The Automatic Sesame Hot Sauce Paste Jar Bottling Filling Line Machine is a cutting-edge solution for businesses looking to efficiently fill jars with sauces, pastes, and other viscous products. This advanced bottling and filling machine is designed to fill a wide range of products into jars, including sesame hot sauce paste, salad dressings, mayonnaise, honey, and more.

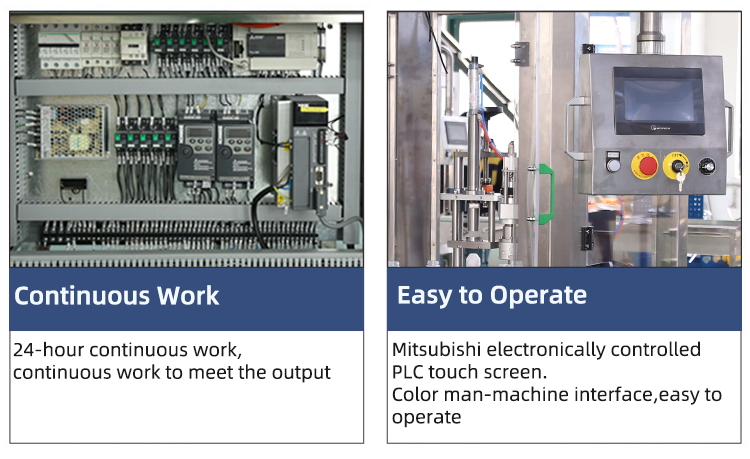

One of the key advantages of the Automatic Sesame Hot Sauce Paste Jar Bottling Filling Line Machine is its high level of automation. The machine is fully automatic and can fill, cap, and label jars at a rate of up to 100 jars per minute, significantly increasing production efficiency and reducing labor costs. The machine is also designed with a user-friendly interface and easy-to-use controls, making it simple to operate and maintain.

The Automatic Sesame Hot Sauce Paste Jar Bottling Filling Line Machine is equipped with advanced features such as an automatic bottle sorting system, a high-precision filling system, and a cap sorting and screwing system. The filling system uses a piston-type filling method, which ensures high accuracy and consistency in filling volume. The machine also has an automatic cap-feeding system, which can sort and feed caps automatically, and a cap-screwing system that can automatically tighten caps to the desired level of tightness.

This bottling and filling machine is made of high-quality stainless steel and other durable materials, ensuring a long lifespan and resistance to wear and tear. The machine is also designed to meet the requirements of GMP standards, ensuring that the product is hygienic and safe for consumption.

The Automatic Sesame Hot Sauce Paste Jar Bottling Filling Line Machine has a wide range of applications in the food and beverage industry, and its use is growing rapidly. With the increasing demand for packaged food products, the demand for bottling and filling machines is expected to rise in the future. This machine is an excellent choice for businesses looking to improve their production efficiency, reduce labor costs, and meet the high standards of the food and beverage industry.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, [email protected]

- Showroom Location: United States, France, Germany, Indonesia, Spain

- Application: APPAREL, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Textiles, [email protected]

- Packaging Type: Bags, Barrel, Bottles, CANS, Capsule, Cartons, case, Pouch, Stand-up Pouch, [email protected]

- Packaging Material: Glass, Metal, Paper, Plastic, Wood, [email protected]

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 110V/220V/380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2500*1600*1650mm

- Weight: 600 KG

- Warranty: 1 Year, 2 Years with lifelong maintenance

- Key Selling Points: automatic capping machine

- Filling Material: Milk, Water, Oil, Juice

- Filling Accuracy: 99.99%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- After-sales Service Provided: Engineers available to service machinery overseas

- Product name: automatic capping machine

- Filling pump: Peristaltic Pump Filling/Piston Pump Filling

- Company advantage:: OEM with good After-sales Service

- Product advantage: Can be customized/High precision/Space saving/Effective cost

- Material: SUS304/316(Meet GMP Standard)

- Eligibility rate: ≥99%

- After Warranty Service: Spare parts

More Details

The fully automatic liquid paste filling capping machine is with CE & ISO 9001 certification. The machine is applied to bottles or other containers with different sizes and shapes, and suitable for liquid and paste filling. It adopts piston pump for filling. By adjusting the filling volume on touch screen, it can fill liquid with quick speed and high precision. It is widely used for food and beverage industry, chemical industry, cosmetic industry, pharmaceutical industry, and etc.

| Product | Full Automatic Filling Capping Labeling Machine |

| Output | 1500-6000BPH, or customized |

| Filling Volume | 100ml-1000ml, or customized |

| Filling Material | Liquid, Paste, Aerosal, Powder, etc |

| Control | PLC and Touch Screen |

| Driving Motor | Servo Motor |

| Filling Type | Piston Pump, Peristaltic Pump |

| 2.5Power | 1.2KW |

| Machine Frame Material | SS304 |

| Capping Head | Screwing, Pressing, Crimping Head ( According to the cap type) |

Round Bottle Feeding Table

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles or other containers on the table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output tunnel, the machine will be able to work with different size bottle.

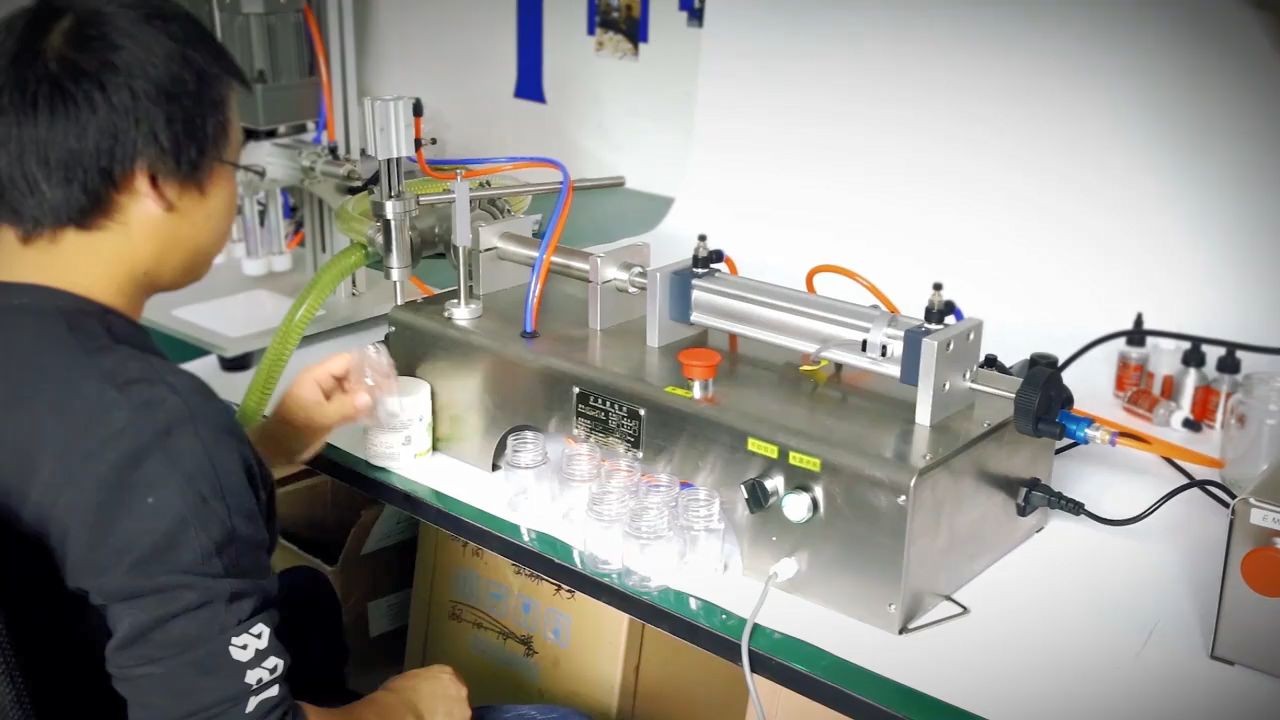

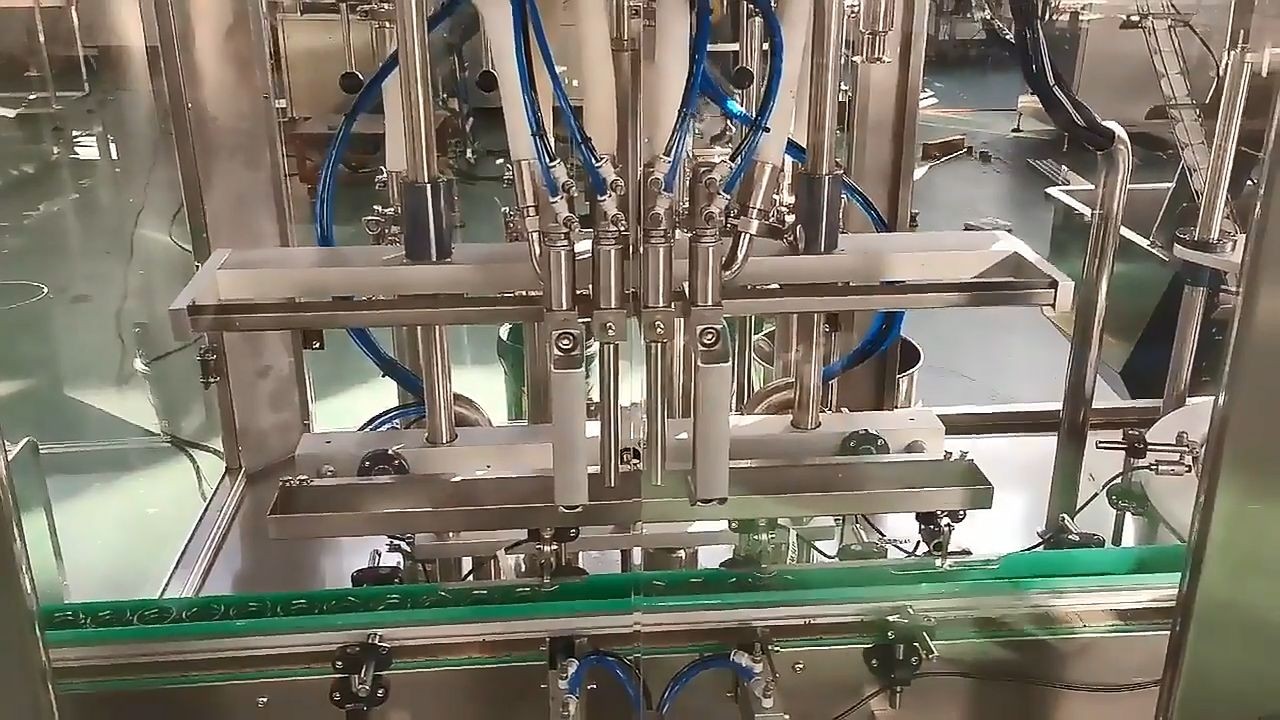

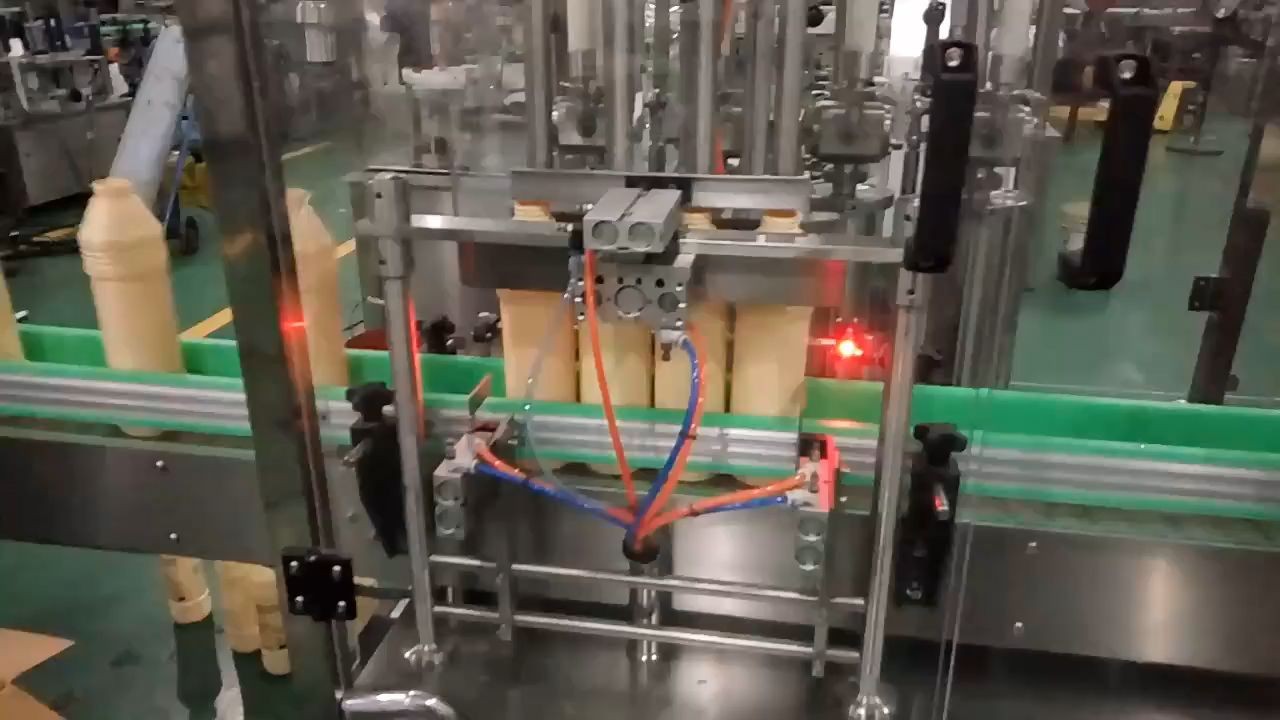

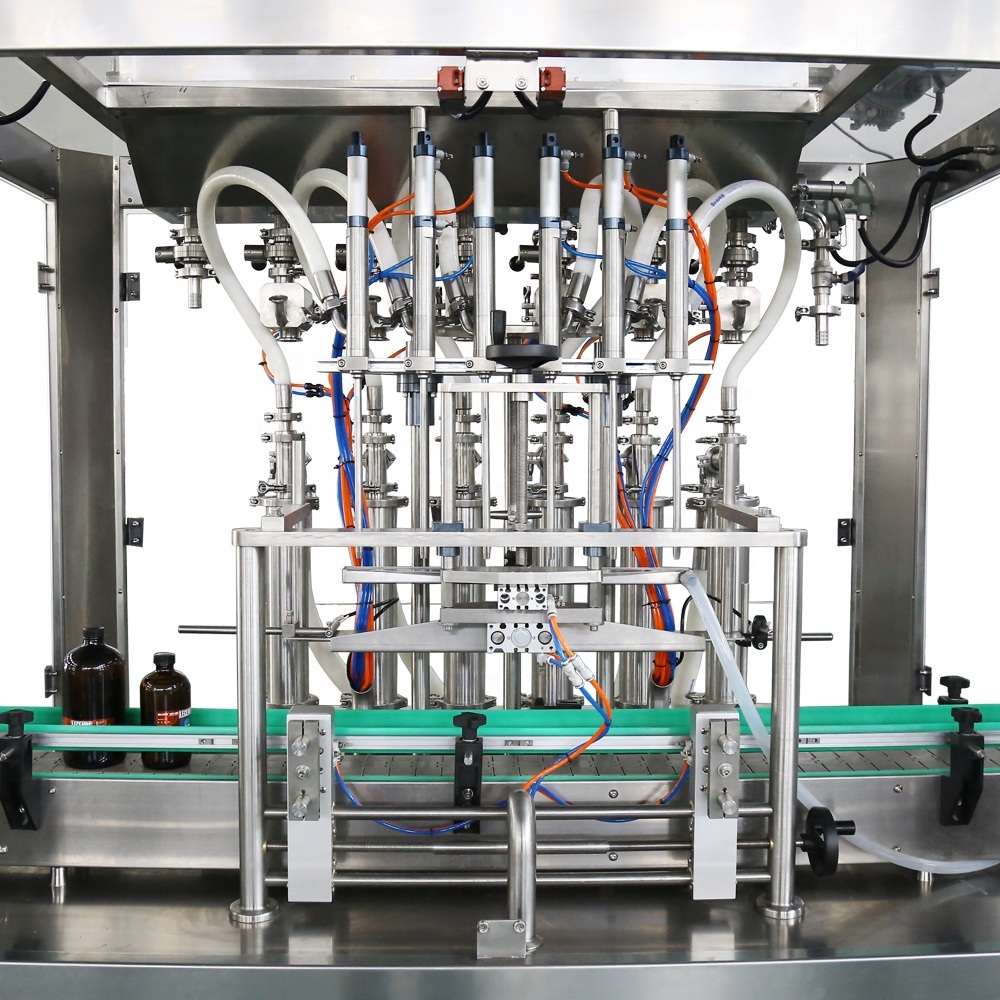

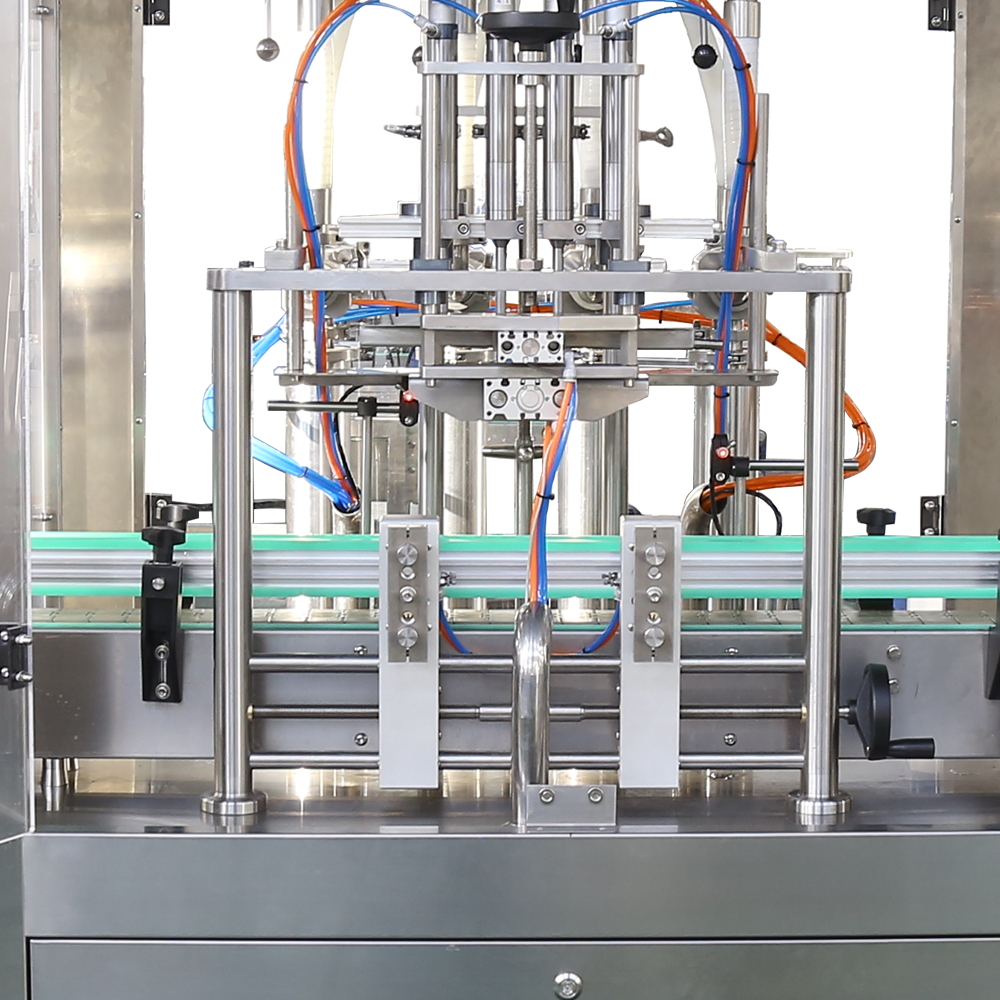

Piston Pump Filling Machine

This filling machine could be linear tor rotary type which is designed according to customers capacity and filling volume. It suits different size of plastic and glass bottles, and the height of the filling nozzles is adjustable. The filling nozzles are made of SS304 or 316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling. Widely used for liquid and paste filling. Also can be customized for other types of filling based on customer requirement.

The filling line adopts piston pump, which is much more accuracy on filling volume and easy to adjust different volume. Piston pumps are ideal for liquid filling within a wide variety of industries: biomedical, pharmaceutical, diagnostic, cosmetics, personal care, food and beverage, as well as specialty chemical industries.

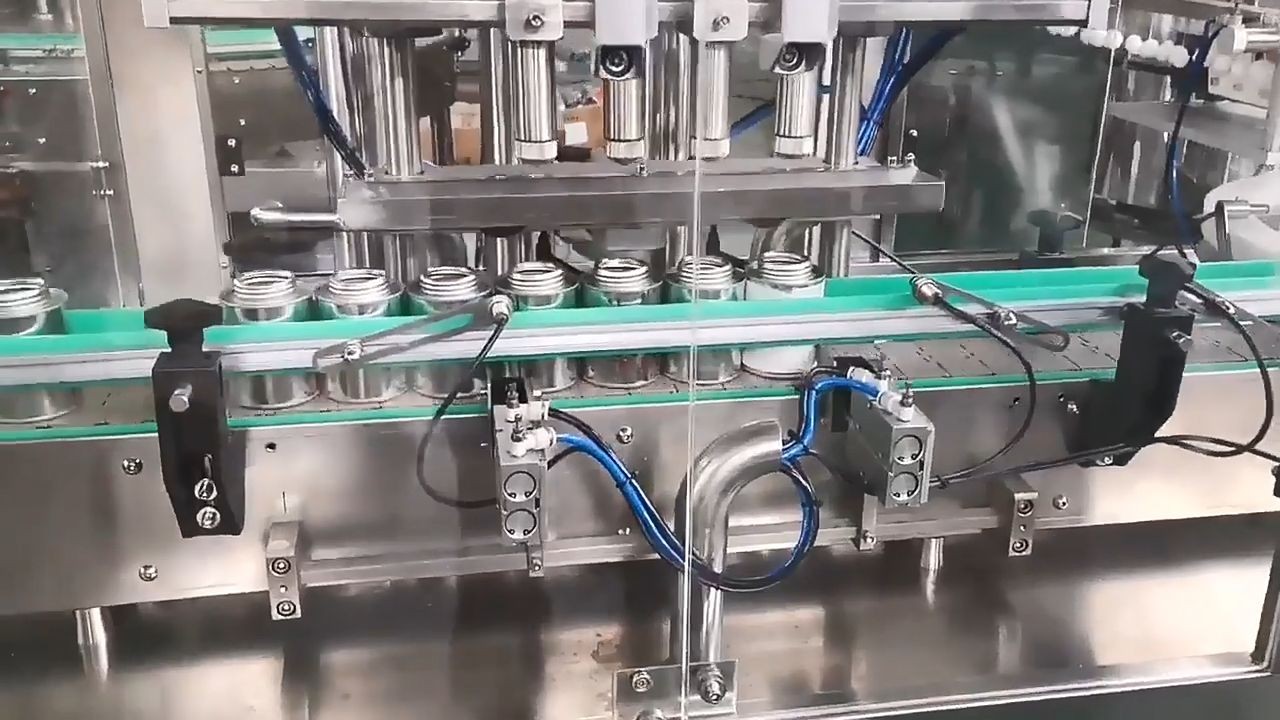

Cap Vibrator and Cap Elevator

Cap vibrator is an automatic assembling equipment for capping process line, which can assort the caps in a series for an automated line. It is combined with automatic capping machine to feed the caps to the bottle automatically.

Cap vibrator is also an automatic assembling equipment for capping process line, which can assort the caps in a series for an automated line with high speed. It is combined with automatic capping machine to feed the caps to the bottle automatically.

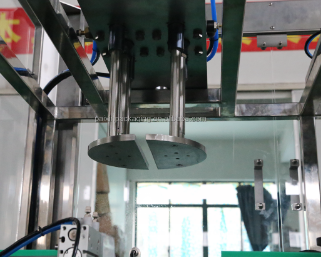

Screw Head Capping Machine

The automatic screwing head capping machine is suitable for various sizes of bottles and plastic or aluminium screw Cap.

Crimping Head Capping Machine

This automatic crimping head capping machine is mainly used for disposable aluminum screw caps of pilfer proof and suitable for various bottle formats.

Pressing Head Capping Machine

The pressing type capping machine is used to snap and tighten the cap onto the container by applying pressure on the cap towards the container.

Round Bottle Labeling Machine

We provide different type of labeling machine according to customers requirement for online using and separate use, such as round label, front and back label, top label and etc. The newest smart labeling machine is working with different kinds of bottle and labels, infrared detection sensor is work with transparent label. With adjustment handle, it is able to work with high, lower, fat, thin bottle and apply labels into accurate station.

Bottle Collecting Table

The rectangle bottle collecting table is designed for collecting the bottles automatically and convenient for workers to stand by the table and packing into box.

Electric Cabinet and Touch Screen