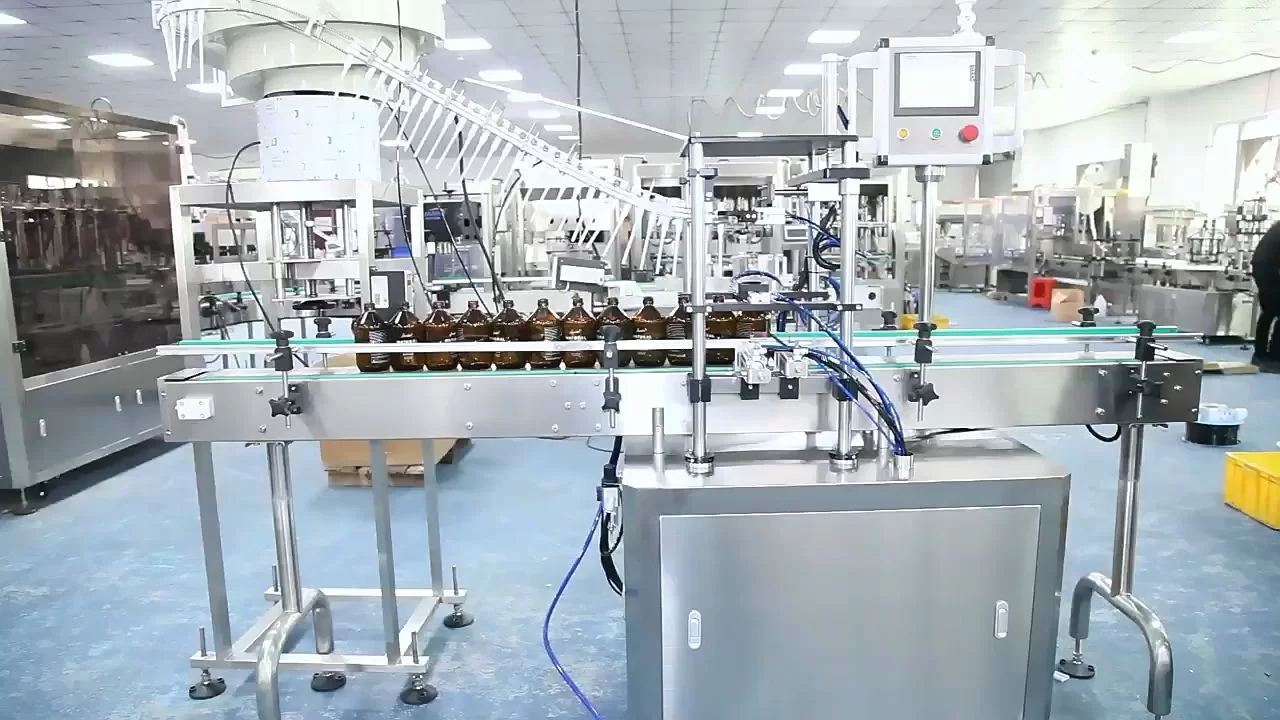

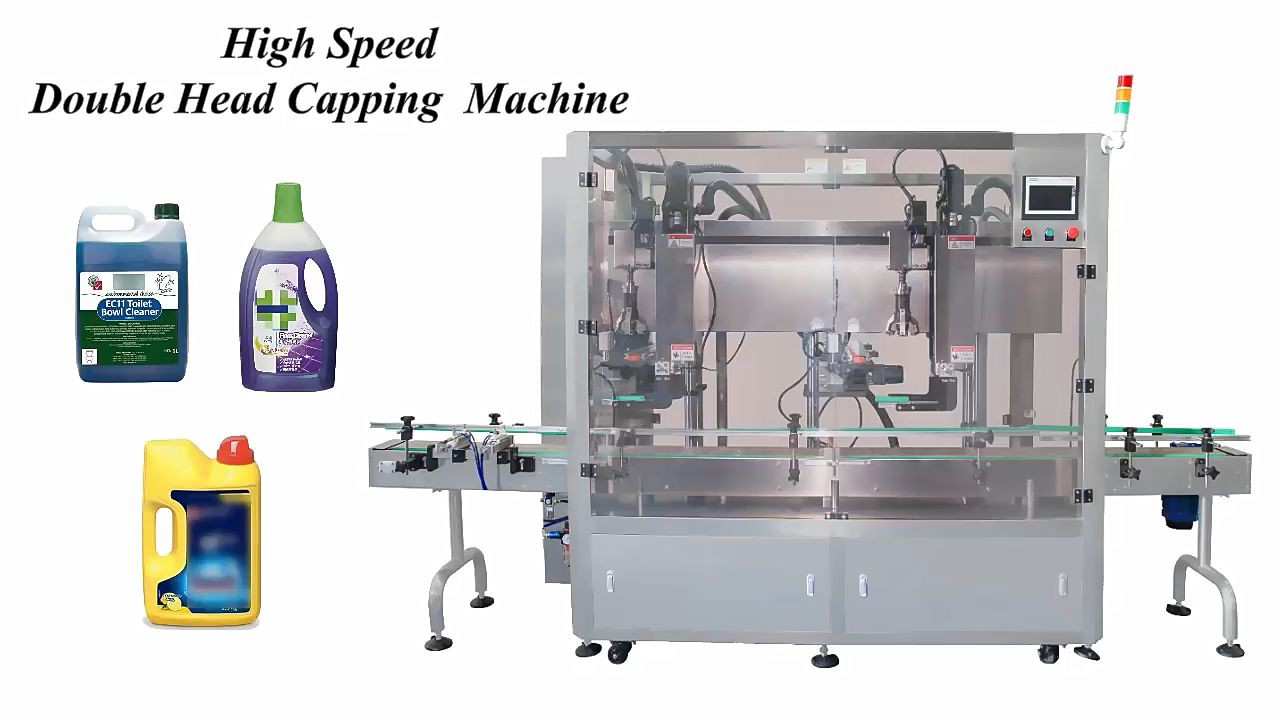

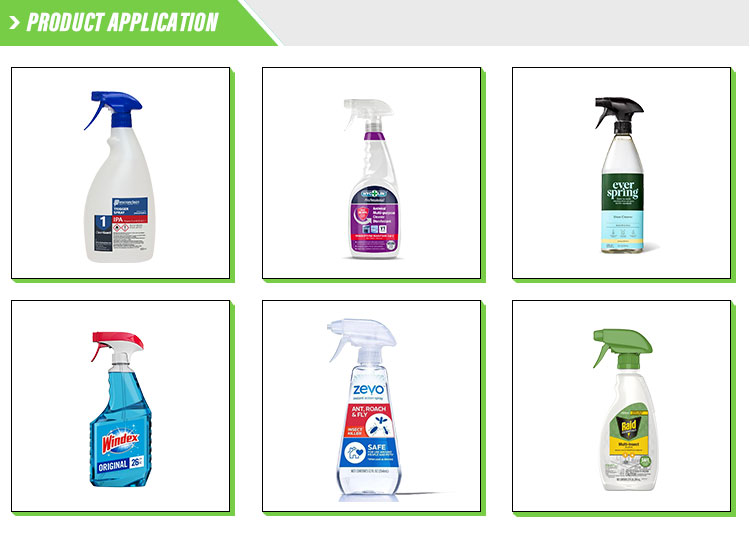

An automatic spray trigger plastic bottle pump screw capping machine is a piece of equipment used in the packaging industry to cap plastic bottles. It is designed to cap bottles with spray trigger pumps, which are commonly used in products such as cleaning solutions, air fresheners, and personal care products.

The machine is fully automated, meaning that it can perform the capping process without the need for manual intervention. It can also cap bottles of various sizes, making it versatile and suitable for use in a variety of industries.

The capping process of the machine involves screwing the cap onto the bottle using a specialized mechanism that ensures a tight seal. The machine also includes a sensor system that checks the caps to ensure that they are properly screwed onto the bottles. If a cap is not applied correctly, the machine will automatically reject the bottle to prevent it from being sent to the market with a faulty cap.

Overall, the automatic spray trigger plastic bottle pump screw capping machine is an essential tool in the packaging industry that can help companies increase production efficiency and reduce errors in the capping process.

Quick Description

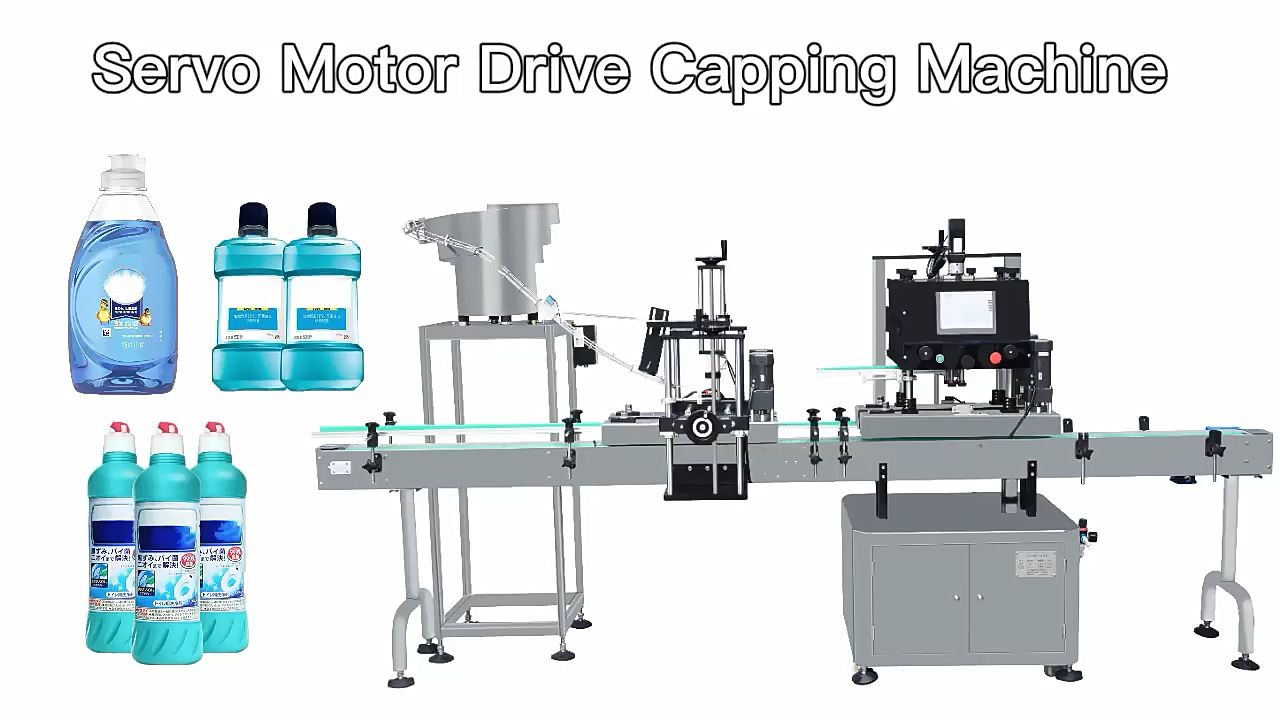

- Type: Capping Machine

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Egypt, Philippines, South Korea, Japan

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Warranty of core components: 5 years

- Core Components: PLC, Bearing, Motor, Pump

- Condition: New

- Application: Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, Can be customized

- Driven Type: Electric

- Automatic Grade: Automatic

- Voltage: AC220V/50Hz

- Packaging Type: Cartons

- Packaging Material: Plastic, Paper, Metal, Glass, Wood

- Place of Origin: Shanghai, China

- Brand Name: VKPAK

- Dimension(L*W*H): 2450*2650*2480mm

- Weight: 550 KG

- Warranty: 3 years

- Key Selling Points: Automatic, Easy To Operate

- After-Sales Service Provided: Automatic Four Wheel Servo Rotor Pneumatic Screw Capping Machine

- Product Name: Rotating Head Close The Spray Trigger Type Bottle Capping Machine

- Capping Distributor Way: Vibration Shaking Plate( Different Types Need Exchange The Set)

- Suitable Bottles: Spray trigger bottle

- Cap Feeding Way: Pneumatic Fetch

- Keywords: Servo Rotor Capping Machine

- Capping Way: Servo Drive Screw Capping

- Advantage: High Efficiency, Competitive price

- After Warranty Service: Online support, Video technical support, Spare parts

- After-sales Service Provided: Online support, Free spare parts, Repair service

- Marketing Type: New Product 2021

More Details

Description:

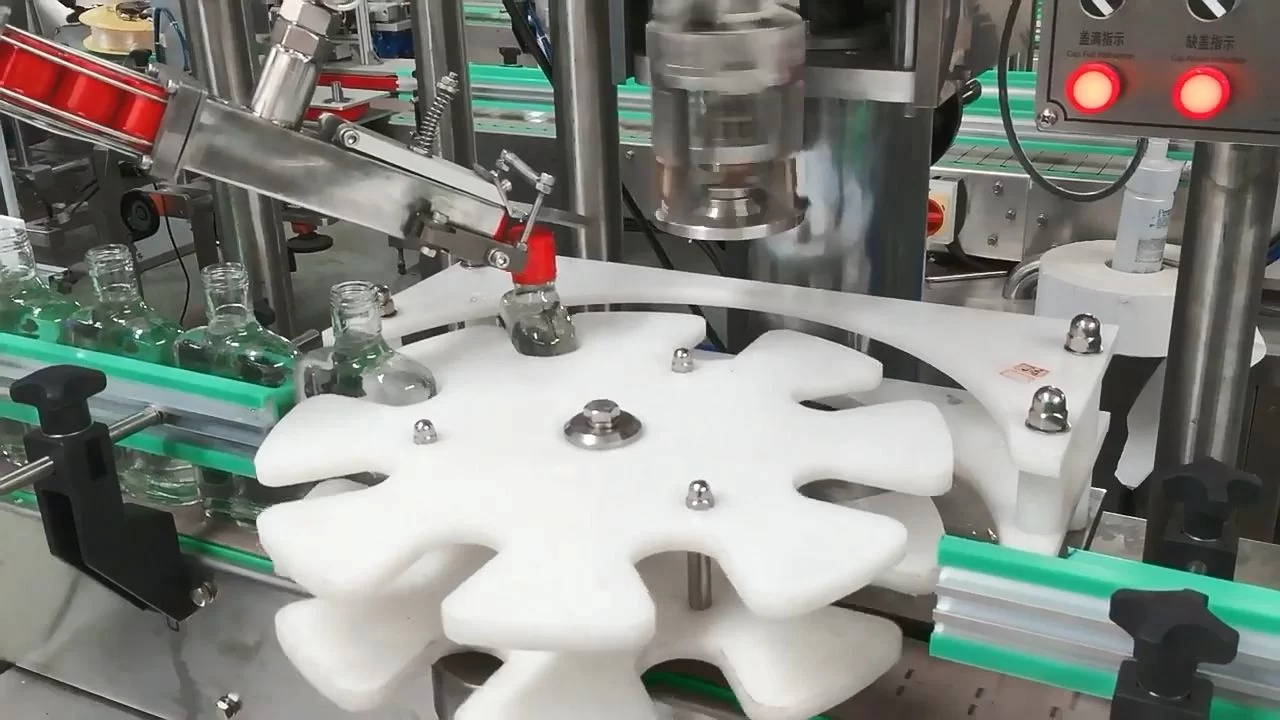

The capping machine is suitable for capping of spray trigger cap, spray cap, pump cap, round bottle cap and other bottle caps. It can be used in daily chemical, pharmaceutical and food industries. It adopts electrical combination to control movement with high stability. It can seal caps of different shapes and specifications. The speed can be adjusted, and the tightness can be adjusted according to different caps.

Features:

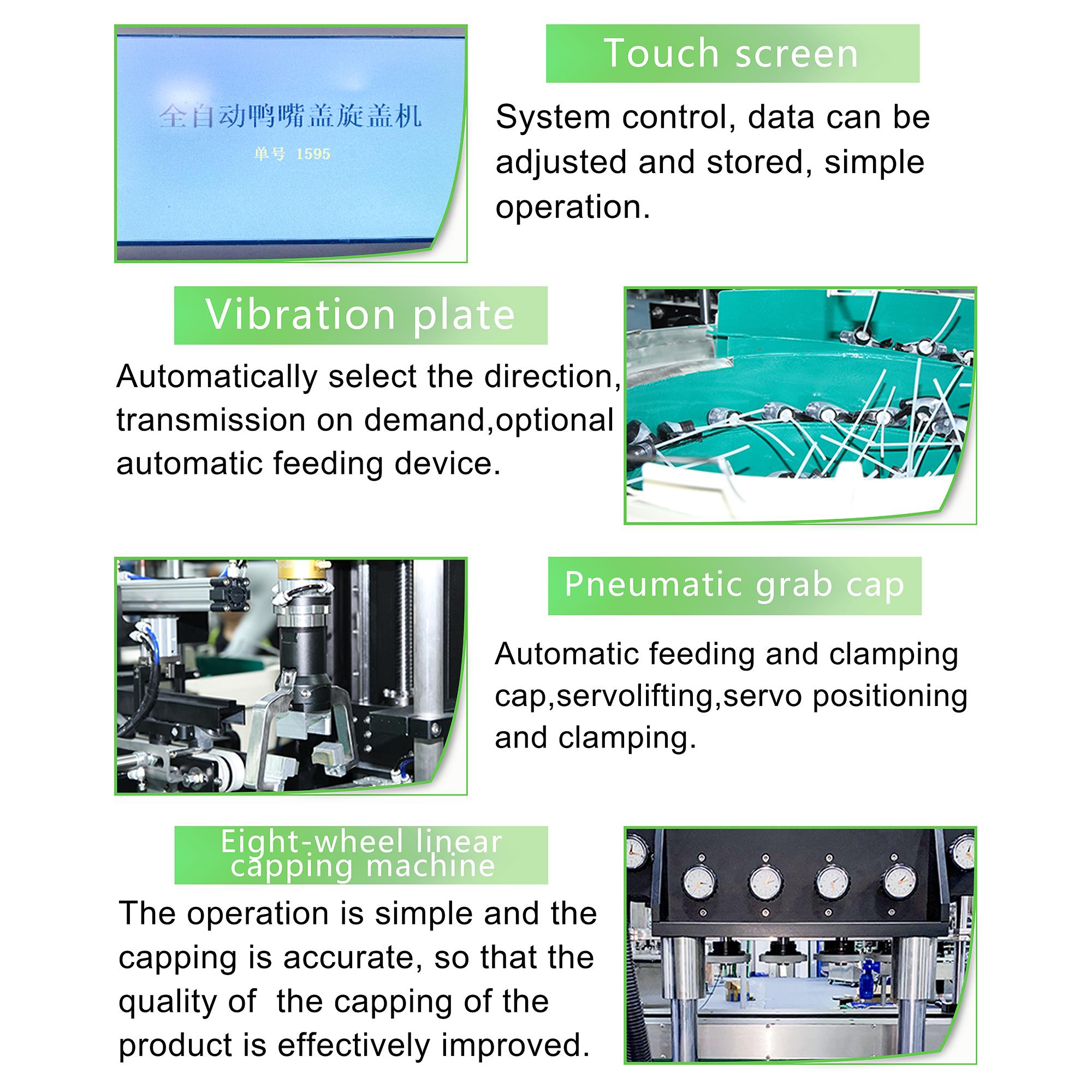

1. PLC touch screen electrical control system.

2. Positioning device, easy to operate and adjust.

3. Suitable for variety of cap types and specifications.

4. Adjustable capping speed, and the tightness can be adjusted according to different caps.

5. The main machine is installed with movable casters to facilitate equipment handling.

| Technical Parameter | |

| Apply the bottle cap | According to samples provided by customer |

| Bottle feeding method | Put the bottle manually |

| Cap sorter method | Vibration plate cover, elevator cap sorter replenishment |

| Cap putting form | Automatic pneumatic cap |

| Capping form | Servo grip |

| Capping speed | 20-30 bottles/min |

| Voltage | 2KW, AC220V, 50/60Hz, single phase |

| The material of frame is stainless steel | |

| Dimension | 2500×800×1950mm(L×W×H) |

| Program control | PLC Touch screen |

| Machine weight | About 400KG |