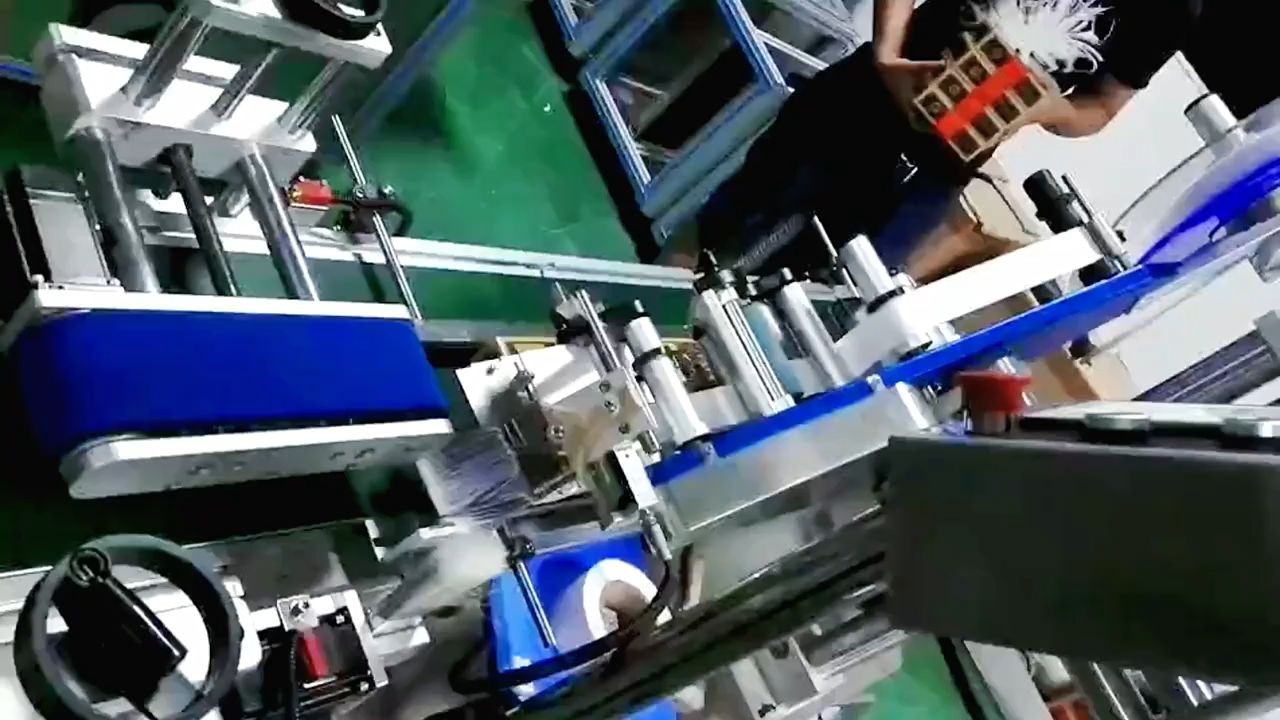

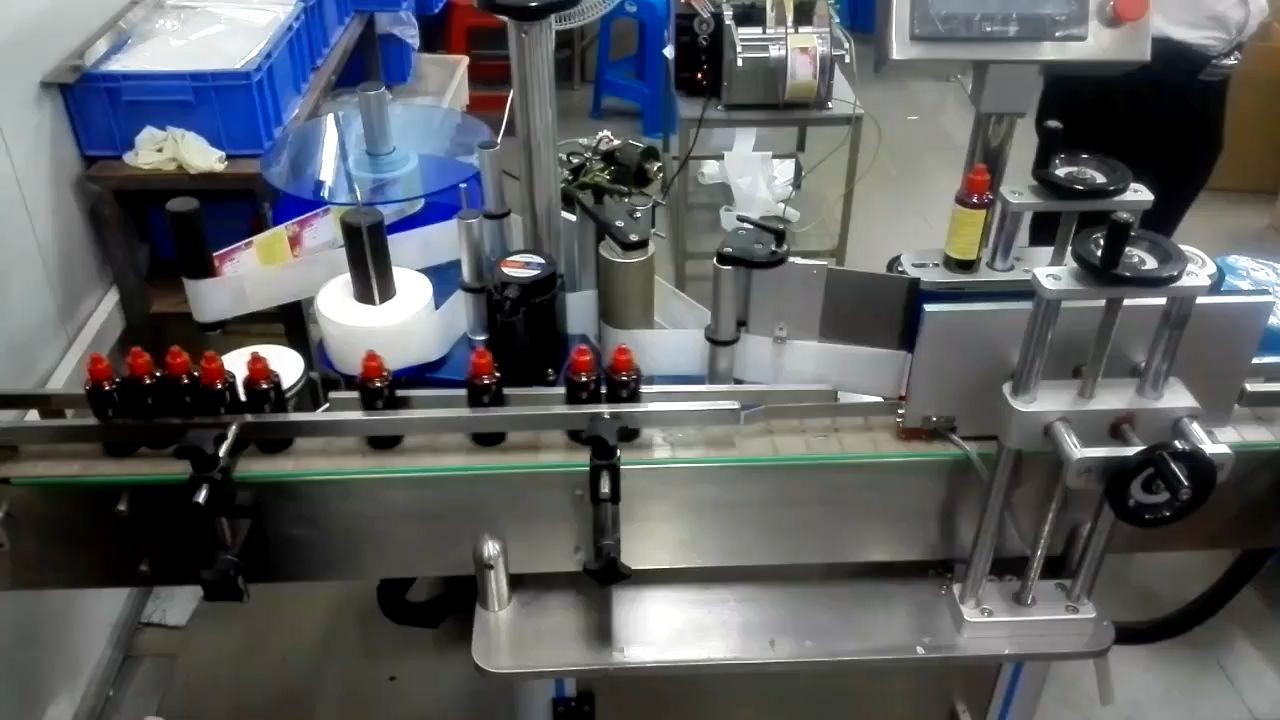

Automatic double sides labelling machine also called front and back labelling machine, double sides labeller, it is application for labelling round, square, flat and unshaped and shaped bottles & containers.

Labeling Speed | 60-350pcs/min (Depending on label length and bottle thickness) | ||

| Height of Object | 30-350mm | ||

| Thickness of Object | 20-120mm | ||

| Height of Label | 15-140mm | ||

| Length of Label | 25-300mm | ||

| Label Roller Inside Diameter | 76mm | ||

| Label Roller Outside Diameter | 420mm | ||

| Accuracy of Labeling | ±1mm | ||

| Power Supply | 220V 50/60HZ 3.5KW Single-phase | ||

| Gas Consumption of Printer | 5Kg/cm^2 | ||

| Size of Labeling Machine | 2800(L)×1650(W)×1500(H)mm | ||

| Weight of Labeling Machine | 450Kg | ||

An automatic shampoo flat bottle labeling machine is an advanced equipment designed to automatically apply labels onto flat bottles of shampoo, conditioner, and other similar products. The machine is built with a conveyor belt that moves the bottles along the production line while the labeling machine applies the labels onto the bottles.

The labeling process is fully automated, with the machine detecting the bottle's size and shape to ensure that the label is applied precisely and accurately onto the bottle. The machine's high-speed capabilities allow for fast and efficient labeling, ensuring that large quantities of bottles can be labeled in a short amount of time.

The automatic shampoo flat bottle labeling machine is user-friendly, with an easy-to-use interface that allows for quick and easy adjustments to the labeling process. It is also equipped with safety features that ensure the safety of the operator and prevent accidents from occurring.

Overall, the automatic shampoo flat bottle labeling machine is an essential piece of equipment for any manufacturer looking to improve their production efficiency and output. With its high-speed capabilities and accuracy, it can significantly increase productivity while reducing labor costs and minimizing labeling errors.