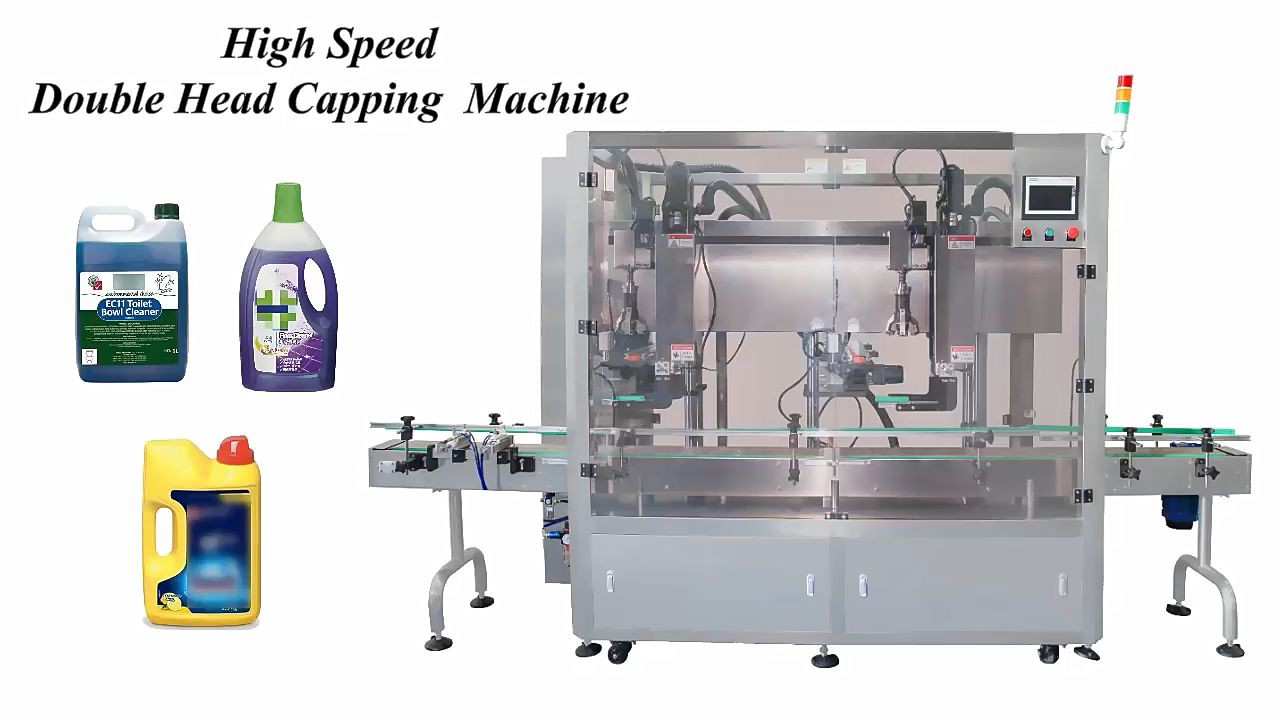

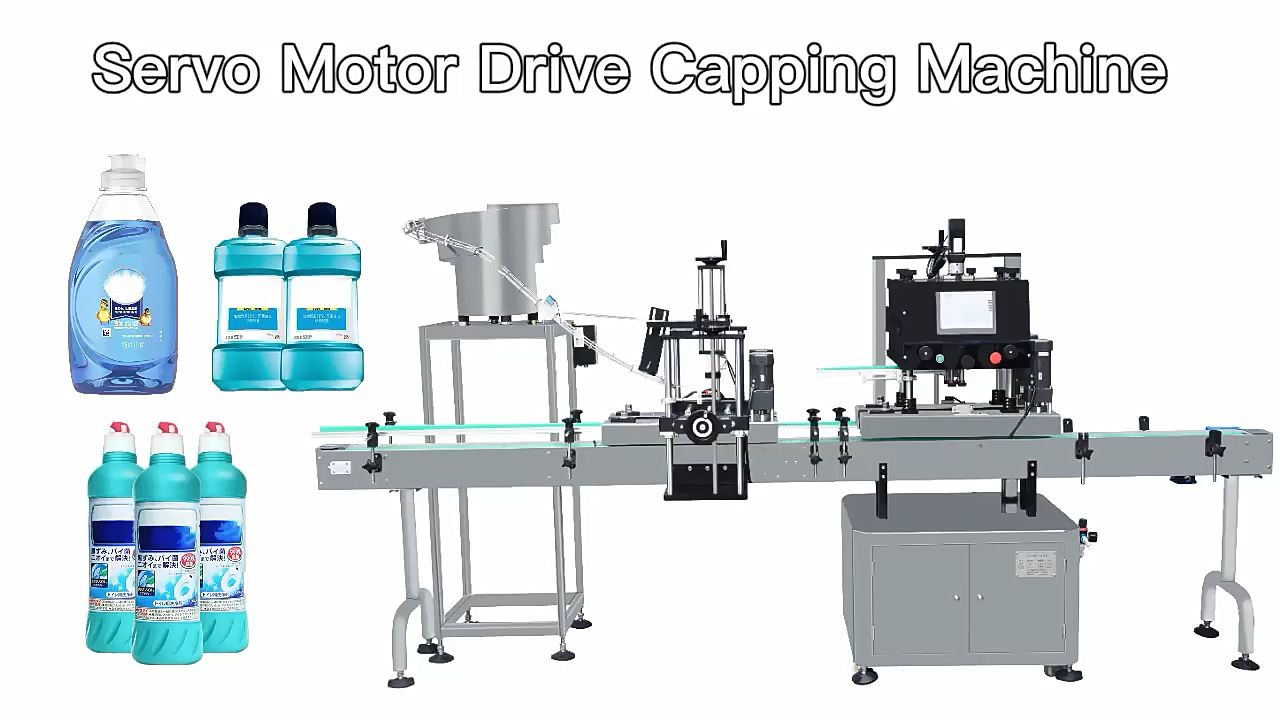

Rotary capping machine adapts one screwing capping or snapping nozzles for packaging lines . It is flexible and durable and works with most containers and caps including flat caps, sport caps, metal lids and so on.

Advantage

1. high qualified ratio of cap hanging &rotating (sealing)

2. Plate positioning, convenient to change size, and large range of adjusting.

3. Frequency control speed.

1. The VK-RC automatic capping machine is designed for closing various types of containers (made of plastic, glass and metal) with aluminum caps. The machine is especially suitable for use in the food-processing, cosmetic and chemical industries.

2. The machine can be equipped with different types of cap unscrambler (vibrating, rotary, belt type) depending on the type and size of the cap. For feeding the caps into the cap unscrambler the caps hopper is available.

3. For placing difficult caps onto the container neck the "Pick and Place" system can be used.

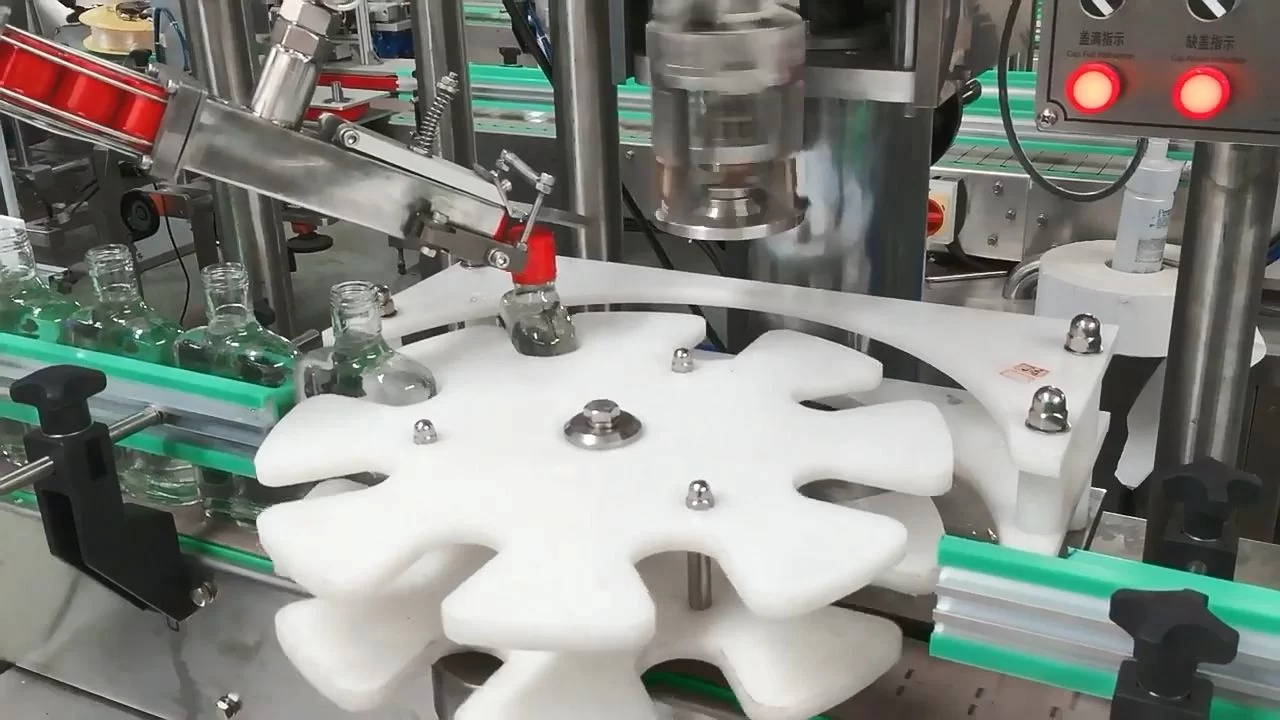

4. Working Function:The containers are transferred to the star wheel by means of the conveyor. The star wheel (indexing type for one-head capper or continuous motion for multiple-head capper) takes the containers and carries them to the caps placing station and than to the closing head. The closing head tightens the cap with the necessary torque (if the head is of the pressure type, it will press the cap on the bottle neck by means of a spring unit). The torque can be set on the closing head by means of magnetic clutch. After completion of the closing process, the star wheel moves the container to next station for press the black small cap, after that the star wheel moves the container to the finish products conveyor.

The Automatic Rotary Glass Olive Oil Bottle ROPP Capping Machine is a state-of-the-art packaging equipment designed to cap glass bottles containing olive oil. This machine uses the Roll-On Pilfer Proof (ROPP) capping technology, which ensures a secure and tamper-proof seal for your product.

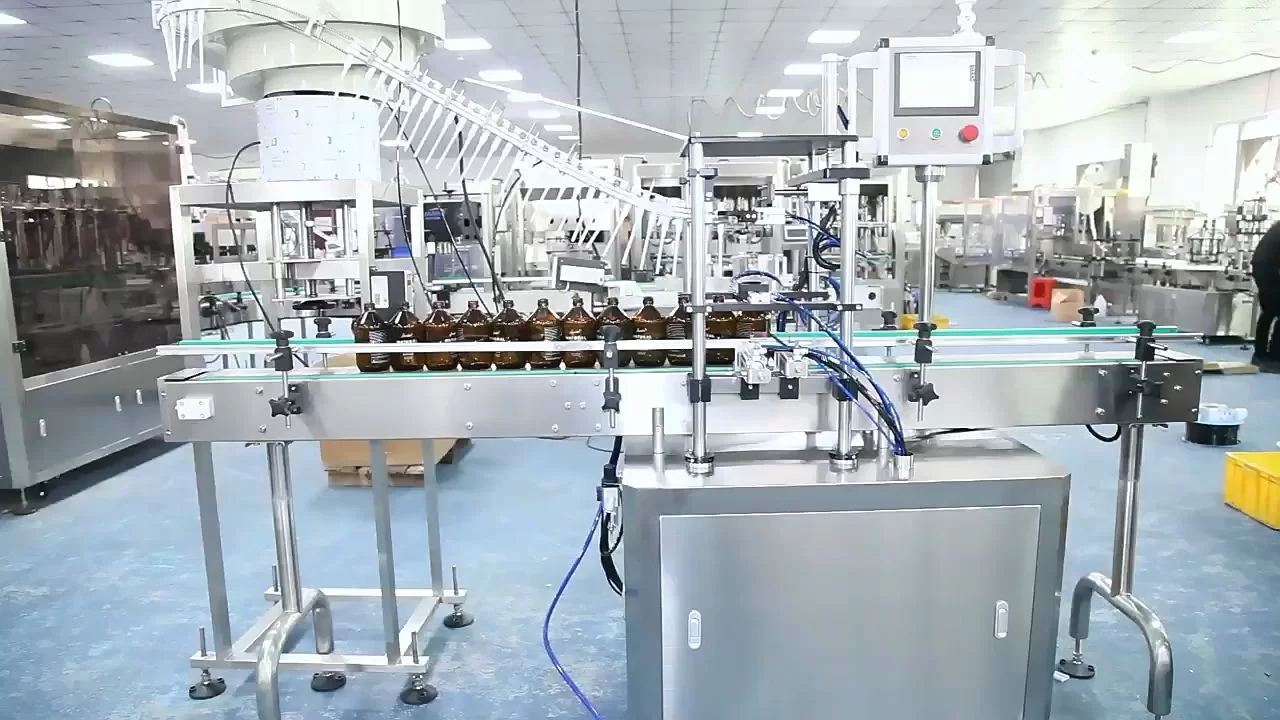

The machine operates on a rotary system, which means it can cap multiple bottles simultaneously, making it highly efficient and ideal for large-scale production. The capping process is fully automated, which minimizes the risk of errors and increases productivity.

The Automatic Rotary Glass Olive Oil Bottle ROPP Capping Machine is versatile and can handle a wide range of bottle sizes and shapes. It is also customizable to fit your specific requirements, ensuring that you get the perfect fit for your production line.

One of the key benefits of this capping machine is its high level of precision. The ROPP capping technology ensures that the cap is applied to the bottle with just the right amount of torque, which prevents leaks and ensures a consistent seal.

The machine is also easy to operate and maintain, with a user-friendly interface and simple maintenance requirements. This ensures that downtime is minimized, and your production line runs smoothly and efficiently.

In summary, the Automatic Rotary Glass Olive Oil Bottle ROPP Capping Machine is a cutting-edge packaging equipment that offers precision, efficiency, and versatility. It is an ideal solution for large-scale olive oil production, providing a tamper-proof seal that ensures the safety and quality of your product.