The Automatic Essential Oil Bottle Filling Capping Machine Bottling Line is an advanced packaging system designed to provide a seamless solution for filling and capping essential oil bottles. The system is fully automated and can fill, cap and label essential oil bottles of different sizes and shapes with great accuracy and efficiency.

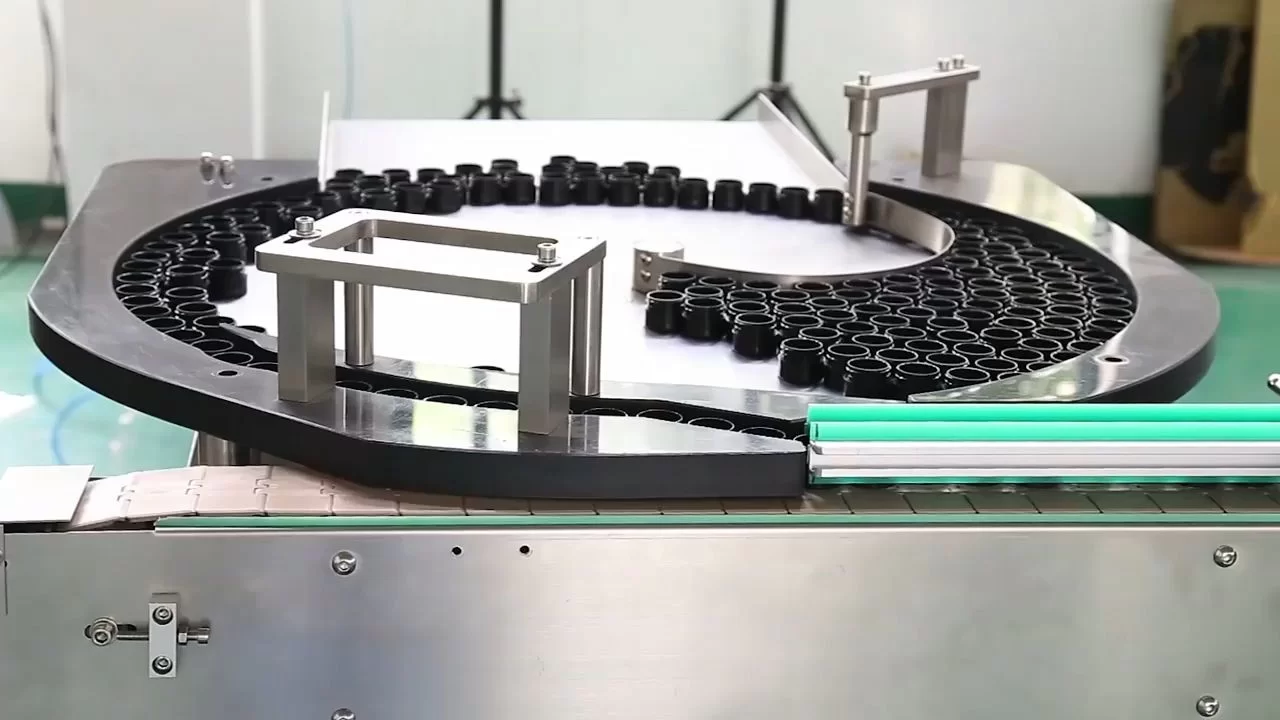

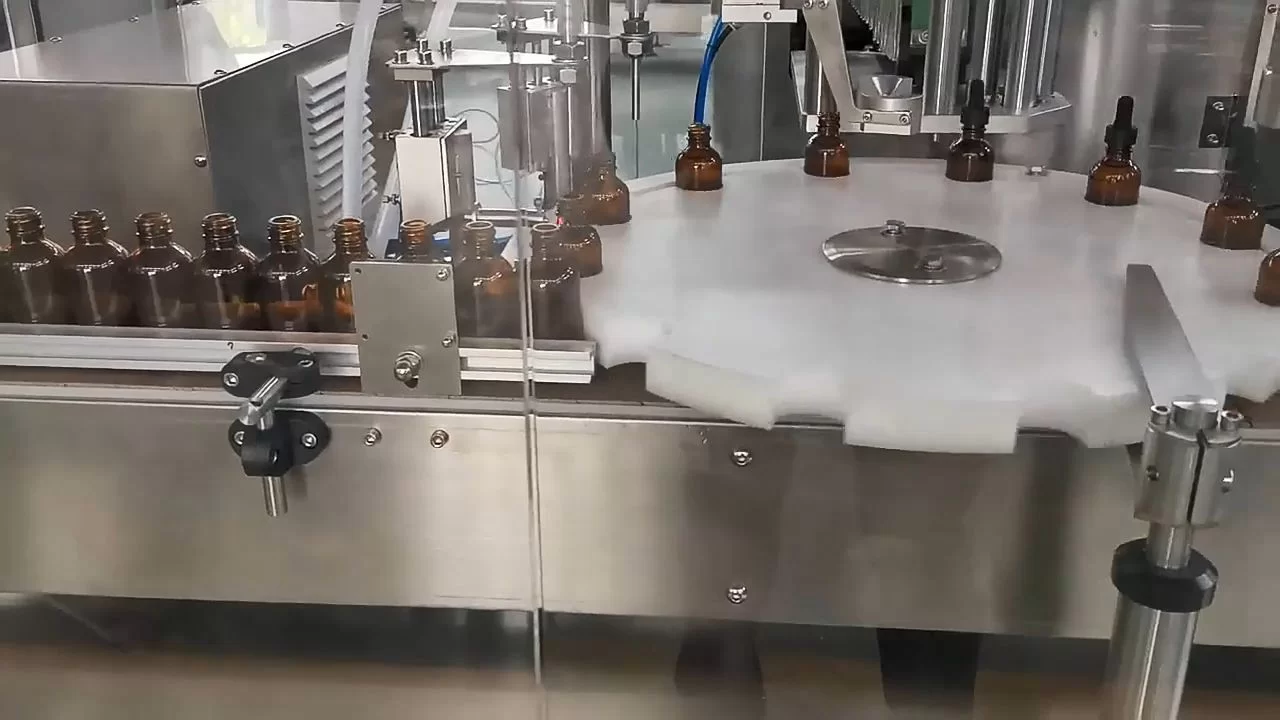

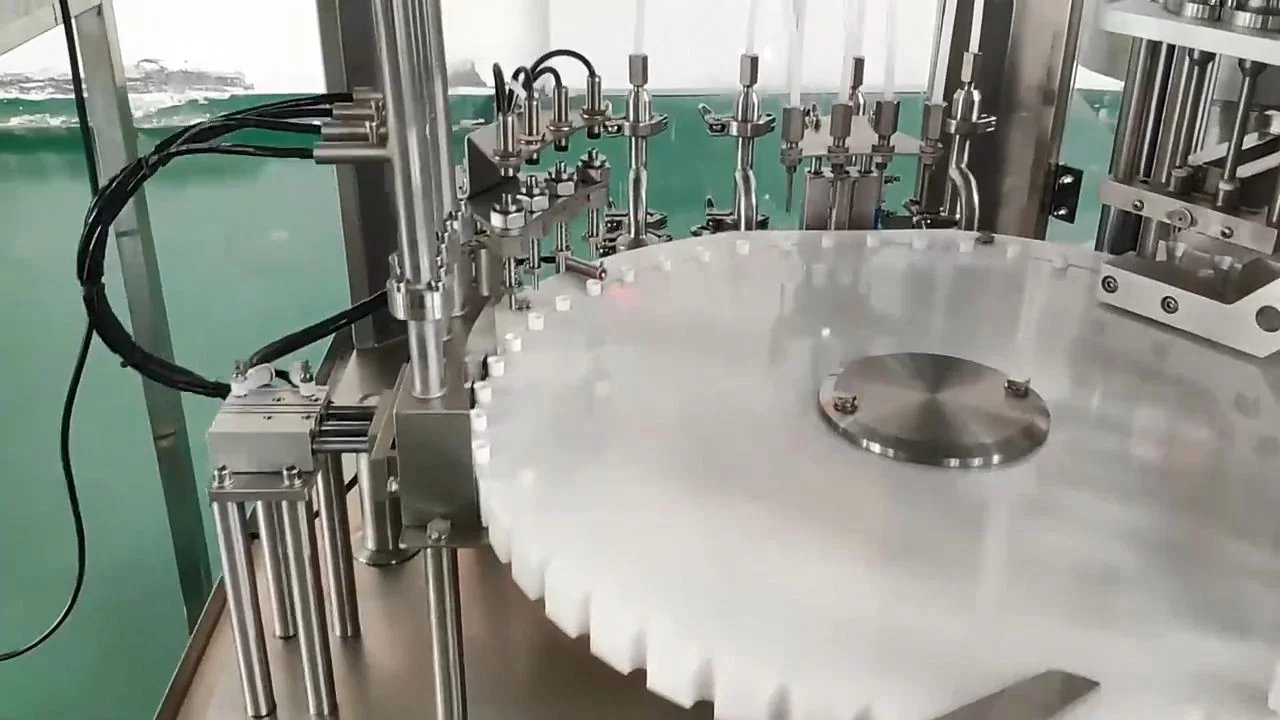

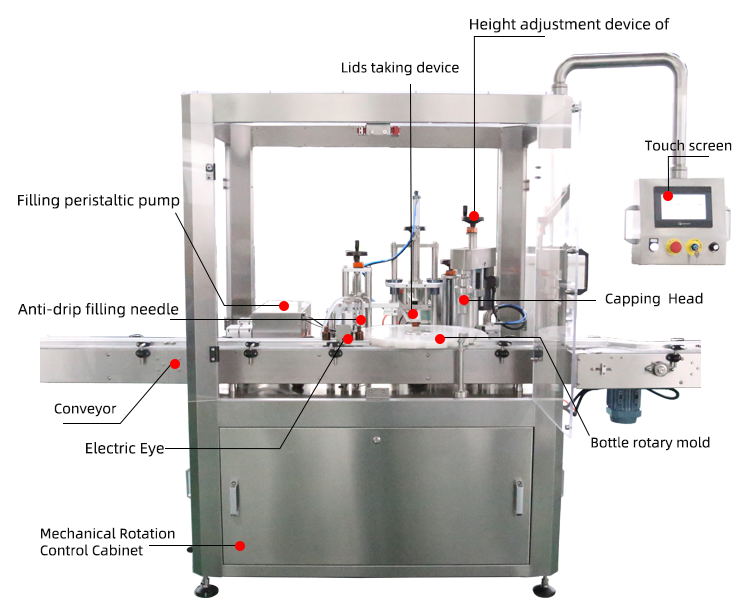

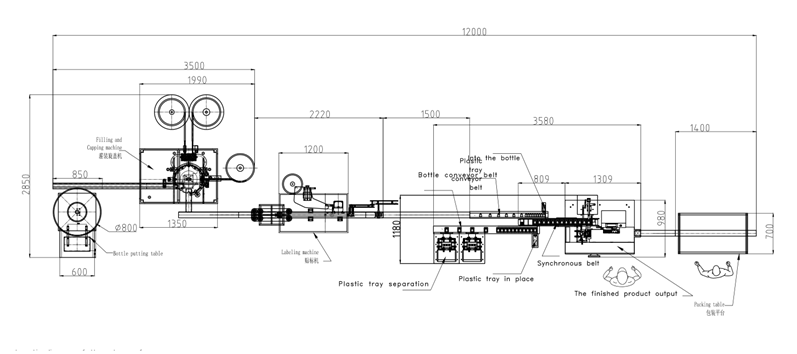

This bottling line is composed of several machines that work together to provide a complete solution for essential oil bottling. The machines include an automatic bottle feeder, filling machine, capping machine, labeling machine, and a conveyor belt. The filling machine is designed to fill the essential oil bottles to a predetermined level, while the capping machine tightens the caps to ensure a secure fit. The labeling machine is used to print and apply labels on the bottles with information such as product name, ingredients, and usage instructions.

One of the key advantages of this automatic bottling line is its high level of precision and efficiency. The filling machine uses a volumetric filling system that ensures accurate and consistent fill levels for every bottle. Additionally, the capping machine uses a torque control system to apply consistent torque levels to each cap, ensuring a secure fit and preventing leaks.

The automatic essential oil bottle filling capping machine bottling line is widely used in the essential oil manufacturing industry, providing a fast, reliable and efficient solution for bottling essential oils. It is also used in the cosmetic and pharmaceutical industries for filling and capping small bottles of creams, lotions, and other products.

In recent years, the demand for essential oils has been increasing rapidly due to their therapeutic properties, which has led to the growth of the essential oil industry. The use of automated bottling lines, such as the automatic essential oil bottle filling capping machine bottling line, has become increasingly popular due to their efficiency, precision, and reliability. This technology has helped manufacturers to increase their productivity, reduce waste, and improve their product quality.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: United Kingdom, United States, Italy, Australia, None

- Application: APPAREL, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Textiles

- Packaging Type: Bags, Barrel, Bottles, CANS, Capsule, Cartons, case, Pouch, Stand-up Pouch

- Packaging Material: Glass, Metal, Paper, Plastic, Wood

- Automatic Grade: Automatic

- Driven Type: Pneumatic

- Voltage: 110V/220V/380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2500*1600*1650mm

- Weight: 600 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Filling Material: Milk, Water, Oil, Juice, Powder

- Filling Accuracy: 99

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

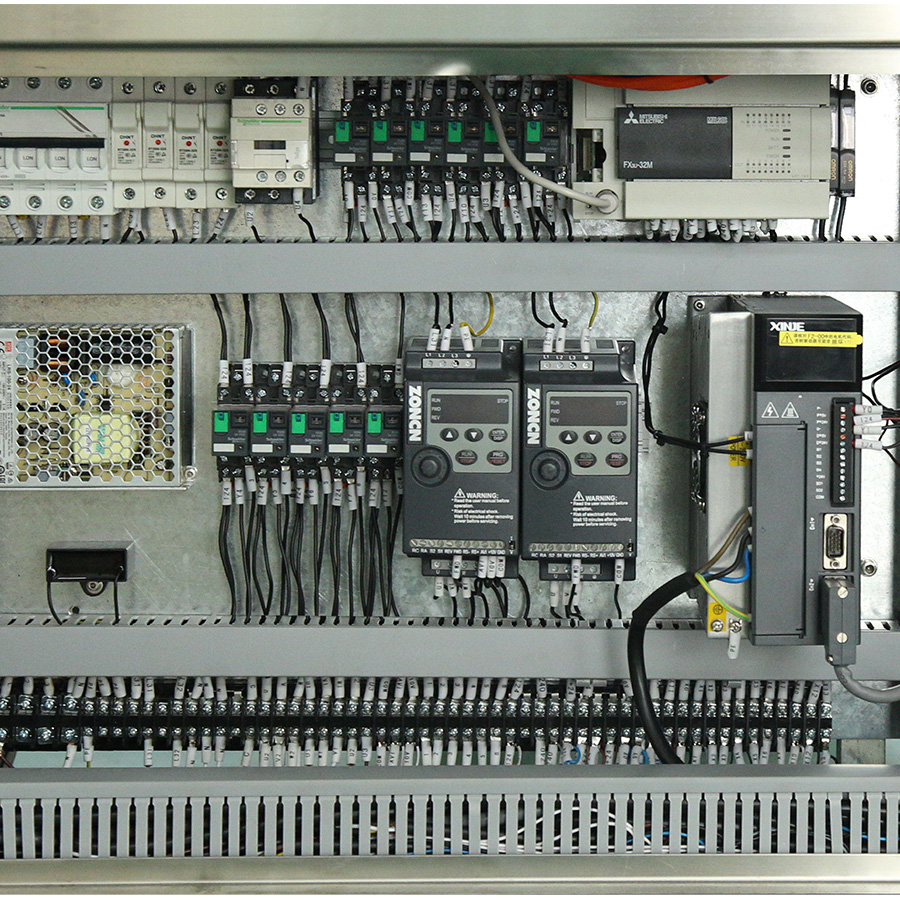

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- After-sales Service Provided: Engineers available to service machinery overseas

- Company advantage:: OEM with good After-sales Service

- Product advantage: Can be customized/High precision/Space saving/Effective cost

- Filling pump: Peristaltic Pump Filling/Piston Pump Filling

- Material: SUS304/316(Meet GMP Standard)

- Eligibility rate: ≥99%

- After Warranty Service: Online support

More Details

Product Description

The fully automatic small vail bottle liquid filling capping machine is with CE & ISO 9001 certification.The machine is applied to glass or plastic bottles with different sizes and shapes, and suitable for different filling volume. By adjusting the filling volume on touch screen, it can fill liquid with quick speed and high precision. It is widely used for essential oil, eye dropper, perfume, nail polish, lotions and other vial bottle filling.

Product Paramenters

| Product | Automatic Essential Oil Bottle Filling Capping Machine Bottling Line |

| Output | 1000-6000BPH, or customized |

| Filling Volume | 10-100ml, or customized |

| Filling Material | Liquid, Gel or etc |

| Control | PLC and Touch Screen |

| Driving Motor | Servo Motor |

| Filling Type | Piston Pump, Peristaltic Pump |

| 2.5Power | 1.5KW |

| Machine Frame Material | SS304 |

| Capping Head | Screwing, Pressing, Crimping Head ( According to the cap type) |

| Suitable Industry | Cosmetic, medical, food, detergent, etc |

Application