Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 1000-4000BPM

- Applicable Industries: Food & Beverage Factory, Retail, Pharmaceutical Packaging Factory

- Showroom Location: Egypt, Philippines

- Application: Food, Beverage, Commodity, Chemical

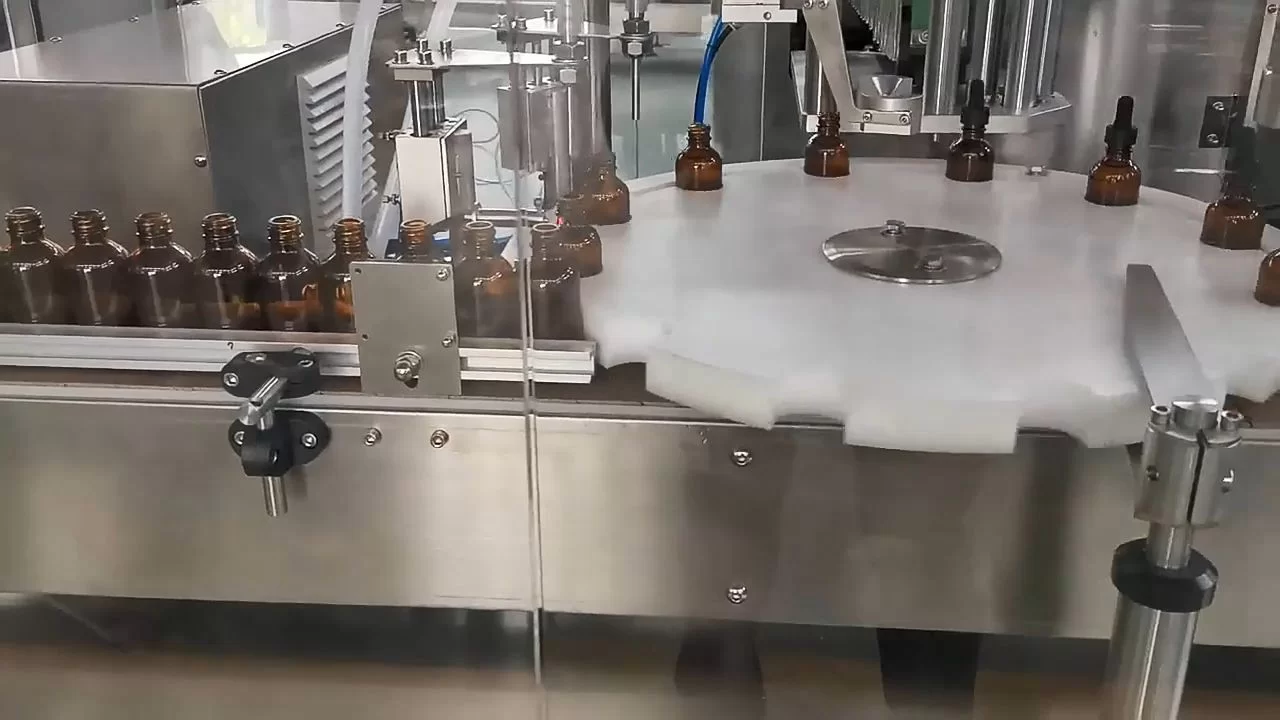

- Packaging Type: Bottles, Vial

- Packaging Material: Plastic, Metal, Glass

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Place of Origin: Shanghai, China

- Brand Name: VKPAK

- Dimension(L*W*H): 1500*1500*1700mm

- Weight: 500 KG

- Warranty: 1-3 Year

- Key Selling Points: Automatic

- Filling Material: Water, Oil, Juice, Honey

- Filling Accuracy: ±1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: standard

- Core Components: standard

- Product name: Glass Jar Bottle Honey Piston Filling Machine Equipment

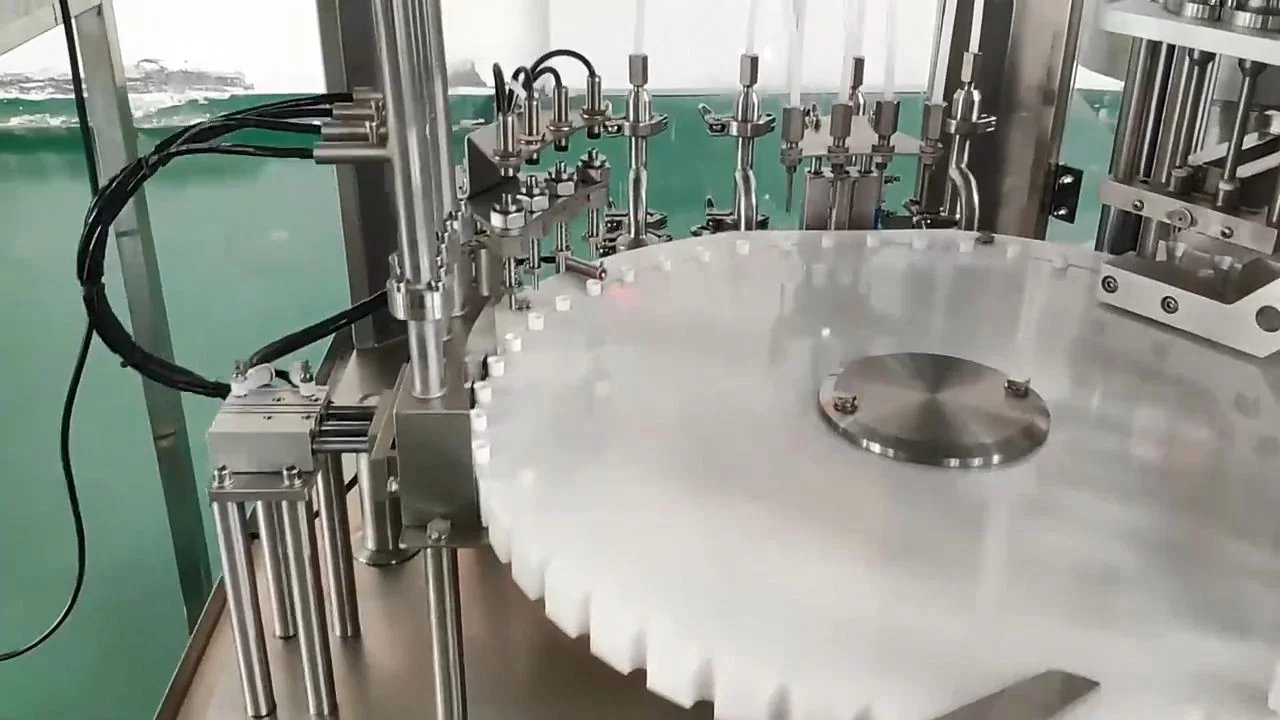

- Number of filling heads: 4 heads or customized

- Filling capacity: 50ml-500ml

- Filling form: Servo piston filling

- Filling speed: 25-30 bottles/hour (50-150ml bottle)

- Filling accuracy: ±1%

- Air pressure: 0.6-0.8MPa

- Power: About 2KW/380V three-phase five-wire

- Groove capacity: 10 liters

- Protection device: The liquid storage tank is shut down and the alarm is stopped.

More Details

| Technical Parameter | |

| Number of filling heads | 2 filling heads |

| Filling capacity | 50-500ml |

| Filling form | 2 heads into bottle bottom fast or slow tracking filling |

| Filling speed | 20-45 bottles/minute |

| Filling accuracy | ±1% |

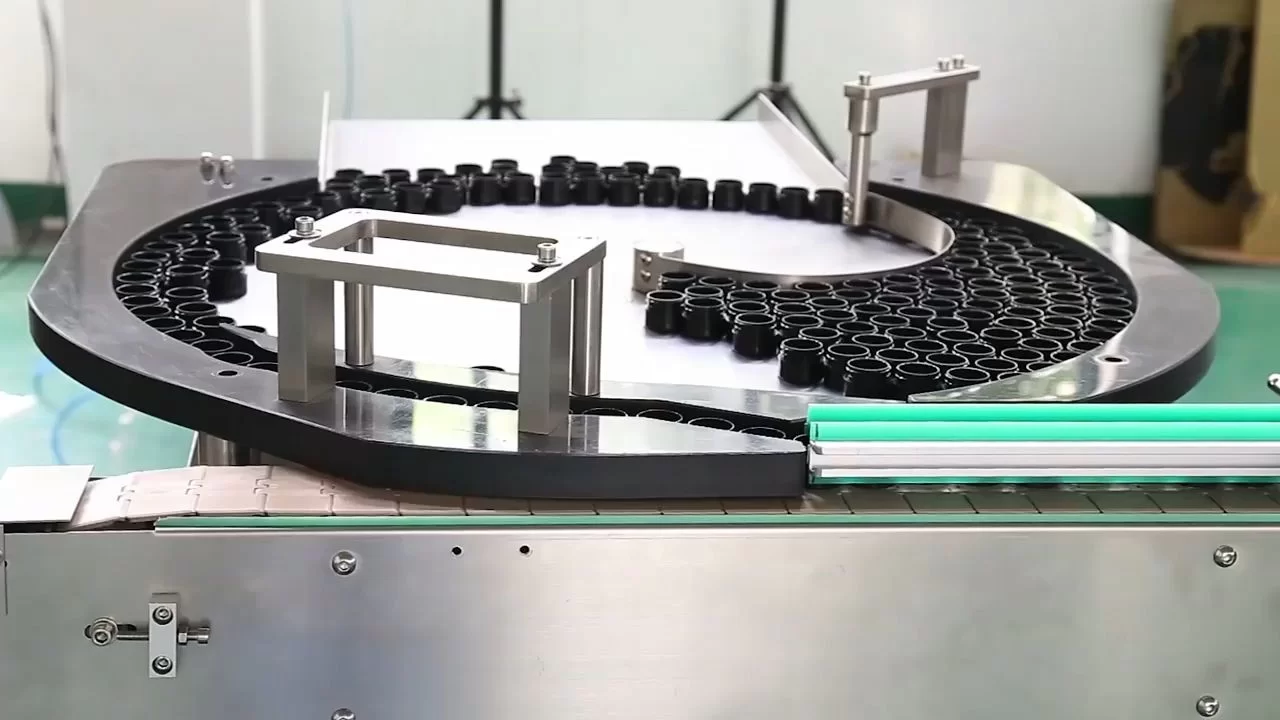

| Cap putting form | Vibration cap sorter feeding |

| Capping form | High speed screw locking |

| Total power | 2KW/AC220V/380V, 50/60HZ |

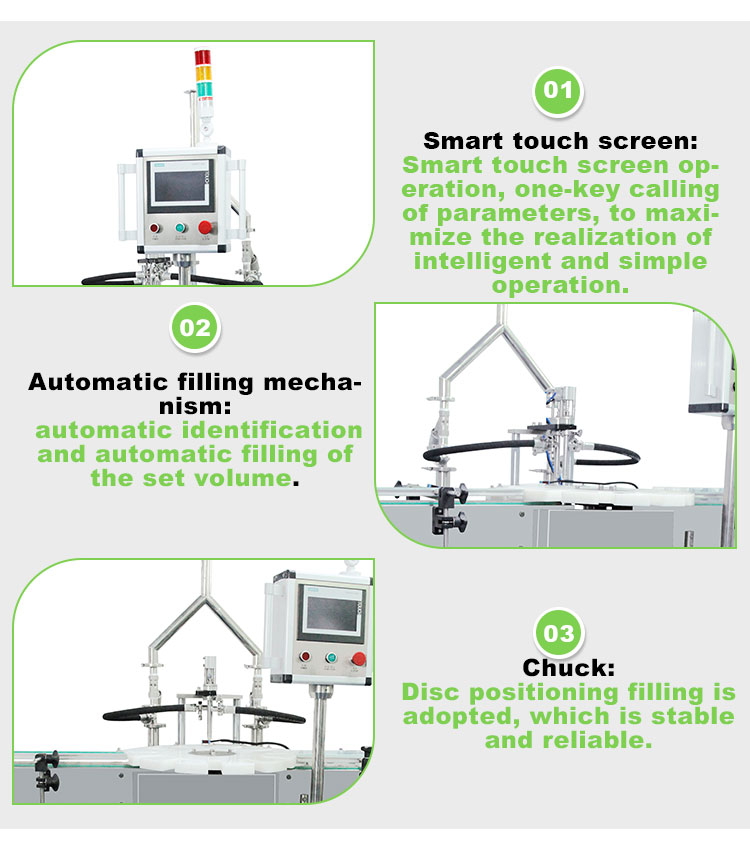

| Program control | PLC touch screen |

| Net weight | 500KG |

| Materials of liquid contacting parts such as filling nozzle and chute: 316L # stainless steel and PVC pipe. | |

Description:

The locking filling capping machine is carefully designed for liquid medicine, syrup vial , and serum, 50ml to 500ml arbitrary adjustable of a new generation of packaging equipment, using microcomputer PLC automatic control.

High precision measurement, large filling range, smooth operation, easy to clean, suitable for various shapes of container filling.