Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: custom

- Applicable Industries: Manufacturing Plant, Retail, Bottle Liquid Product Filling Factory

- Showroom Location: None

- Application: Commodity, Chemical

- Packaging Type: CANS, Bottles, Barrel, Stand-up Pouch, Bags, Pouch

- Packaging Material: Plastic, Metal, Glass

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 380V

- Dimension(L*W*H): customized size

- Weight: 300 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Filling Material: custom

- Filling Accuracy: 1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing

- Product name: glass water bottle filling capping machine

- Number of filling heads: 6 heads or customized

- Filling capacity: 0.5L-5L

- Filling speed: 6-8 bottles / minute (4L bottle)

- Filling accuracy: ±1%

- Material: The filling frame is made of 304# stainless stee

- Program control: PLC touch screen

- Air pressure: 0.6-0.8MPa

- After Warranty Service: Online support

More Details

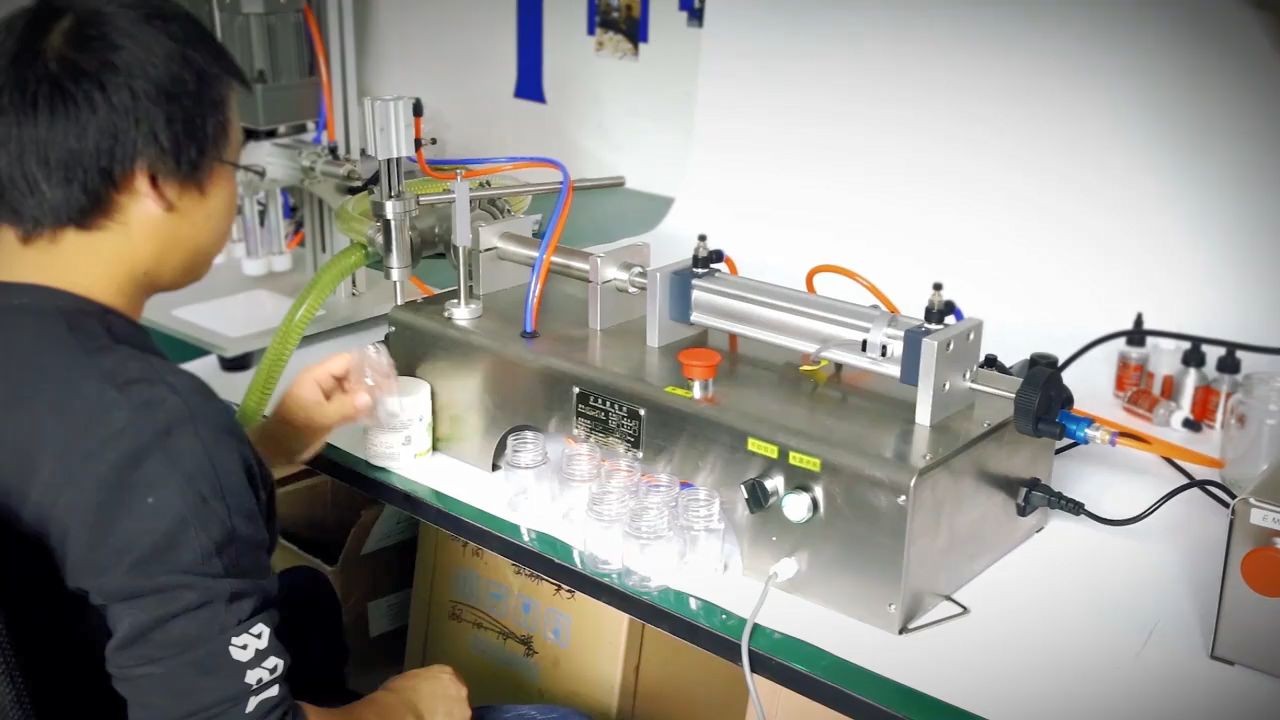

Equipment Brief Introduction:

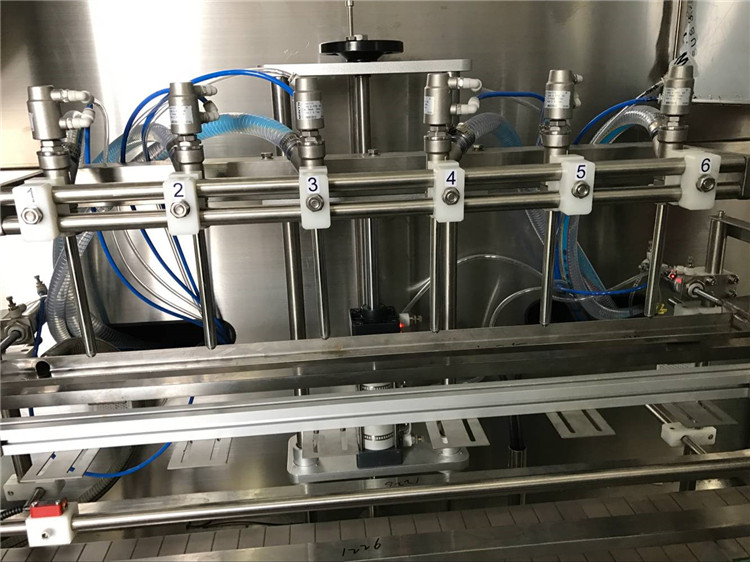

This Production Line Includes A 6 Self-Flow Filling Machine, A Pneumatic Claw Capping Machine, A Linear Capping Machine, A Double Side Labeling Machine And A Bottle Carousel Machine;

The Machine Type, Number Of Machines, Speed, Capacity, Size, Etc. Of The Production Line Can Be Customized According To The Customer'S Production Needs; We Can Develop A Professional Integrated Filling And Packaging Production Line Plan For The Customer.

This Automatic Filling Line can be customized to fill various products,such as : Laundry detergent, shampoo, softener, dish soap,conditioner, hand soap, mouthwash, facial cleanser, face cream, various essential oils, etc.

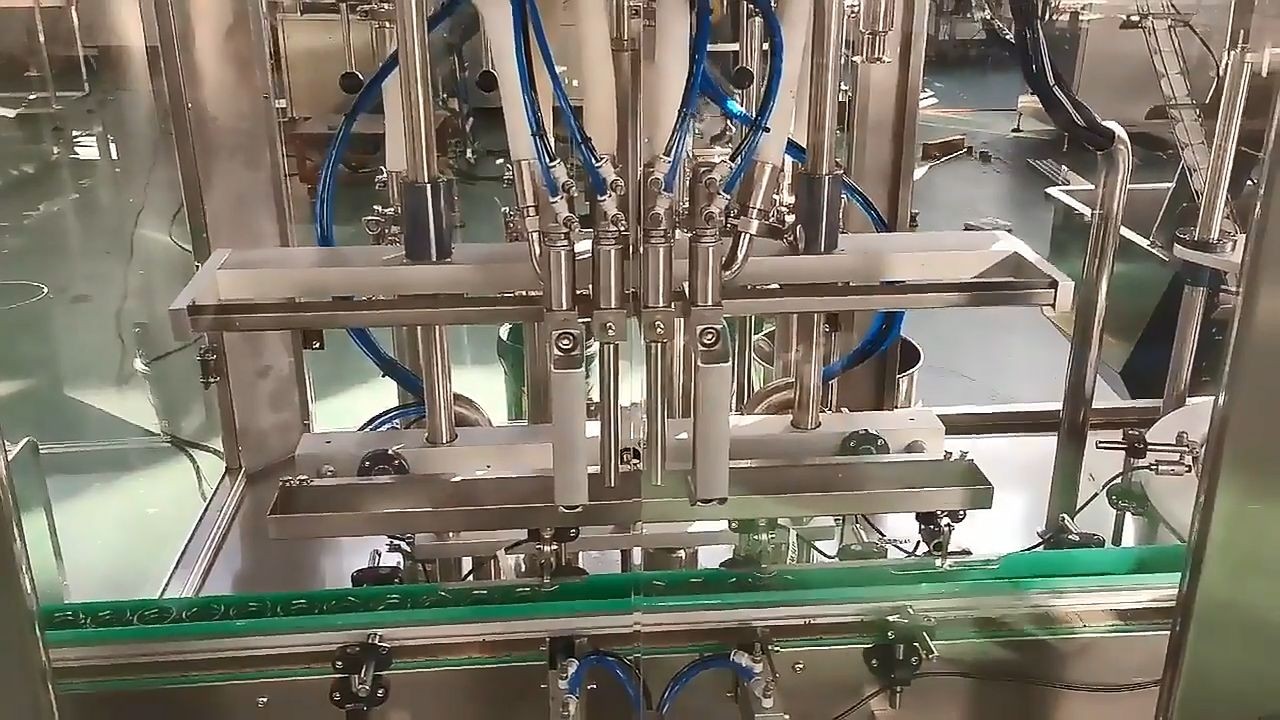

| Parameters of 6 Self-Flow Filling Machine | |

| Number of filling heads | 6 |

| Filling capacity | 0.5L-5L |

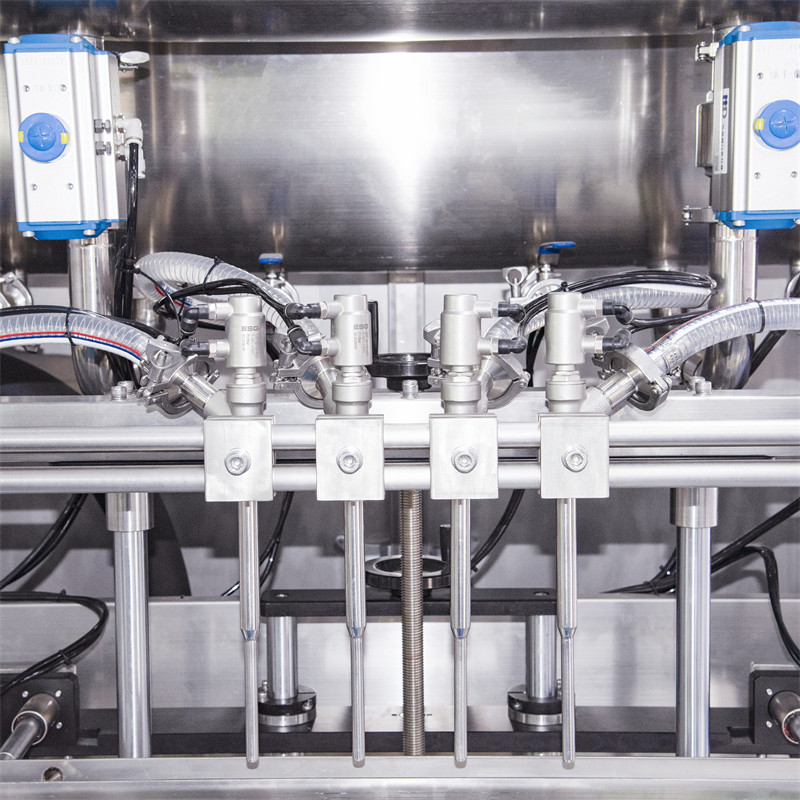

| Filling form | Self-flowing multi-headed into the bottom of the bottle and fast and slow side edge |

| Filling speed | 6-8 bottles / minute (4L bottle) |

| Filling accuracy | ±1% |

| Material | The filling frame is made of 304# stainless steel |

| Program control | PLC touch screen |

| Filling mouth and trough contact liquid parts | 316# stainless steel, silica gel, POM |

| Air pressure | 0.6-0.8MPa |

| Conveyor belt | 114mm wide POM chain belt, speed 0-15 m / min, height 750mm ± 25mm off the ground |

| Conveying motor | 750W variable frequency speed regulating motor |

| Power | About 2.2KW/380V three-phase five-wire |

| Main trough capacity | 200 liters (with liquid level switch, the feed tube is inserted into the bottom, and the trough cover needs to prevent foam overflow). |

| Conveyor belt entrance with bilateral bottle placing table | 2000X300mm (length X width) |

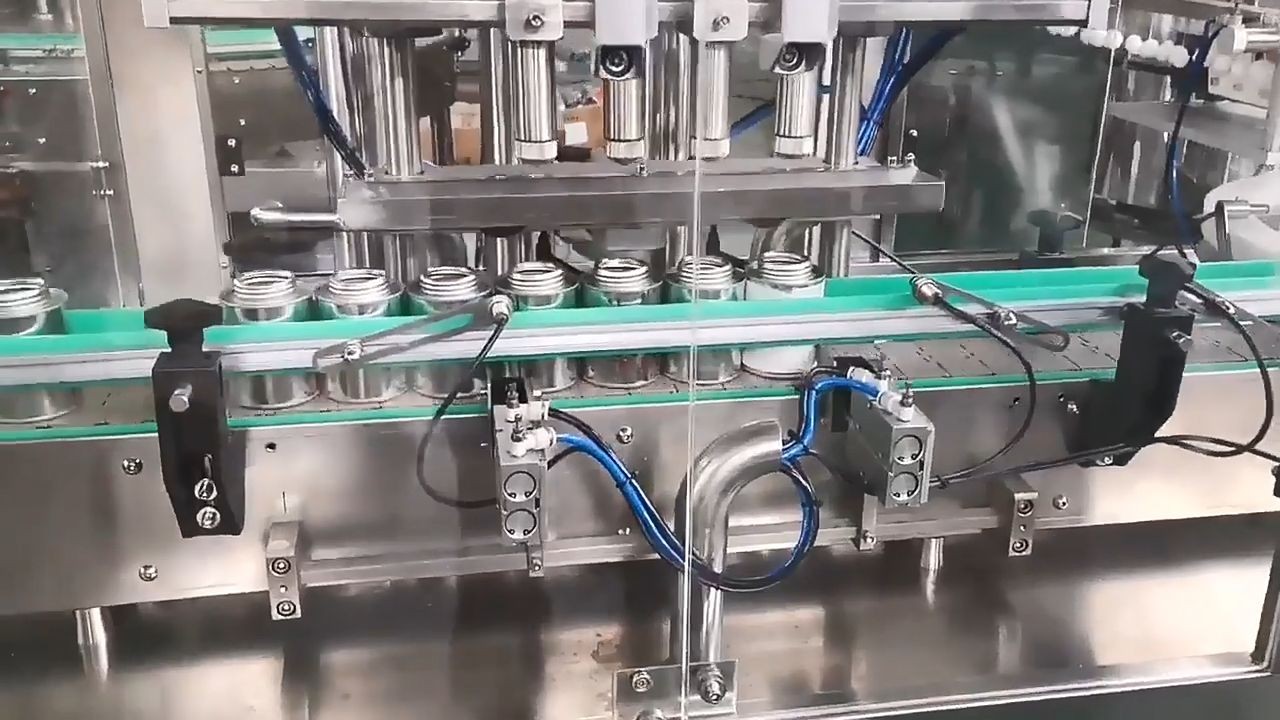

| Parameters of Air Claw Type Capping Machine | |

| Suitable specifications | According to the sample provided by the customer |

| Cover method | Vibrating plate cover |

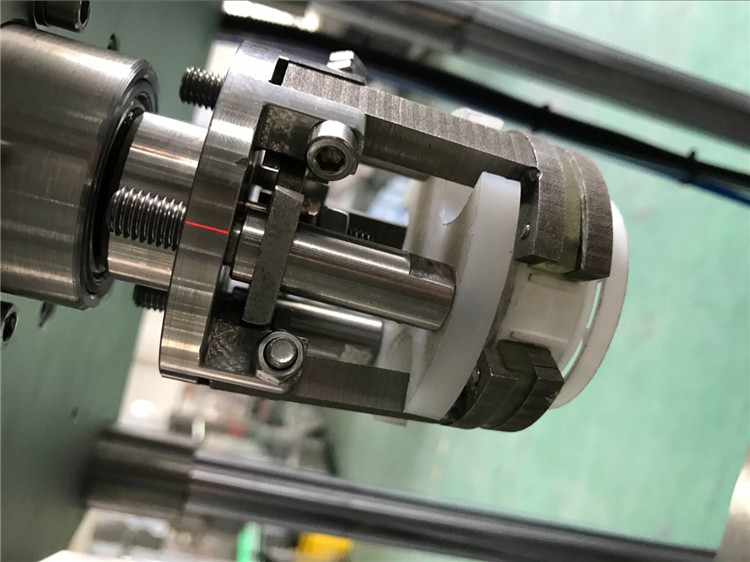

| Cap form | Gripper grip cap |

| Speed | 15-20 bottles / minute |

| Conveyor belt | 114mm wide POM chain belt, speed 0-15 m / min, height 750mm ± 25mm from the ground |

| Material | The frame is made of 304# stainless steel |

| Program control | PLC touch screen man-machine |

| Machine power | About 800W |

| Air pressure | 0.6-0.8MPa |

| Power supply | AC220V, 50/60HZ single phase. |

| Parameters of Linear Capping Machine | |

| Lower cover method | Manual cover (the nozzle bottle needs to be manually placed, and the nozzle cover direction needs to be consistent) |

| Suitable specifications | According to the sample provided by the customer |

| Cap form | 8-round counter-type cap |

| Speed | 20-30 bottles / minute |

| Material | The frame is made of 304 stainless steel |

| Program control | PLC touch screen |

| Machine power | 200W |

| Air pressure | 0.6-0.8MPa |

| Conveyor belt | Shared with the filling machine |

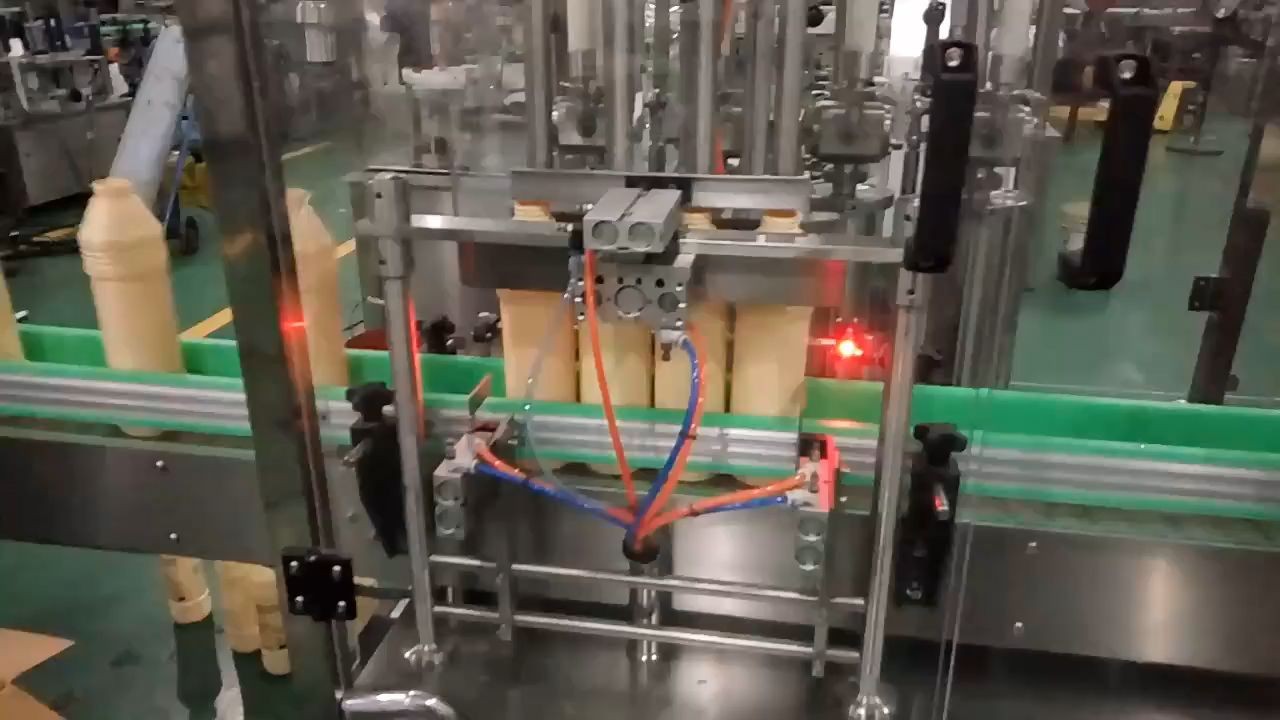

| Parameters of Double Side Labeling Machine | |

| Applicable labeling position | Partial bottle and double side stickers |

| Applicable product range | Provide samples according to customers |

| Applicable label rang | Sample provided by customer |

| Production capacity | >30 bottles / minute |

| Labeling accuracy | Plane ± 1m (except for the error of the partial bottle itself) |

| Voltage | 220V |

| Power | About 1.2KW |

| Conveyor belt | 114mm wide POM chain belt, speed 0-15 m / min, height 750mm ± 25mm from the ground |

| Program control | PLC touch screen man-machine interface |

| Applicable paper roll | inner diameter 76mm, outer diameter maximum 300mm |

| Conveyor belt | shared with the filling machine |

| Parameters of Bottle Carousel Machine | |

| Suitable specifications | According to the sample provided by the customer |

| Turntable diameter | 800mm |

| Height of the table top from the ground | 750mm |

| Material | The turntable adopts 304# stainless steel |

| Power supply | 220V, 140W, 50HZ single phase |

| Drive motor | 140W domestic brand AC motor |

| Speed control mode | About 1.2KW |