The Automatic Linear Hot Sauce Squeeze Bottle Filling Capping Machine is a machine designed for filling and capping hot sauce squeeze bottles. The machine is fully automated, and it can fill and cap bottles at a high speed, making it ideal for large-scale production.

The machine has a linear design, which means that the bottles are filled and capped in a straight line. The hot sauce is stored in a hopper, and the machine uses a piston pump to fill the bottles accurately. The capping system is also automated, and it can handle different types of caps.

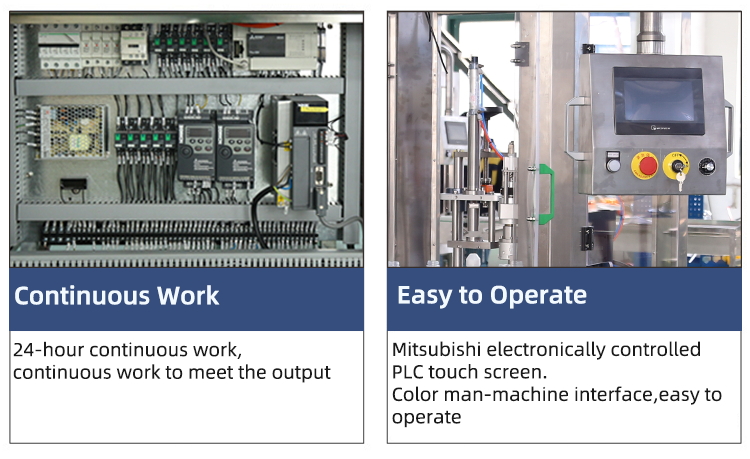

The machine is made of high-quality materials, and it is easy to operate and maintain. It is equipped with a touch screen control panel that allows the operator to adjust the settings and monitor the production process. The machine is also equipped with sensors that detect when a bottle is not in place, and it stops automatically to prevent spills and other accidents.

The Automatic Linear Hot Sauce Squeeze Bottle Filling Capping Machine is suitable for filling and capping different types of hot sauce squeeze bottles, including plastic and glass bottles. It is ideal for hot sauce manufacturers who want to increase their production capacity and improve their efficiency.

In conclusion, the Automatic Linear Hot Sauce Squeeze Bottle Filling Capping Machine is a reliable and efficient machine that can help hot sauce manufacturers improve their production processes. It is easy to operate, maintain, and it can fill and cap bottles accurately and quickly, making it a valuable investment for any hot sauce production line.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Ukraine, Uzbekistan, Japan, Malaysia, Australia, None

- Application: APPAREL, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Textiles, MEDICAL

- Packaging Type: Bags, Barrel, Bottles, CANS, Capsule, Cartons, case, Pouch, Stand-up Pouch

- Packaging Material: Glass, Metal, Paper, Plastic, Wood

- Automatic Grade: Automatic

- Driven Type: Pneumatic

- Voltage: 110V/220V/380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2500*1600*1650mm

- Weight: 600 KG

- Warranty: 1 Year

- Key Selling Points: oil bottles filling machine

- Filling Material: Milk, Water, Oil, Juice

- Filling Accuracy: 99

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Product name: small oil bottles filling machine

- Company advantage:: OEM with good After-sales Service

- Product advantage: Can be customized/High precision/Space saving/Effective cost

- Filling pump: Peristaltic Pump Filling/Piston Pump Filling

- Material: SUS304/316(Meet GMP Standard)

- Eligibility rate: ≥99%

- Touch screen: Siemens(According to customer)

- Main motor: Servo motor(ABB)

- Certification: CE

More Details

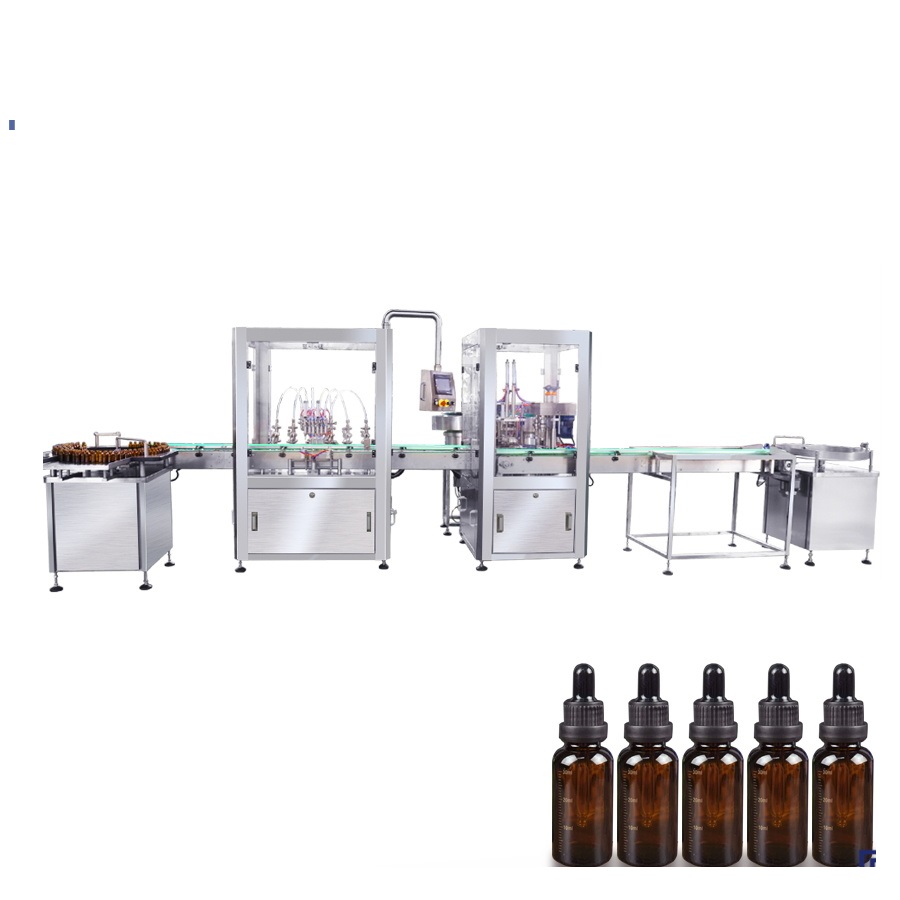

| Product | Hot Sauce Filling Capping Labeling Machine |

| Output | 1500-6000BPH (Customized) |

| Filling Volume | 5ml, 10ml, 30ml, 50ml, 100ml, or customized |

| Control | PLC and Touch Screen |

| Driving Motor | Servo Motor |

| Filling Type | Piston Pump or Peristaltic Pump |

| Power | 1.2KW |

| Machine Frame Material | SS304 |

| Capping Motor | Magnetic Torque Motor |

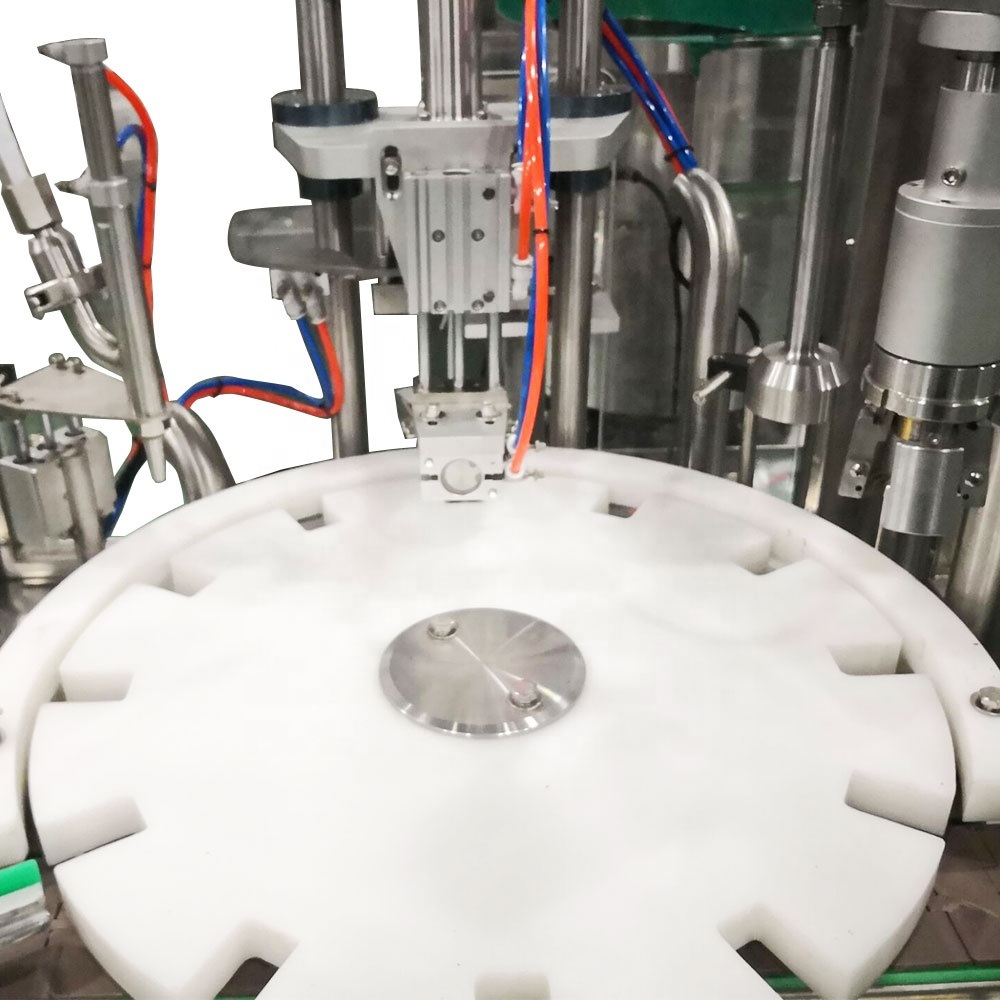

Round Bottle Feeding Table

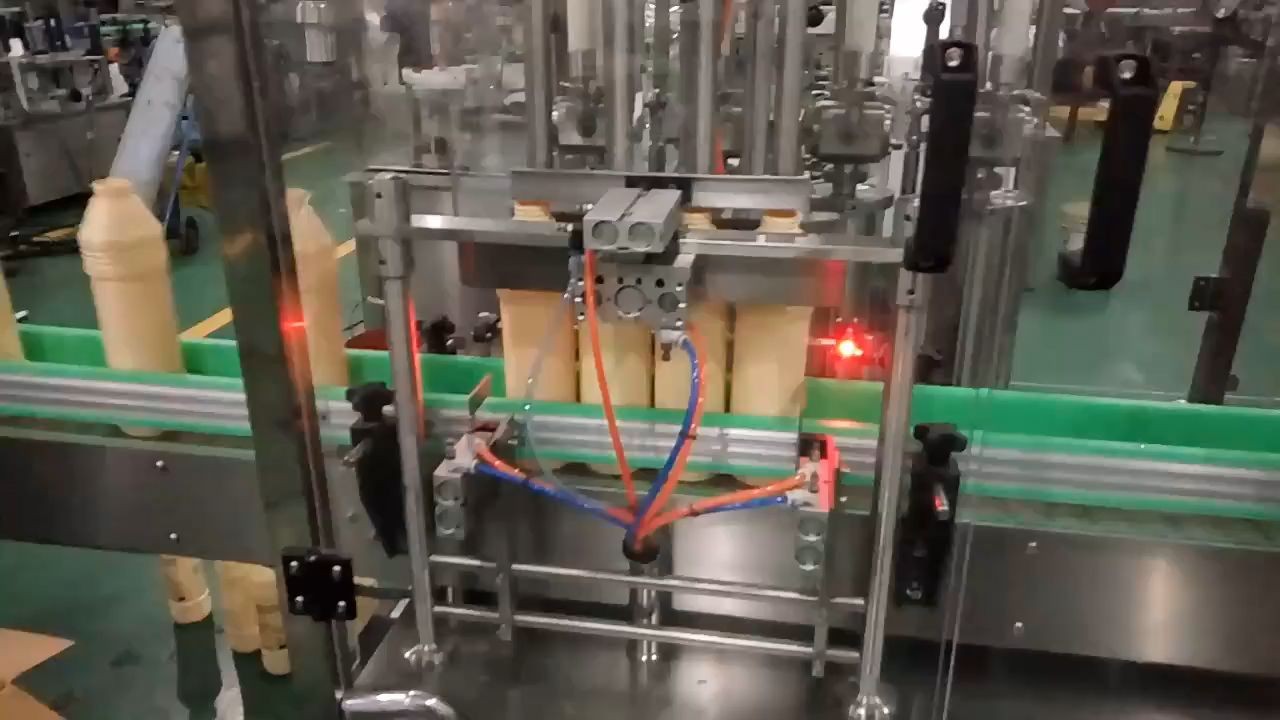

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output tunnel, the machine will be able to work with different size bottle.

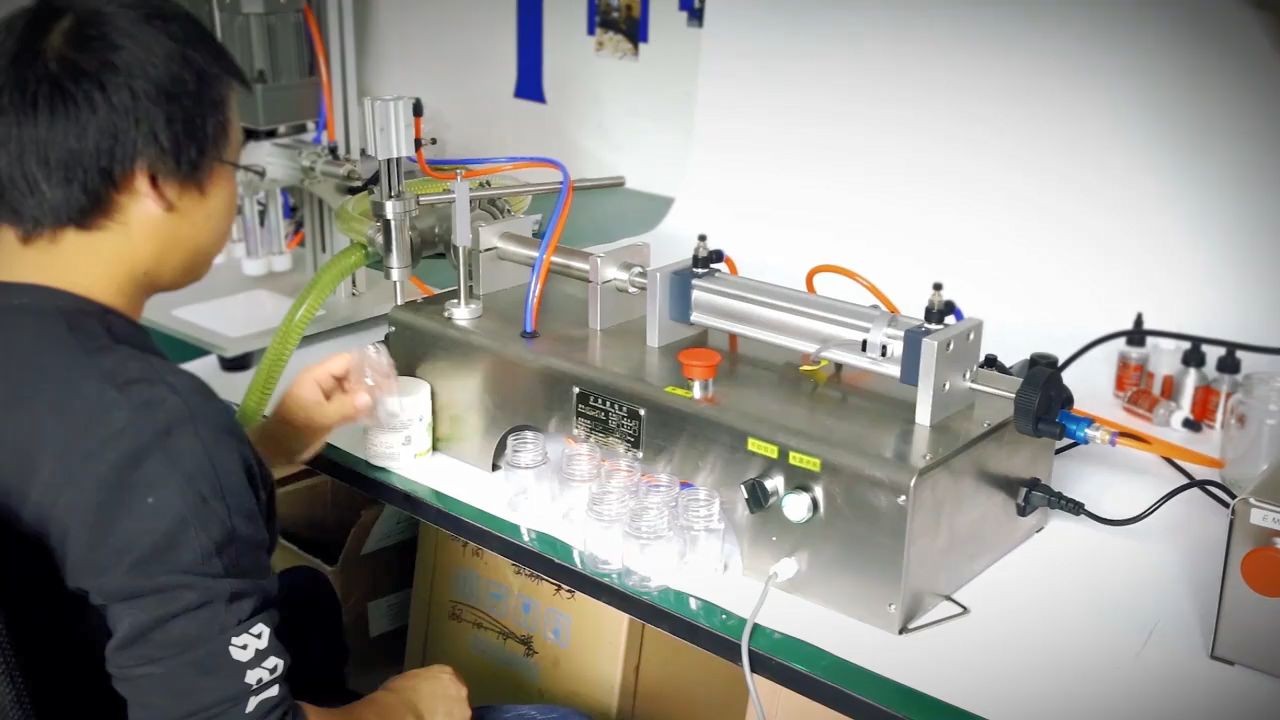

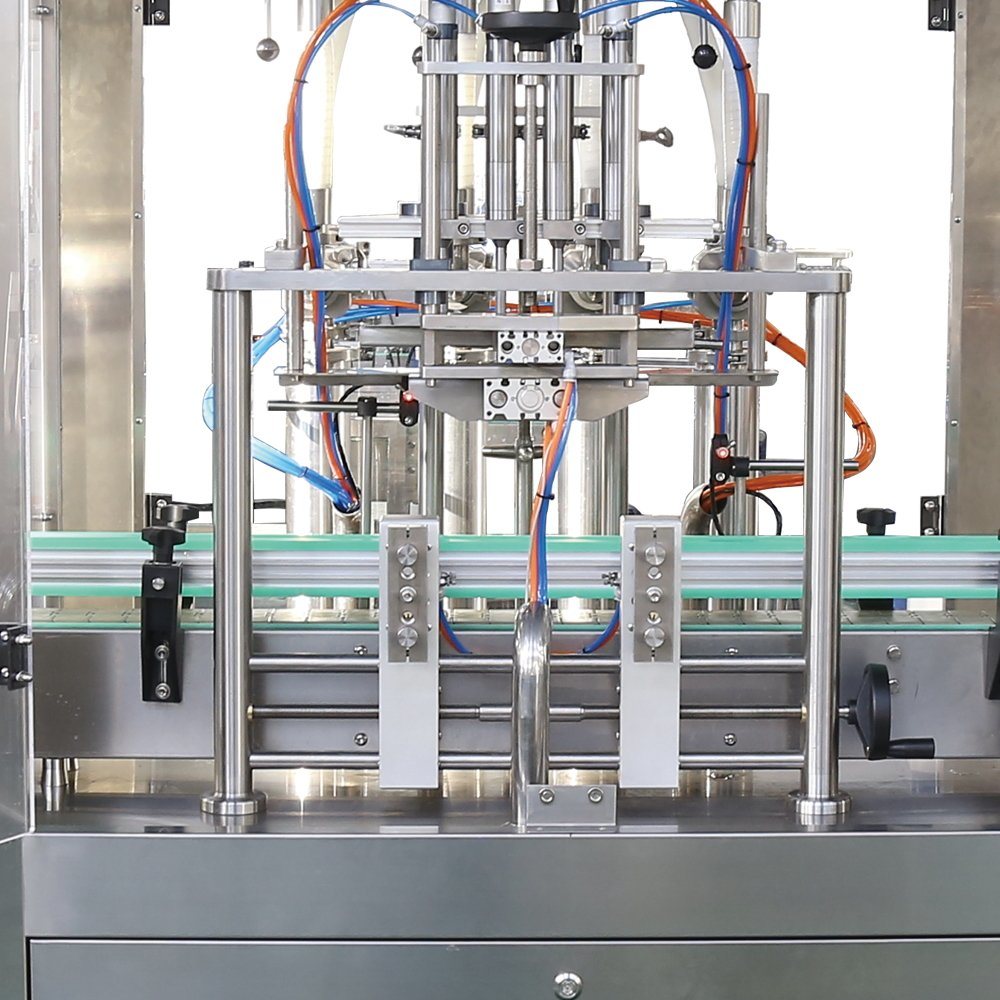

Piston Pump Filling Machine

This is wheel type piston pump filling machine which is designed for small bottle and low capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

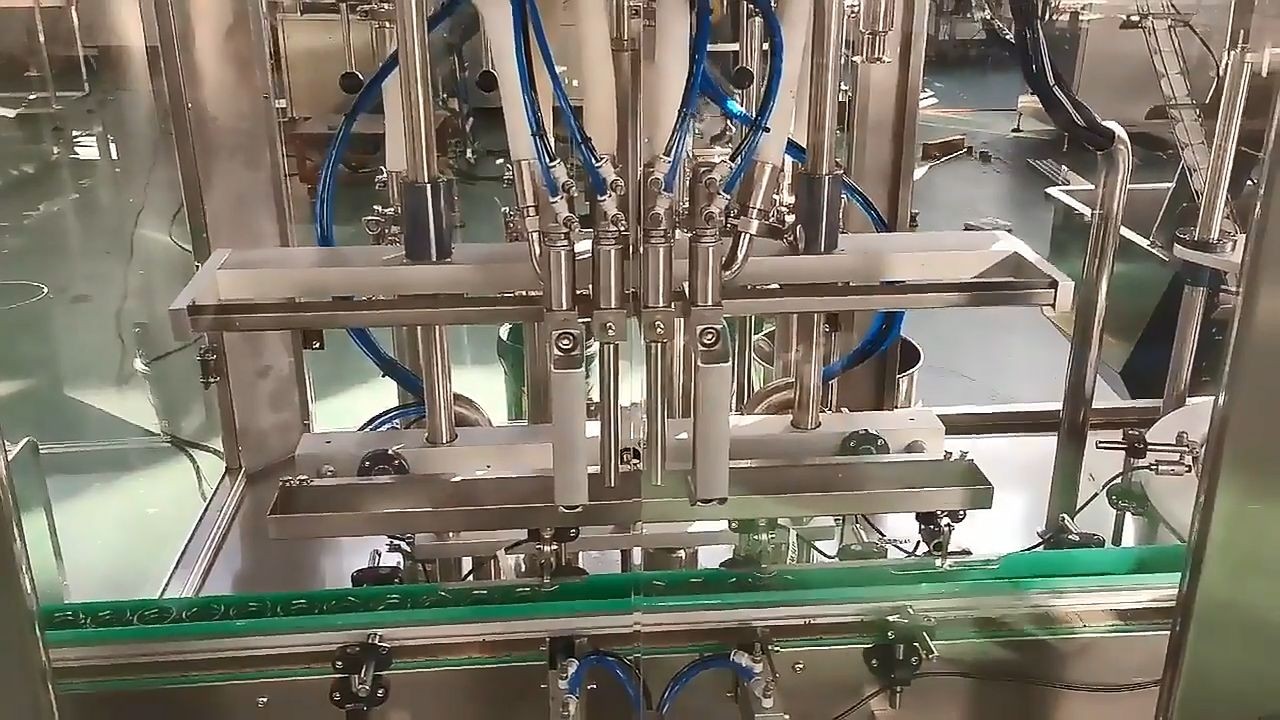

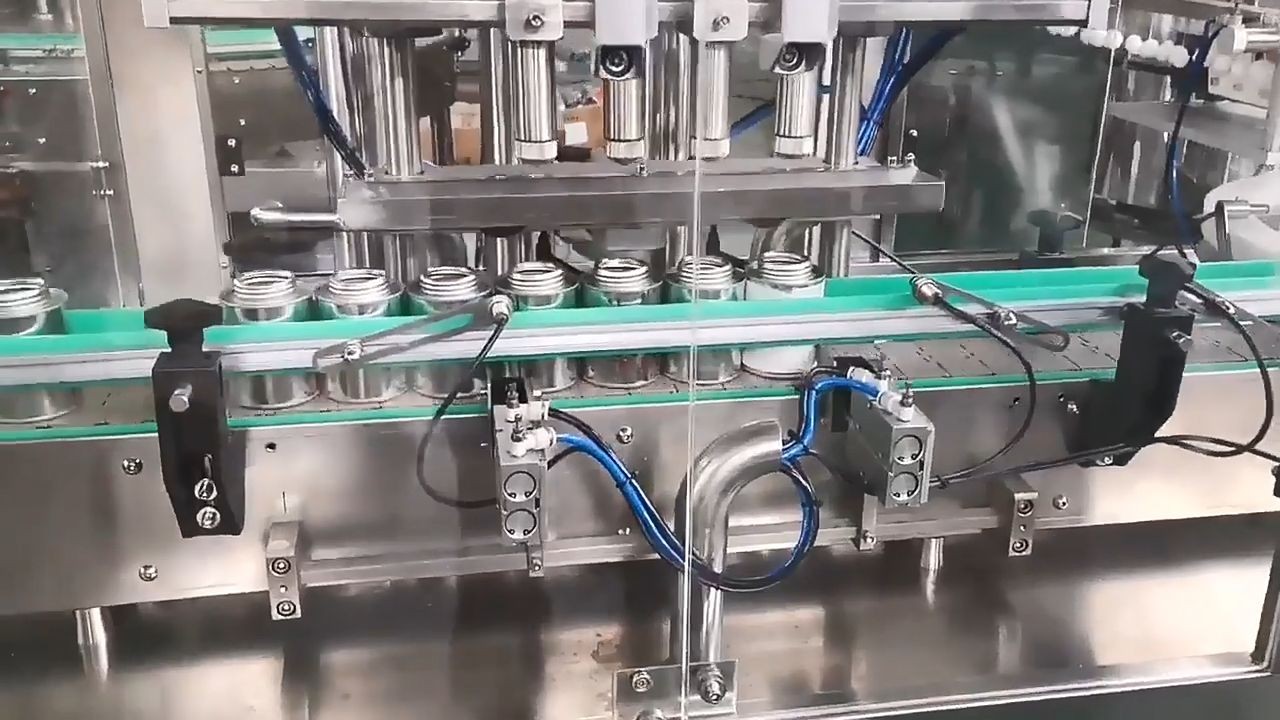

This is linear type peristaltic pump ( can be piston pump) filling machine which is designed for high capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof, via photoelectric detection to ensure no bottle no filling.

Magnetic Torque Capping Machine

With three-jaw capping head, the capping machine is able to work with different kinds of lid torquing process. Contradicted to traditional machinery adjustment in capping torque, new smart filler adapt Magnetic torque motor in driving, which control torque by switch. Human-friendly design is always convenience.

Round Bottle Labeling Machine

The newest smart round bottle labeling machine is working with different kinds of bottle and labels, infrared detection sensor is work with transparent label. With adjustment handle, it is able to work with high, lower, fat, thin bottle and apply labels into accurate station.

Bottle Collecting Table

The rectangle bottle collecting table is designed for collecting the bottles automatically and convenient for workers to stand by the table and packing into box.

Electric Cabinet and Touch Screen