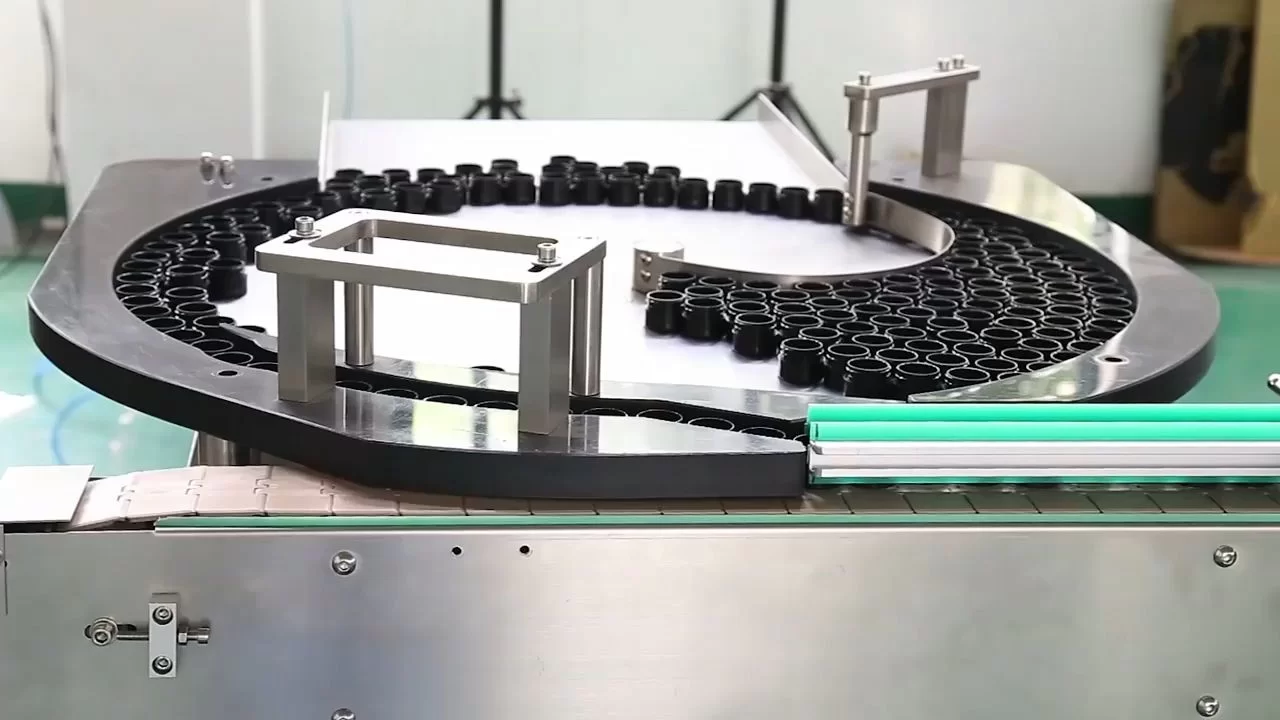

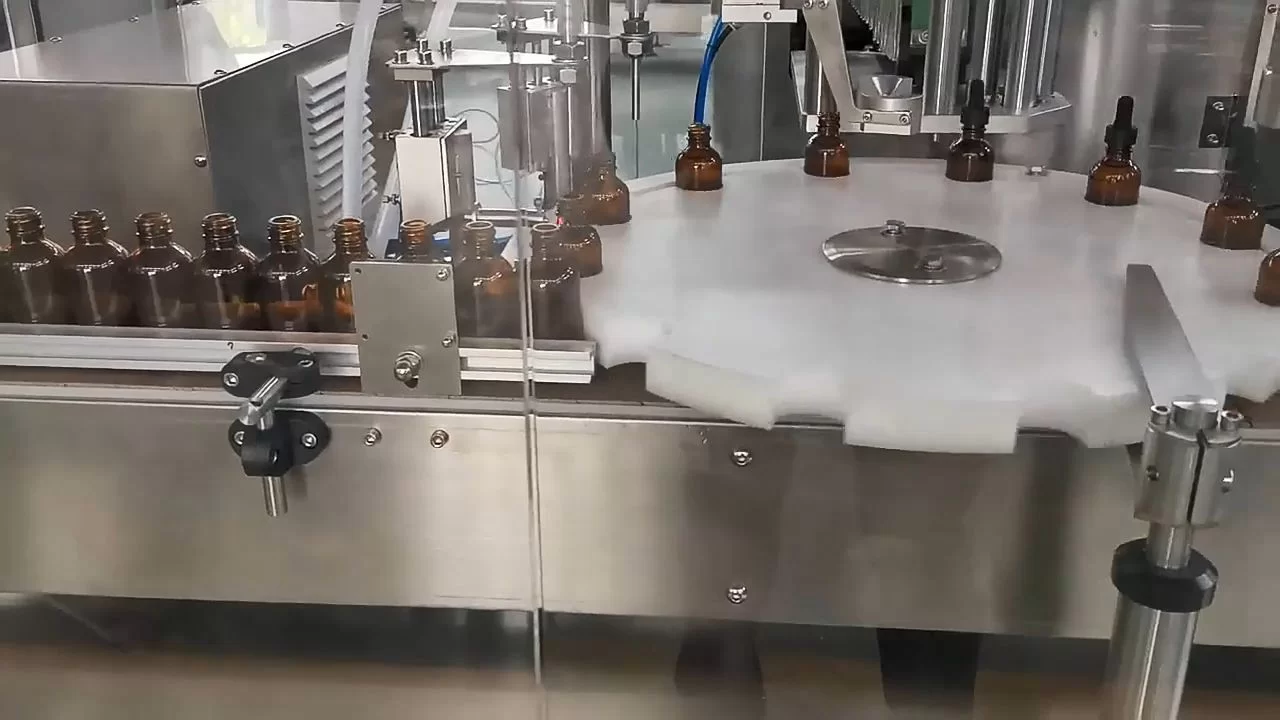

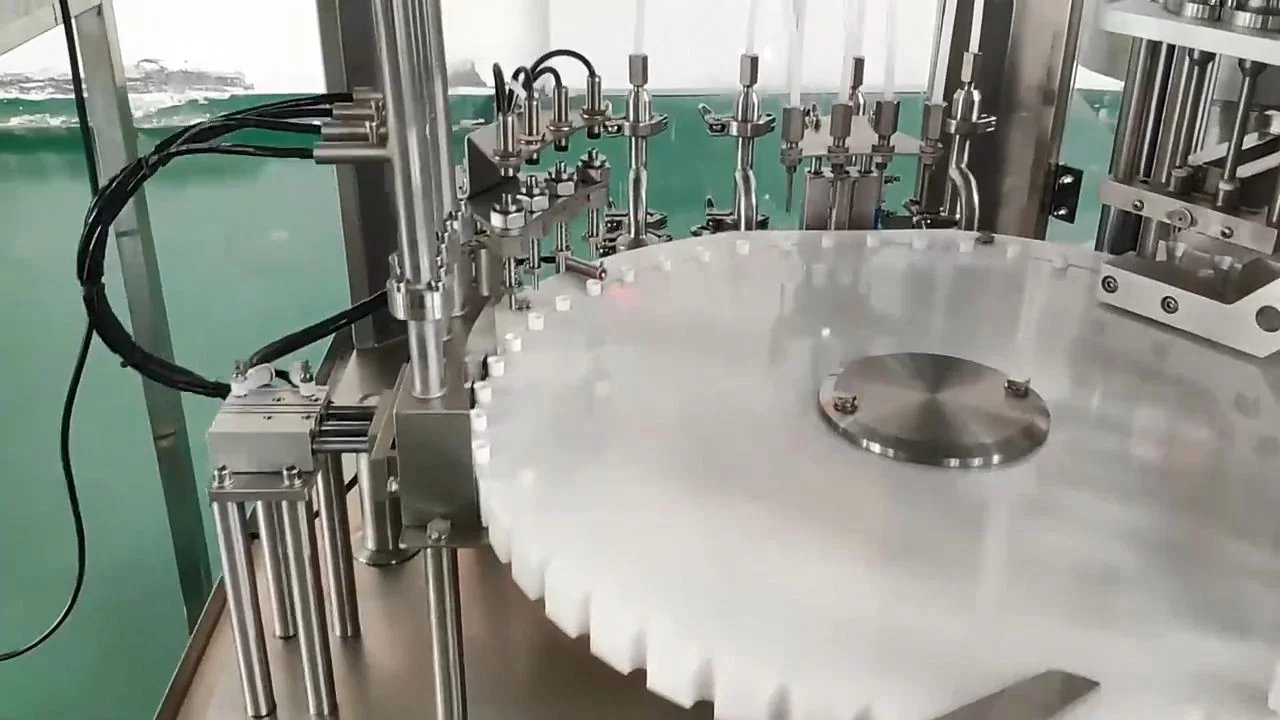

This machine has the functions such as automatic l screw type bottle feeding, bottle detecting (no bottle no filling, no bottle no cap feeding), filling, cap feeding and capping automatically.

1. Filling speed: 30bottles/min

2. Filling precision: ≥99%

3. Finished product rate of cap drop: ≥99%

4. Main machine power: 1KW 220V stepless shift

| Filling speed | 30bottles/min |

| Filling precision | ≥99% |

| Finished product rate of cap drop | ≥99% |

| Main machine power | 1KW 220V stepless shift |

Main features

1. It functions as bottle unscrambling, filling, cap screwing and collecting etc.

2. Modularized control system, Easy to Maintain, low cost.

3. Panel microsoft can be updated by USB.

4. Online cleaning function is optional.

An automatic rotary cosmetic cream body filling and capping machine is a specialized industrial equipment designed to automatically fill and cap cosmetic cream and body care products such as lotions, moisturizers, and creams. This machine is commonly used in the cosmetic and personal care industry.

The machine works by placing empty containers onto a conveyor belt, which then moves them through the filling and capping stations. The filling station uses a rotary piston system to dispense the cream or lotion into the containers. The capping station uses a rotary capping system to cap the containers with pre-threaded caps. The machine can fill and cap up to 50 containers per minute, depending on the specific design of the machine.

One of the key advantages of the automatic rotary cosmetic cream body filling and capping machine is its high accuracy and consistency in filling and capping products. The machine's rotary piston and capping systems ensure that each container is filled with the same volume of product and capped with the same level of tightness. This results in a high-quality product with minimal waste and minimal variation in fill levels and cap tightness.

Another advantage of this machine is its versatility. It can handle a wide range of container sizes and shapes, thanks to its adjustable conveyor and filling and capping heads. The machine's flexibility also allows for easy switching between different types of creams and lotions, minimizing downtime and maximizing productivity.

Additionally, the machine is equipped with a user-friendly touch screen interface that makes it easy to control and monitor the filling and capping process. The interface allows operators to adjust the filling volume, capping speed, and other settings, ensuring optimal performance and efficiency.

Overall, an automatic rotary cosmetic cream body filling and capping machine is an essential piece of equipment for any company that needs to fill and cap large quantities of cosmetic cream and body care products quickly and accurately. Its accuracy, consistency, versatility, and ease of use make it an ideal solution for improving production efficiency and quality in the cosmetic and personal care industry.