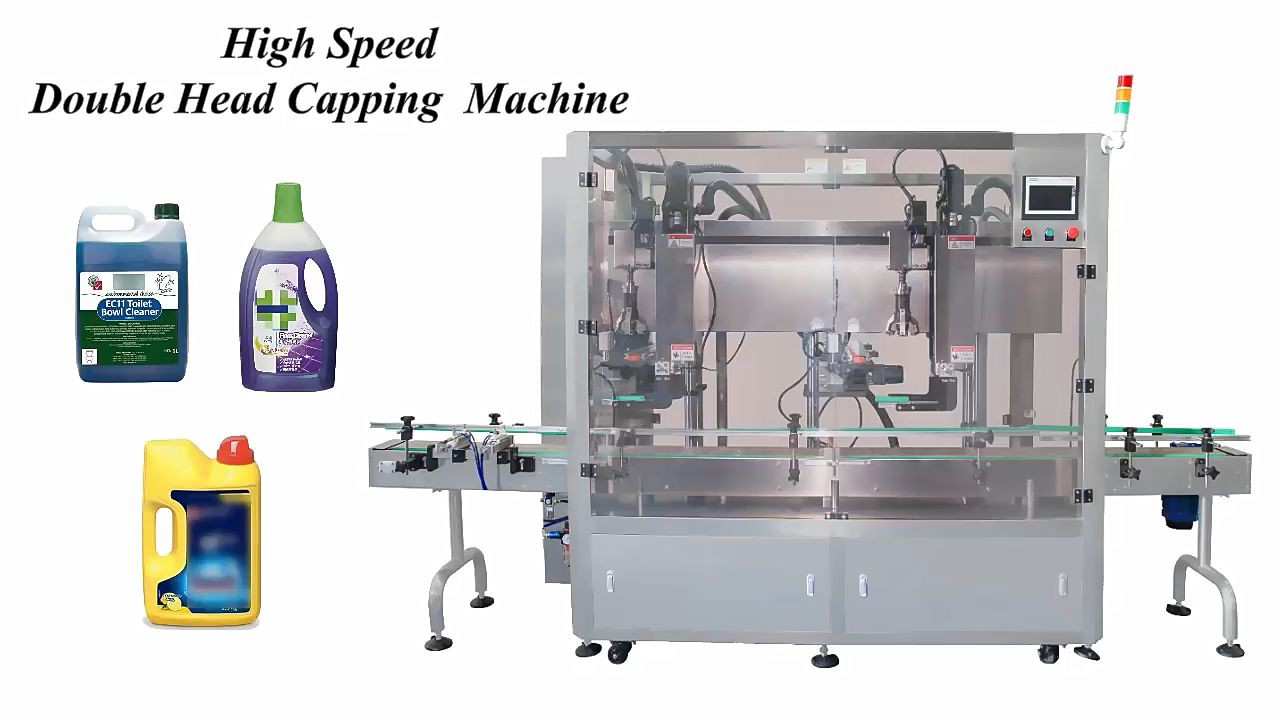

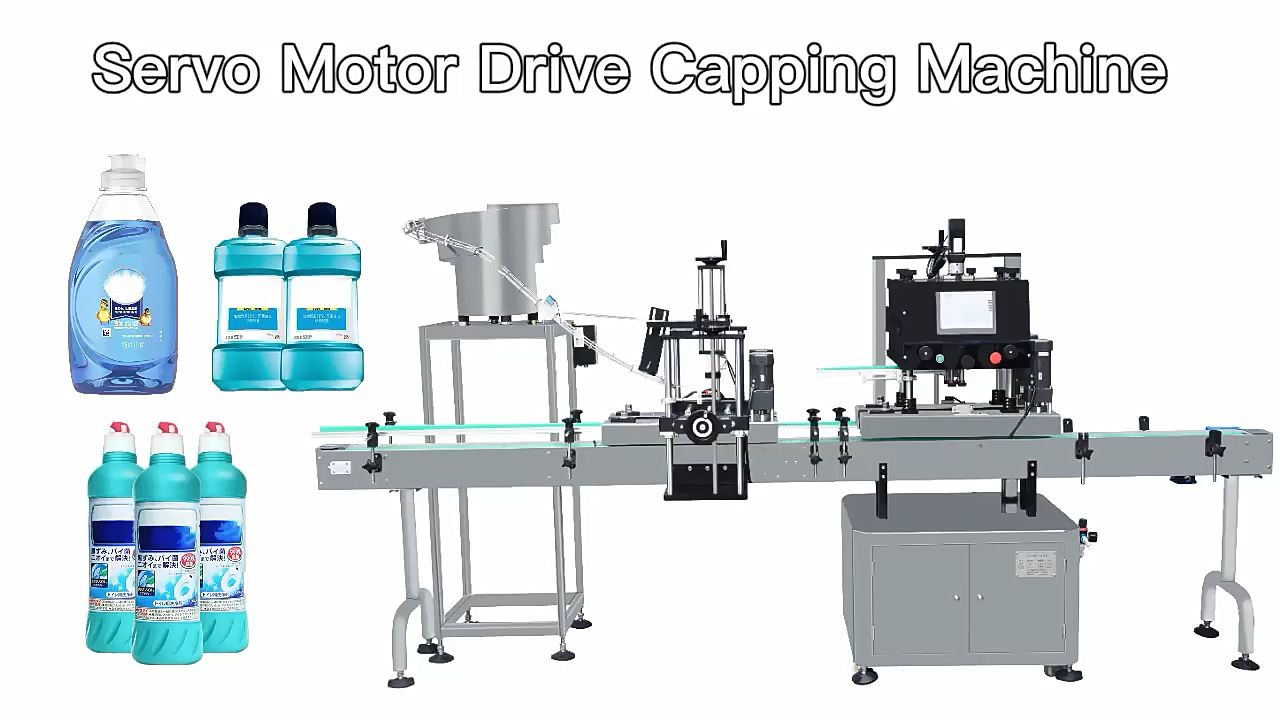

The automatic tracking capping machine is designed base on inline pick and place capping machine, it solve the low capacity of the inline pick and place capping machine, its movement is control by Motion Controller more efficient and accuracy than PLC, the capping heads are moving tracing with the bottles going when capping. it can be equipped with one or two capping heads, capacity is from 40b/m to 70b/m without thinking the size of the bottle and cap (base on 100ml to 5000ml bottle)

This machine has the advantage of bottle non-stop working, so after the filling machine, even almost full of liquid inside, the liquid will not splash out when capping. It applies high efficient servo system, including the belt servo, horizontal moving servo, up and down moving servo, and servo capping head system Automatic gripping and capping are completed by the servo motor, and the movement is precise and the speed is fast.

| No. | Model | VK-LC-2 | |

| 1 | Speed | 0-80pcs/Min | |

| 2 | Cap Type | Screw cap | |

| 3 | Bottle Diameter | 30-160mm | |

| 4 | Bottle Height | 50-280mm | |

| 5 | Cap Diameter | 18-80mm | |

| 5 | Power | 3.5KW | |

| 6 | Air Pressure | 0.6-0.8Mpa | |

| 7 | Voltage | 220V/380V, 50Hz/60Hz | |

| 8 | Weight | 800KG | |

| 9 | Dimension | 2200mm*1400mm * 2150mm | |

Main Featrue

1. The servo system + torque module controls the capping head, and the cap tightness is freely set.

2. The whole machine is made of 304 stainless steel material without any dead corner.

3. The cap feeding system is adapt Cap elevator which can storage around 500caps at a time.

4. For different size of bottle and cap, only need adjust no need change parts excluding the capping head.

5. No Liquid Shakes Out---Bottles no need to stop for capping

6. Wide Application--- fast switching for various caps

7. High success rate cap loading---pick-place capping

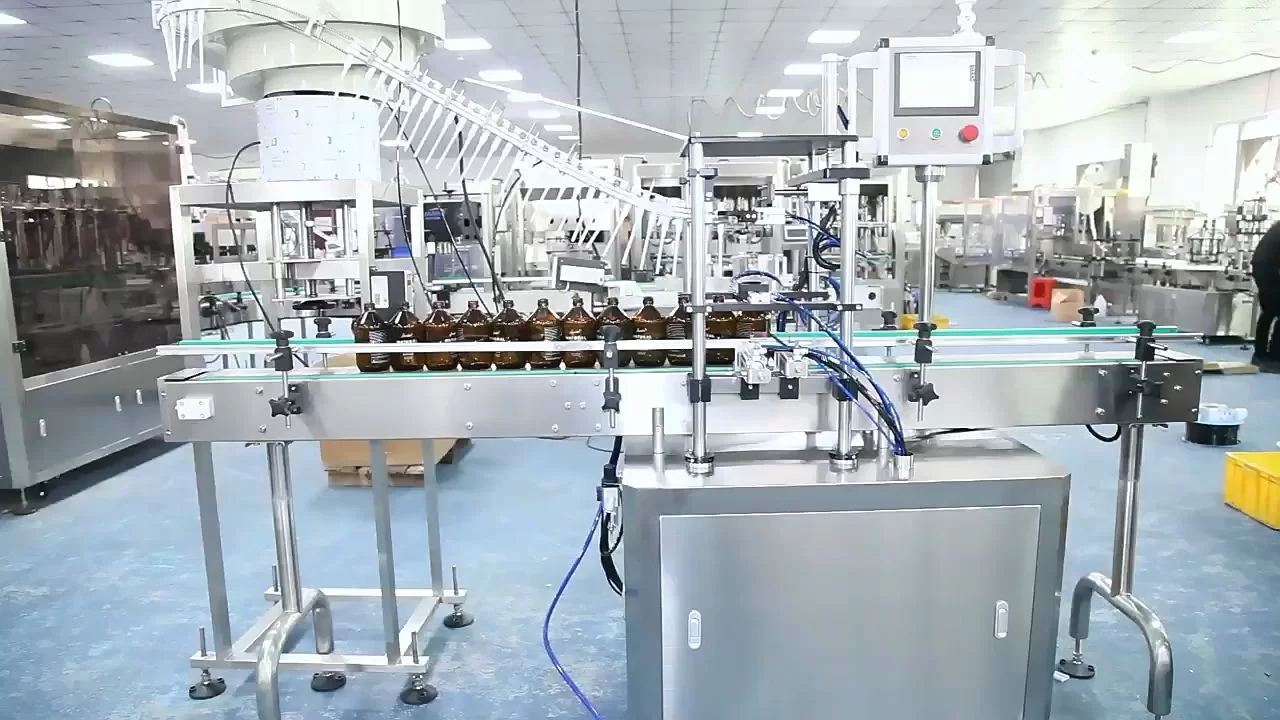

The automatic tracking bottle closer capping machine is a specialized machine designed to efficiently and accurately cap bottles with a variety of caps. The machine is equipped with advanced technology that ensures consistent and reliable capping, making it an ideal solution for manufacturers looking to increase productivity and efficiency.

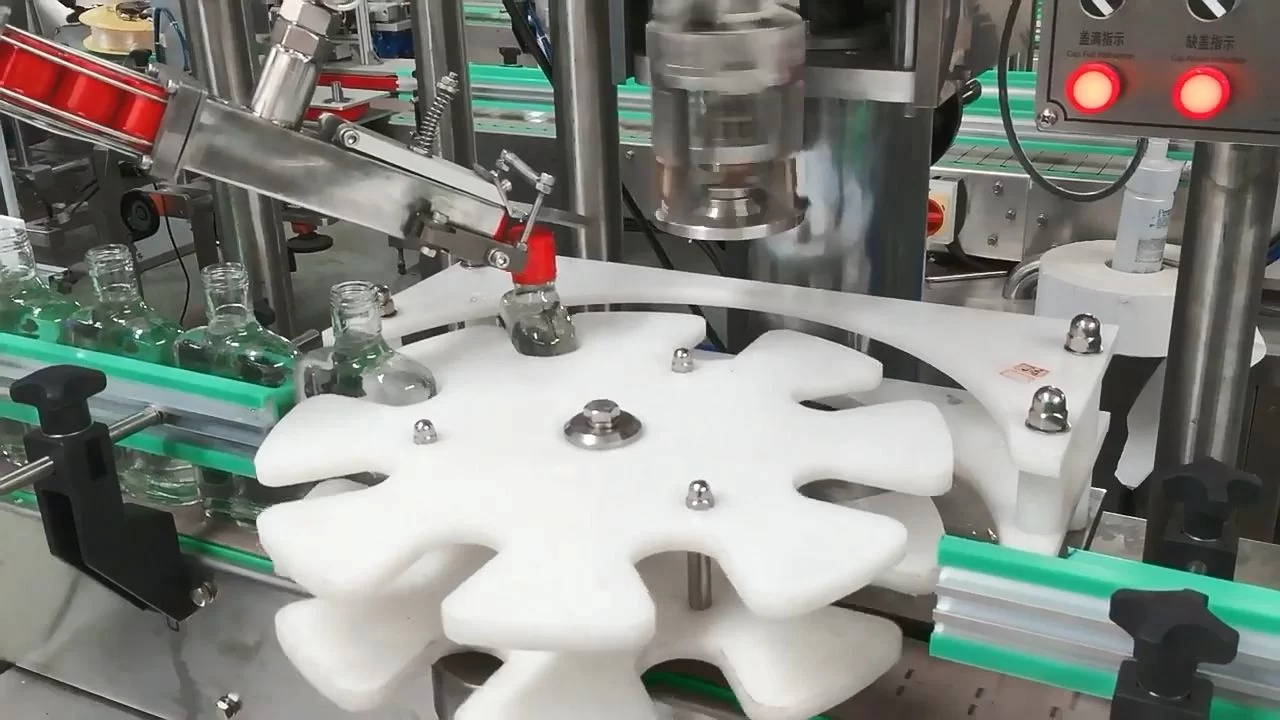

The machine is designed to handle different bottle sizes and shapes, making it versatile and suitable for different production requirements. It is equipped with a conveyor system that moves the bottles to the capping station, where the caps are applied to the bottles.

The capping mechanism uses a tracking system that ensures the caps are applied evenly and consistently on each bottle. The machine is also equipped with sensors that detect the position of the bottles and caps, ensuring that the caps are aligned properly before they are applied to the bottles.

The automatic tracking bottle closer capping machine is designed to operate at high speeds, ensuring that the production process is efficient and fast. The machine is equipped with a touch screen interface that allows the operator to control the entire production process. The interface is user-friendly, making it easy for operators to adjust the capping speed, torque, and other parameters as required.

The machine is also equipped with a cleaning system that ensures that the capping station and other parts of the machine are kept clean and free from contaminants. This helps to maintain the quality of the product and ensures that it is safe for consumption or use.

In conclusion, the automatic tracking bottle closer capping machine is a specialized machine that provides an efficient and automated process for capping bottles with a variety of caps. Its advanced technology ensures consistent and reliable capping, making it an ideal solution for manufacturers looking to increase productivity and efficiency. Its versatility, high speed, user-friendly interface, and cleaning system make it a valuable asset in any production facility.