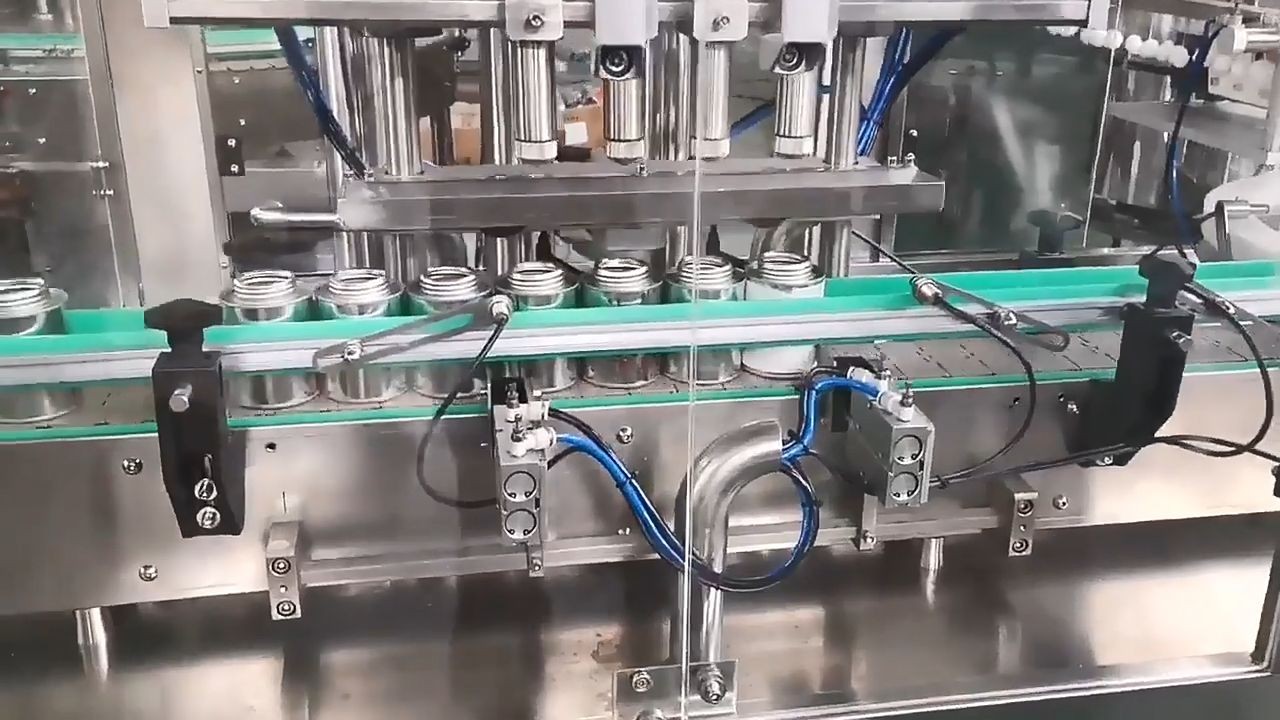

Linear Single Lobe Pump Filling Machine has the advantages of high efficiency and high precision, and can be filled with thin and extremely viscous products without foam. Such as sauce, paste, cream, cosmetic, honey and so on. It has a separate servo motor to drive the lobe pump and supply products to each separate filling head.

| 1 | Filling nozzles | 1 nozzles | ||||||

| 2 | Filling range | 10-500ml (customsized) | ||||||

| 3 | Filling accuracy | ≤±0.5% | ||||||

| 4 | Hopper size | 40L | ||||||

| 5 | Working speed | 15-30bottle/min | ||||||

| 6 | Suitable bottle diameter | 30-110mm(customized) | ||||||

| 7 | Suitable bottle height | 50-250mm(customized) | ||||||

| 8 | Machine size | About 220*80*120CM | ||||||

| 9 | Machine weight | About 150kg | ||||||

Main features

1. High speed---15-25 bottles/min with only 1 filling nozzles

2. Wide Application---fast switching for various bottles and products

3. Easy but High Clean---rotor pump control

4: Touch screen operation interface

5: Support up and down movement type filling to effectively prevent foam generation

6: The filling accuracy can reach ±0.5% (depending on the product, the filling accuracy is different)

7: The filling cylinder is treated and ground by hard chromium, with a unique filling valve design, no leakage

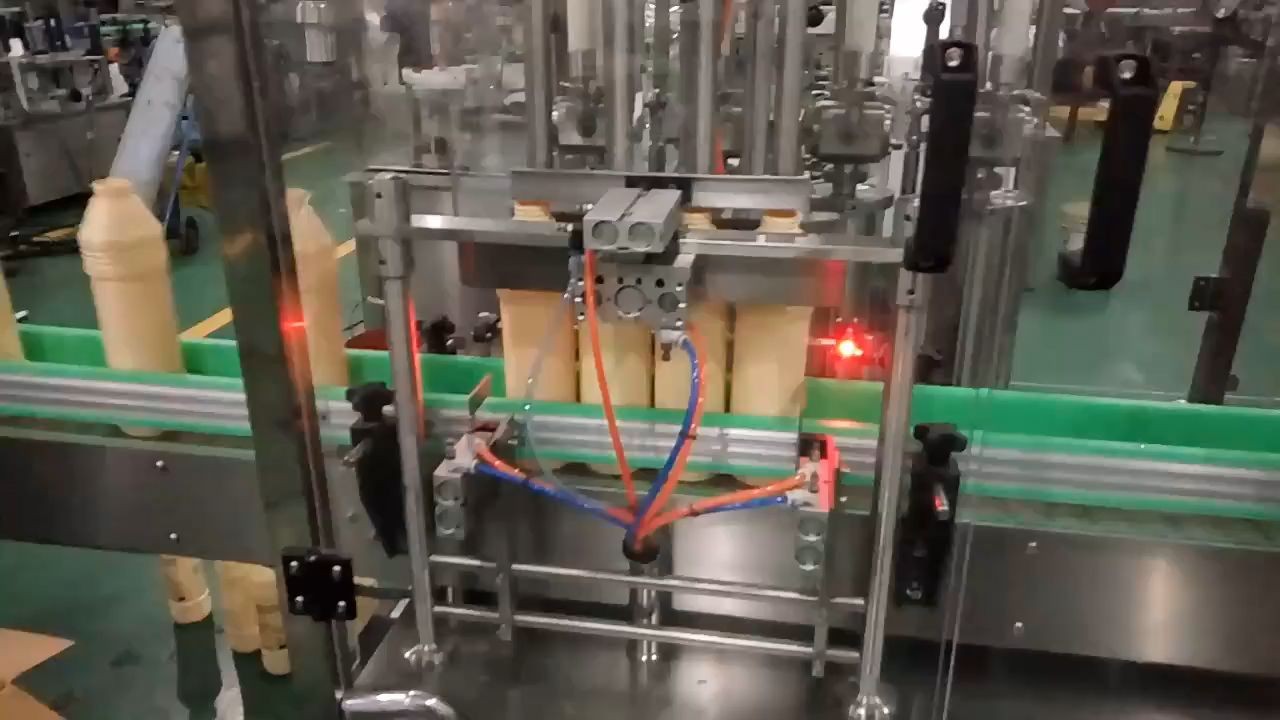

8: No bottle no filling function

9: Design different positioning devices according to the actual situation of the bottle

10: Automatic cleaning function: without manual disassembly, it can be set once on the touch screen to automatically clean and drain the sewage.

11: The equipment and material contact are all made of 304# stainless steel

12. less area occupancy

13. Linear single Lobe Pump Filling Machine is adjustable for many different types of bottles,Custom donot need to adjust the traditional cylinder block bottle and nozzle position according to different bottle. this machine can save much time to change bottle.

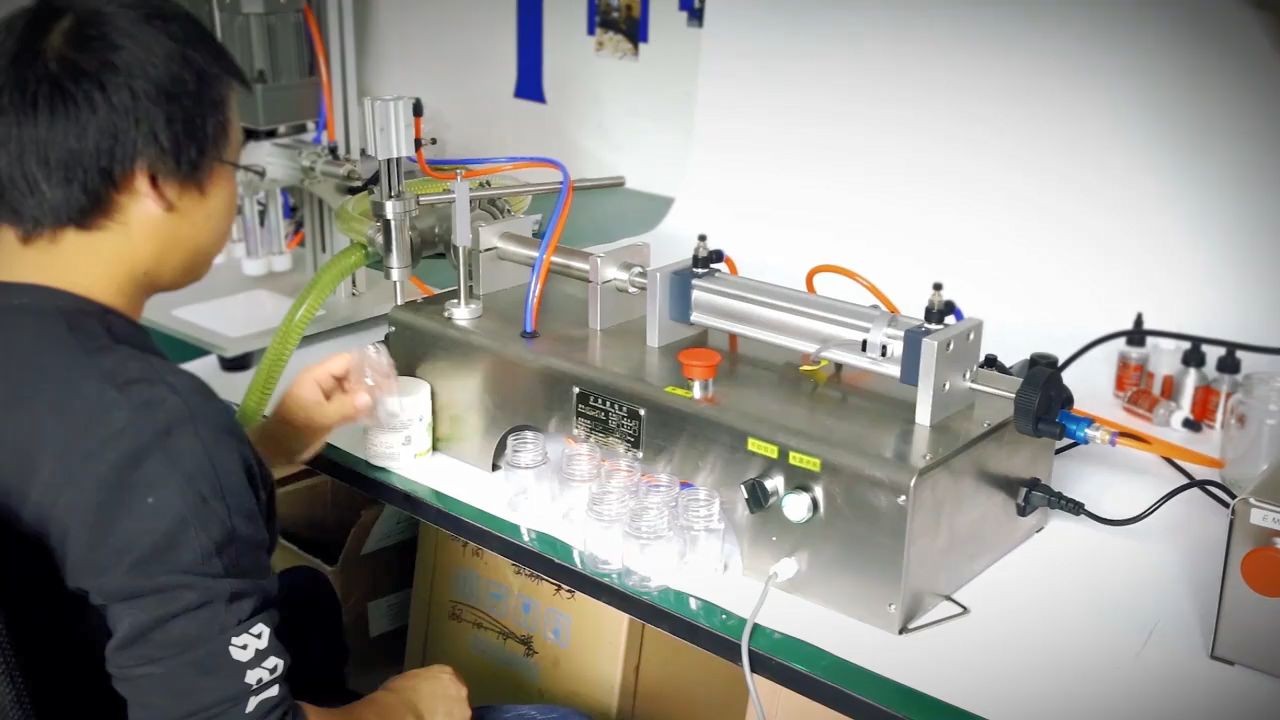

An automatic single nozzle high viscosity cream paste filling machine is a specialized industrial equipment designed to automatically fill high viscosity cream or paste into containers. This machine is commonly used in the food and beverage, pharmaceutical, and cosmetic industries.

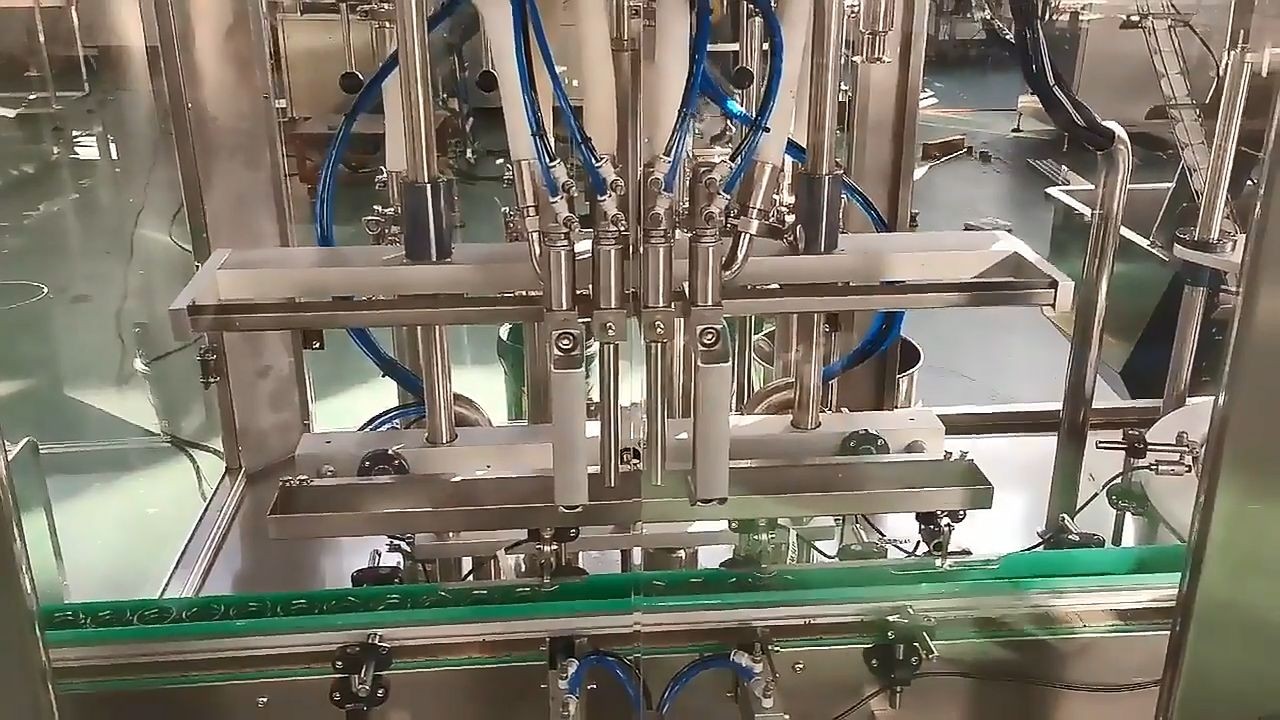

The machine works by placing the containers onto the conveyor belt, which then moves them through the filling station. The machine uses a high-speed, precision filling head that accurately dispenses the cream or paste into the containers at a predetermined volume. The filling volume can be adjusted depending on the size of the containers, ensuring that each container is filled to the correct level.

One of the key advantages of the automatic single nozzle high viscosity cream paste filling machine is its high speed and accuracy. With the ability to fill multiple containers simultaneously, this machine can achieve a filling speed of up to 30 containers per minute, depending on the viscosity of the cream or paste. This level of automation significantly increases production efficiency, reduces labor costs, and improves overall product quality.

Another advantage of this machine is its versatility. It can handle a wide range of container sizes and shapes, thanks to its adjustable conveyor and filling head. The machine's flexibility also allows for easy switching between different types of creams and pastes, minimizing downtime and maximizing productivity.

Additionally, the machine is equipped with a user-friendly touch screen interface that makes it easy to control and monitor the filling process. The interface allows operators to adjust the filling volume, conveyor speed, and other settings, ensuring optimal performance and efficiency.

Overall, an automatic single nozzle high viscosity cream paste filling machine is an essential piece of equipment for any company that needs to fill high viscosity products into containers quickly and accurately. Its speed, accuracy, versatility, and ease of use make it an ideal solution for improving production efficiency and quality in various industries.