The Automatic Disinfection Body Aerosol Spray Filling and Sealing Machine is a cutting-edge packaging solution designed for the pharmaceutical, personal care, and chemical industries. This advanced machine is designed to fill and seal disinfection body aerosol spray products automatically, providing a high-speed, high-accuracy, and efficient production process.

This innovative machine is equipped with a series of advanced components that ensure precision and reliability during the packaging process. It features an automatic filling system that is capable of filling a wide range of disinfection body aerosol spray products accurately and efficiently. Additionally, the machine is equipped with an automatic sealing system that ensures a tight and secure seal for each product.

One of the major advantages of the Automatic Disinfection Body Aerosol Spray Filling and Sealing Machine is its high speed and accuracy. With a production capacity of up to 60 cans per minute, this machine can handle large production runs quickly and efficiently. It also features an automatic capping system that ensures each product is sealed securely and consistently.

This machine is also designed with user-friendly features that make it easy to operate, maintain, and clean. Its compact design requires minimal floor space, and it is built with high-quality materials that ensure durability and longevity.

The Automatic Disinfection Body Aerosol Spray Filling and Sealing Machine is widely used in the pharmaceutical, personal care, and chemical industries, where high-speed and high-accuracy packaging is required. As the demand for disinfection body aerosol spray products continues to increase, this machine has become an essential tool for manufacturers looking to streamline their production processes and improve efficiency.

In conclusion, the Automatic Disinfection Body Aerosol Spray Filling and Sealing Machine is an advanced packaging solution that offers high speed, accuracy, and efficiency. Its user-friendly features and durable construction make it an ideal choice for manufacturers looking to optimize their production processes and meet the growing demand for disinfection body aerosol spray products.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, 1000-8000BPH

- Applicable Industries: Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Advertising Company

- Showroom Location: Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Chile, Colombia, Malaysia, Australia

- Application: Beverage, Commodity, Food, Textiles

- Packaging Type: Barrel, Bottles, CANS, case, Cartons

- Packaging Material: Wood, Metal

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V/380V/440V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 1200*900*2200mm

- Weight: 580 KG

- Warranty: 6 Months

- Key Selling Points: High-accuracy

- Filling Material: Water, Oil, Other

- Filling Accuracy: ≥99%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 6 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Machine Name:: Aerosol Paint Spray filling machine

- Driven type:: Servo motor(ABB)

- Control:: PLC and Touch Screen

- Warranty:: Six months free

- Price:: Reasonable and Competitive

- steel:: SS304 SS316

- Filling Speed:: Customized

- Product advantage:: High accuracy/Customized/Effective cost

- Package:: Wooden case

- After Warranty Service: Online technical support

More Details

Automatic aerosol tin can spraying filling line use booster pump, which will convert the mixed liquid and gas to totally liquid. Then put it into add pump to storage, When the gas charging, add the pump suction the liquid from the quantitative tank. And then Quantitative cylinder piston work, gas charging finished. As the inflated gas has been completely transformed into liquid, so it can ensure the accuracy of inflation. The machine uses Quantitative SS316L stainless steel piston pump: corrosion, durable, quantitative criteria. When charging different specifications, it will adjust the charging quantity. There is a graduated scale at the piston pump, simply twist the hand wheel to adjust the gas charging quantity.

| Product | Automatic aerosol tin can spraying filling line |

| Output | 1500-6000BPH (Customized) |

| Filling Volume | 200-550ml (can be customized) |

| Control | PLC and Touch Screen |

| Driving Motor | Servo Motor |

| Filling Precision | ±1% |

| Valve Feeding Precision | ±1% |

| Air Consumption | 0.6-0.8Mpa |

| Power | 1.0KW |

| Machine Frame Material | SS304 |

| Power Supply | 220/380V, 50/60Hz |

| Bag inserting | Manually |

| Metal ball inserting | Automatically |

| Size | 1200-900-2200 (unit) |

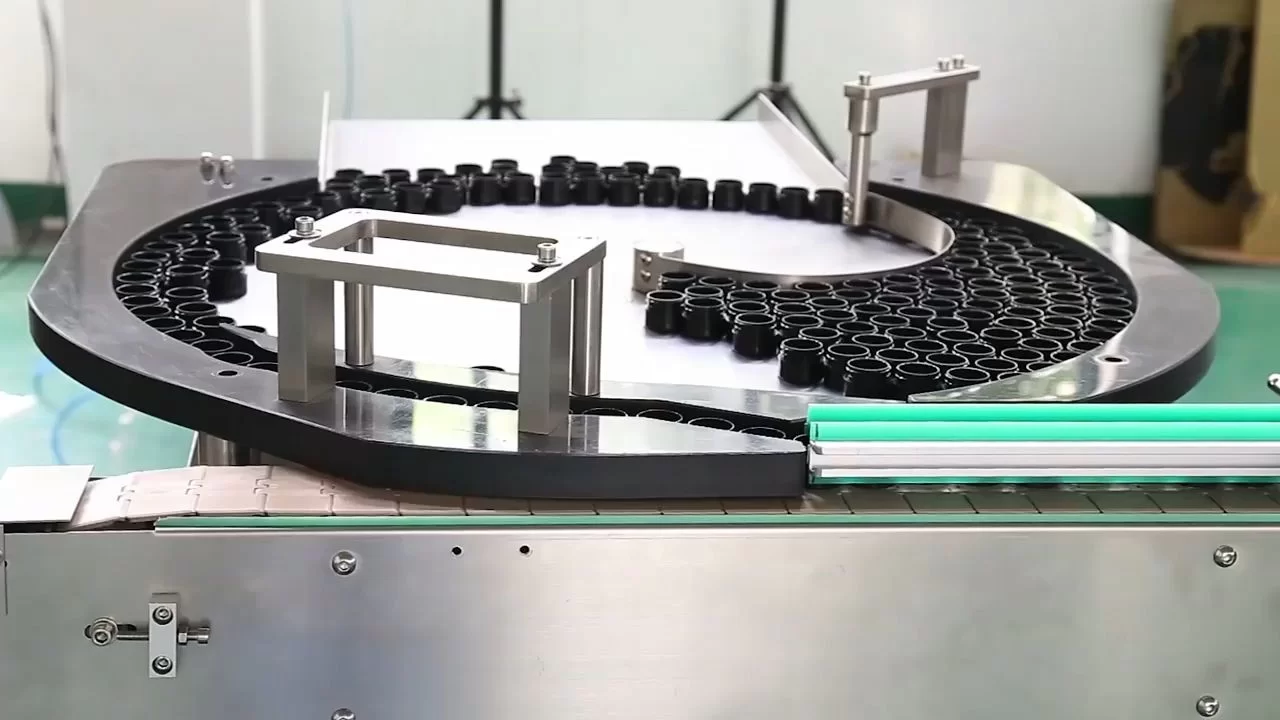

Bottle Feeding Table

Variable speed bottle feeding table is the basic feeding system of aerosol spray bottle filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to the conveyor, the machine will be able to work with different size bottle.

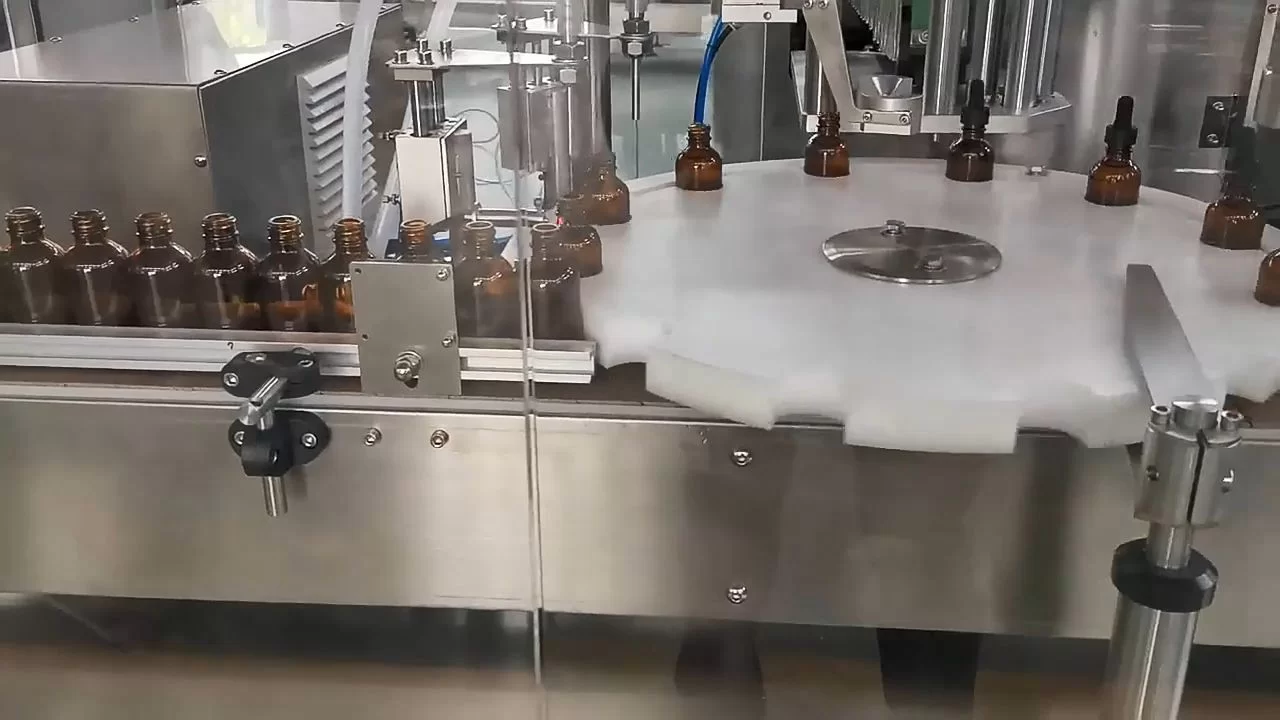

Liquid Filling Machine

This machine adopts position pump, which is suitable for different kinds liquids, with high filling speed and high filling precision. The pump uses quick-fit removal structure: easy cleaning and disinfection. The filling nozzles adopt anti-drip and anti-drawing filling device. The machine adopts PLC and human-computer touch screen control system.

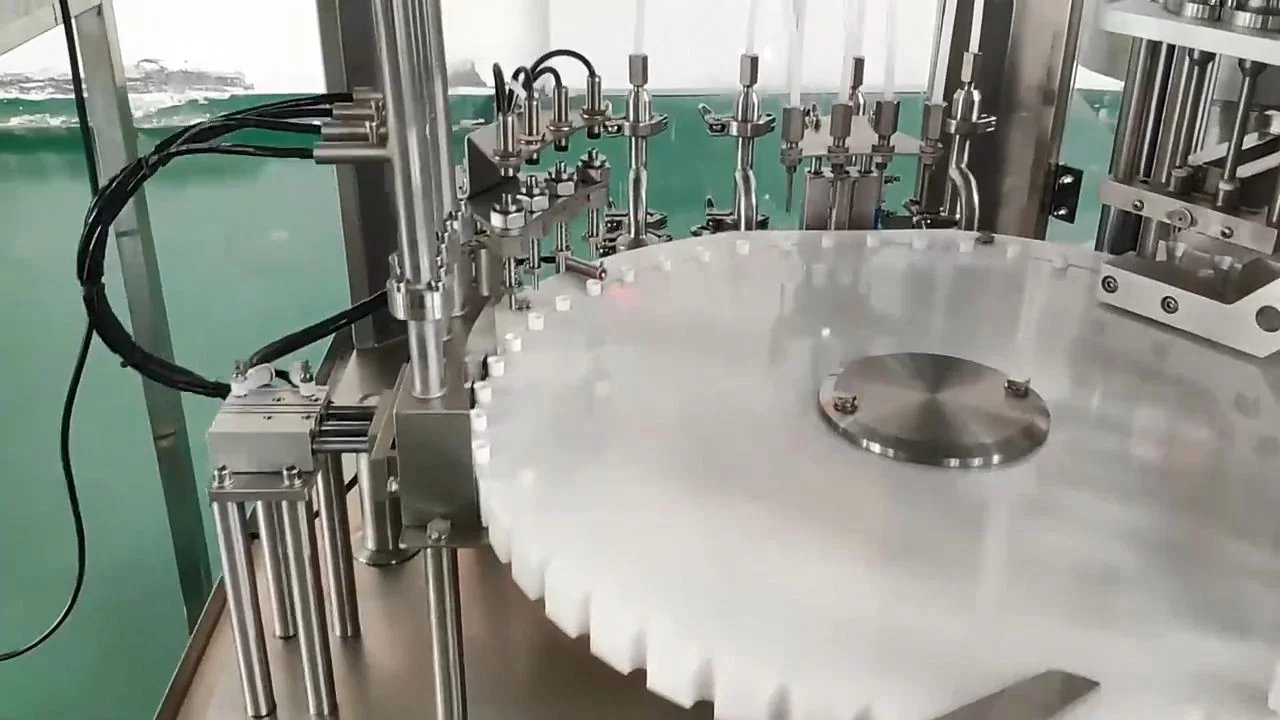

Spray Valve feeding machine

This valve putting part worked with stable speed and high efficiency. The machine adopts PLC and human-computer touch screen control system. The valve sorter and feeding parts can be easy to change for the different size.

Spray Valve Sealing Machine

The sealing head is specially designed according to valve. When sealing the bottle, first step press valve to position it, then sealing claw will seal the bottle. The air proof circle inside the valve will tightly linked to the bottle, so it is beautiful without leakage.

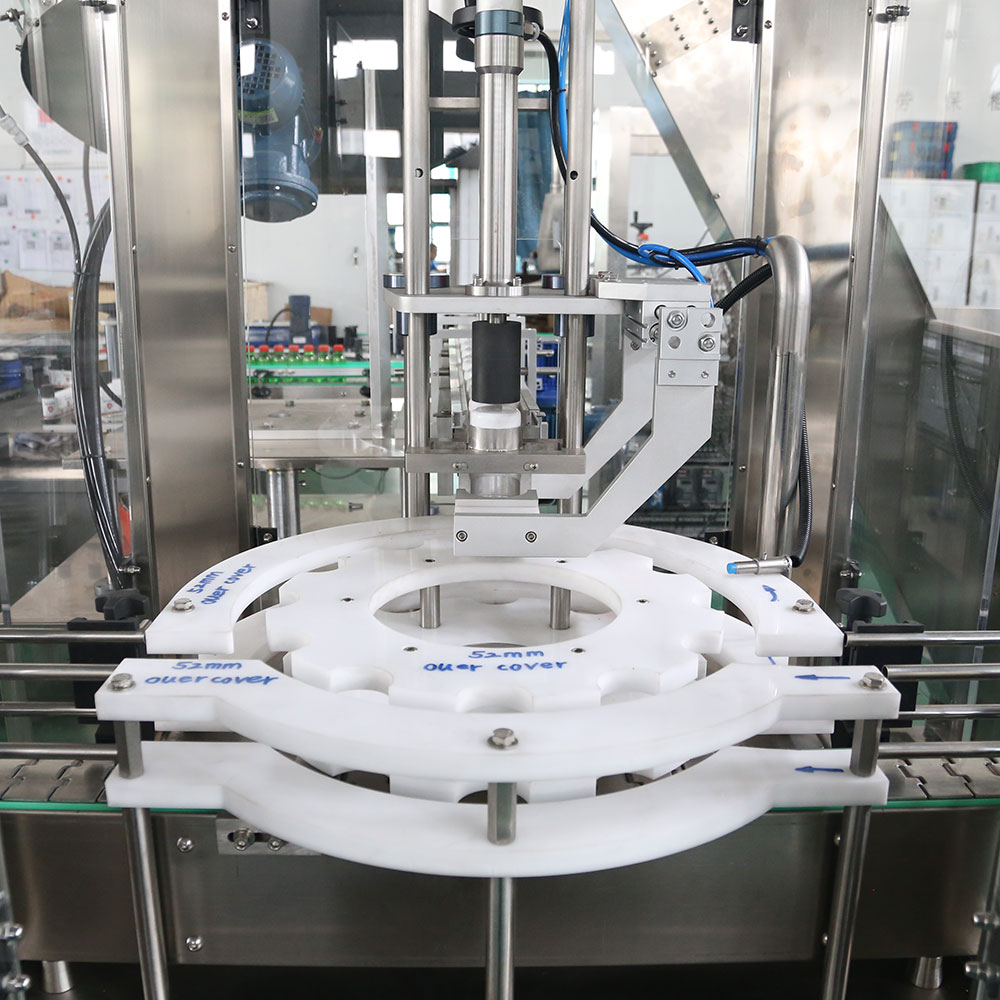

Spray Head Pressing Machine

The vibrating cap feeder will arrange the spray heads automatically, sending the caps to the production line from the pipe under the air power. It can save labors and increase productivity.