The Automatic Essential Oil Body Oil 2 Head Liquid Filling Capping Machine is a state-of-the-art packaging equipment designed for the filling and capping of essential oils, body oils, and other liquid products. It is an automated machine that offers high-speed, accurate, and consistent filling and capping of products with minimum human intervention. This machine is widely used in the cosmetics, pharmaceutical, and food industries.

The Automatic Essential Oil Body Oil 2 Head Liquid Filling Capping Machine has several advantages. It is made of high-quality materials that are durable, reliable, and easy to maintain. The machine is equipped with advanced technology that ensures precise filling and capping of products. It is designed with a user-friendly interface that allows operators to monitor and adjust the machine settings easily. This machine has a compact design that occupies minimal space in the production line, making it suitable for small to medium-sized businesses.

One of the outstanding characteristics of this machine is its ability to handle a wide range of products. It can fill and cap various types of containers, including bottles, jars, and vials. The machine can also handle different types of liquids, including thin, viscous, and foamy liquids. It can fill products ranging from 5ml to 5000ml with a filling accuracy of ±0.5%.

The Automatic Essential Oil Body Oil 2 Head Liquid Filling Capping Machine is versatile and can be used for various applications. It is commonly used for filling and capping essential oils, body oils, perfumes, e-liquids, and other similar products. The machine is also suitable for filling and capping products that require a sterile environment, such as pharmaceuticals and laboratory products.

In conclusion, the Automatic Essential Oil Body Oil 2 Head Liquid Filling Capping Machine is an innovative solution for businesses looking to improve their liquid filling and capping processes. Its advanced technology, user-friendly interface, and versatility make it a valuable asset to businesses in the cosmetics, pharmaceutical, and food industries. The increasing demand for liquid products and the need for efficient packaging solutions make this machine a vital investment for businesses looking to stay competitive in the market.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Saudi Arabia, Indonesia, Pakistan, Mexico, Spain, Morocco, Kenya, Argentina, South Korea, Colombia, Algeria, Romania, Bangladesh, South Africa, Malaysia, None

- Application: APPAREL, Beverage, Chemical, Food, Machinery & Hardware

- Packaging Type: Bags, Bottles, CANS, Capsule, Cartons, case, Pouch, Stand-up Pouch

- Packaging Material: Glass, Metal, Paper, Plastic, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V/380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 1400*2000*1600

- Weight: 500 KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Filling Material: Milk, Water, Oil, Juice, Powder

- Filling Accuracy: 99%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 6 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Product name: small vials coconut essential oil filling machine

- Product advantage: Adaptable for all formats product

- Eligibility rate: ≥99%

- Bottle type: PET/GLASS/PLASTIC

- HS code: 8422303090

- Capacity: 1500BPH

- Control: Plc Touch screen

- Keywords: Chubby Gorilla

- Filling products: nitroglycerin

More Details

VKPAK is a professional manufacturer of filling line for over 12 years, customized filling lines for different industry customers like food and beverage, cosmetic, medical industry, chemical industry and etc, lots of successful cases for your reference. The full automatic liquid filling machine is designed for saving time on adjusting and testing machine, it can fill liquid or paste accurately by entering a certain filling volume. The PLC control method makes it easy to operate and thigh speed working efficiency is ideal for different scale production. It can work with the automatic capping machine and labeling machine and other equipment based on customer requirement. VKPAK filling line is widely used in the following industries:

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical and Pharmaceutical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

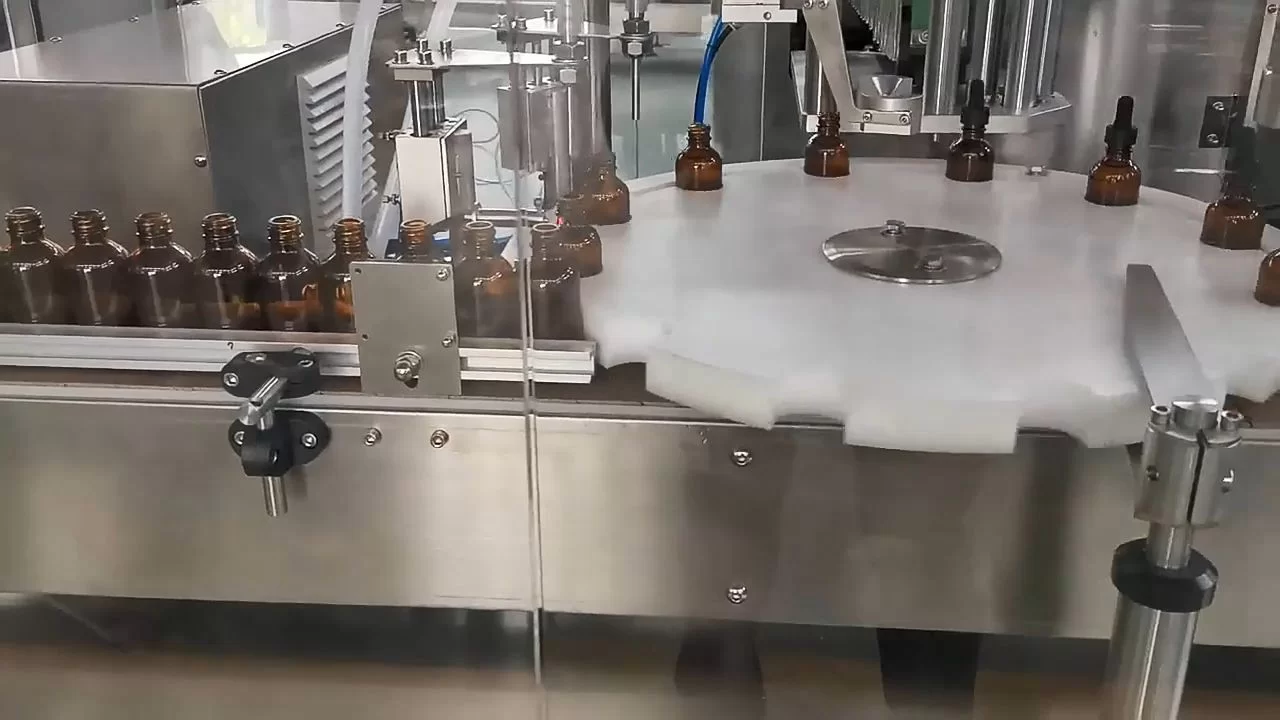

The fully automatic small vail bottle liquid filling capping machine is with CE & ISO 9001 certification. The machine is applied to glass or plastic bottles with different sizes and shapes, and suitable for different filling volume. By adjusting the filling volume on touch screen, it can fill liquid with quick speed and high precision. It is widely used for essential oil, eye dropper, perfume, nail polish, lotions and other vial bottle filling.

| Product | Automatic Essential Oil Body Oil 2 Head Liquid Filling Capping Machine |

| Output | 1000-6000BPH, or customized |

| Filling Volume | 10-100ml, or customized |

| Air compressor | 0.6-0.8Mpa |

| Filling Material | Nitroglycerin |

| Control | PLC and Touch Screen |

| Driving Motor | Servo Motor |

| Capping motor | Magnetic motor |

| Torque | 0-100N |

| Detection | Photocell |

| Filling Type | Piston Pump, Peristaltic Pump |

| Power | 1.5KW |

| Material | SS304 |

| Capping Head | Screwing, Pressing, Crimping Head ( According to the cap type) |

| Suitable Industry | Cosmetic, medical, food, detergent, etc |

| Human protection | Complete safety switch alarm |

| Cap type | Chubby Gorilla bottle |

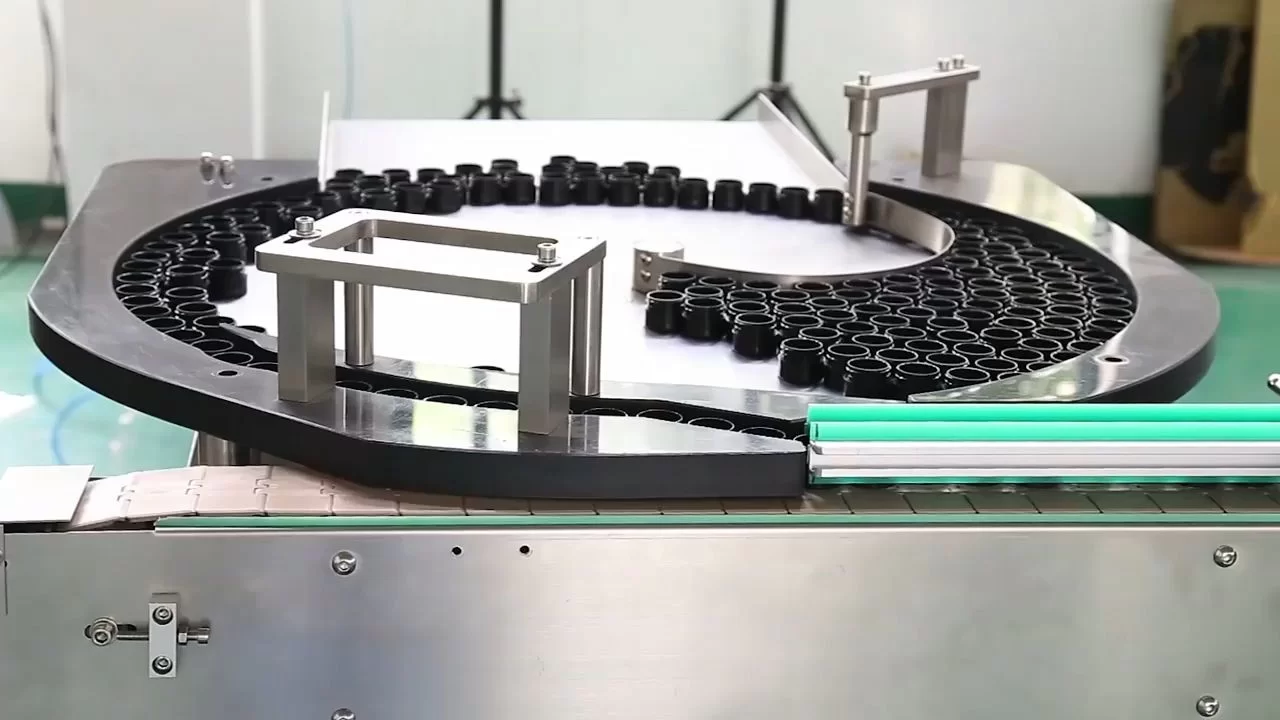

Bottle feeding table

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output tunnel, the machine will be able to work with different size bottle.

Unscrambler is another good choice

Sometimes we run bottle unscramber , especially for 10 ml , due to heavy low weight , 10 ml gorilla can not stand well on the table , we invent unscrambler , you just put bottle inside , then it arrange bottle direction and output into filling machine automatically .Different size botle with different molds , it works with many different formats gorilla , of course , the bigger the bigger .

How to work with so many different size vials? Especially when you run 10-120 ml

10ml vials unscrambler

15/30/60 ml vials unscrambler

Combination of the unscrambler and feeding table

To save budget cost , most customer select to run 10 ml with unscrambler , others are feed by rotary table .

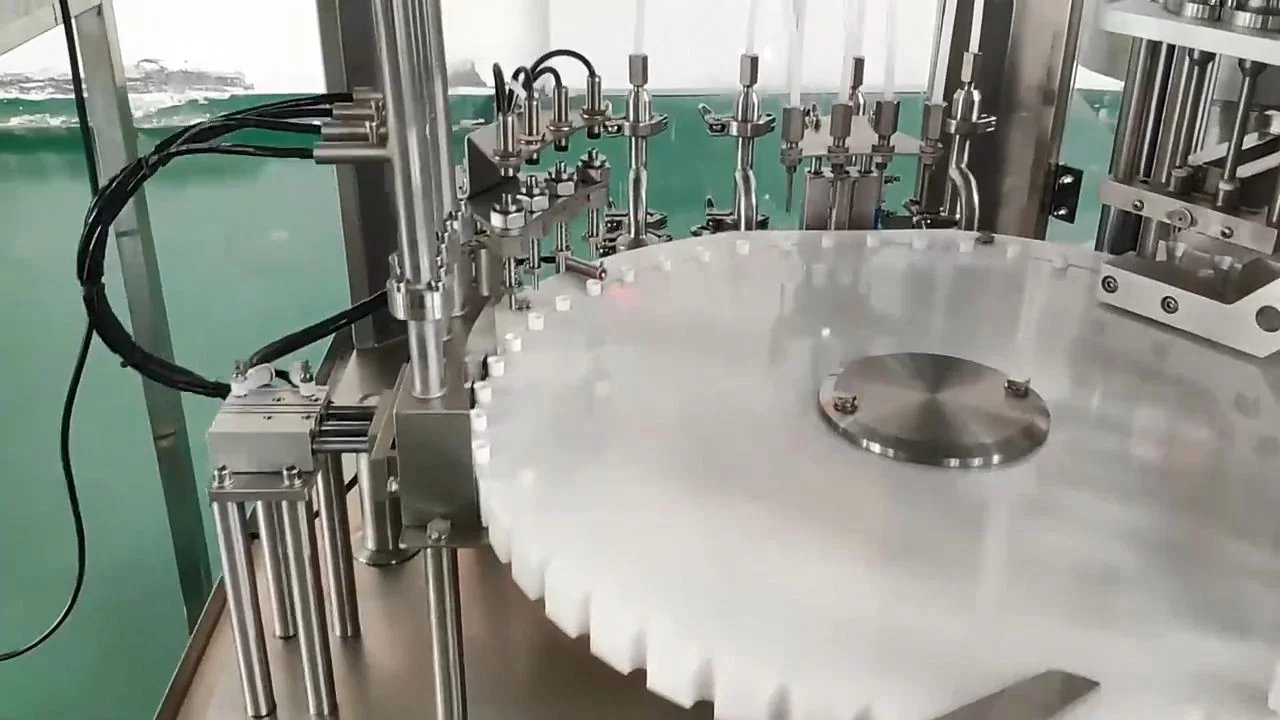

How to ensure fast filling speed and high precision?

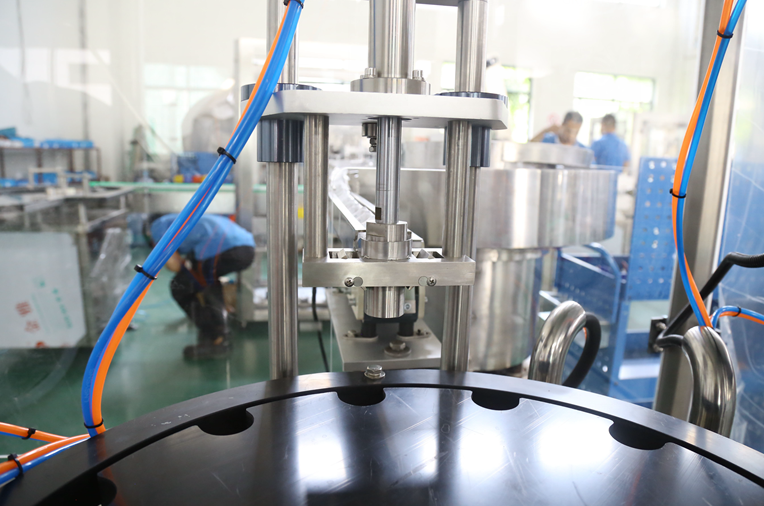

This is wheel type piston pump filling machine which is designed for small bottle and low capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

Servo motor driving

Different from traditional air driving , paixie customize machine by servo motor , it is contributed to precision control and different volume change, everything will be done by HMI adjustment

Servo filling station construction

1- High precison , we control the servo motor by PLC , the servo contected with the piston pump by screw , the motor running up ,push the screw , then screw push piston at the opposite , so actually the filling volume is equal to motor running distance .

How to have the cap to be inserted accurately ?

Cap vibrator

With the customzied mold , all format spray can be inserted into bottle accurately

Cap inserting station with mold

With the customzied mold, all formats dropper can be inserted into the bottle accurately

Vibrator construction

By replace the top hopper, we are able to work with different caps

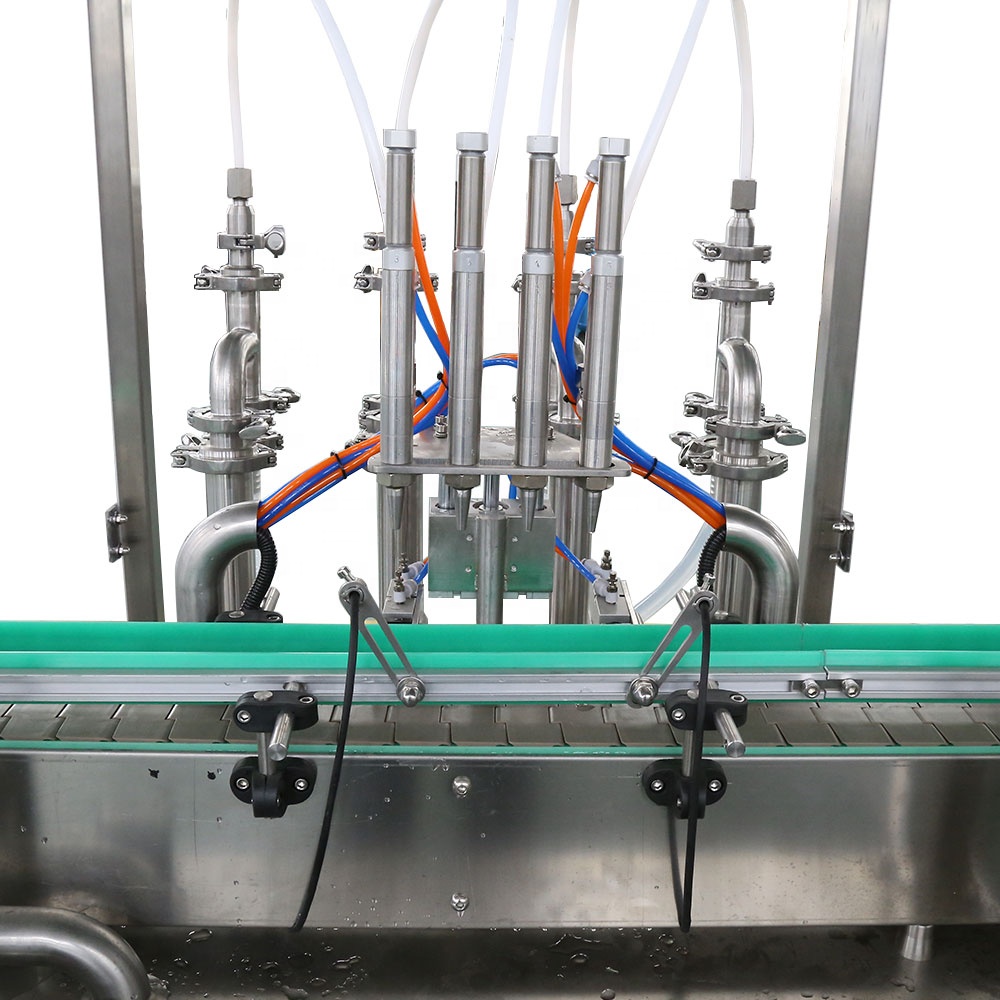

How to Ensure the capping torque and protect from broken?

Three-jar capping head application

The three-Jaw capping head is the newest design for different cap size, it is easy adjusted .

Magnetic cap torquing motor

To be different from traditional capping motor , Paixie uses magnetic motor in torquing , you can set all power as the cap need so that we prevent cap from broken or liquid leaking beucase of toure over or few

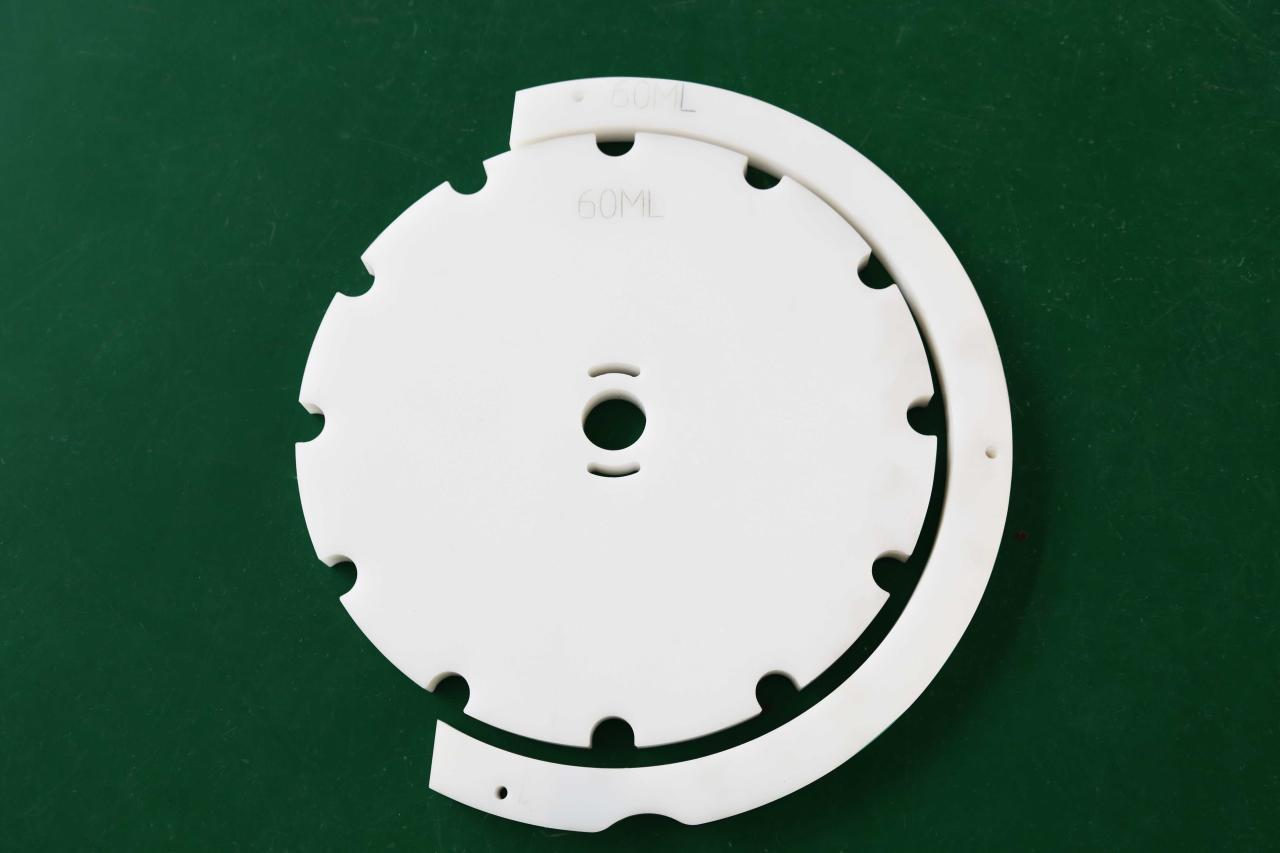

How to replace bottle from one format to another format ?

We do bottle star wheel for each size bottle , that is the only part you have to replace , one bottle one wheel .

There is always a collecting table at the end of the packing line to collect all your gorillas .