The Automatic Industry PVC Adhesive High Viscosity Glue Filling Machine is a state-of-the-art packaging equipment that is specifically designed for the precise filling of PVC adhesive high viscosity glue into containers. The machine is highly automated, which means that it can efficiently fill containers with little to no operator intervention. This feature makes it a perfect choice for high-volume production environments where consistent and accurate filling is essential.

One of the key advantages of this machine is its high filling accuracy. It has a precision filling system that ensures that the adhesive glue is filled accurately into the containers, minimizing product wastage. The machine is also highly efficient and can fill a large number of containers in a short period. Additionally, it is easy to operate and maintain, which means that it requires minimal operator training and has a low maintenance cost.

The Automatic Industry PVC Adhesive High Viscosity Glue Filling Machine has several unique features that make it stand out in the packaging equipment industry. It is equipped with an advanced PLC control system, which allows the operator to program and control the filling process easily. The machine is also made of high-quality materials that are corrosion-resistant, ensuring that it lasts for many years.

The machine is versatile and can be used in a wide range of industries that require the precise filling of high viscosity products such as PVC adhesive glue. These industries include but are not limited to, the chemical industry, adhesive industry, and the pharmaceutical industry.

As the packaging equipment industry continues to grow, the Automatic Industry PVC Adhesive High Viscosity Glue Filling Machine is expected to play an essential role in enhancing the efficiency of the packaging process. With its high filling accuracy, efficiency, and ease of operation, this machine is set to become an indispensable asset to manufacturers and packaging companies across the globe.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Machinery Repair Shops, Home Use, Retail, Construction works , Energy & Mining, Other, Advertising Company

- Showroom Location: Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Brazil, Saudi Arabia, Mexico, Russia, Spain, Thailand, Argentina, South Korea, Kazakhstan, Malaysia, Australia

- Application: Commodity, Chemical, Machinery & Hardware

- Packaging Type: Barrel, Bottles, CANS, Other

- Packaging Material: Metal, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 110V 220V 380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2200*900*1800mm

- Weight: 600 KG

- Warranty: 6 Months, Six months free

- Key Selling Points: High Productivity

- Filling Material: Other, Water, Oil, glue

- Filling Accuracy: ≥99%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 6 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Machine Name: PVC adhesive Glue vacuum feeding filling machine

- Yield: 1500-6000BPH(Customized)

- Accuracy: ≥99%

- Driving: Servo motor

- Metal Quality: SS304 and SS316

- Work voltage: 110/220/380V 50/60HZ

- Power: 1-3.5KW

- package: Wooden case

- After-sales Service Provided: Online technical support

More Details

Product Description

This machine suits for various packing such as bottle, jar, can, cup, bag, barrels, etc.. This equipment can be used for different material of cans, such as glass, plastic, iron, aluminum and so on, and the different size of cans is allowed. The tin can filling machine can be designed according to your requirements.

Main technical parameter:

| Product Name | PVC adhesive Glue vacuum feeding filling machine |

| Yield | 1500-6000BPH (customized) |

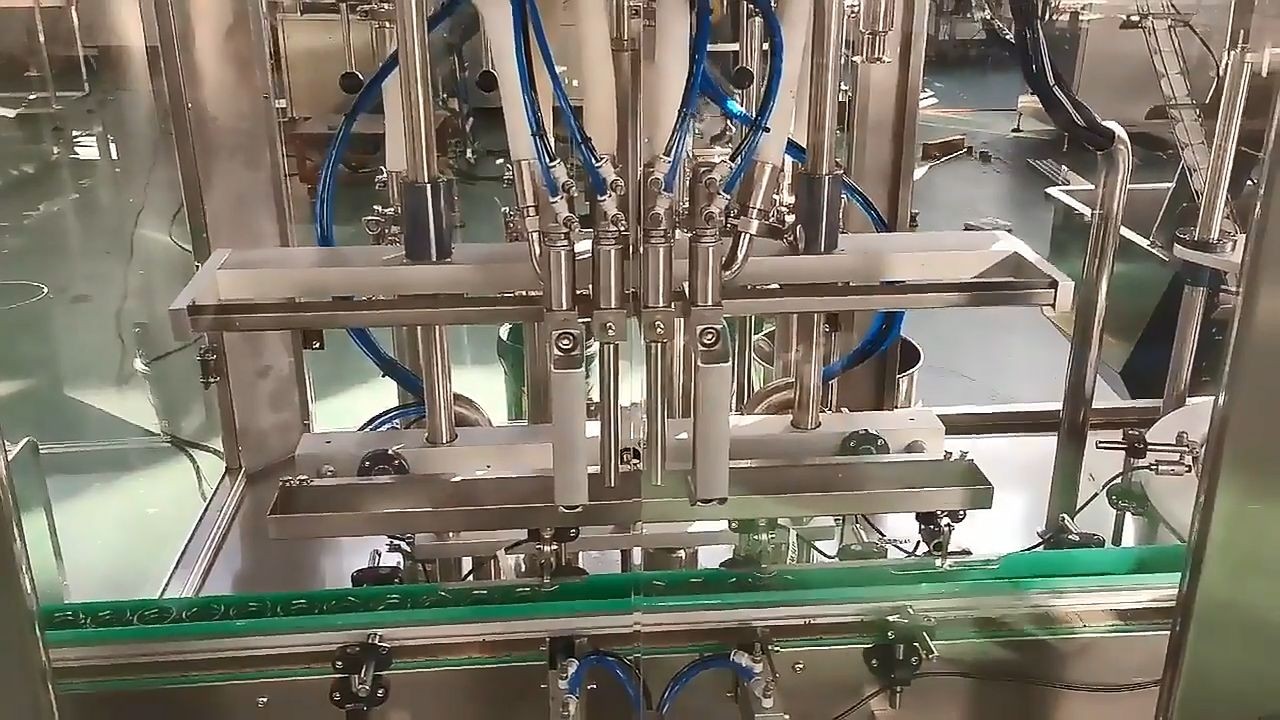

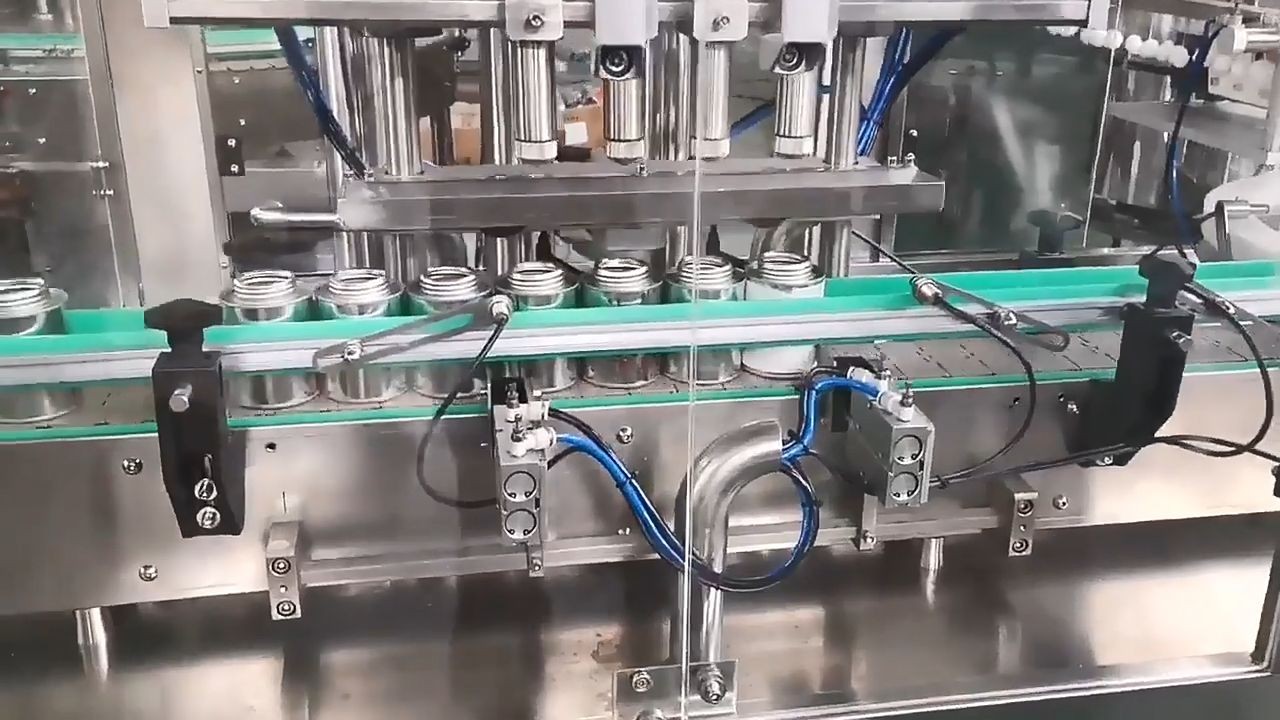

| Filling heads | 1/2/4/6 (Customized) |

| Filling pump | Piston pump |

| Work voltage | 110/220/380V 50/60HZ |

| Air presstion | 0.6MPA |

| Accuracy | ≥99% |

| Power | 2.2KW |

| Driving | Servo motor |

| Pump volume | 100-150ml |

| United size | 2200*900*1800mm |

| Single machine noise | ≤50dB |

| Weight | 600KG |

| Material | SS304 SS316 |

| HMI | 7.5” Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Speed controller | Variable Speed Controls |

| Detecting system | Vial Detector & Counter |

| Label size | Width : 20-180mm Length : 30-350mm |

| Label color | Transparent /colorful label |

| Label application principle | Rolling labeling /positioning labeling |

| Labeling driving | Servo / steeper system |

| Labeling position | Round /square/top/single /double sides |

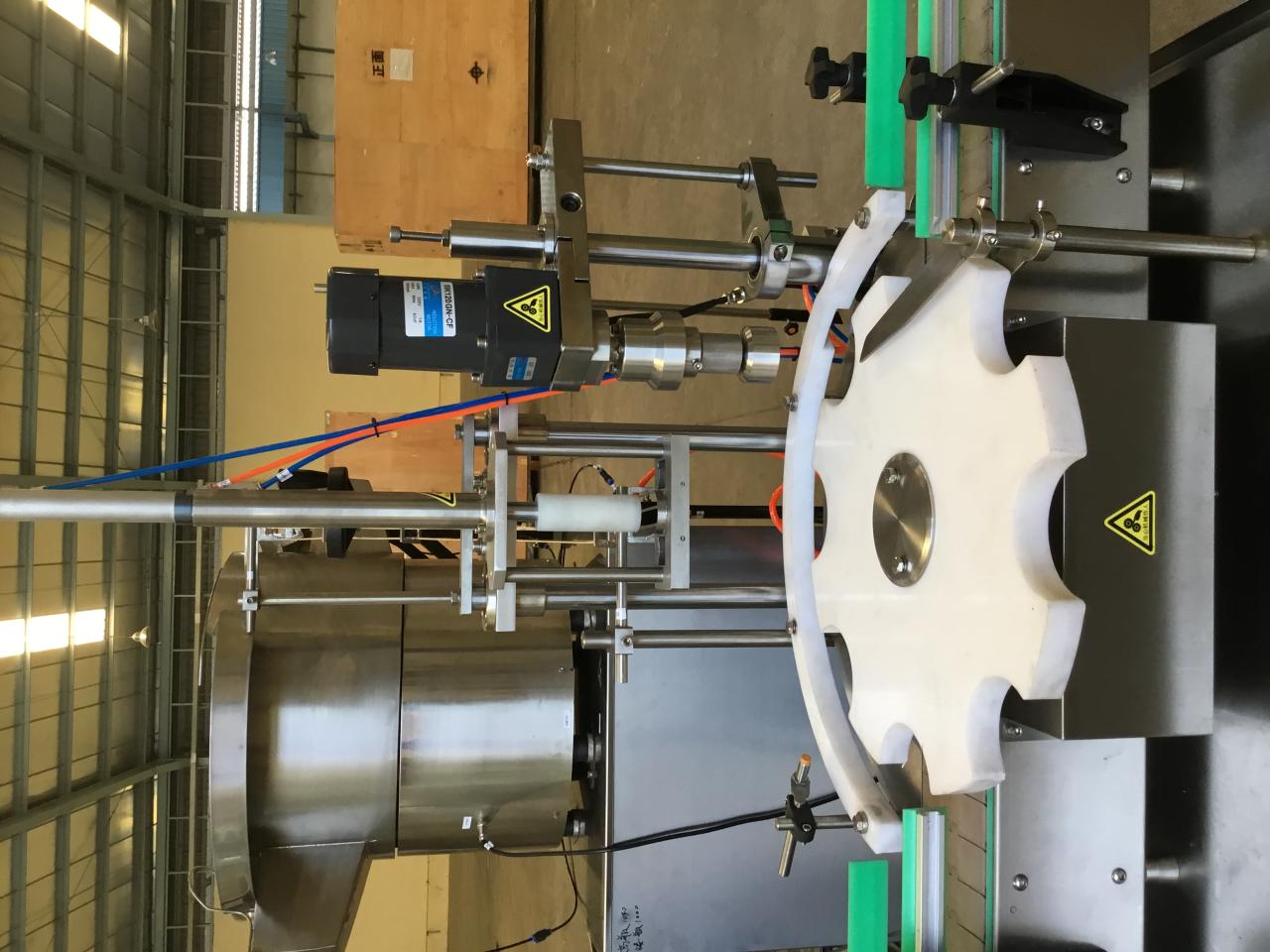

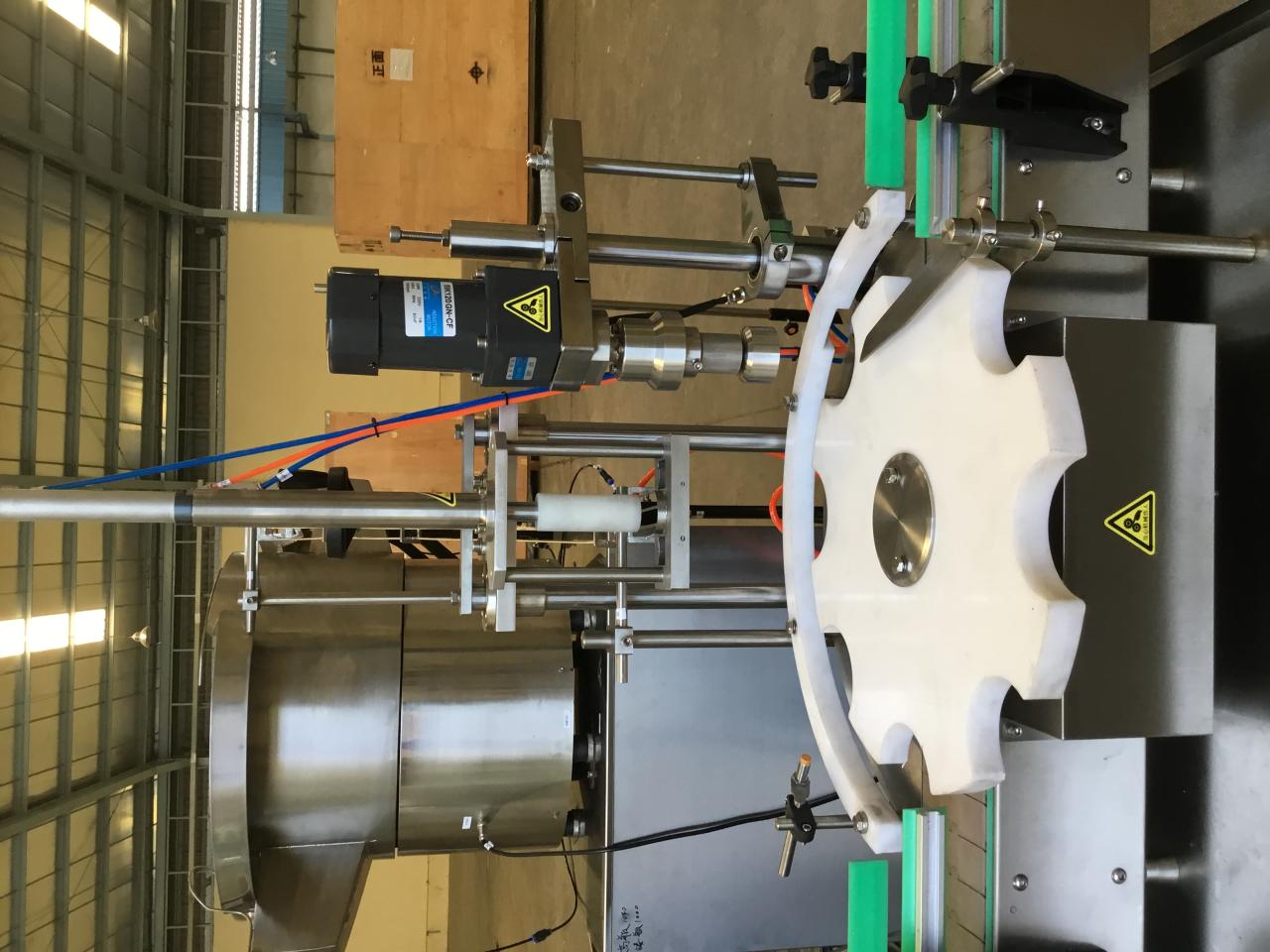

Feeding table

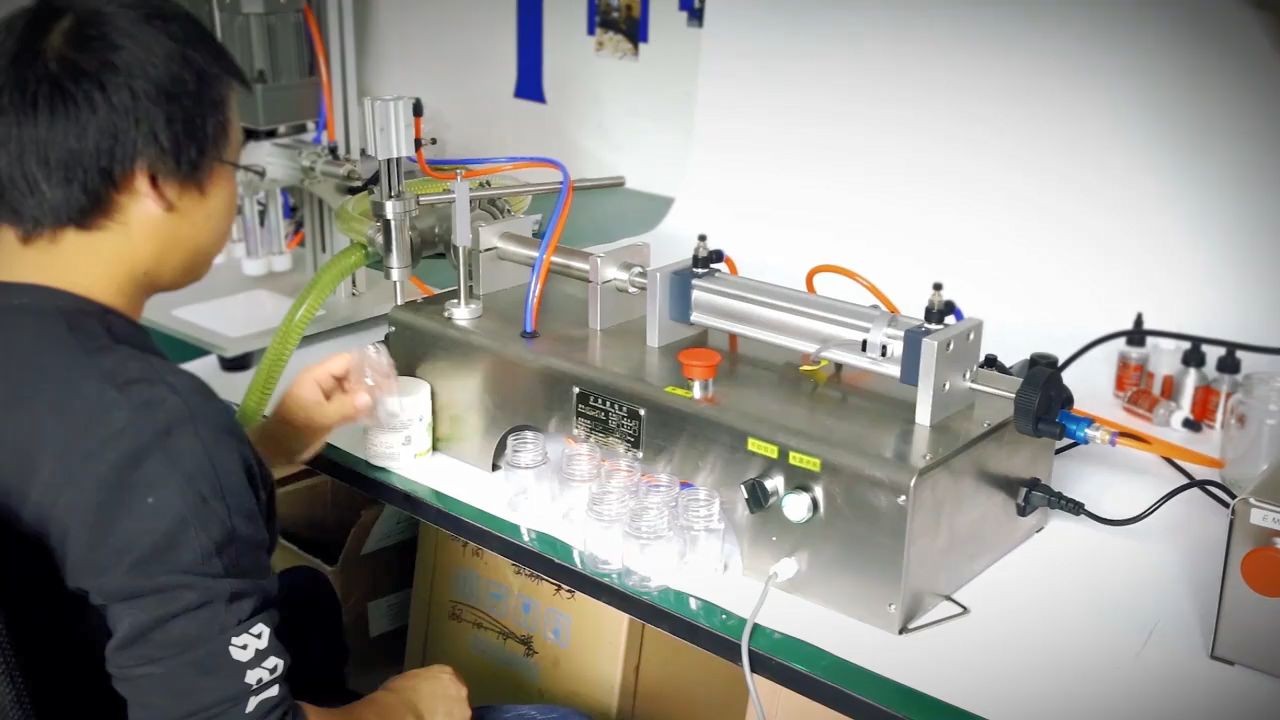

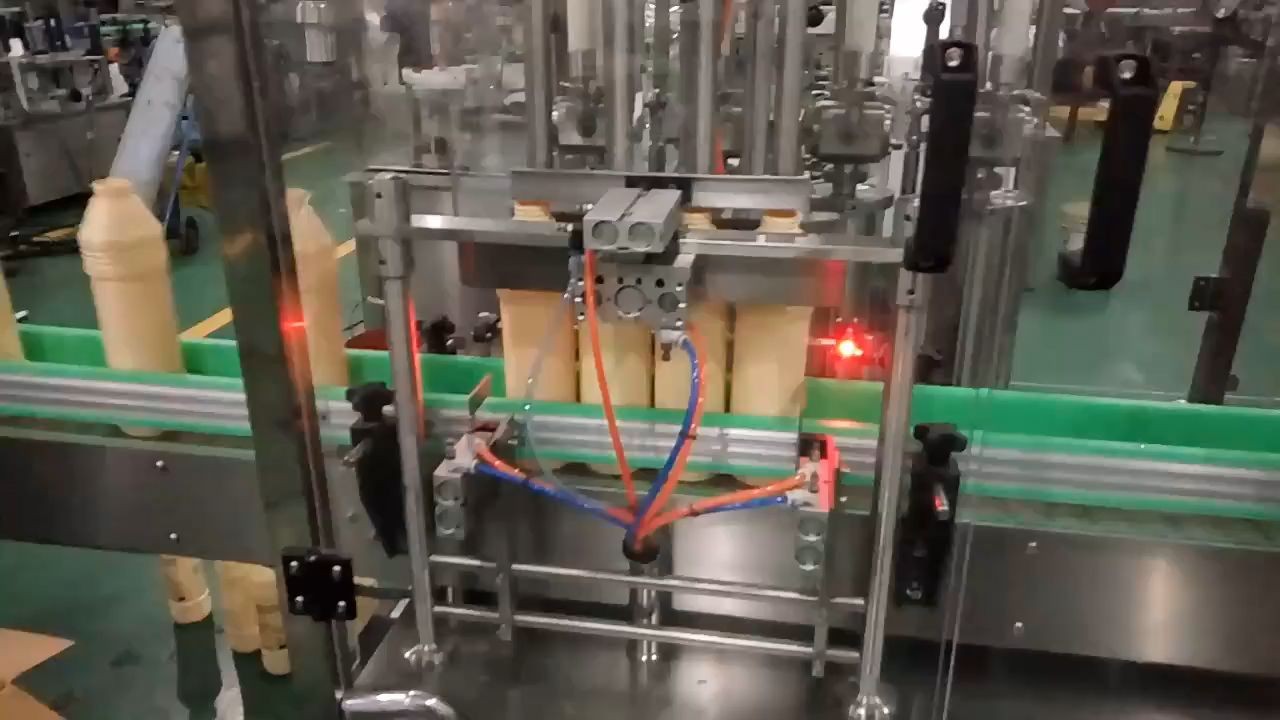

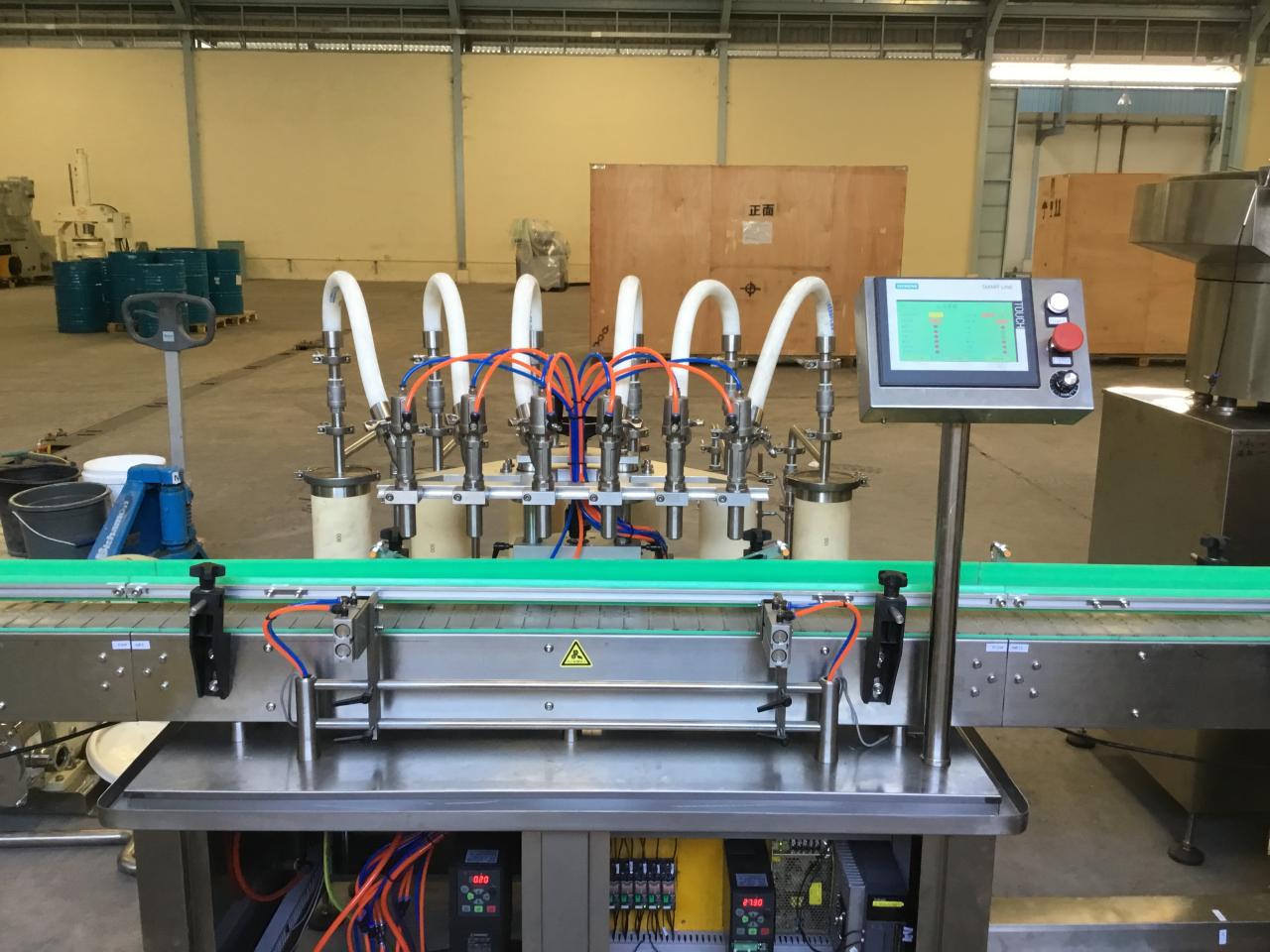

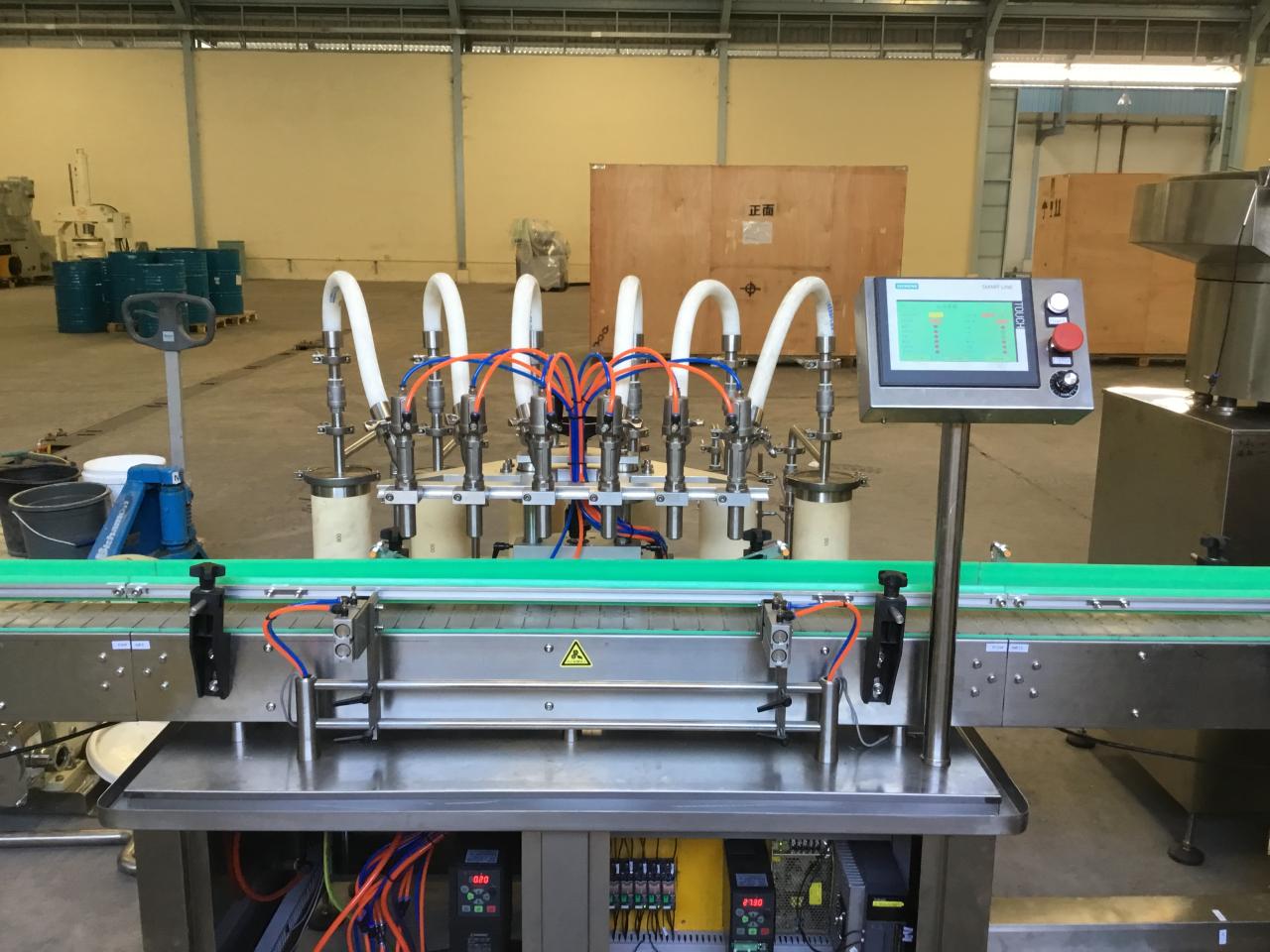

Filling machine

Sealing part