Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 6000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Factory Production workshop

- Showroom Location: Egypt, Philippines, South Korea, Japan

- Application: Food, Beverage, Commodity, Chemical, Machinery & Hardware

- Packaging Type: CANS, Bottles, Barrel, Stand-up Pouch, Pouch, case

- Packaging Material: Plastic, Metal, Glass, Other

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Dimension(L*W*H): 1500*1300*1850mm, 4 Nozzles

- Weight: 300 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Filling Material: Oil, Jam, Peanut Butter, Cream, Honey, Sauce

- Filling Accuracy: ±1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Pressure vessel, PLC, Gearbox, standard

- Product name: Jam Sweet Bean Sauce Filling And Capping Machine

- Keywords: Honey Stick Liquid Filling Machine

- Filling speed: 20-25pcs/min, 2L bottle

- Processing Types: Automatic filling production line

- Filling head: 4-12, can be customized

- Filling volume: 50-5000ml, can be customized

- Bottle type: Plastic glass bottle or barrel

- After-sales Service: Overseas after service, whole life

- Machine advantage: High production, competitive price

- Company type: Integration of industry and trade

More Details

Main configuration:

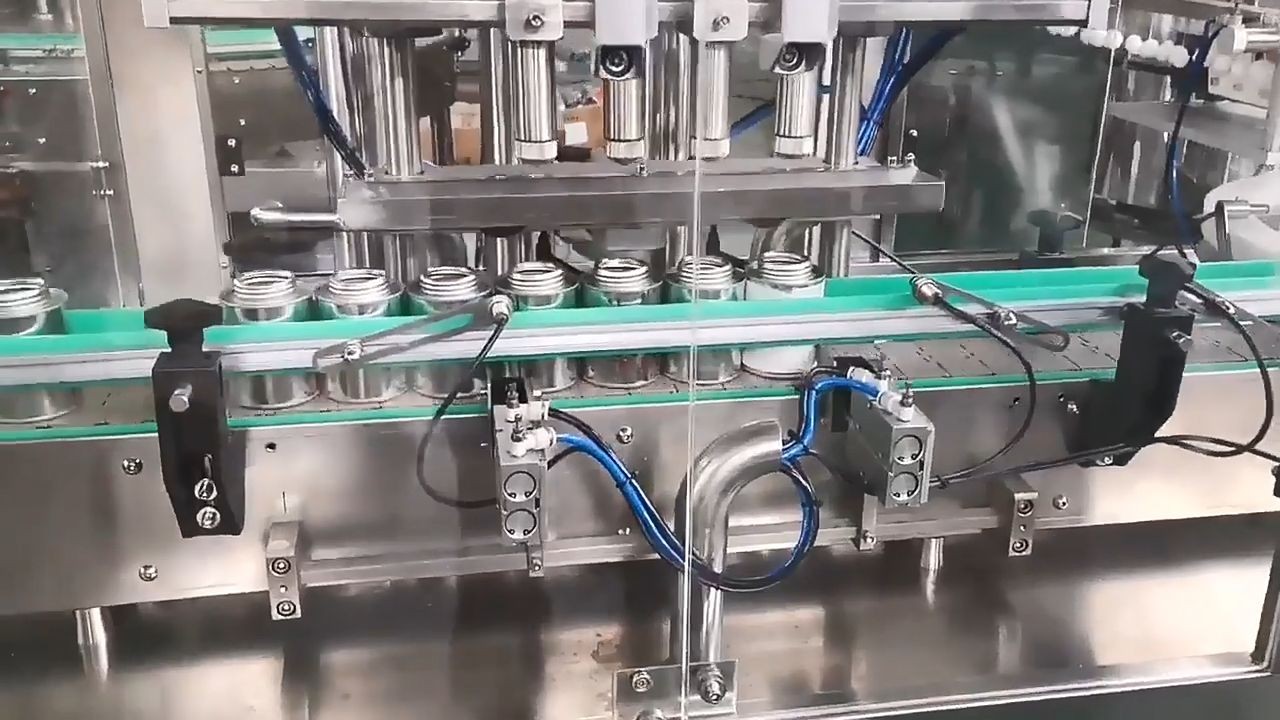

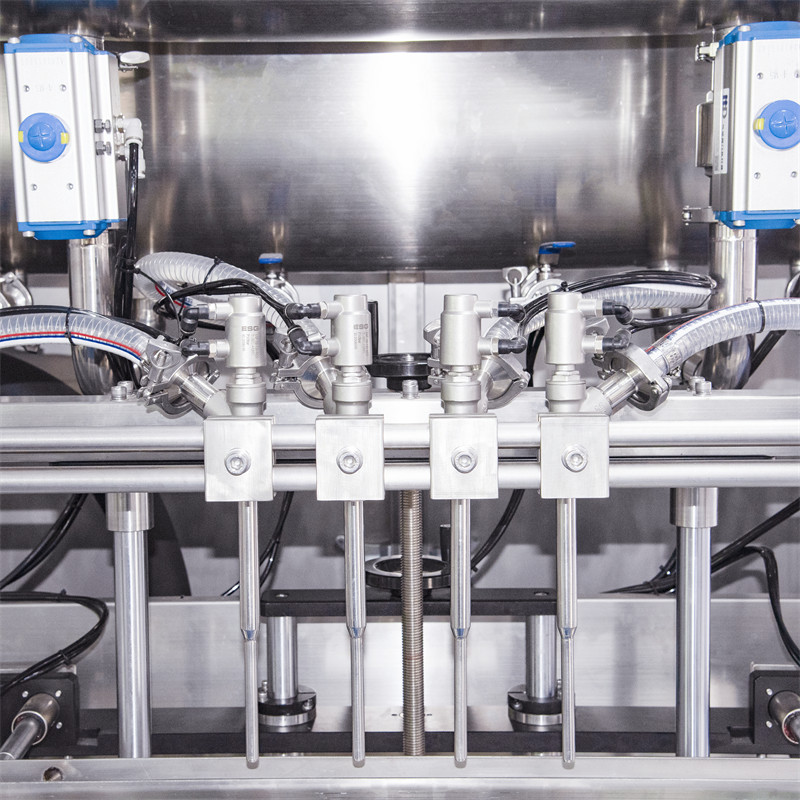

1. Frame, foot and guardrail materials: aluminum profile, 304 stainless steel

2. Pneumatic components: Taiwan brand AIRTAC

3. Program controller: German brand Siemens

4. Man machine interface: German brand Siemens 7-inch color touch screen

5. Photoelectric sensor: German brand Leuze

6. Relay and air switch: French brand Schneider

7. Motor frequency converter: German brand Siemens

8. Materials of exposed parts: aluminum profile, stainless steel, anodized aluminum alloy, electroplated 45 steel and plastic parts

| Technical Parameters | |

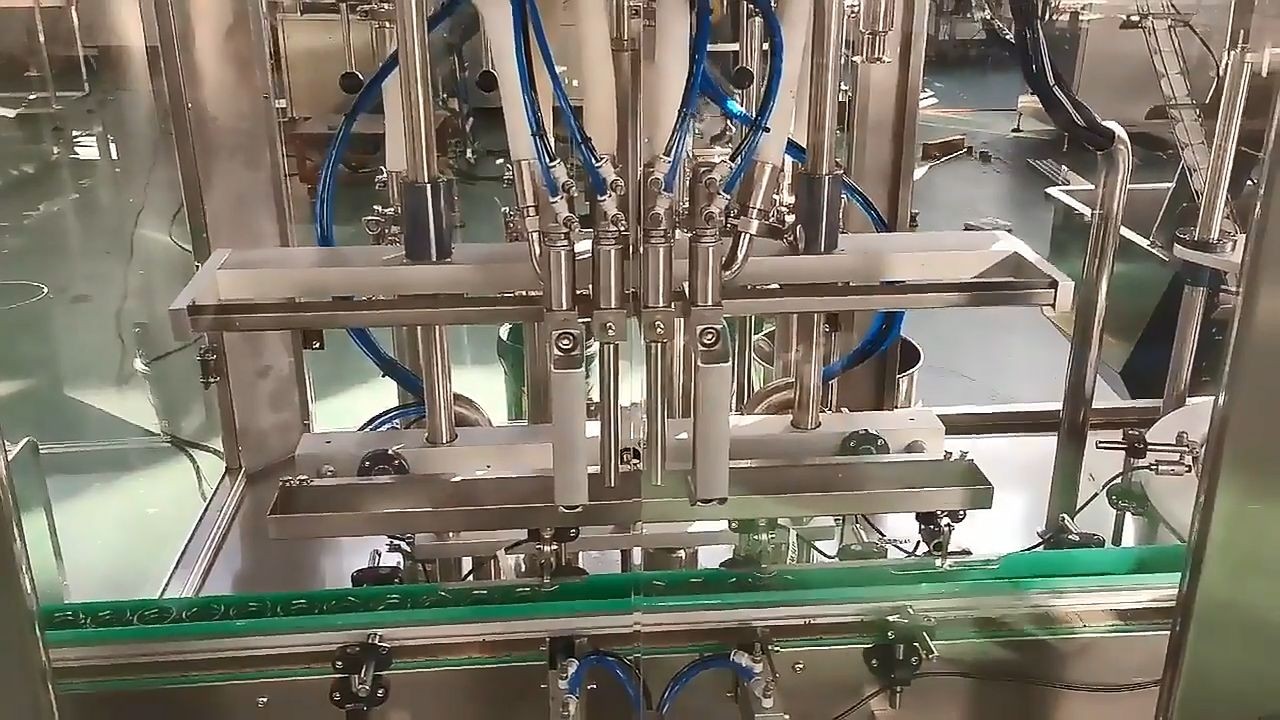

| Filling head | 4(can be custimized according to speed) |

| Filling speed | 1000-3000 BPH |

| Filling volume | 500ml-5000ml(cusotmization) |

| Filling form | Piston filling |

| Filling accuracy | ±1.0% |

| Power supply | About 220V 50/60Hz, 3KW |

| Air pressure | 0.6-0.8MPa |

| Net weight | 500KG |

Wide Range of Applications

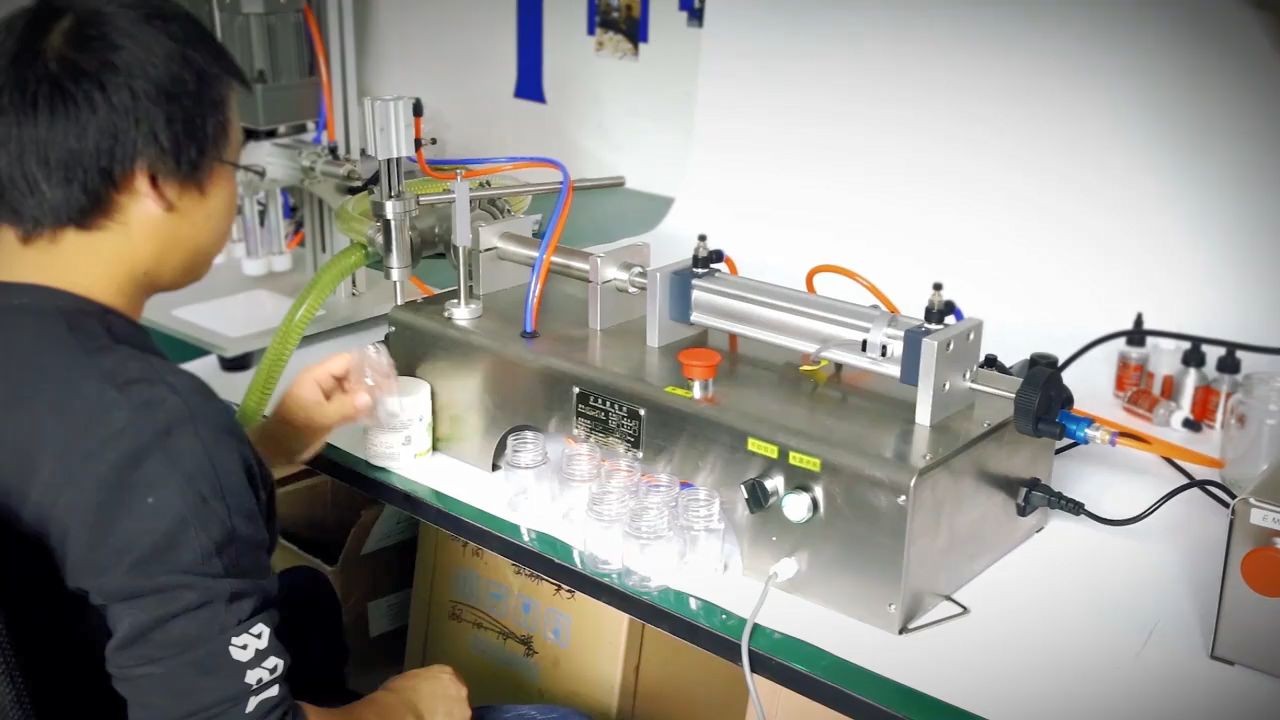

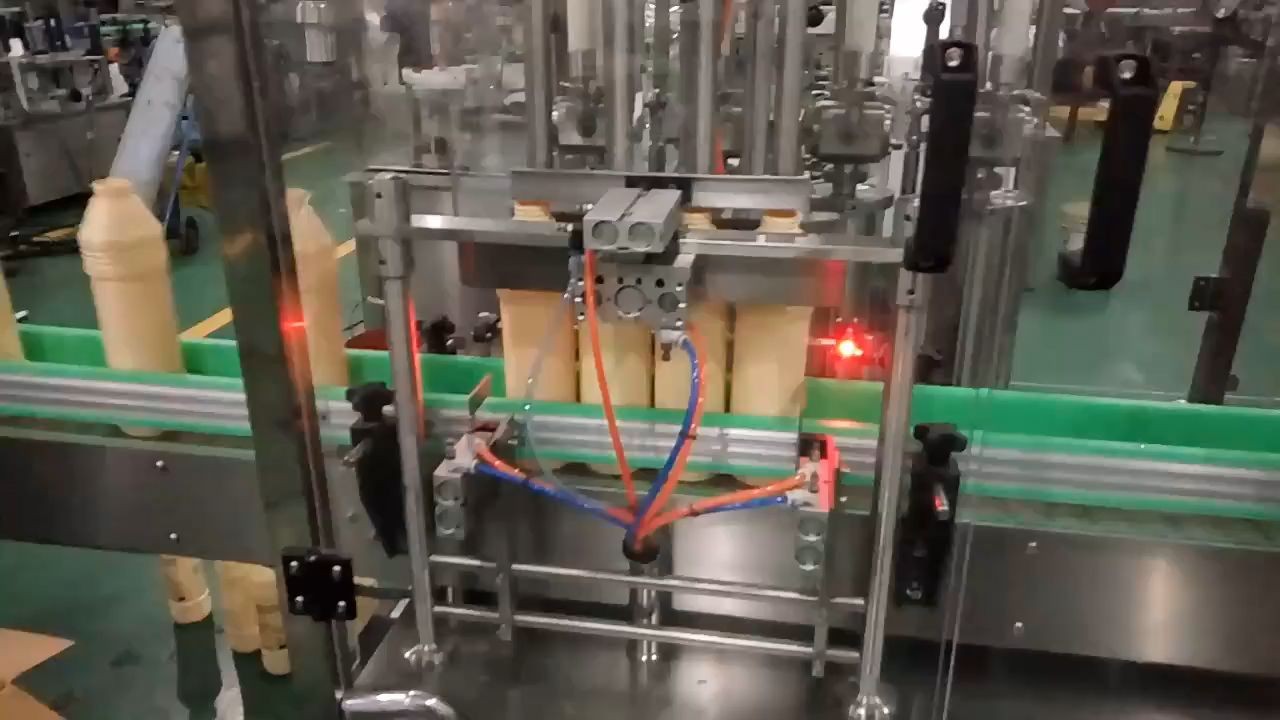

The Automatic Honey Paste Tomato Sauce Bottle Filling and Capping Machine is a fully automated system designed to fill and cap bottles with various types of liquids such as honey, paste, tomato sauce, and other viscous products. This machine is widely used in the food and beverage industry and is an essential component of many manufacturing facilities.

The machine is equipped with a high-precision piston filling system that ensures accurate and consistent filling of each bottle. The filling volume can be easily adjusted using the touch screen interface, and the machine can handle bottles of different sizes and shapes.

After the filling process, the bottles are automatically transported to the capping station, where the caps are applied with precision and accuracy. The machine is designed to handle different types of caps, including screw caps, press-on caps, and snap-on caps. The capping head is adjustable, allowing it to accommodate bottles of different sizes.

The Automatic Honey Paste Tomato Sauce Bottle Filling and Capping Machine is constructed using high-quality materials that ensure durability, reliability, and easy maintenance. The machine is easy to clean and is designed to meet all safety and hygiene standards.

In addition to its high-speed performance, the machine has a compact design, making it easy to install in any manufacturing facility. The machine can be operated by a single operator, reducing labor costs and improving overall efficiency.

Overall, the Automatic Honey Paste Tomato Sauce Bottle Filling and Capping Machine is a highly reliable and efficient solution for any food and beverage manufacturing facility looking to improve its production processes.