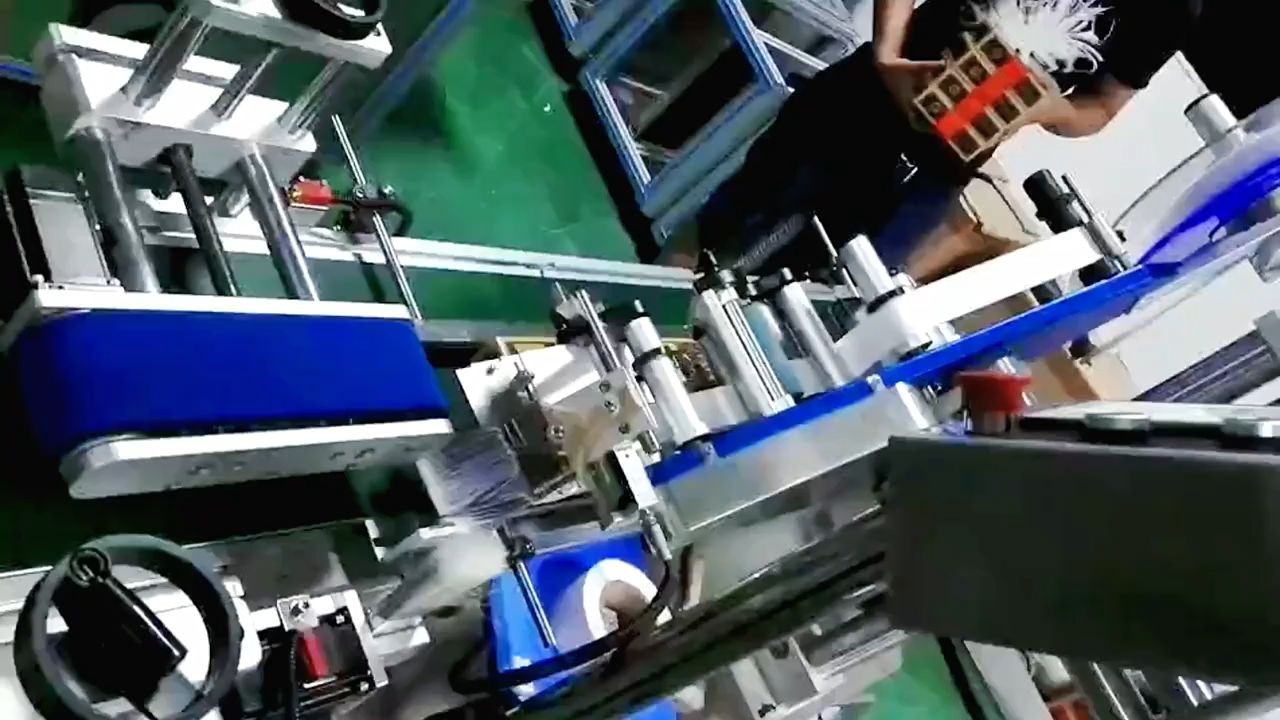

Automatic double sides labelling machine also called front and back labelling machine, double sides labeller, it is application for labelling round, square, flat and unshaped and shaped bottles& containers.

| Technical Parameters | |||

| Labeling Speed | 60-350pcs/min (Depending on label length and bottle thickness) | ||

| Height of Object | 30-350mm | ||

| Thickness of Object | 20-120mm | ||

| Height of Label | 15-140mm | ||

| Length of Label | 25-300mm | ||

| Label Roller Inside Diameter | 76mm | ||

| Label Roller Outside Diameter | 420mm | ||

| Accuracy of Labeling | ±1mm | ||

| Power Supply | 220V 50/60HZ 3.5KW Single-phase | ||

| Gas Consumption of Printer | 5Kg/cm^2 | ||

| Size of Labeling Machine | 2800(L)×1650(W)×1500(H)mm | ||

| Weight of Labeling Machine | 450Kg | ||

An automatic lubricating oil square bottle double side labeling machine is a specialized industrial equipment designed to automatically apply labels to both sides of square-shaped lubricating oil bottles. This machine is commonly used in the packaging industry, specifically in the production of lubricating oils and other fluids.

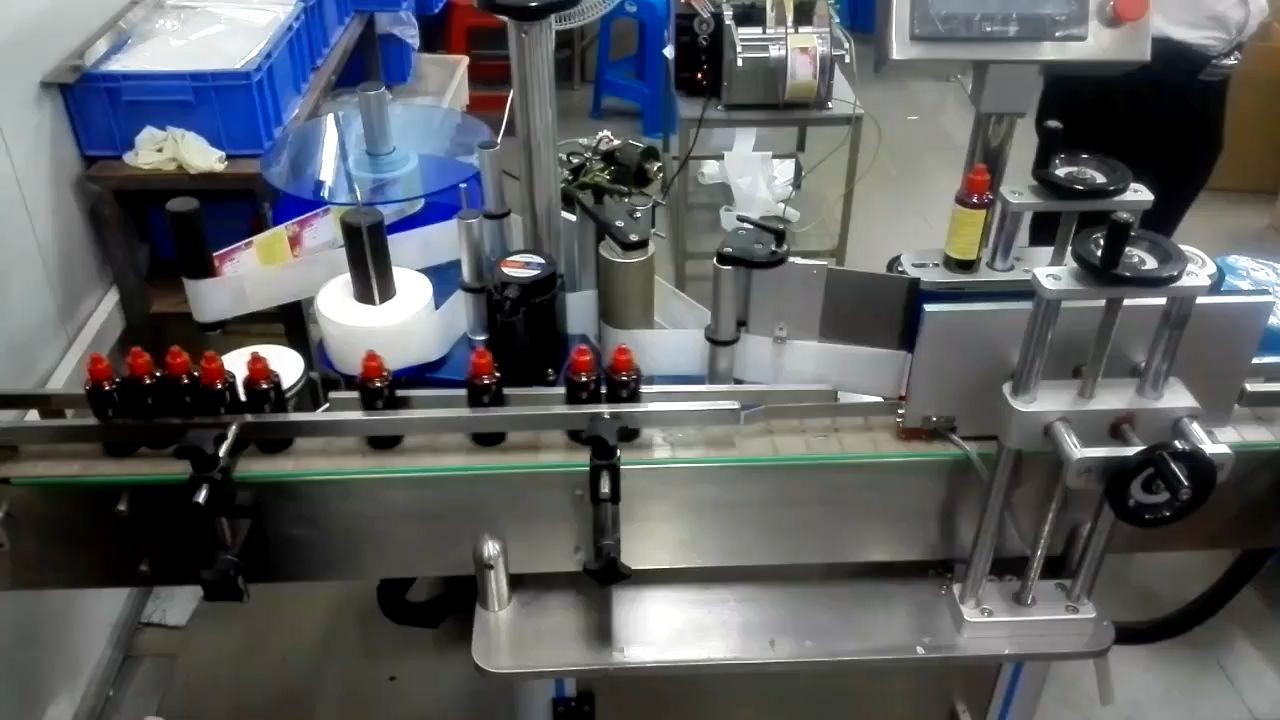

The machine works by feeding the bottles onto a conveyor belt, which then moves them through the labeling station. The labeling station uses two labeling heads to apply labels to both sides of the bottle simultaneously. The labels are applied with precision and accuracy, ensuring that they are centered and aligned correctly.

One of the key advantages of the automatic lubricating oil square bottle double side labeling machine is its high speed and efficiency. With the ability to label up to 200 bottles per minute, this machine significantly increases production efficiency, reduces labor costs, and improves overall product quality. The machine also has a high level of accuracy, ensuring that each label is applied correctly and consistently, minimizing the risk of mislabeling and improving product identification.

Another advantage of this machine is its versatility. It can handle a wide range of bottle sizes and shapes, thanks to its adjustable conveyor and labeling heads. The machine's flexibility also allows for easy switching between different types of labels, minimizing downtime and maximizing productivity.

Additionally, the machine is equipped with a user-friendly touch screen interface that makes it easy to control and monitor the labeling process. The interface allows operators to adjust the labeling speed, conveyor speed, and other settings, ensuring optimal performance and efficiency.

Overall, an automatic lubricating oil square bottle double side labeling machine is an essential piece of equipment for any company that needs to label large quantities of square-shaped lubricating oil bottles quickly and accurately. Its speed, efficiency, accuracy, versatility, and ease of use make it an ideal solution for improving production efficiency and quality in the packaging industry.