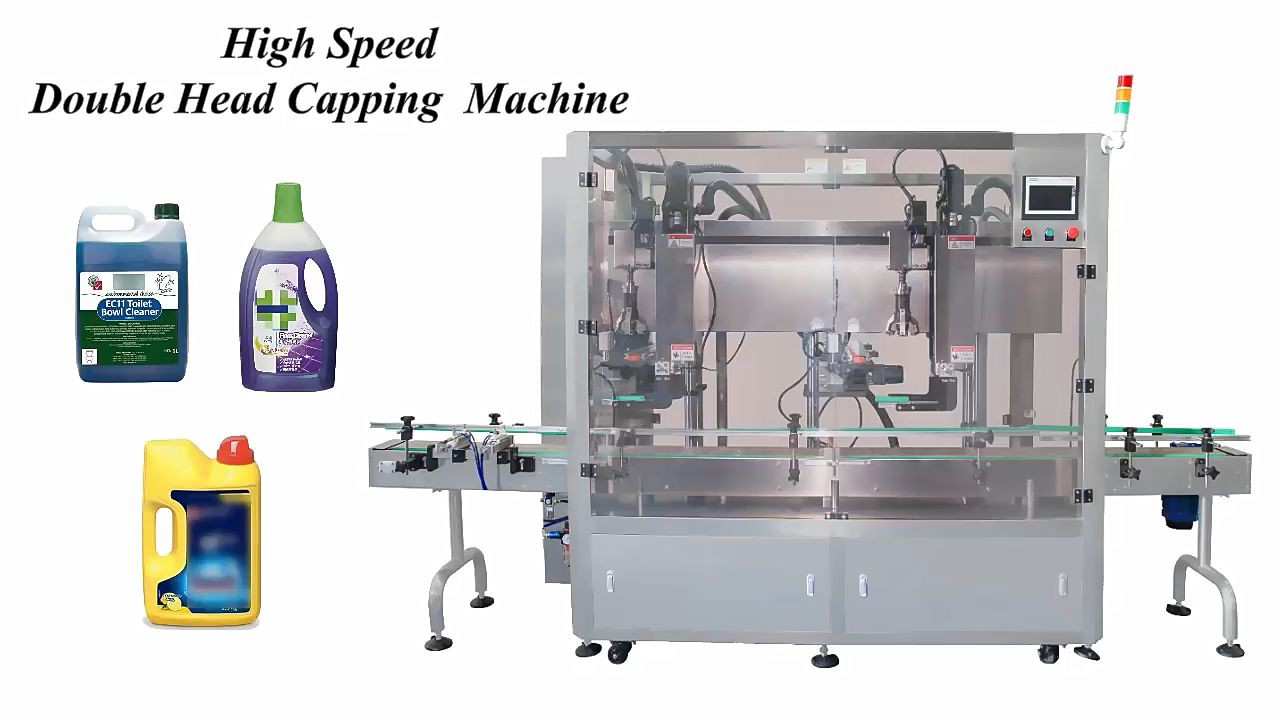

The Automatic 4 Wheels Plastic Lid Capping Machine For Hand Soap Bottle is a cutting-edge piece of equipment designed to meet the demands of the liquid packaging industry. This machine is specifically designed to handle the capping process of plastic lids for hand soap bottles.

One of the most notable features of this machine is its four-wheel design, which ensures stability and allows for easy mobility. This design feature makes it easier to transport the capping machine from one location to another within your production line, as well as minimizing the risk of the machine tipping over during operation.

The capping machine is also fully automatic, which means that it requires minimal human intervention during operation. This not only increases efficiency but also reduces the likelihood of human error, which can lead to costly production mistakes.

The plastic lid capping machine is also designed to work with a wide range of bottle sizes, making it a versatile addition to any production line. The machine's adjustable height and cap torque settings allow it to handle bottles of varying heights and cap sizes.

In addition, the machine is designed with durability and ease of maintenance in mind. It is made from high-quality materials and requires minimal maintenance, ensuring that it operates at optimal performance for an extended period.

Overall, the Automatic 4 Wheels Plastic Lid Capping Machine For Hand Soap Bottle is a reliable and efficient addition to any liquid packaging production line. Its ability to handle a wide range of bottle sizes, combined with its fully automatic operation and easy mobility, make it a must-have piece of equipment for any business looking to streamline their capping process and increase efficiency.