The Automatic Perfume Pet Plastic Glass Bottle Filling Sealing Machine is a state-of-the-art packaging equipment designed to streamline and automate the perfume packaging process. This machine is equipped with advanced technology that ensures fast, accurate, and efficient filling and sealing of PET, plastic, and glass bottles.

The machine's automatic filling system features a high-precision pump that accurately measures the exact amount of perfume to be filled in each bottle. The machine's filling speed can be easily adjusted to suit different production rates, and it can handle a wide range of bottle sizes and shapes.

The machine also features an automatic capping system that ensures the perfect seal of each bottle. The capping system applies the right amount of pressure to the cap, ensuring that it is tightly sealed and secure. The machine's sealing system is equipped with a high-quality heater that ensures a consistent and reliable seal every time.

The Automatic Perfume Pet Plastic Glass Bottle Filling Sealing Machine offers many advantages, including improved productivity, reduced labor costs, and increased product quality. The machine's automation ensures a faster and more efficient production process, reducing the need for manual labor and minimizing the risk of errors.

The machine's design is also easy to clean and maintain, ensuring that the production process remains hygienic and efficient. The machine is ideal for use in a wide range of industries, including cosmetic, fragrance, and personal care product manufacturing.

Overall, the Automatic Perfume Pet Plastic Glass Bottle Filling Sealing Machine is an excellent investment for any company looking to improve their packaging process. With its advanced technology, efficient performance, and reliable results, this machine is sure to help businesses achieve their production goals and maintain a competitive edge in their industry.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: United States, Italy, France, Germany, Philippines, Peru, Indonesia, Pakistan, Russia, Spain, Thailand, Morocco, Argentina, Algeria, Romania, South Africa, Kazakhstan, Nigeria

- Application: APPAREL, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Textiles

- Packaging Type: Bags, Bottles, CANS, Capsule, Cartons, case, Pouch, Stand-up Pouch

- Packaging Material: Glass, Metal, Paper, Plastic, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V/380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2200X2100X2200MM

- Weight: 500 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Filling Material: Milk, Water, Oil, Juice, Powder

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- After-sales Service Provided: ON-site service

- Certification: CE

- model: PX-BFC80

- Product advantage: Space saving/Effective cost/Easy operation

- Bottle type: Tin can/Glass/Plastic bottle

- Eligibility rate: ≥99%

- HS code: 8422303090

- Product name: bottle filling machine

- Capacity: 2000-5000bph

More Details

Product Description

The fully automatic small vail bottle liquid filling capping machine is with CE & ISO 9001 certification.The machine is applied to glass or plastic bottles with different sizes and shapes, and suitable for different filling volume. By adjusting the filling volume on touch screen, it can fill liquid with quick speed and high precision. It is widely used for essential oil, eye dropper, perfume, nail polish, lotions and other vial bottle filling.

| Product | Full automatic perfume filling capping machine |

| Model | VK-bfc80 |

| Output | 1000-6000BPH, or customized |

| Filling Volume | 10-100ml, or customized |

| Filling Material | Liquid, Gel or etc |

| Control | PLC 7.5” Color Touch Screen |

| Filling driving | Servo system |

| Capping driving | Magnetic /Air/servo system |

| Filling pump | Piston/peristaltic pump/weighing/flowmeter |

| Filling precison | 99% |

| Torquing | 0-100N |

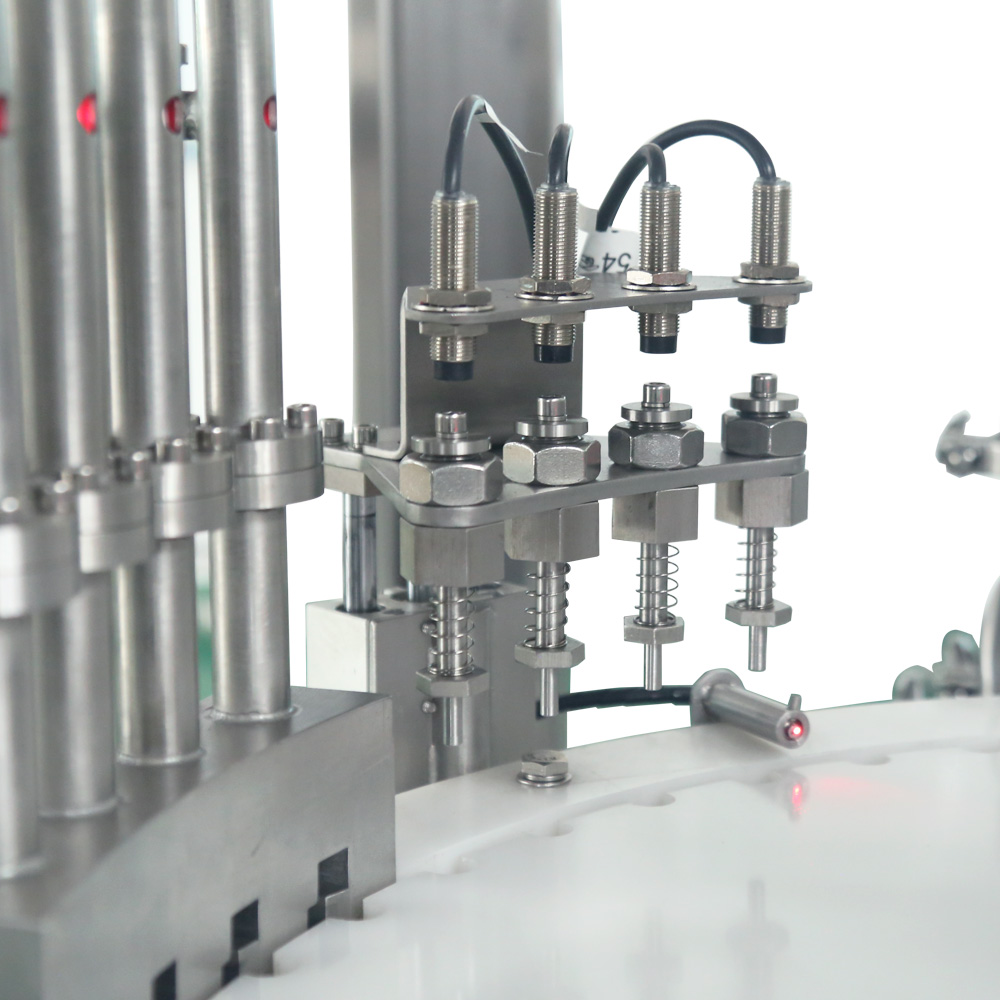

| Detection | Photocell detecting |

| Filling temperature | Normal |

| Loading way | Self-absorbing |

| Unit size | 1200*900*2000 L*W*H |

| Power | 1.5KW |

| Machine Frame Material | SS304 |

| Capping Head | Screwing, Pressing, Crimping Head ( According to the cap type) |

| Suitable Industry | Cosmetic, medical, food, detergent, etc |

| Human protection | Comprehensive Safety Alarm System |

| Label material | Paper ,stiker ,pvc |

| Label pan cabality | 10KG |

| Label size | width 10-180mm length 30-330mm |

| Printing | Ribbon printer |

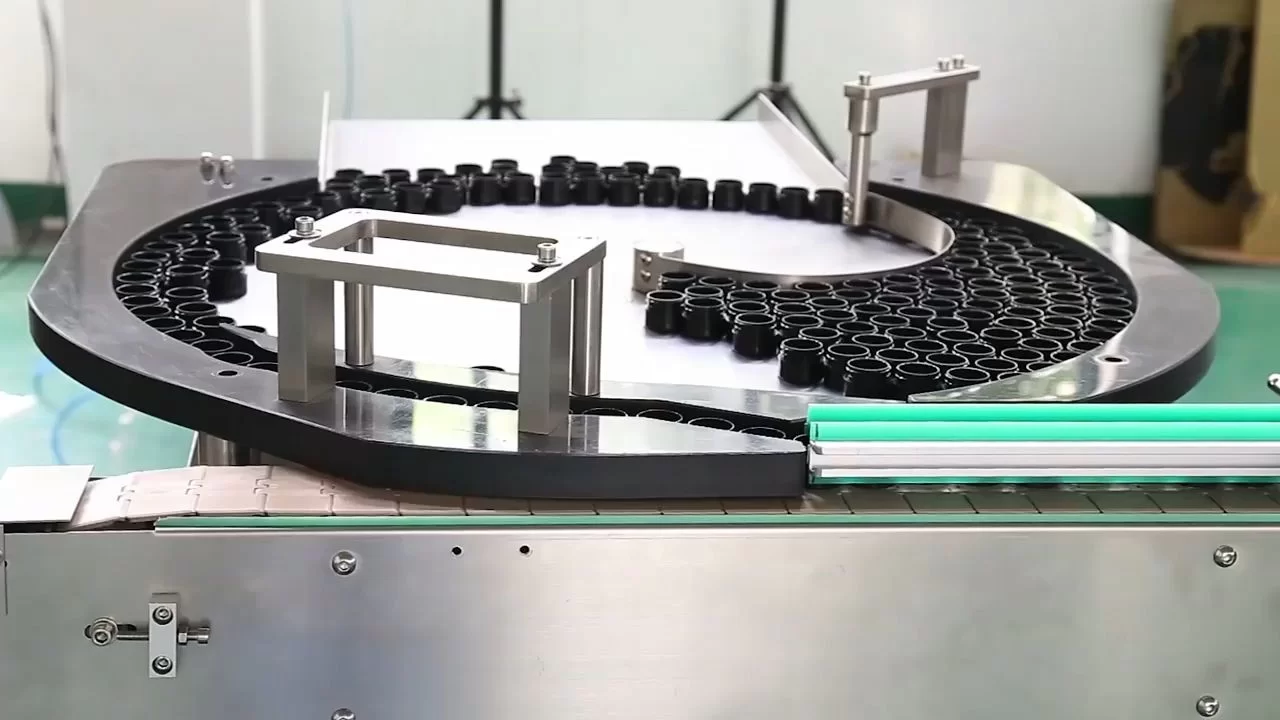

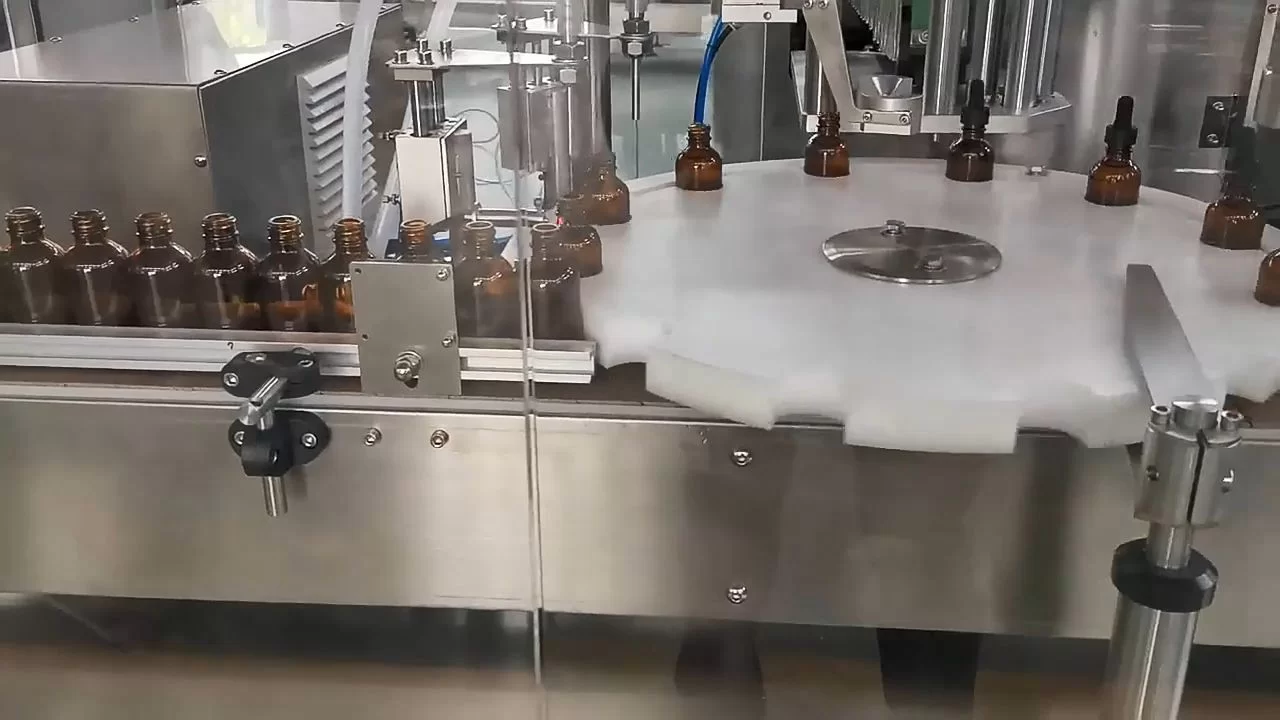

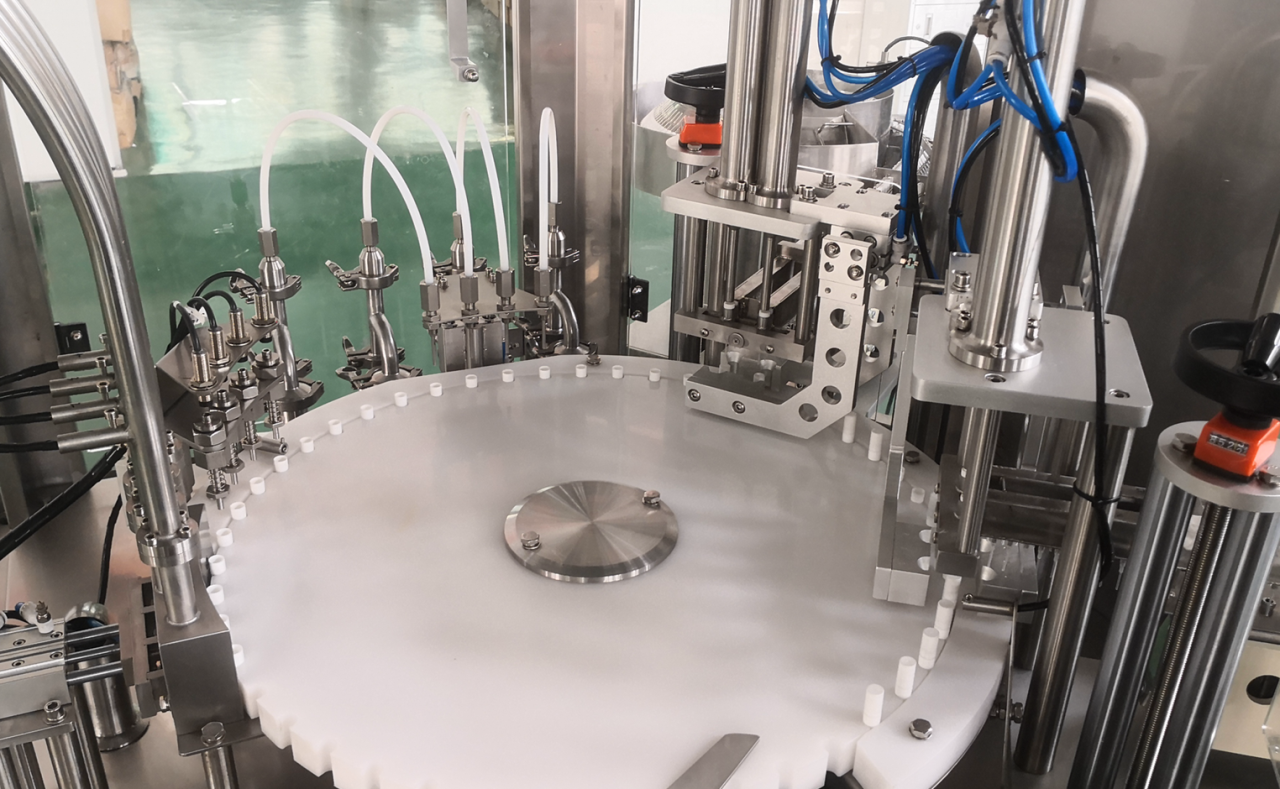

Round Bottle Feeding Table

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output tunnel, the machine will be able to work with different size bottle.

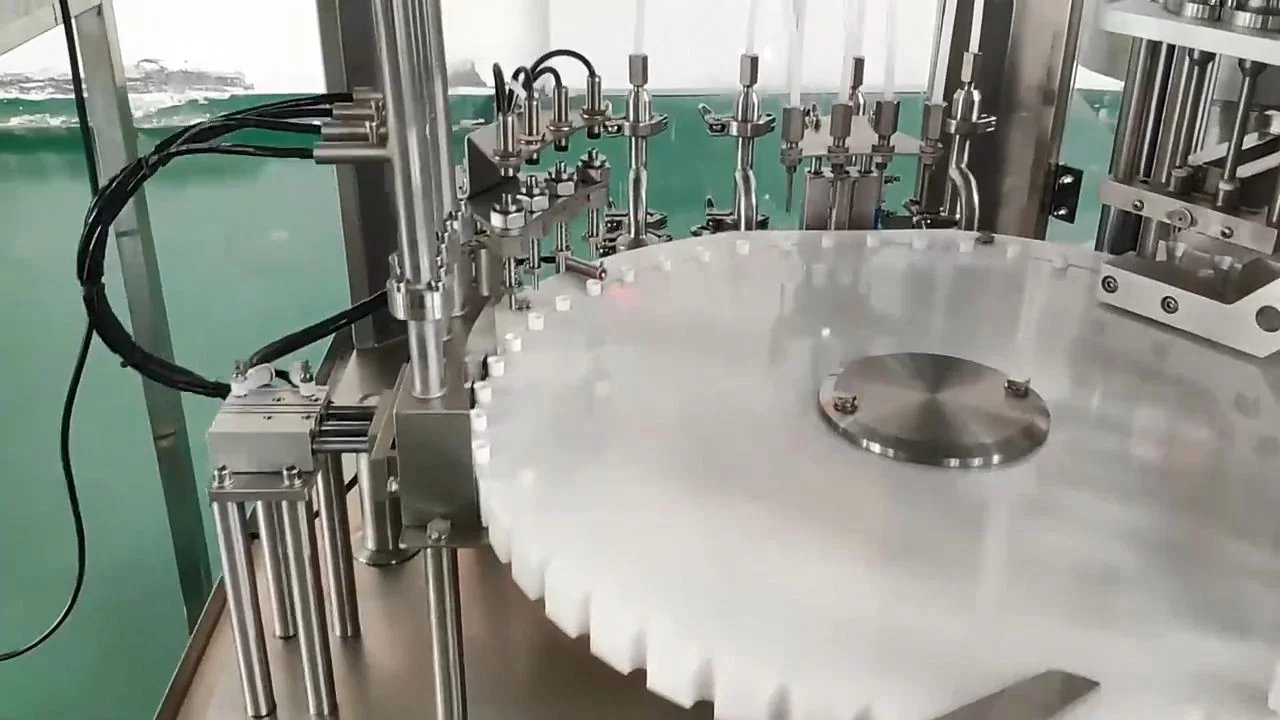

Piston Pump Filling Machine

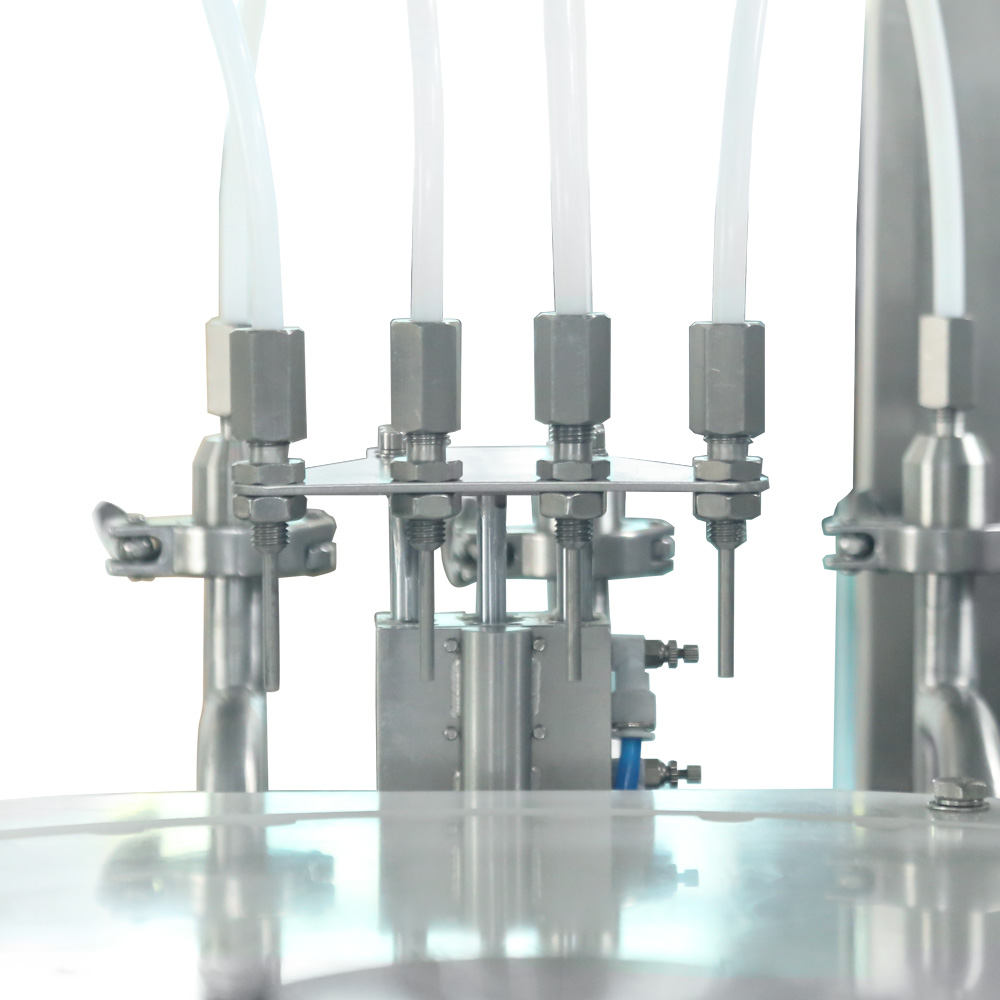

This is wheel type piston pump filling machine which is designed for small bottle and low capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

This is wheel type piston pump filling machine which is designed for small bottle and low capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

This is linear type peristaltic pump ( can be piston pump) filling machine which is designed for high capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof, via photoelectric detection to ensure no bottle no filling.

Perfume spray cap application

With three-jaw capping head, the capping machine is able to work with different kinds of lid torquing process. Contradicted to traditional machinery adjustment in capping torque, new smart filler adapt Magnetic torque motor in driving, which control torque by switch. Human-friendly design is always convenience.

Round Bottle Labeling Machine

The newest smart round bottle labeling machine is working with different kinds of bottle and labels, infrared detection sensor is work with transparent label. With adjustment handle, it is able to work with high, lower, fat, thin bottle and apply labels into accurate station.