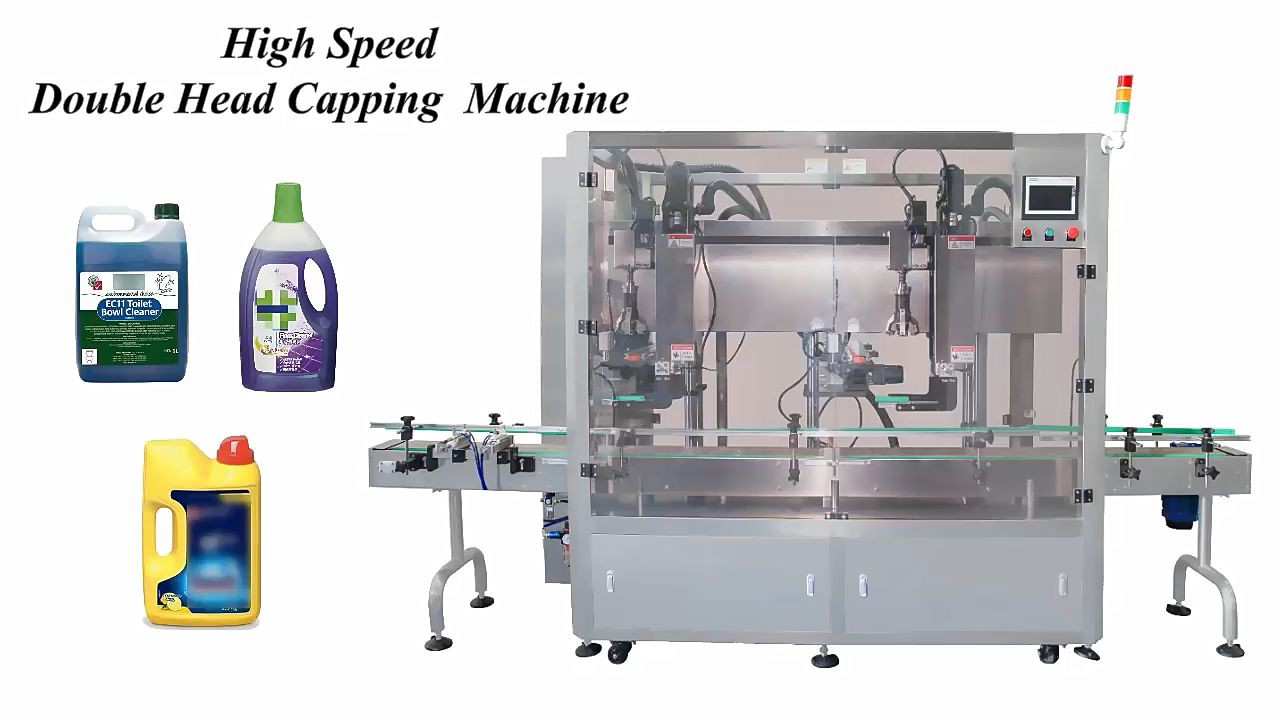

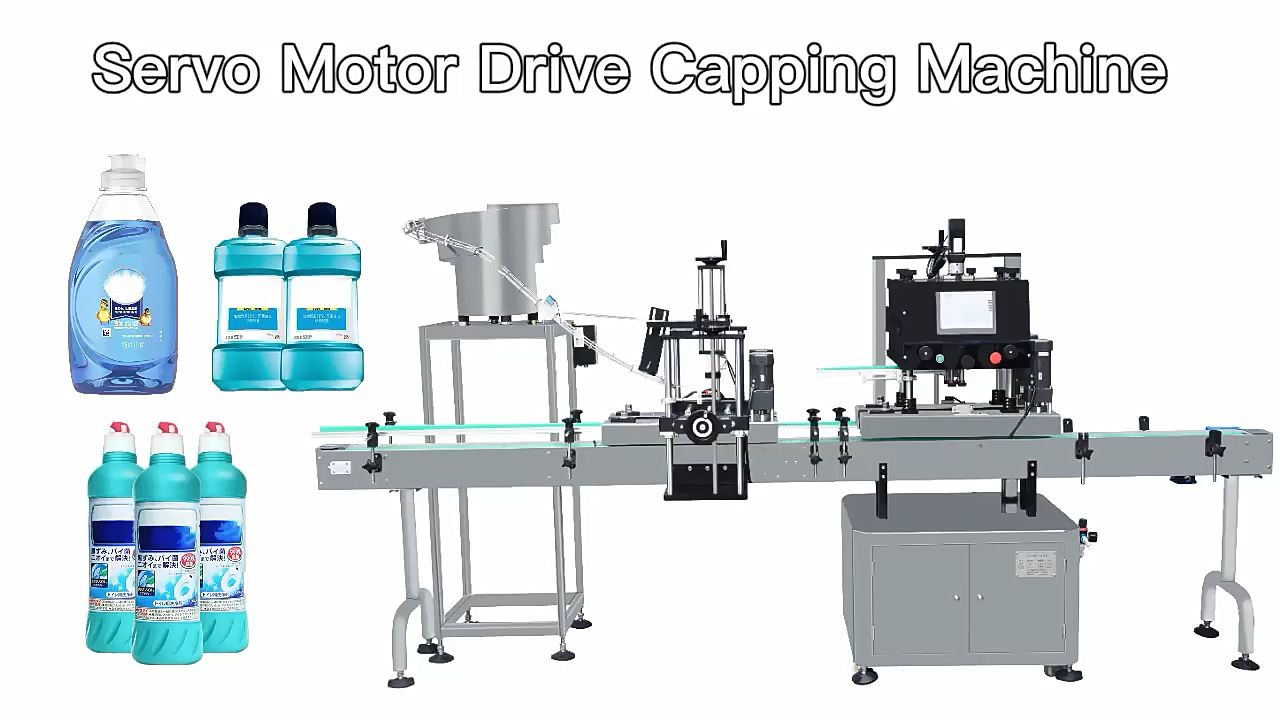

The main structure is made of durable 304 stainless steel. The machine is control by touch screen,parameter can be set on touch screen very easily. It is very flexible for different sizes of round bottles, square bottles and flat bottles by adjustment.Capping time can be set to fit different caps and different levels of tightness. It is very easy for exist line upgrade.

MAIN FEATURE

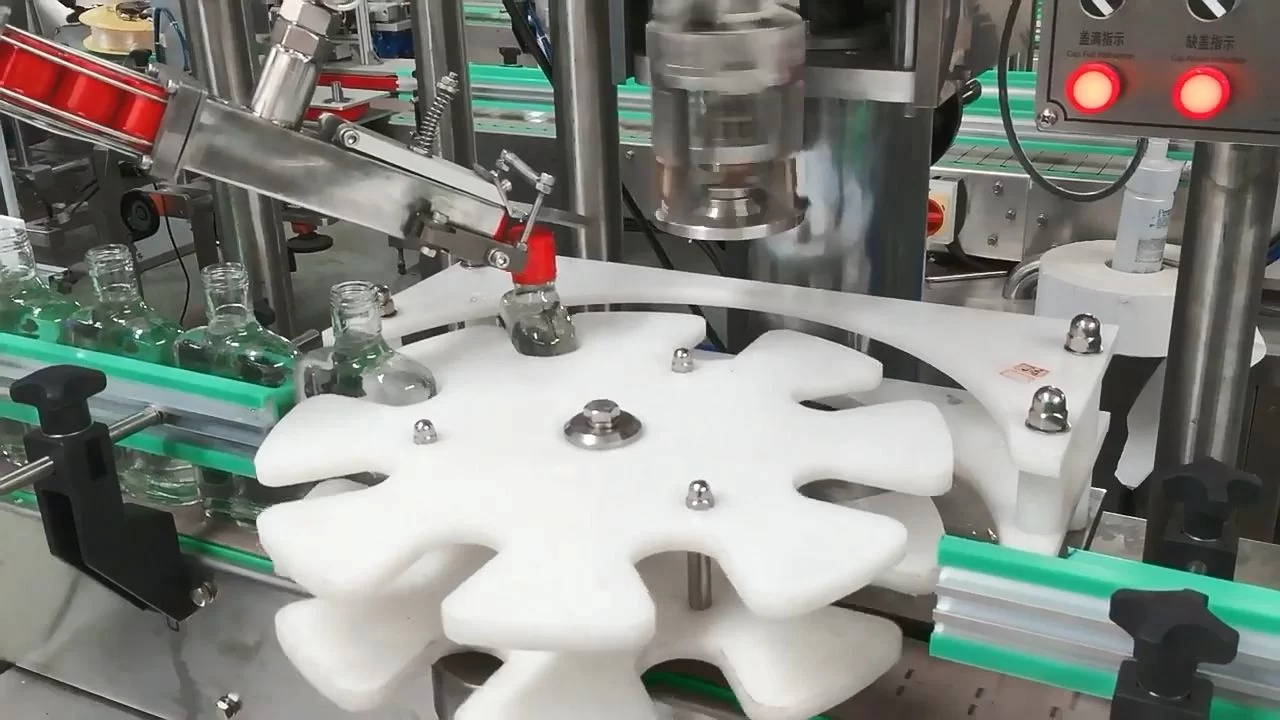

1. Automatic cap feeding system, vibrating tray.

2. No tools requirements for different size adjust for capping system.

3. Output meet the filling machine, but max 30 bottles/ min.

4. No bottle No capping.

5. Control panel with touch screen. capping programs saving.

6. Machine’s body of SS 304.

| 1 | Capping Head | 1 Heads | |

| 2 | Production Capacity | 25-35BPM | |

| 3 | Cap diameter | Up to 70MM | |

| 4 | Bottle Height | Up to 460MM | |

| 5 | Voltage/Power | 220VAC 50/60Hz 450W | |

| 5 | Driven way | Motor with 4 wheels | |

| 6 | Interface | DALTA Touch Screen | |

| 7 | Spare Parts | Capping Wheels | |

Main Component List

| No. | Descriptions | BRAND | ITEM | Remark |

| 1 | Capping Motor | JSCC | 120W | Germany Technology |

| 2 | Reducer | JSCC | Germany Technology | |

| 3 | Touch Screen | DALTA | TAIWAN | |

| 4 | PLC | DALTA | TAIWAN | |

| 5 | Pneumatic Cylinder | AIRTAC | TAIWAN | |

| 6 | Air Filter | AIRTAC | TAIWAN | |

| 7 | Main Structure | 304SS | ||

| 8 | Press Controller | AIRTAC | TAIWAN |

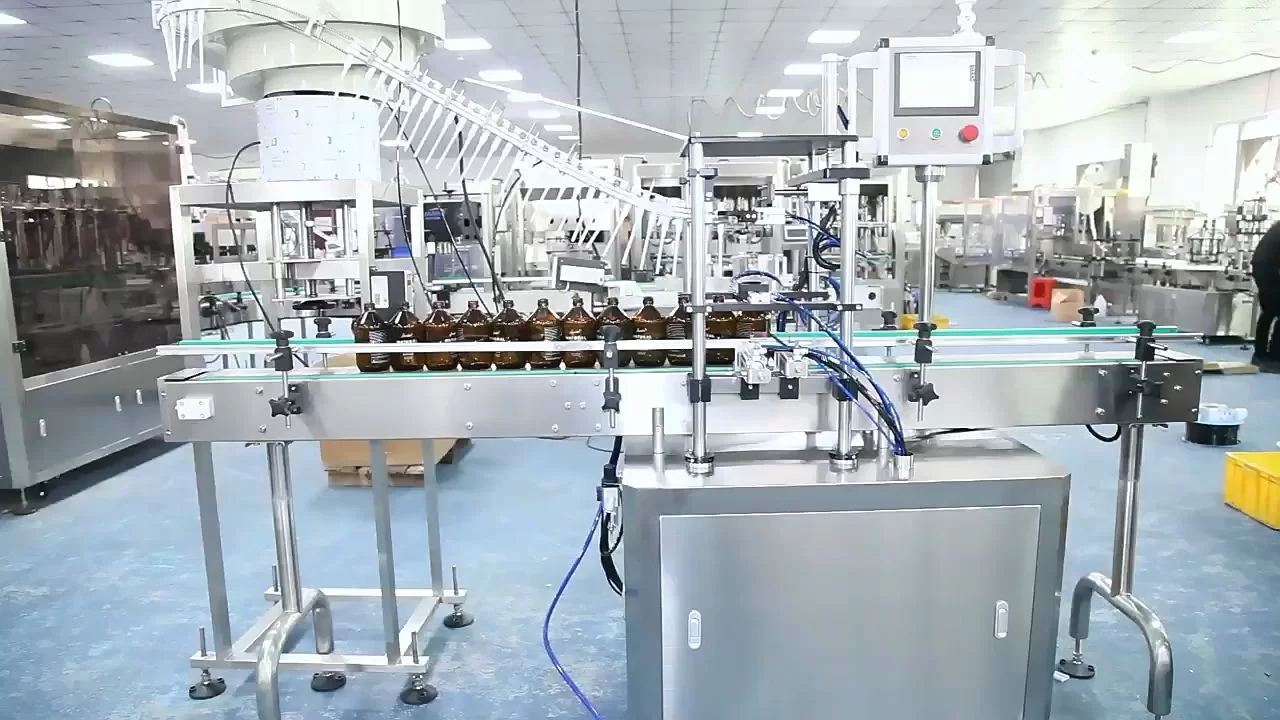

The automatic pneumatic PET plastic bottle screw capping machine is a specialized piece of equipment designed to efficiently and accurately cap PET plastic bottles. The machine is equipped with advanced technology that ensures precise and consistent capping, making it an ideal solution for manufacturers looking to increase productivity and efficiency.

The machine is designed to handle PET plastic bottle sizes and shapes, making it versatile and suitable for different production requirements. It is equipped with a conveyor system that moves the bottles to the capping station, where the cap is screwed onto the bottle. The capping process is highly precise and accurate, ensuring that each bottle is capped to the desired level.

The machine is also equipped with a sensor that detects the bottle's position and ensures that the cap is screwed on accurately and precisely. This technology helps to eliminate errors and ensures that each bottle is capped consistently.

The machine is also equipped with a touch screen interface that allows the operator to control the entire capping process. The interface is user-friendly and intuitive, making it easy for operators to adjust the capping speed, torque, and other parameters as required.

The machine is designed to operate at high speeds, ensuring that the production process is efficient and fast. It can cap up to 120 bottles per minute, depending on the bottle size and cap specifications.

The automatic pneumatic PET plastic bottle screw capping machine is also easy to set up and maintain. It requires minimal training to operate, and its compact size makes it easy to move and transport. The machine is also equipped with a cleaning system that ensures that the capping station and other parts of the machine are kept clean and free from contaminants. This helps to maintain the quality of the product and ensures that it is safe for use.

In conclusion, the automatic pneumatic PET plastic bottle screw capping machine is a specialized machine that provides an efficient and automated process for capping PET plastic bottles. Its advanced technology ensures precise and consistent capping, making it an ideal solution for manufacturers looking to increase productivity and efficiency. Its versatility, high speed, user-friendly interface, and cleaning system make it a valuable asset in any production facility.