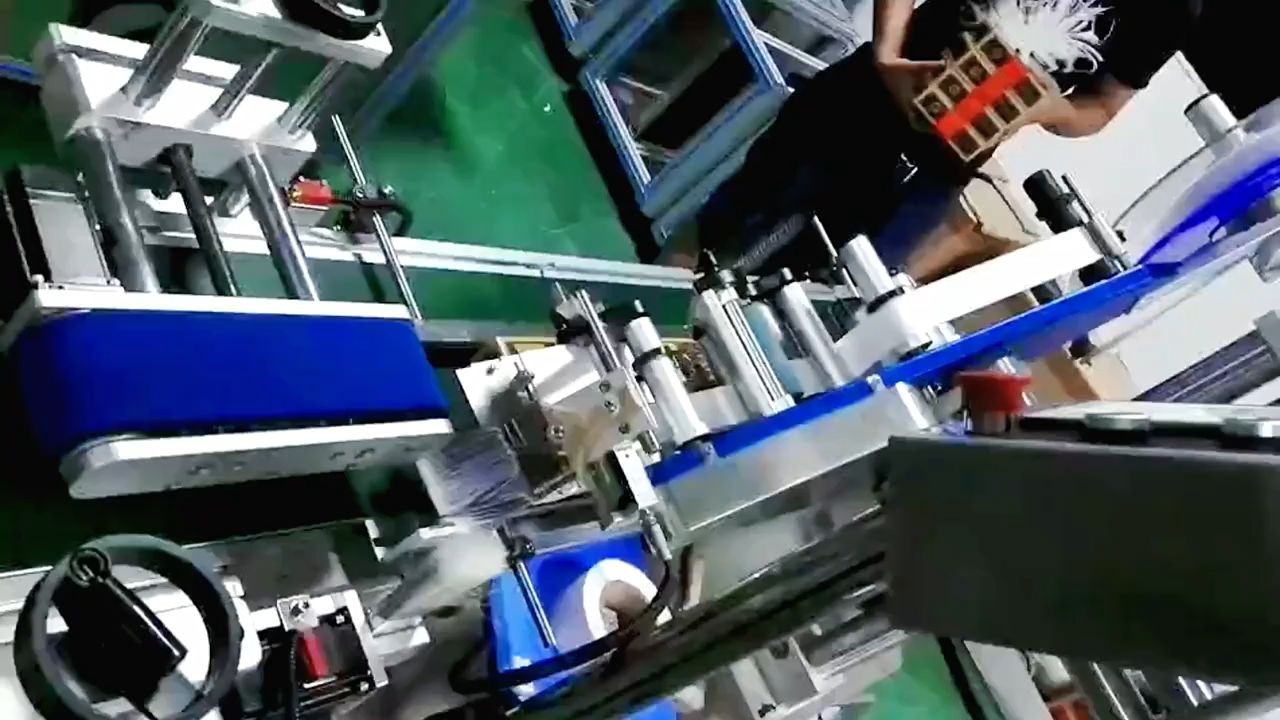

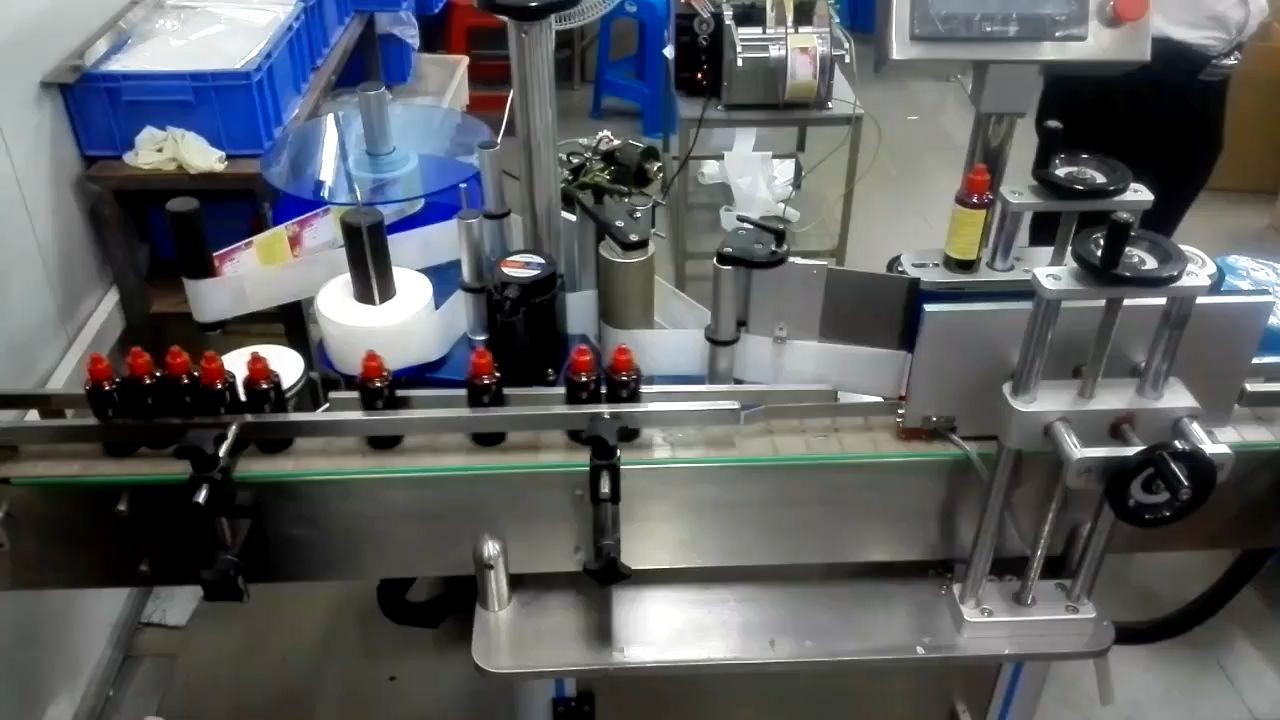

The automatic labeling machine is a plane labeling machine, it is suitable for labeling films or stickers on flat surface like card, bottle lids, packaging bags. it can be affixed with the following two labels at one time, such as labeling on the top and bottom of the box; separated separately and converted into two universal plane labelers.

| Technical Parameters | |||

| Machine Size | 1600(L)×1000(W)×1250(H)mm | ||

| Output Speed | 20-100pcs/min depends on label and bottle size | ||

| Height Label Object | 30-280mm | ||

| Bag size | max L60cm; max W 40cm; max H10cm | ||

| Label Height | 15-140mm | ||

| Label Length | 25-300mm | ||

| Pastes the sign precision | ±1mm | ||

| Roll inside | 76mm | ||

| Roll Outside Diameter | 300mm | ||

| Power Supply | 220V 0.8KW 50/60HZ | ||

| Power Supply | 2800(L)×1650(W)×1500(H)mm | ||

| Weight of Labeling Machine | 450Kg | ||

The automatic high-speed plane labeling machine for bags is a versatile and efficient piece of equipment designed to apply labels onto the plane surfaces of bags in high-speed production lines. This machine is ideal for use in a wide range of industries, including food and beverage, pharmaceuticals, and cosmetics.

The machine is equipped with a conveyor system that moves the bags to the labeling station. At the labeling station, a sensor detects the bag's position and accurately applies the label onto the plane surface. The labeling process is highly precise and accurate, ensuring that each bag is labeled to the desired level.

The machine can label up to 600 bags per minute, depending on the bag size and label specifications. This high-speed capability makes it a valuable asset in any production facility looking to increase productivity and efficiency.

The automatic high-speed plane labeling machine for bags is also easy to set up and maintain. It requires minimal training to operate, and its compact size makes it easy to move and transport. The machine is also equipped with a cleaning system that ensures that the labeling station and other parts of the machine are kept clean and free from contaminants. This helps to maintain the quality of the product and ensures that it is safe for use.

The machine is also equipped with a user-friendly interface that allows the operator to control the entire labeling process. The interface is intuitive, making it easy for operators to adjust the labeling speed, pressure, and other parameters as required.

In conclusion, the automatic high-speed plane labeling machine for bags is a specialized machine that provides an efficient and automated process for labeling the plane surfaces of bags in high-speed production lines. Its advanced technology ensures precise and consistent labeling, making it an ideal solution for manufacturers looking to increase productivity and efficiency. Its high-speed capability, user-friendly interface, and cleaning system make it a valuable asset in any production facility.