Quick Description

- Type: Capping Machine

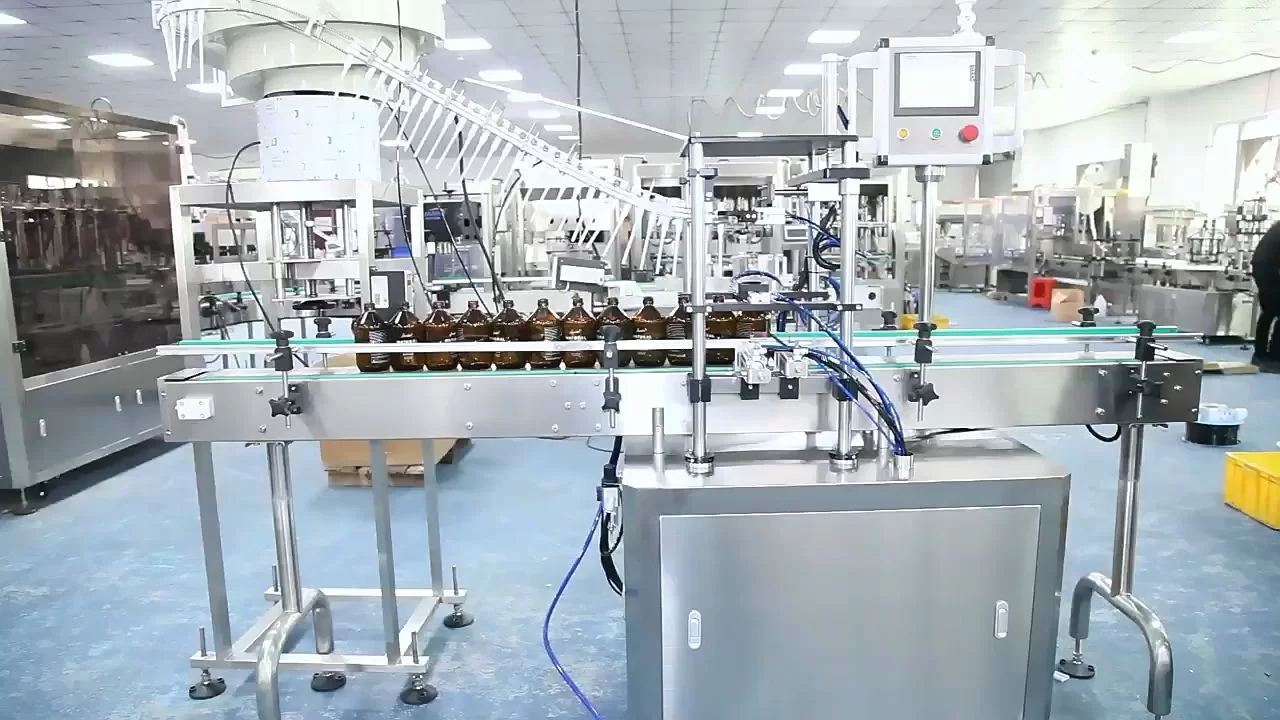

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Egypt, Philippines

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing

- Condition: New

- Application: Food, Beverage, Medical, Chemical

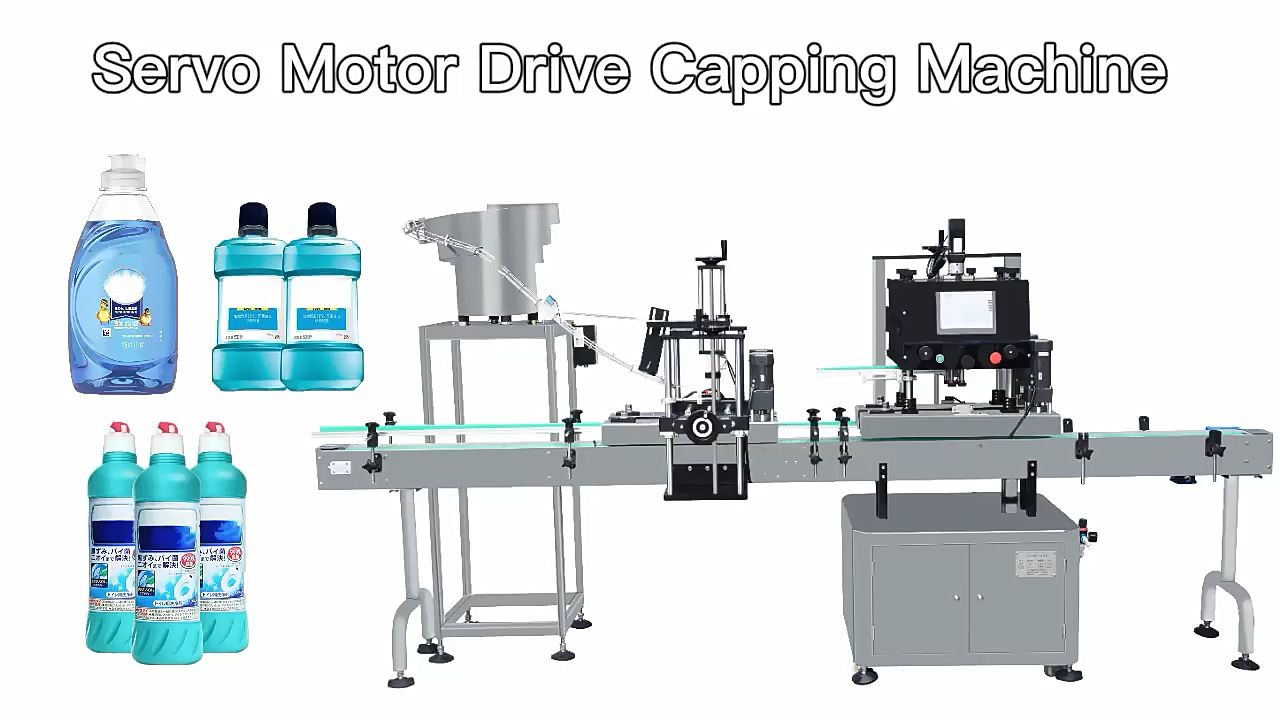

- Driven Type: Pneumatic

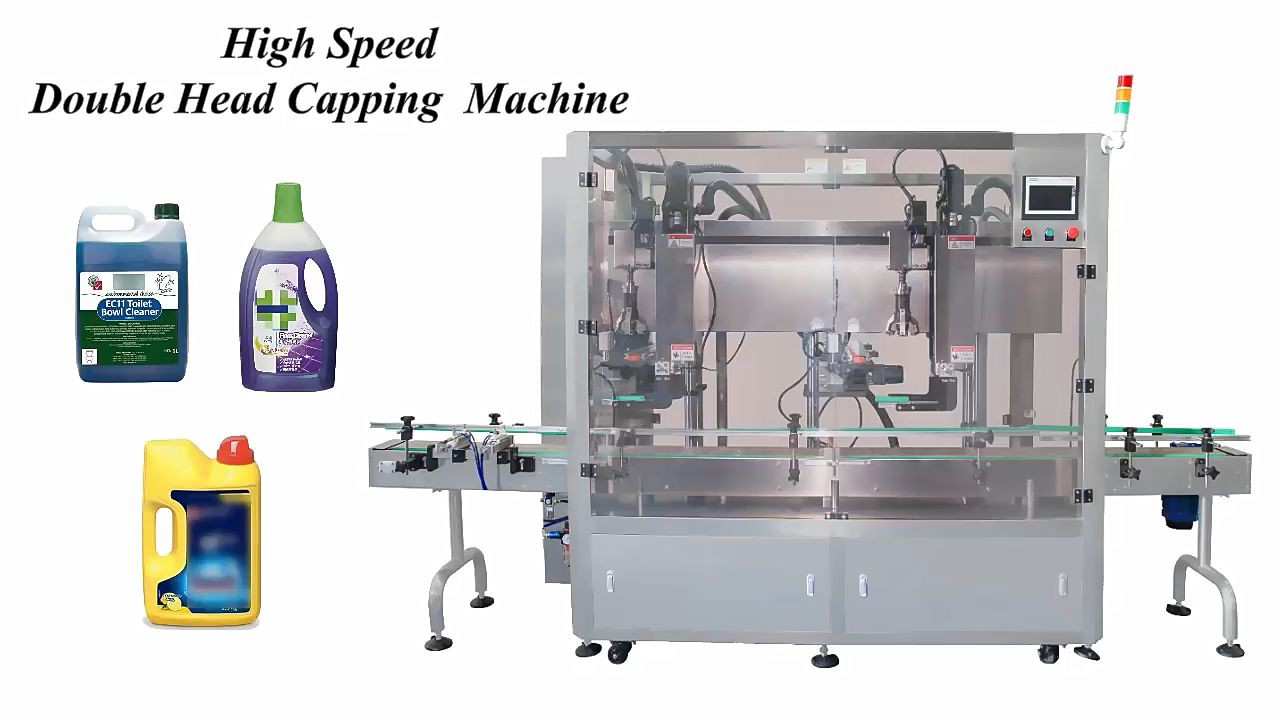

- Automatic Grade: Automatic

- Voltage: AC220V/50Hz

- Packaging Type: Bottles

- Packaging Material: Plastic, Metal, Glass

- Dimension(L*W*H): 1300*800*1600mm

- Weight: 400 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Working Voltage: AC220V/50Hz

- Size: 2600*1100*1950mm

- Equipment Weight: Full Automatic Servo Capping Machine

- Air Source Pressure: 0.7Mpa

- Use Air Pressure: 0.4-0.6Mpa

- Production Capacity: 2500-3000 bottles / hour

- Keywords: Servo Rotor Capping Machine

- Bottle Type: Any Bottle Provided By Customers

- Company Type: Integration Of Industry And Trade

- Machine Advantage: Professtion technical service, 24 hours service time

The big drum bucket pressing capping machine is an automatic machine designed to cap big drum buckets with precision and efficiency. It is commonly used in industries such as food processing, chemical, and pharmaceuticals, where large quantities of liquid or viscous products need to be packaged in big drum buckets.

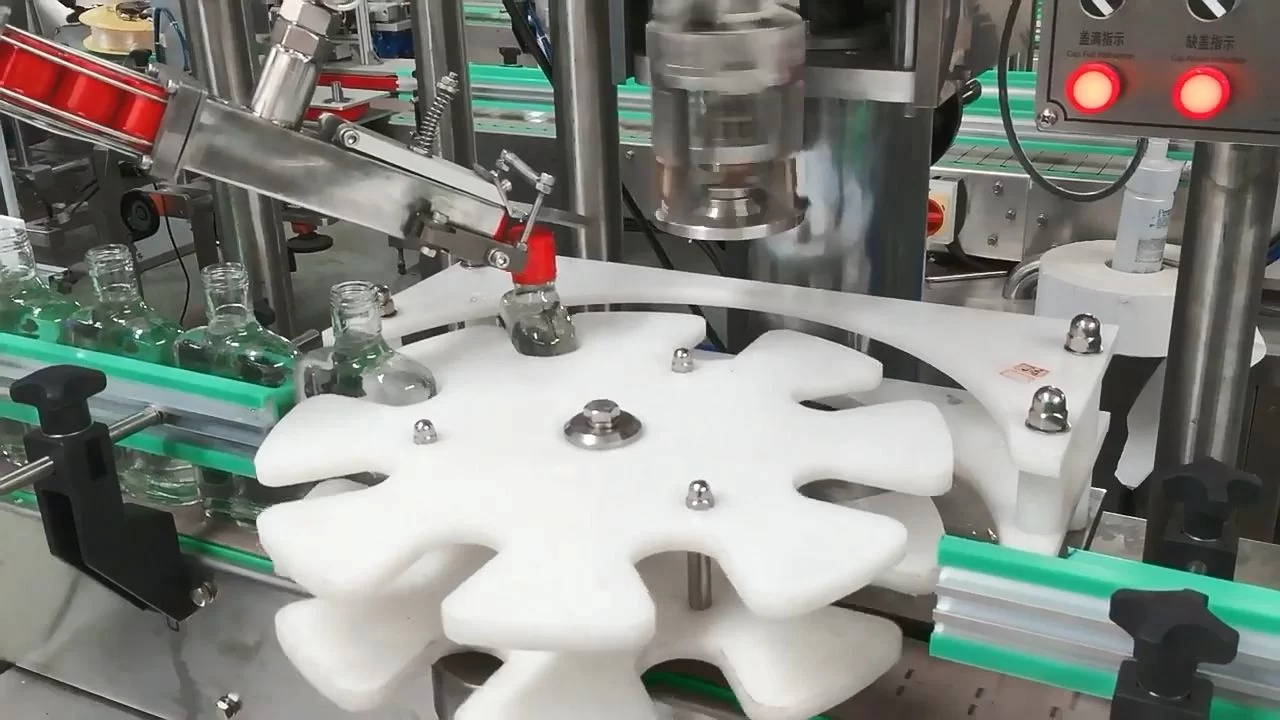

The machine is made of high-quality stainless steel and is designed with a user-friendly interface that makes it easy to operate. It comes with a pressing and capping head that is adjustable to fit different sizes of big drum buckets. The capping process is done automatically, ensuring that the caps are tightly sealed to prevent any leakage.

The big drum bucket pressing capping machine is capable of capping up to 600 buckets per hour, depending on the size of the buckets and the viscosity of the product. The capping process is also gentle, ensuring that the products are not damaged during the packaging process. Additionally, the machine is equipped with safety features such as emergency stop buttons, ensuring that the operator is safe during operation.

One of the advantages of the big drum bucket pressing capping machine is its versatility. It can be used to cap a wide range of products such as food sauces, syrups, chemicals, and pharmaceuticals. This makes it a suitable option for businesses that package different products in big drum buckets.

In conclusion, the big drum bucket pressing capping machine is a reliable and efficient option for businesses that require precise and consistent capping of big drum buckets. It is easy to use, versatile, and capable of handling large volumes of products. Its high-quality construction and safety features make it a worthwhile investment for businesses looking to improve their packaging process.