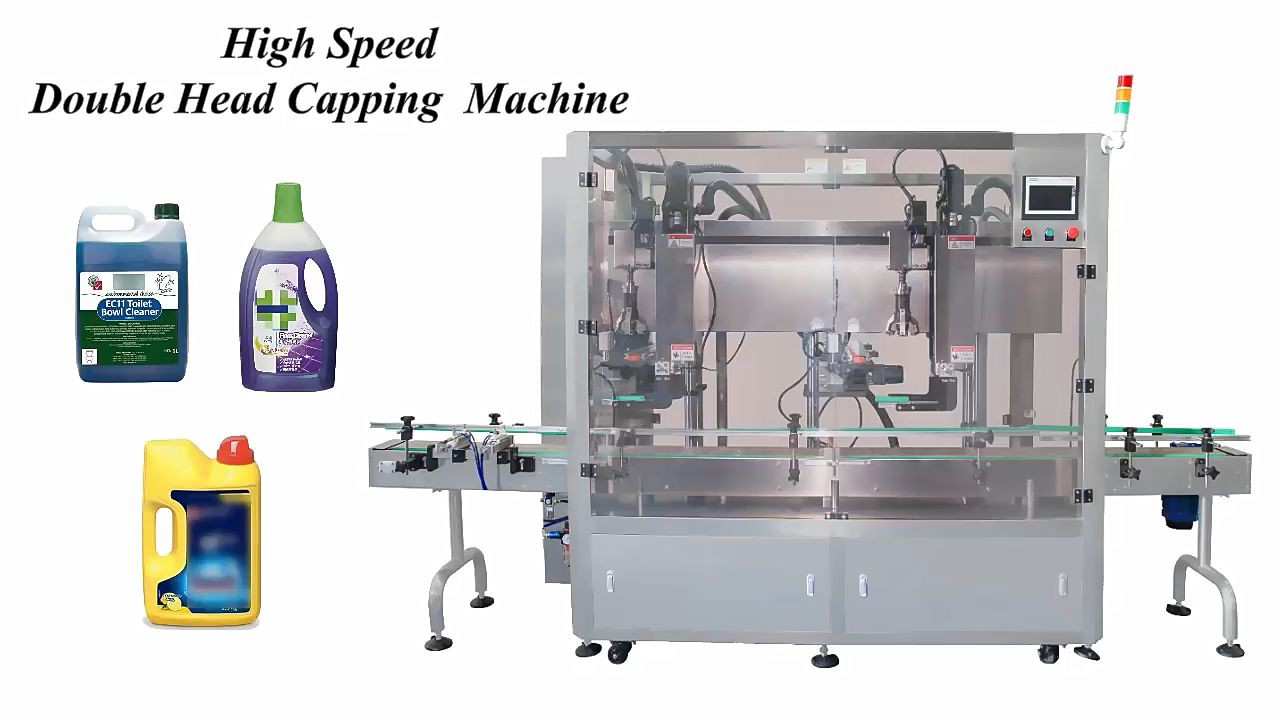

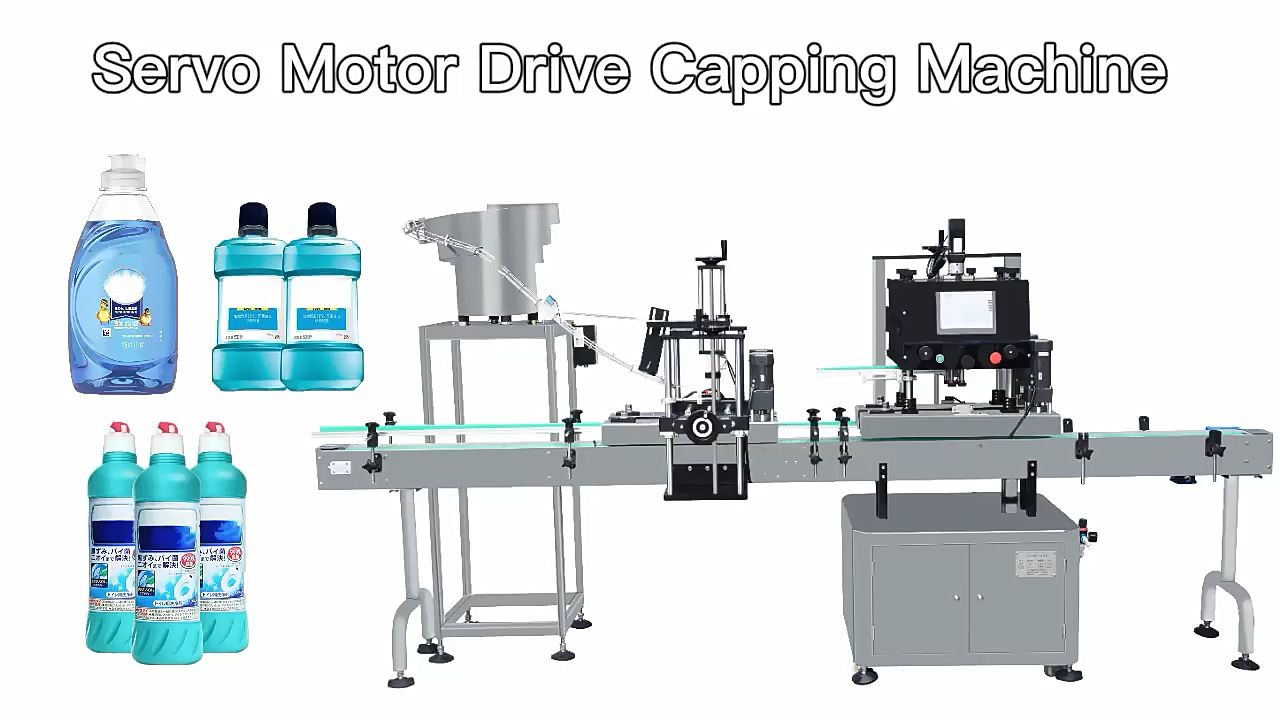

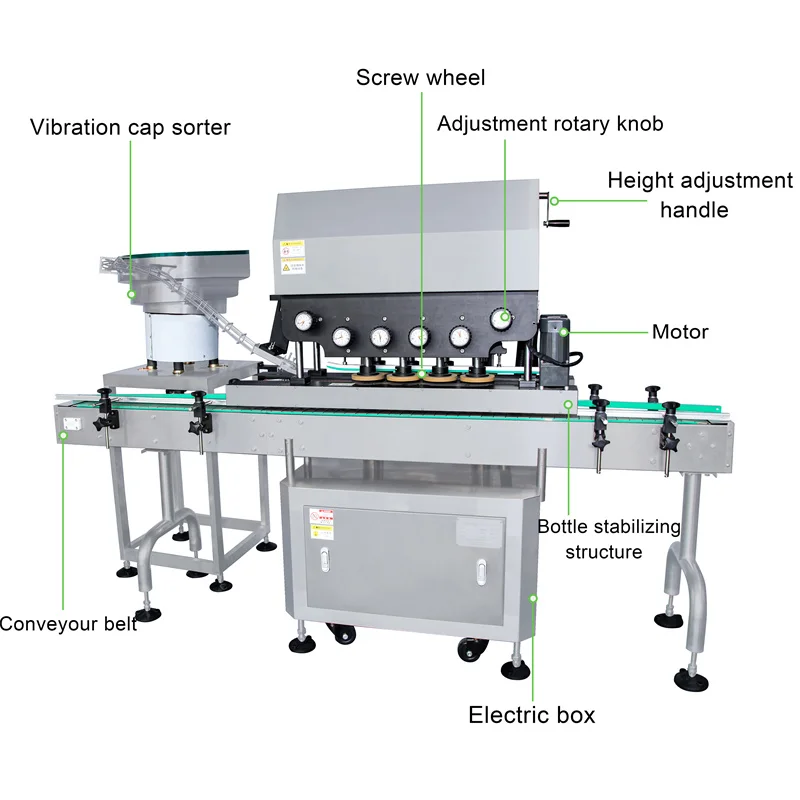

An automatic small glass bottles plastic bottle capping machine is a device used in the food, beverage, and pharmaceutical industries to automatically cap glass and plastic bottles with a variety of caps including twist-off, lug, and snap-on caps.

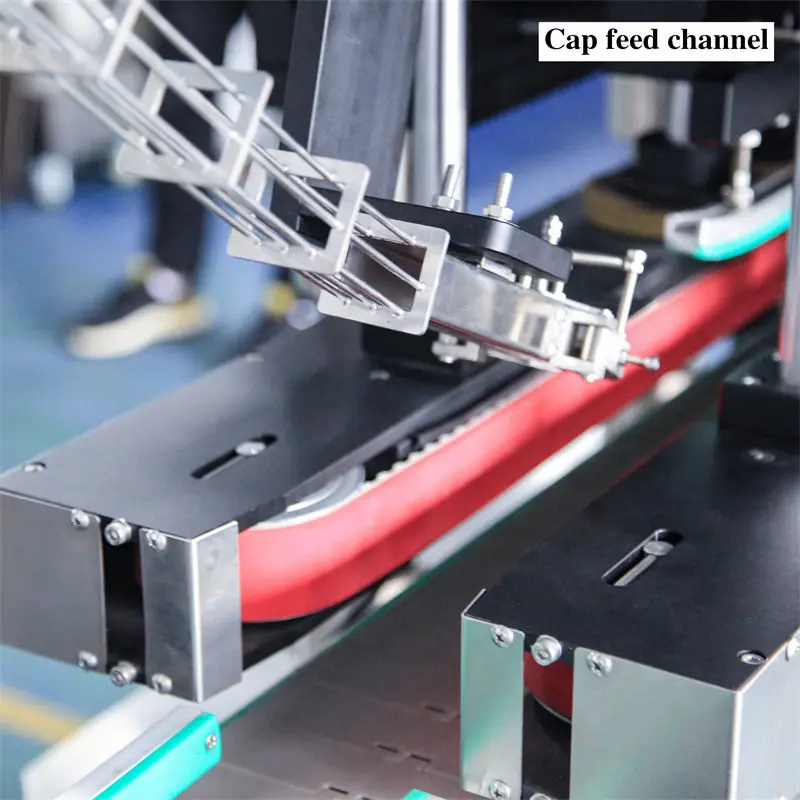

The machine is designed to handle a range of bottle sizes and shapes, making it versatile and adaptable to different production requirements. It is also equipped with features such as an automatic cap feeder and a cap sorter to ensure that the capping process is continuous and precise.

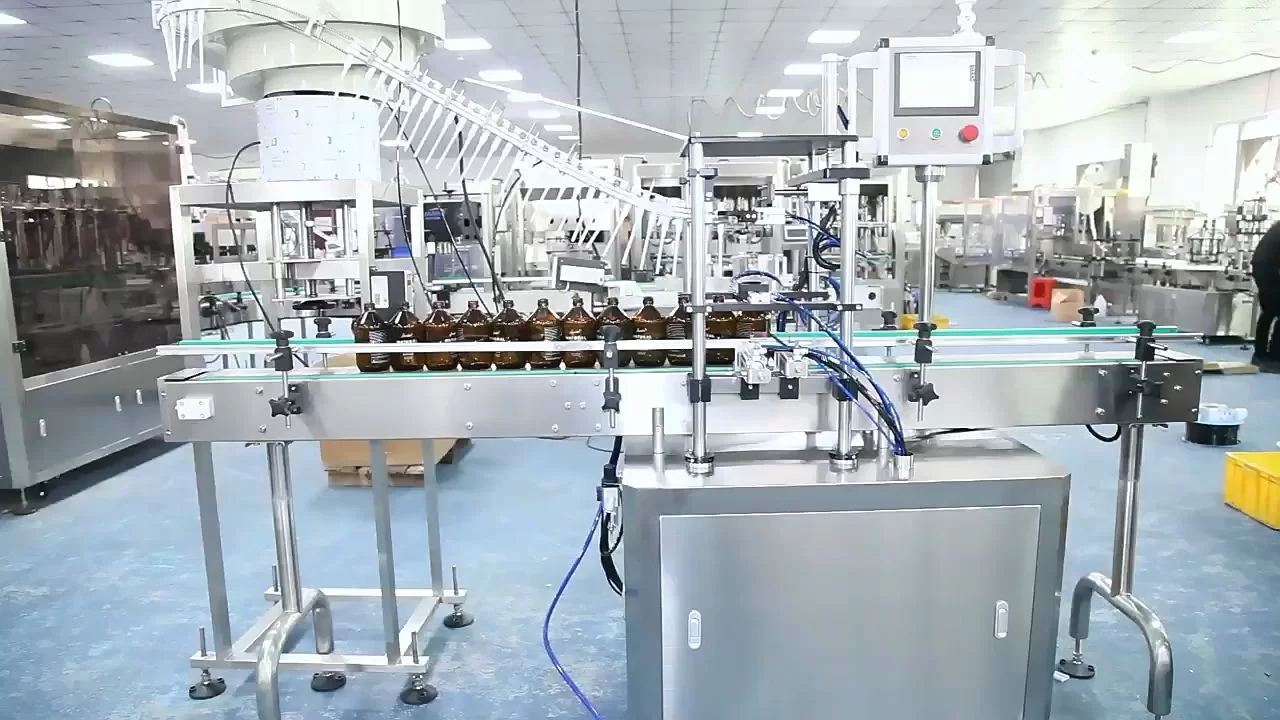

The automatic small glass bottles plastic bottle capping machine operates by feeding bottles into the machine via a conveyor belt. The machine then uses its automated technology to sort and feed caps onto the bottles, before tightening them with precision and accuracy. The capping process can be customized to meet specific production needs, and the machine can cap up to thousands of bottles per hour.

One of the advantages of using an automatic small glass bottles plastic bottle capping machine is that it eliminates the need for manual labor, thereby improving production efficiency and reducing the risk of human error. The machine is also capable of capping bottles at a much faster rate than manual capping, which means that manufacturers can increase their production output without compromising on the quality of the product.

Another advantage of using an automatic small glass bottles plastic bottle capping machine is that it ensures that each bottle is properly sealed, thereby protecting the product from contamination and ensuring longer shelf life. The machine's automated technology ensures that each cap is tightened to the correct level, preventing leaks and spills that could compromise the product's quality.

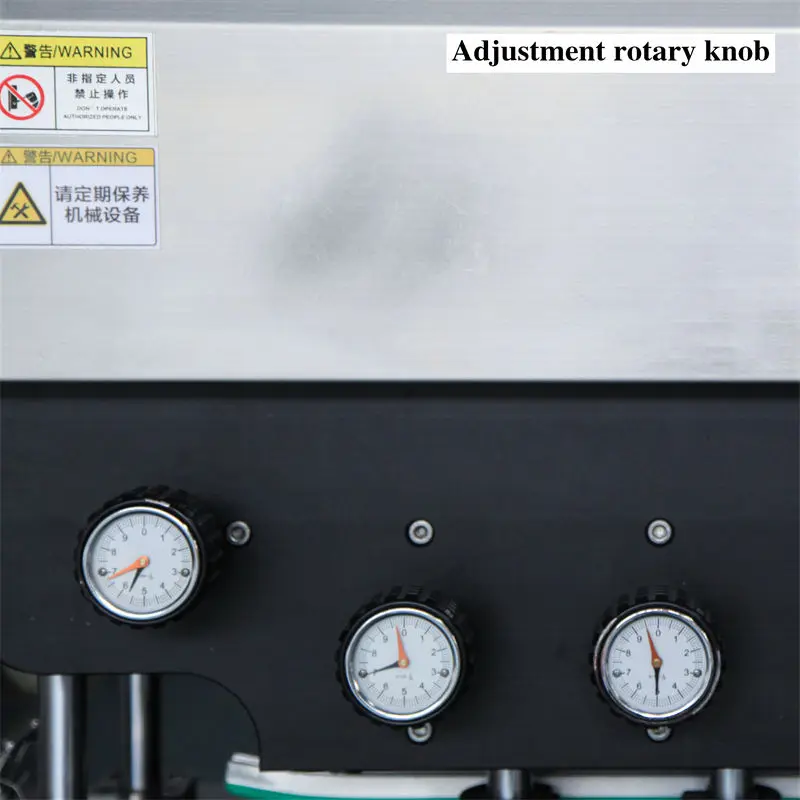

In addition to its efficiency and accuracy, the automatic small glass bottles plastic bottle capping machine is also easy to operate and maintain. The machine is designed with user-friendly controls, making it simple to use, and its automated features require minimal supervision, reducing the need for highly skilled labor.

In conclusion, the automatic small glass bottles plastic bottle capping machine is an essential piece of equipment for the food, beverage, and pharmaceutical industries. It offers a fast, accurate, and efficient way to cap bottles, improving production efficiency, ensuring product quality, and reducing the risk of human error. Its user-friendly features and minimal maintenance requirements make it a valuable investment for manufacturers looking to improve their production processes.

Quick Description

- Type: Capping Machine

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

- Showroom Location: Egypt, Philippines

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Warranty of core components: 1 Year

- Core Components: PLC, Engine, Bearing, Motor

- Condition: New

- Application: Food, Beverage, Medical, Chemical

- Driven Type: Pneumatic

- Automatic Grade: Automatic

- Voltage: AC220V/50Hz

- Packaging Type: Bottles

- Packaging Material: Plastic, Metal, Glass

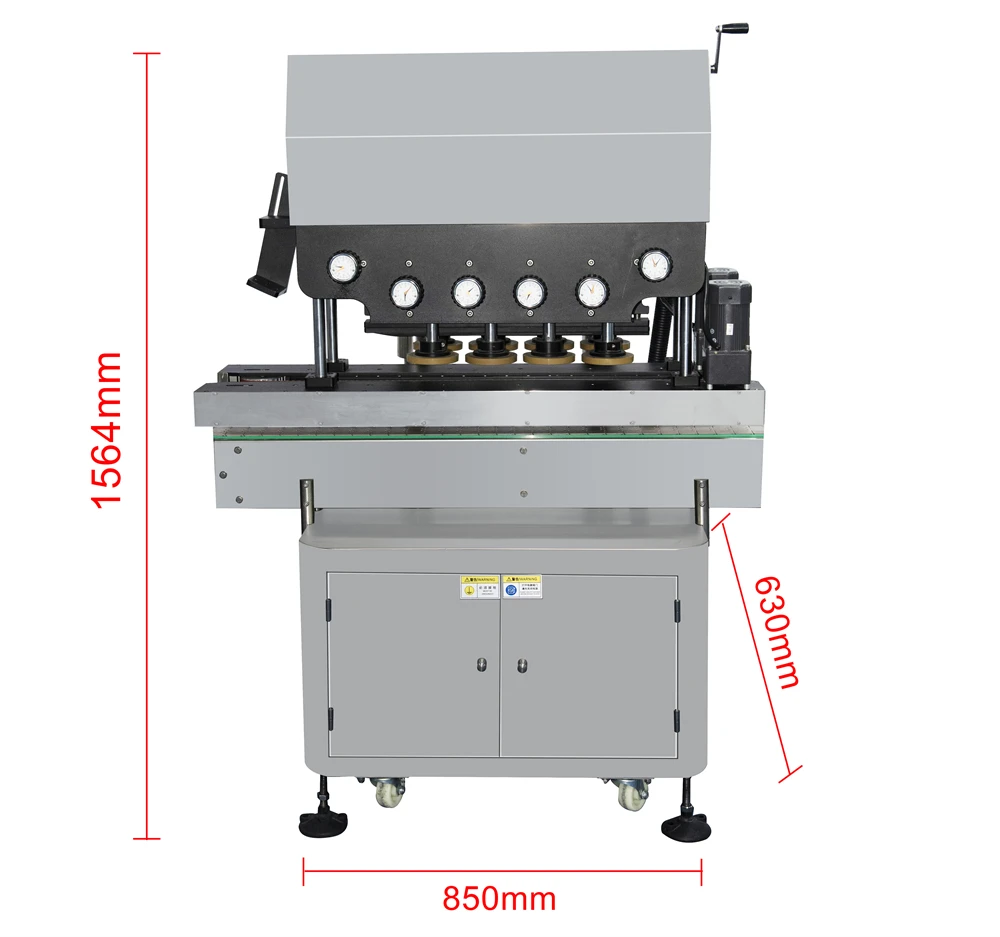

- Dimension(L*W*H): 1650*1000*1600mm

- Weight: 400 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate, Lifetime after sales services

- Product Name: Linear capping machine

- Air Source Pressure: 0.6-0.7Mpa

- Production Capacity: 2500-3000 bottles / hour

- Keywords: Servo Motor Capping Machine

- Bottle Type: Any Bottle Provided By Customers

- Company Type: Integration Of Industry And Trade

- After-sales Service: Overseas service, Online service

- Advantage: Fast capping speed

- Material: Stainless Steel 304/316

- Cap diameter: According to customer's product

More Details

Description:

This machine is used for automatic capping for plastic bottles and glass bottles in cosmetic, food, beverage, chemical industry and medicine industry. It can be applied to a variety of bottle types with high production efficiency.

| Technical Parameters | |

| Cover method | Elevator sorting cover |

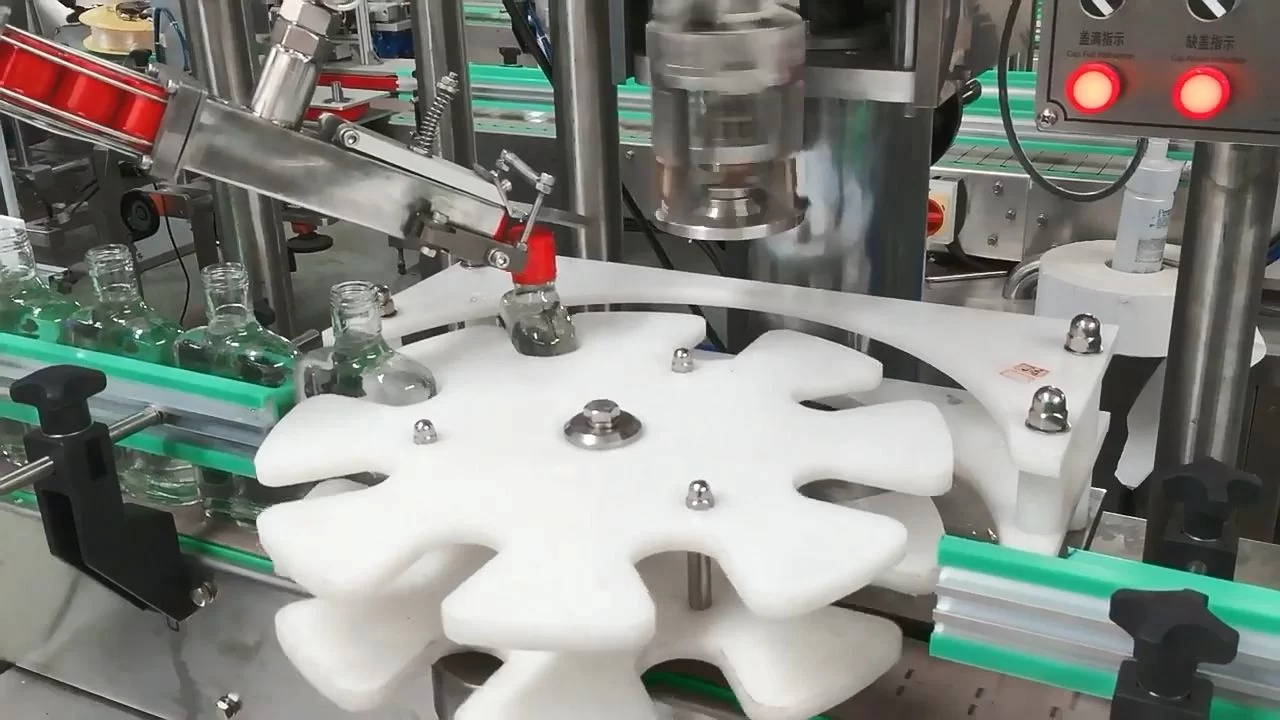

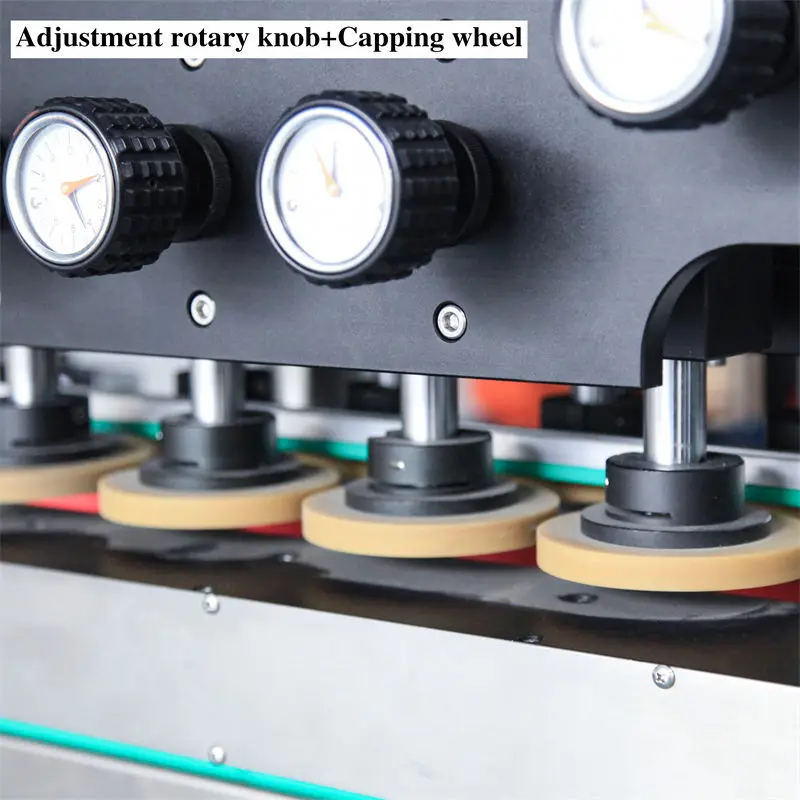

| Capping form | Eight wheel clamp |

| Bottle height | 70-320mm |

| Cap diameter | 20-90mm |

| Bottle diameter | 30-140mm |

| Capping speed | 30-40 bottles/min |

| Capping voltage | 1ph AC 220V 50/60Hz |

| Air pressure | 0.6-0.8MPa |

| Dimension | 1300(L)*800(W)*1600(H)mm |

| Packing size | 1400(L)*900(W)*1800(H)mm |

| Machine weight | About 200KG |