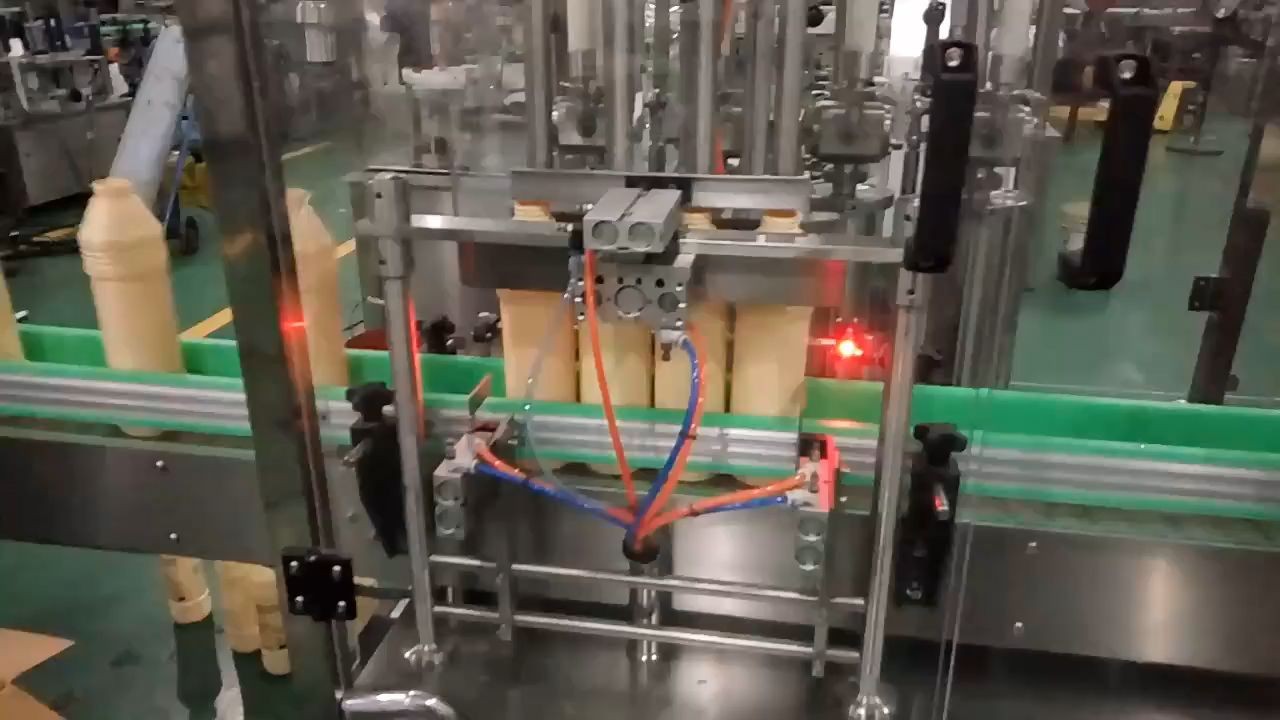

The automatic cooking oil filling machine is designed and manufactured by VKPAK, This full-automatic cooking oil filling machine is controlled by PLC. It is a high-tech product integrating light, machine, electricity and gas. It is easy to install, easy to operate, and suitable for a wide range of bottle types. Due to PLC control, the filling accuracy is 0.1%. The whole machine adopts stainless steel structure, PLC control, mechanical transmission, frequency control, pneumatic positioning and photoelectric detection.The machine can be customized according to the needs of customers, meeting the requirements of GMP.

1. the capacity of the line is range from 800b/hour to 5000bottles per hour

2. the filling volumeof the machine is range from 100ml to 5000ml

| Model | VK-2 | VK-4 | VK-6 | VK-8 | VK-10 | VK-12 | VK-16 |

| Heads | 2 | 4 | 6 | 8 | 10 | 12 | 16 |

| Range(ml) | 100-500,100-1000,1000-5000 | ||||||

| Capacity(bpm)base on 500ml | 12-14 | 24-28 | 36-42 | 48-56 | 60-70 | 70-80 | 80-100 |

| Air Pressure(mpa) | 0.6 | ||||||

| Accuracy(%) | ±0.1-0.3 | ||||||

| Power | 220VAC SINGLE PHASE 1500W | 220VAC SINGLE PHASE 3000W | |||||

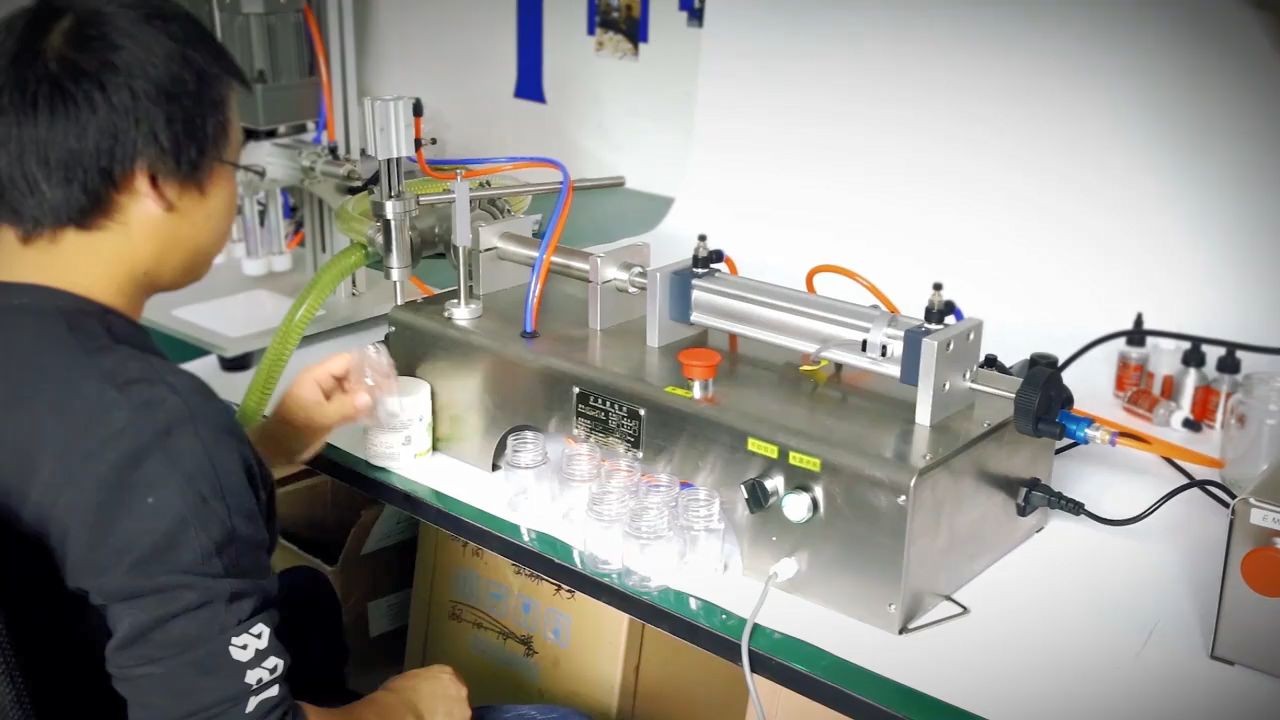

An automatic piston cooking oil filling machine is an important component of an oil production line that is designed to fill cooking oil bottles accurately and efficiently. This machine utilizes a piston system that is controlled automatically to ensure that the correct amount of oil is dispensed into each bottle.

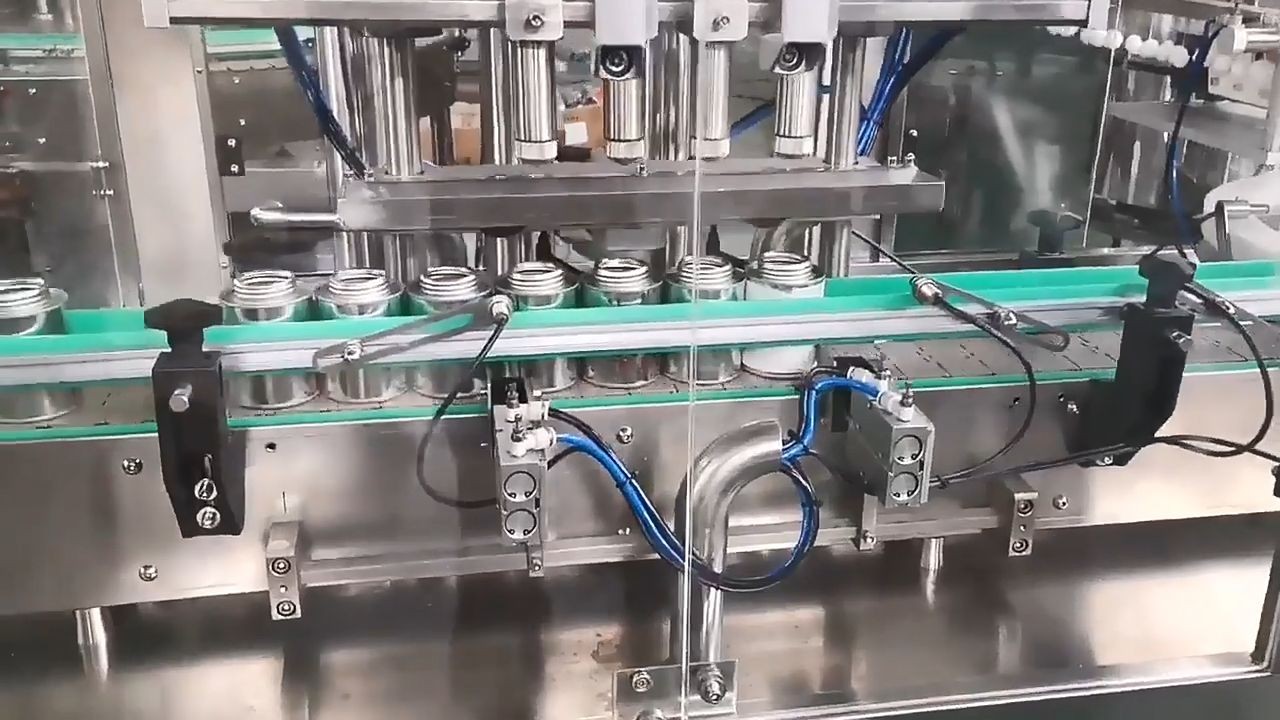

The automatic piston cooking oil filling machine is ideal for use in the food and beverage industry, specifically in cooking oil manufacturing. It can fill bottles of various shapes and sizes, ranging from small bottles to large containers, with volumes ranging from a few milliliters to several liters. The machine can handle different types of cooking oils, including vegetable oil, sunflower oil, soybean oil, and more.

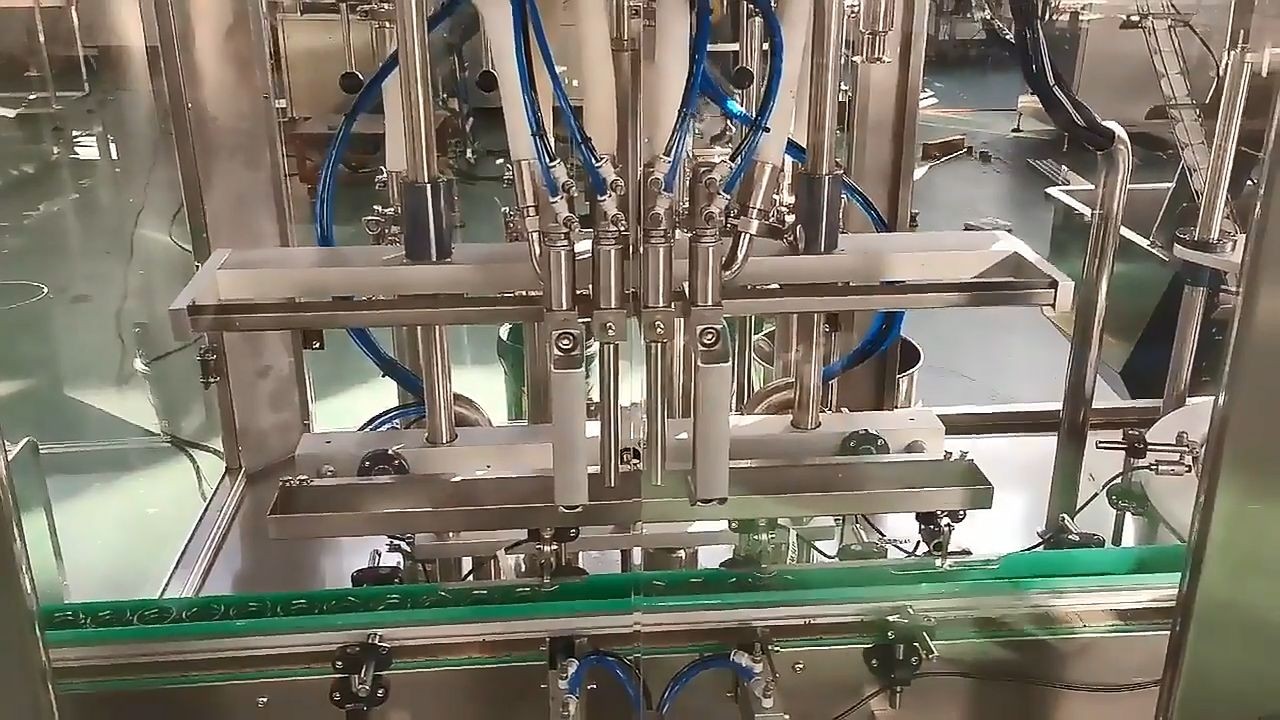

The filling process in the automatic piston cooking oil filling machine is a multi-stage process. First, the empty bottles are conveyed into the machine through a conveyor system, where they are aligned in a single file. The bottles then pass through the filling station, where the piston system is used to dispense the correct amount of oil into each bottle.

The machine can be programmed to fill the bottles to a specific level, ensuring consistent filling volumes and reducing the risk of overfilling or underfilling. Moreover, the machine can be adapted to fill different bottle sizes and shapes, making it highly versatile and adaptable to different production needs.

One of the key benefits of the automatic piston cooking oil filling machine is its high filling accuracy. With the use of automatic controls, the machine can achieve filling accuracy of up to 0.5%, ensuring that each bottle is filled to the desired level consistently. This reduces product waste and increases production efficiency.

Another benefit of this machine is its ease of use. The machine can be operated by a single operator, reducing the need for multiple workers and increasing productivity. The machine is also easy to maintain and clean, reducing downtime and increasing production efficiency.

In conclusion, an automatic piston cooking oil filling machine is an essential component of an oil production line that requires accurate and efficient filling of cooking oil bottles. With its high filling accuracy, versatility, and ease of use, this machine is a reliable and efficient solution to the challenges of cooking oil bottling.