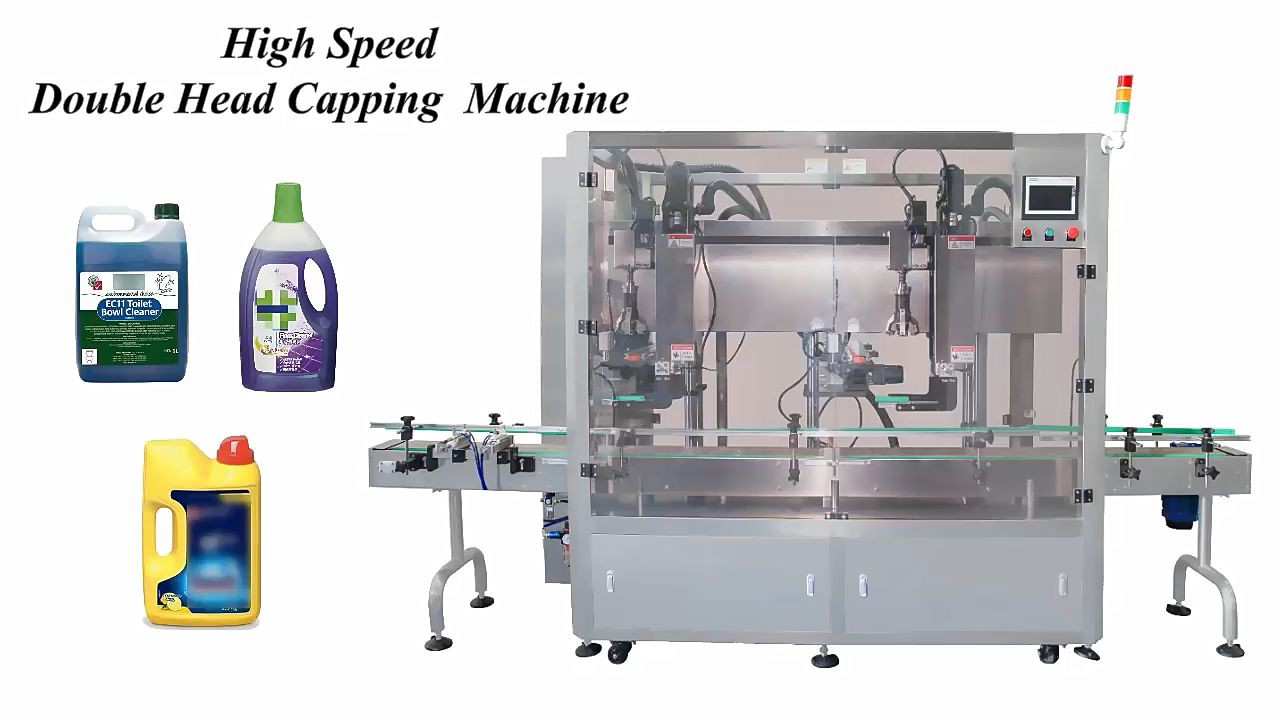

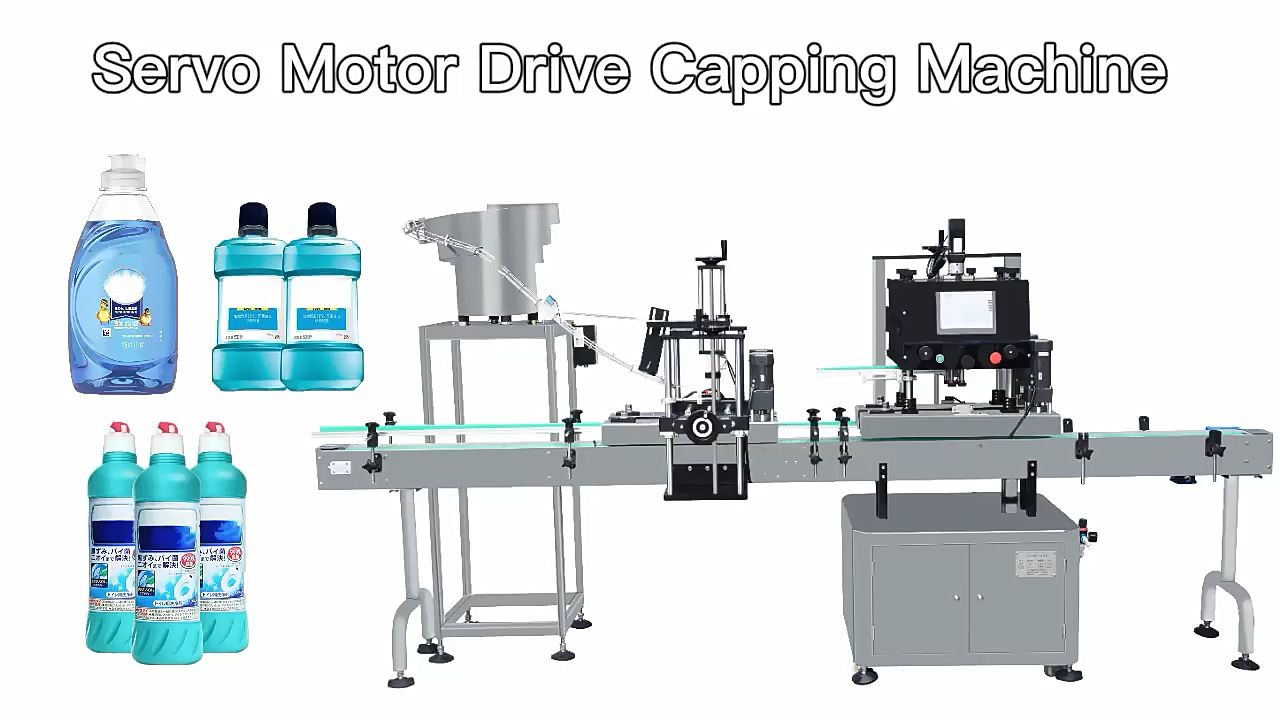

The automatic spindle screw capping machine is extremely flexible, is capable of capping accurately and rapidly any cap, such as trigger cap, metal cap, flip cap and so on.

MAIN FEATURE

1. Variable speed AC motors.

2. Spindle wheels adjustment knobs, with lock nut hand wheel.

3. Meter Index for easy mechanical adjustment.

4. No change parts required for a wide range of containers

5. Comprehensive universal cap chute and escapement

6. With 2 layer bottle clamping belt, suitable for containers of various shap.

| 1 | Name/Model | Automatic linear spindle capping machine | |

| 2 | Capacity | 40-150 bottle/minute (actual capacity depends on bottle and caps | |

| 3 | Cap diameter | 20-120mm | |

| 4 | Bottle Height | 40-460mm | |

| 5 | Dimension | 1060*896*1620mm | |

| 5 | Voltage | AC 220V 50/60HZ | |

| 6 | Power | 1600W | |

| 7 | Weight | 500KG | |

| 8 | Cap feeding system | Elevator Feeder | Vibration cap sorter |

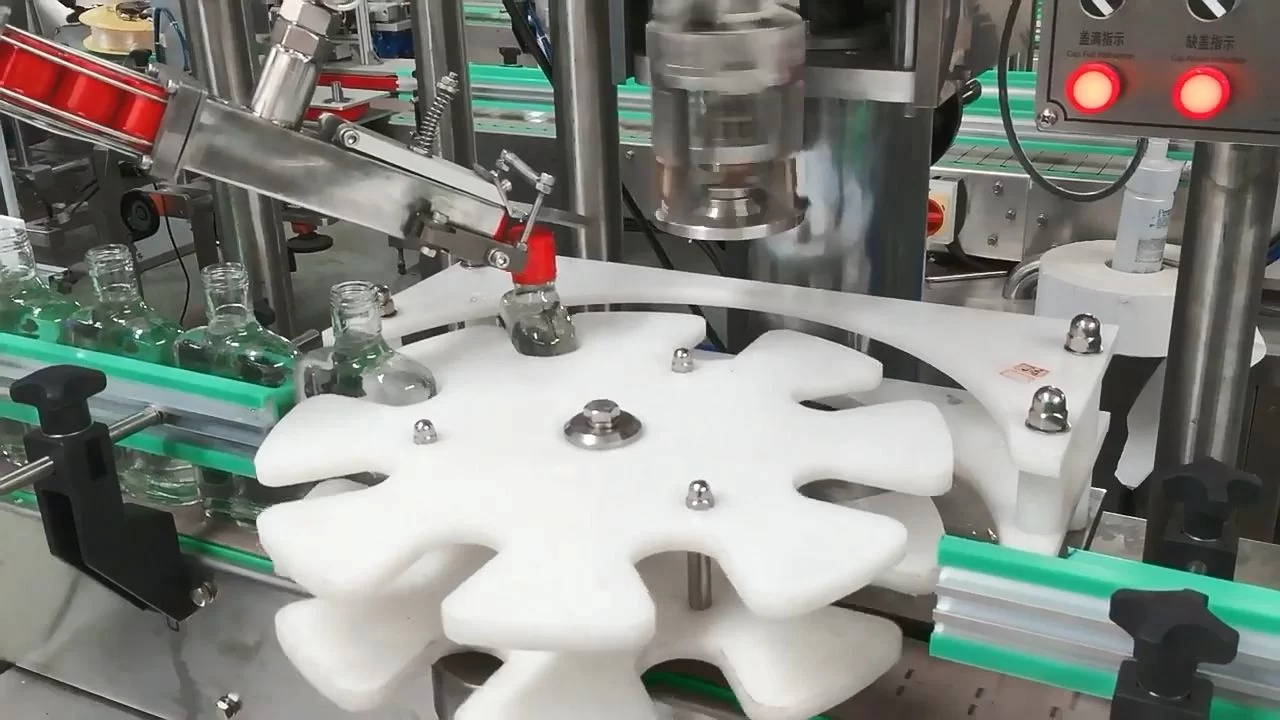

An automatic liquid bottle capping machine is an essential piece of equipment for industries that manufacture and distribute liquids in bottles with pump caps. This machine is designed to automatically apply and tighten pump caps to liquid bottles. The machine's operation involves a series of automated processes, including cap sorting, cap placement, tightening, and bottle release.

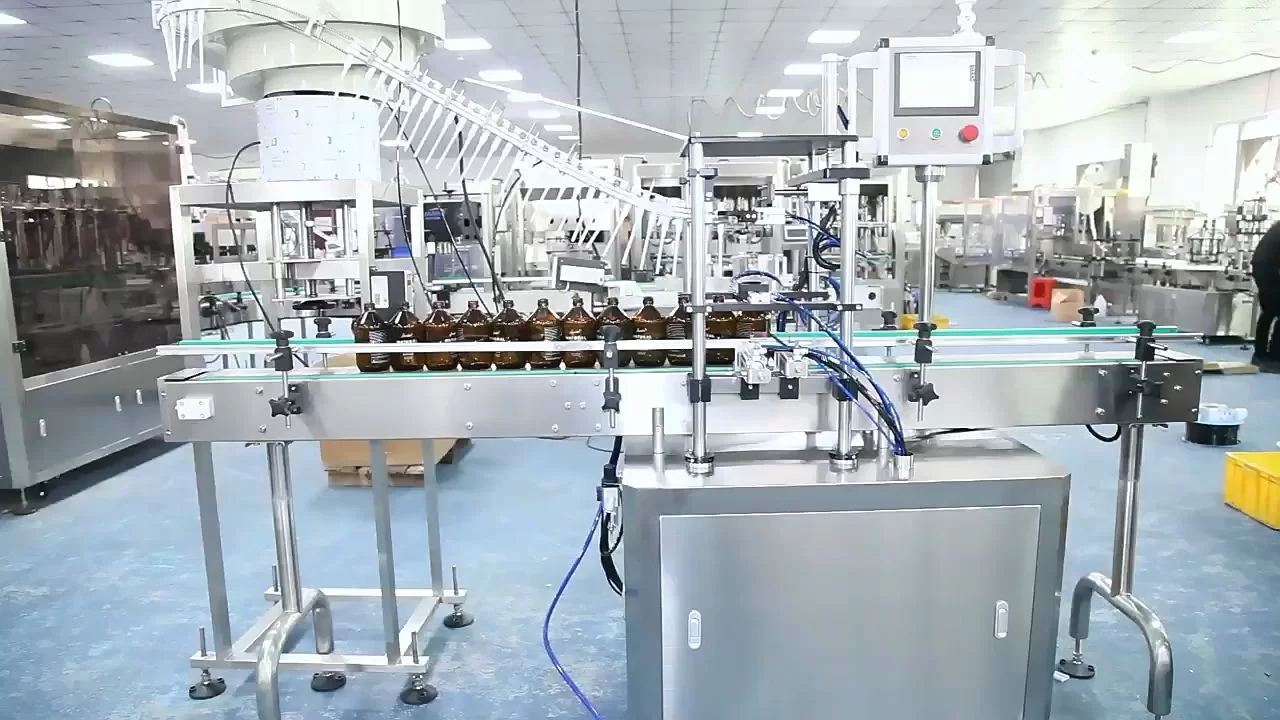

The machine is equipped with a conveyor system that transfers bottles to the capping station. The capping station has a cap sorting and placement mechanism that selects and positions the cap onto the bottle. The bottle then moves to the tightening station where the cap is securely fastened onto the bottle.

This machine is suitable for capping bottles of different shapes and sizes, and it can handle various types of pump caps. It is designed with an adjustable height feature to cater to bottles of varying sizes. The machine's control panel allows operators to adjust the machine's settings, including capping speed, torque, and cap tightness.

In addition, the machine is designed with safety features to protect operators and prevent damage to the bottles. For instance, the machine has an automatic stop mechanism that halts operations when a bottle is not properly positioned, preventing the capping head from applying too much pressure and breaking the bottle.

Overall, an automatic liquid bottle capping machine is an excellent investment for industries that need to cap liquid bottles with pump caps efficiently and with minimal labor.