Quick Description

- Condition: New

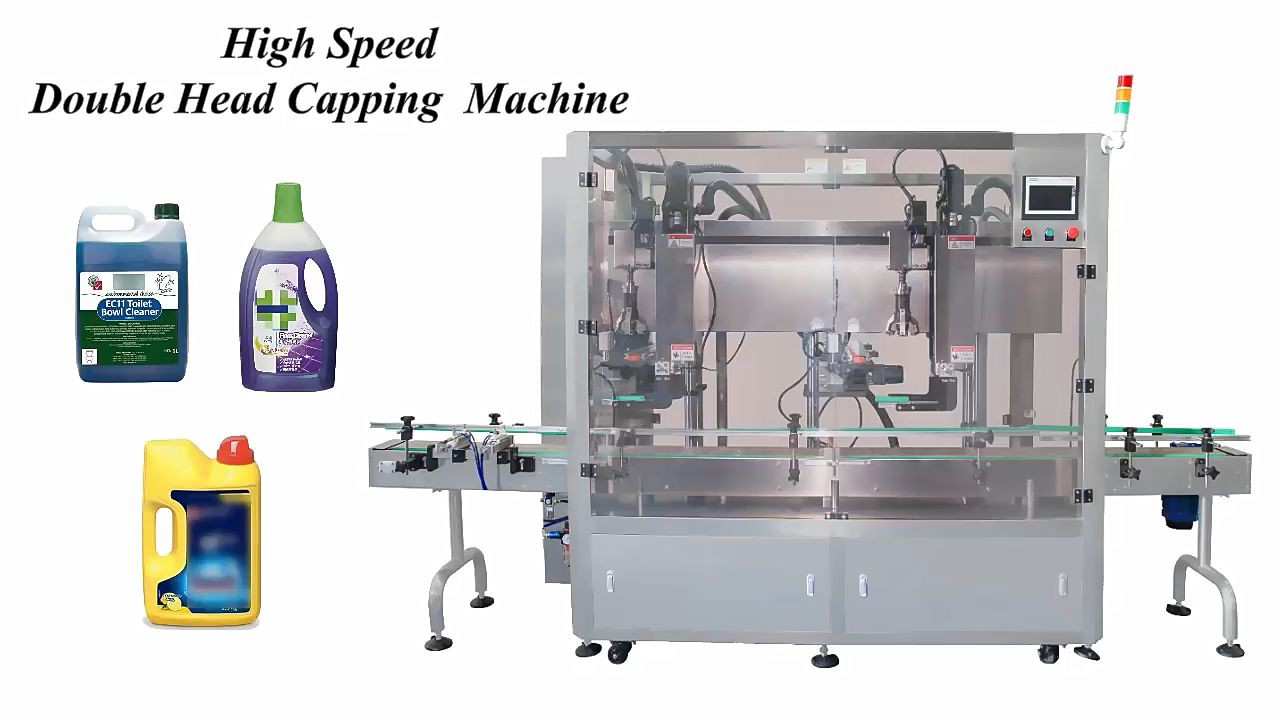

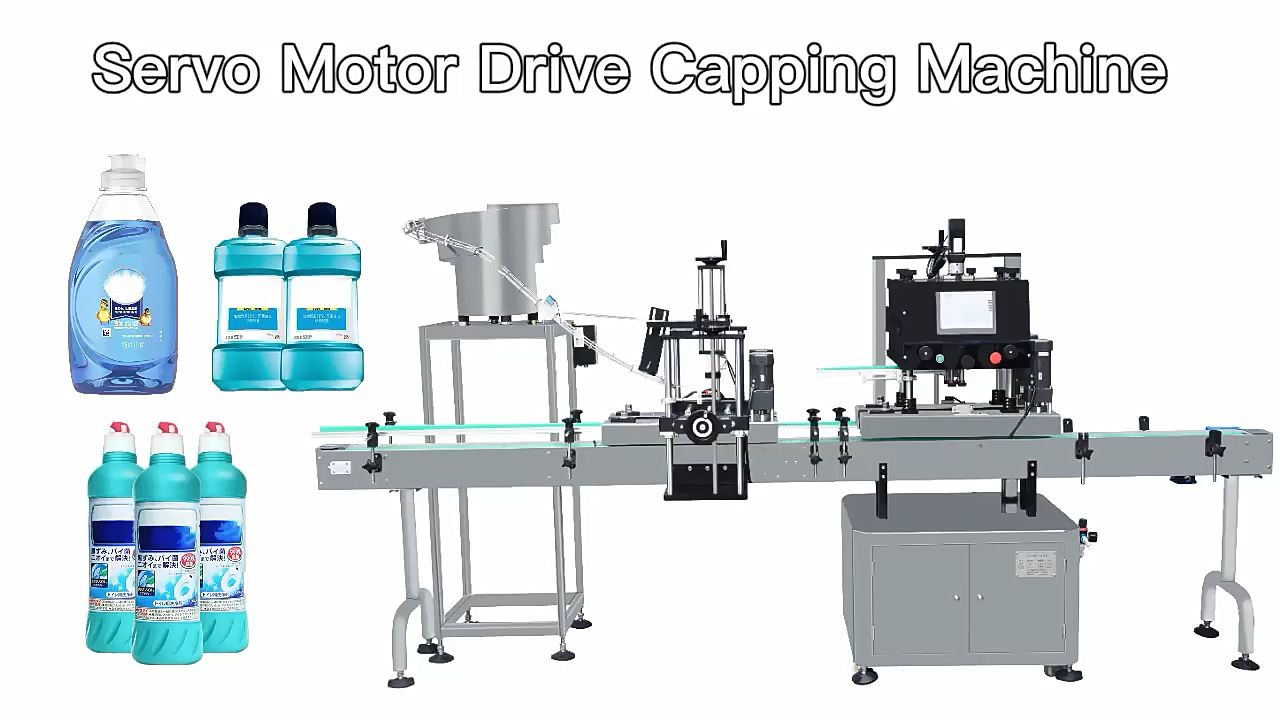

- Type: Capping Machine

- Machinery Capacity: 1000-4000BPM

- Applicable Industries: Food & Beverage Factory, Retail, Pharmaceutical Packaging Factory

- Showroom Location: Egypt, Philippines

- Application: Food, Beverage, Commodity, Chemical

- Packaging Type: Bottles, Vial

- Packaging Material: Plastic, Metal, Glass

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Dimension(L*W*H): 1500*1500*1700mm

- Weight: 300 KG

- Warranty: 1-3 Year

- Key Selling Points: Automatic

- Filling Material: Water, Oil, Juice, Honey

- Filling Accuracy: ±1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: standard

- Core Components: standard

- Product name: Glass Jar Bottle Honey Piston Filling Machine Equipment

- Number of filling heads: 4 heads or customized

- Filling capacity: 50ml-500ml

- Filling form: Servo piston filling

- Filling speed: 25-30 bottles/hour (50-150ml bottle)

- Filling accuracy: ±1%

- Air pressure: 0.6-0.8MPa

- Power: About 2KW/380V three-phase five-wire

- Groove capacity: 10 liters

- Protection device: The liquid storage tank is shut down and the alarm is stopped.

More Details

| Technical Parameter | |

| Number of filling heads | 2 filling heads |

| Filling capacity | 50-500ml |

| Filling form | 2 heads into bottle bottom fast or slow tracking filling |

| Filling speed | 20-45 bottles/minute |

| Filling accuracy | ±1% |

| Cap putting form | Vibration cap sorter feeding |

| Capping form | High speed screw locking |

| Total power | 2KW/AC220V/380V, 50/60HZ |

| Program control | PLC touch screen |

| Net weight | 500KG |

| Materials of liquid contacting parts such as filling nozzle and chute: 316L # stainless steel and PVC pipe. | |

Description:

The locking filling capping machine is carefully designed for liquid medicine, syrup vial , and serum, 50ml to 500ml arbitrary adjustable of a new generation of packaging equipment, using microcomputer PLC automatic control.

High precision measurement, large filling range, smooth operation, easy to clean, suitable for various shapes of container filling.

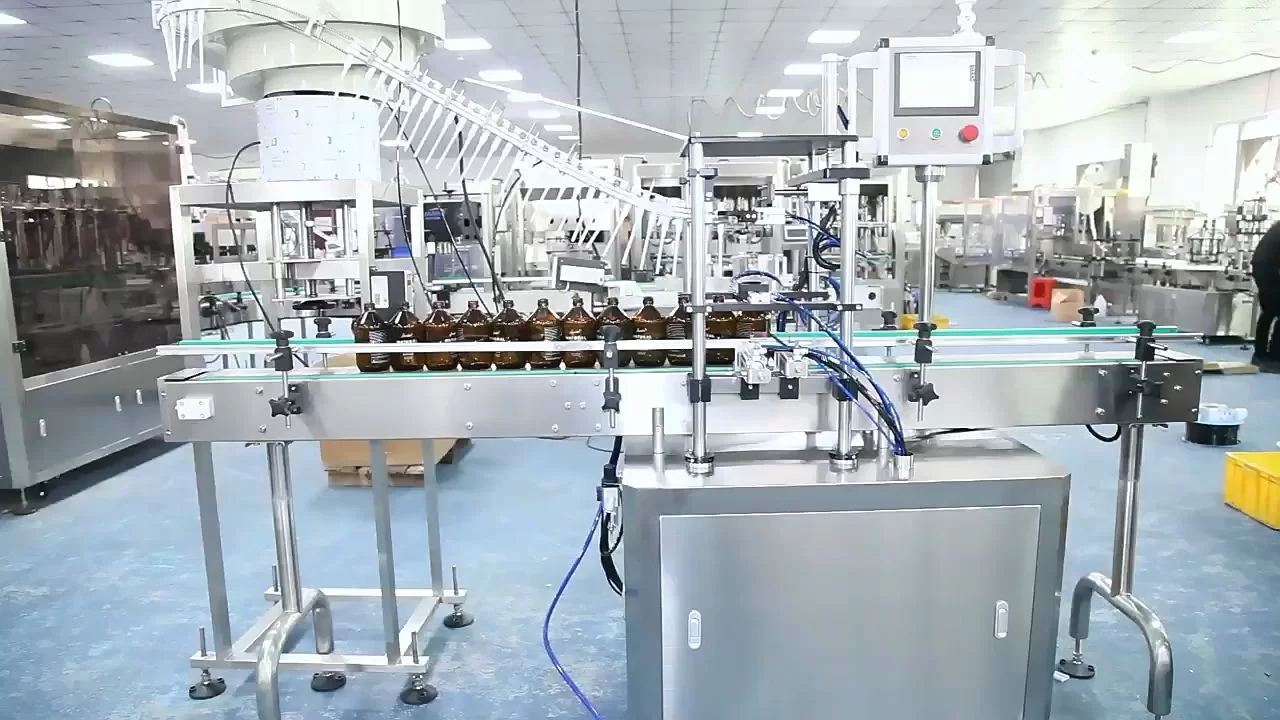

The Automatic Whisky Vodka Brandy Liquor Glass Bottle Capping Machine is a piece of equipment designed to automate the capping process of glass bottles in the liquor industry. It is capable of handling different sizes and shapes of bottles, making it versatile and suitable for a wide range of production lines.

The machine features a conveyor belt that transports bottles to the capping station, where they are securely capped using a specialized mechanism. The capping mechanism is designed to work with a variety of caps, including crown caps, cork stoppers, and screw caps. The machine is equipped with adjustable guides that ensure the bottles are properly positioned for capping, and sensors that detect bottle position and cap presence, ensuring accurate and consistent capping.

The Automatic Whisky Vodka Brandy Liquor Glass Bottle Capping Machine is built with high-quality materials and components, ensuring durability and long-lasting performance. It is also easy to operate, with a user-friendly interface and intuitive controls. The machine is designed to work at high speeds, making it ideal for large-scale liquor production facilities.

Overall, the Automatic Whisky Vodka Brandy Liquor Glass Bottle Capping Machine is a reliable and efficient solution for automating the capping process in the liquor industry. It reduces manual labor, improves production efficiency, and ensures consistent and accurate capping of glass bottles.