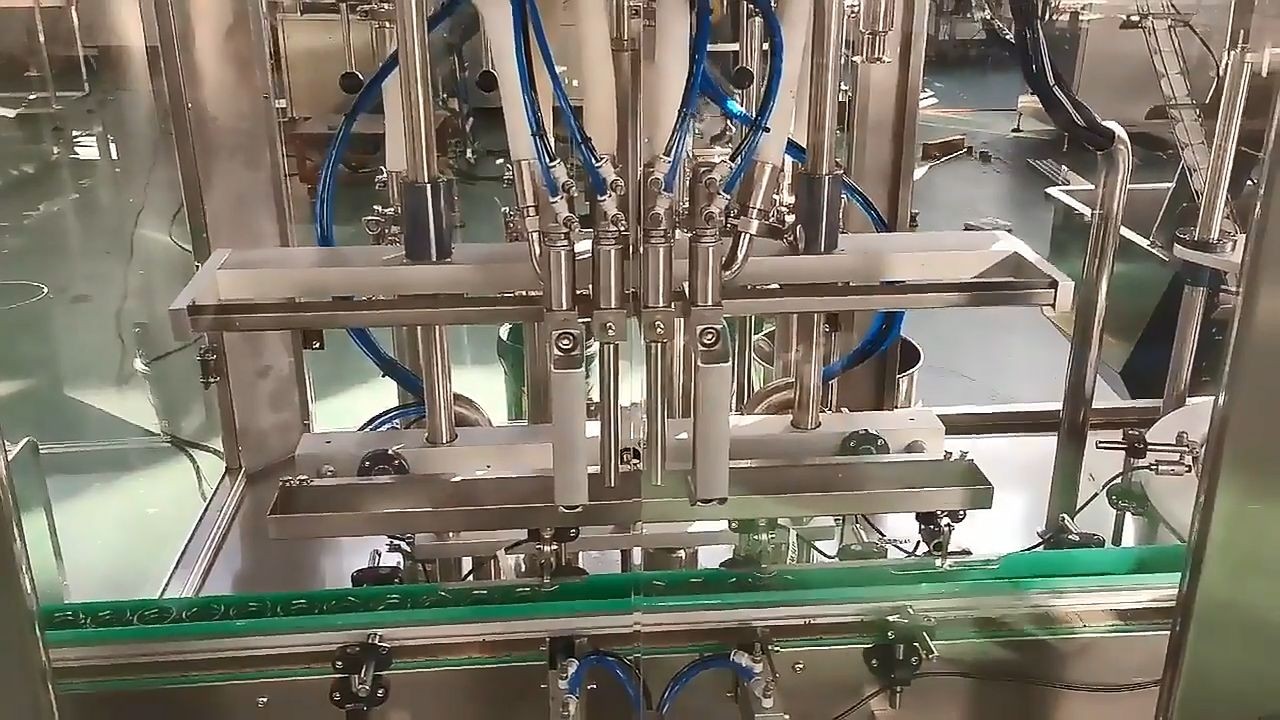

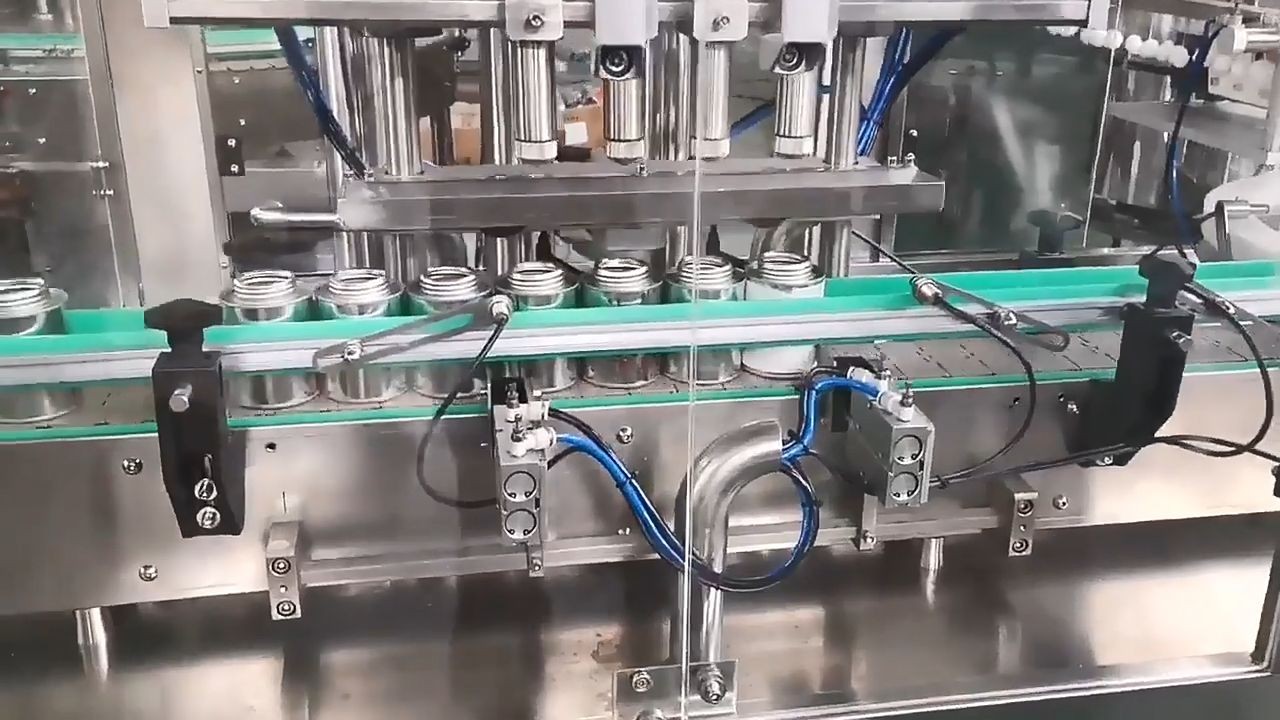

Linear rotary pump liquid tracking filling machine is designed on the basis of straight line cam pump filling machine. It has the advantages of high efficiency and high precision, and can be filled with thin and extremely viscous products without foam. It has a separate servo motor to drive the lobe pump and supply products to each separate filling head. The filling head moves synchronously with the bottle without interruption. This allows filling of various types of containers, from 20g to 5kg barrels. This machine is made of 304SS material, sanitary connection and can be connected to CIP system. It is an ideal machine for filling food jams, such as honey, tomato jam and so on. The machine is controlled by motion controller, which has higher performance than PLC.

| Container size | 100ml to 5000m | ||||||

| Nozzles available | 2 to 4 | ||||||

| Overall dimensions | 1800mm*1300mm*2000mm | ||||||

| Air consumption | 2 to 4 | ||||||

| Electrical | 220 V 50/60hz single phase | ||||||

| Power | 3.5KW | ||||||

| Production rate | 40 to 50 Containers/Minute | ||||||

Main features

1: High speed---40-50 bottles/min with only 2 filling nozzles

2: Wide Application--- fast switching for various bottles and products

3: Easy but High Clean---rotor pump control, CIP cleaning optional

4: Touch screen operation interface

5: Support up and down movement type filling to effectively prevent foam generation

6: The filling accuracy can reach ±1% (depending on the product, the filling accuracy is different)

7: The filling cylinder is treated and ground by hard chromium, with a unique filling valve design, no leakage

8: No bottle no filling function

9: Design different positioning devices according to the actual situation of the bottle

10: The equipment is easy to clean, and it can also be cleaned online or sterilized by high temperature

11: The equipment and material contact are all made of 304# stainless steel

12. less area occupancy

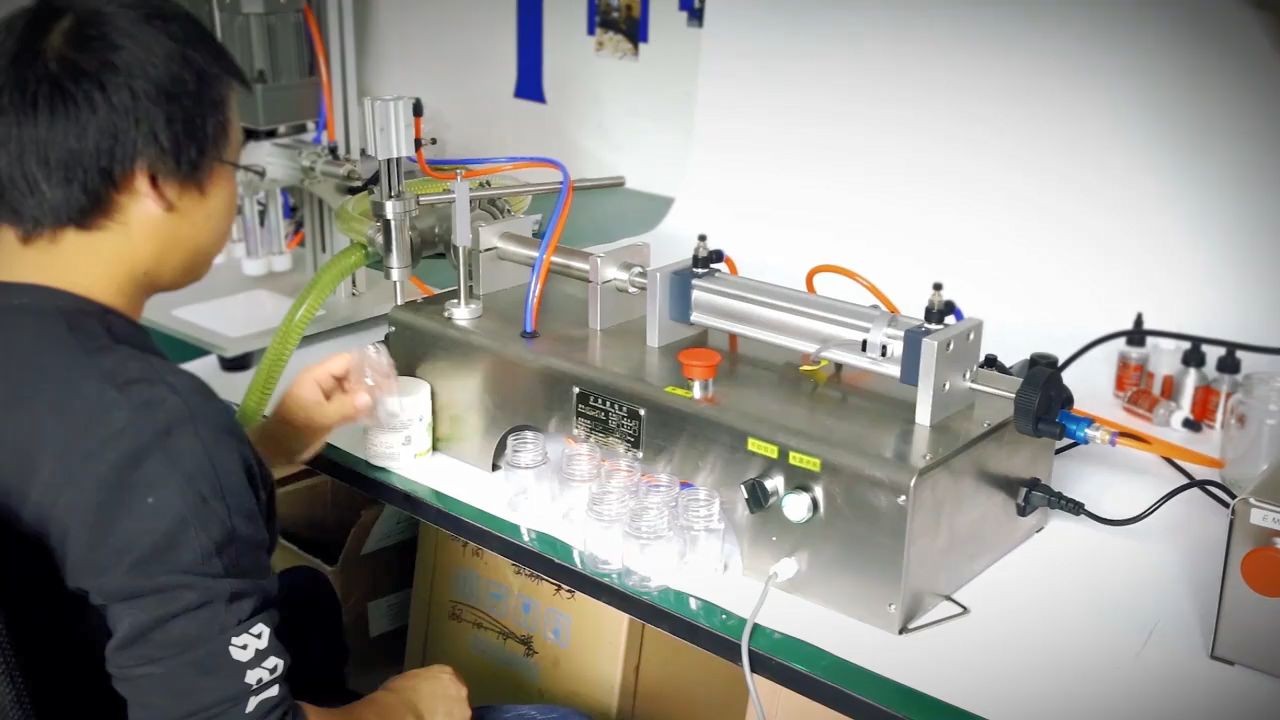

An automatic pneumatic double head hot sauce bottle filling machine is a specialized machine used in the food industry for filling hot sauce into bottles. This machine is designed to increase production efficiency and reduce labor costs by automating the filling process.

The machine operates using a pneumatic system, where air pressure is used to control the filling process. It comes equipped with two filling heads, allowing it to fill two bottles simultaneously. The machine also has adjustable nozzles to accommodate different sizes of bottles and volumes of hot sauce.

The automatic pneumatic double head hot sauce bottle filling machine is made of high-quality materials, which ensures that it is durable, hygienic, and easy to clean. It is also equipped with a touch screen display, making it easy to operate and monitor the filling process. The display shows important information such as the number of bottles filled, the speed of the machine, and any error messages.

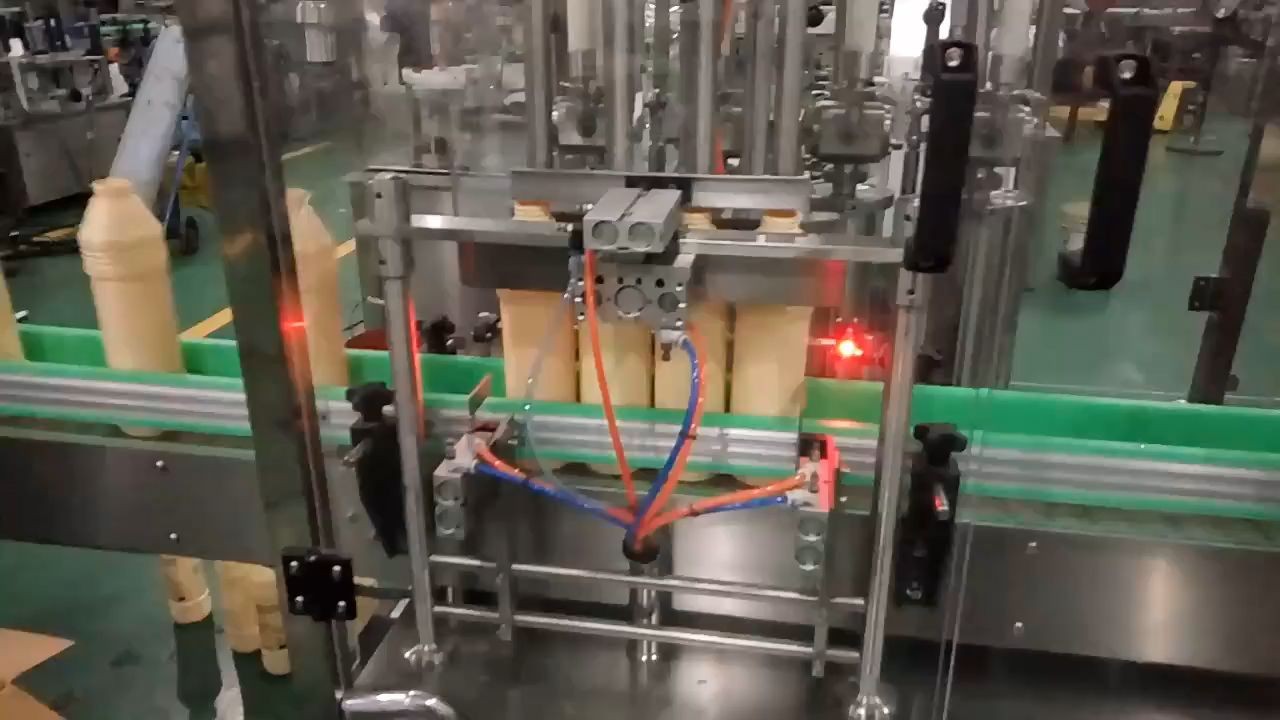

Another important feature of the automatic pneumatic double head hot sauce bottle filling machine is its high-speed capability. It can fill up to 60 bottles per minute, making it ideal for companies that require high production rates and want to minimize downtime. The speed of the machine is controlled by a frequency converter, allowing for easy adjustment of the filling speed.

Furthermore, the machine is equipped with an automatic bottle indexing system that ensures that the bottles are filled in a consistent and uniform manner. This system also prevents spillage and reduces waste, which is important for companies that want to minimize their environmental impact and optimize their production processes.

In conclusion, the automatic pneumatic double head hot sauce bottle filling machine is an advanced technology that offers fast, accurate, and efficient filling capabilities for hot sauce bottles. Its features make it suitable for the food industry, and it is a valuable investment for any company that requires high-speed hot sauce filling.