Quick Description

- Type: Capping Machine

- Applicable Industries: Food & Beverage Factory, Farms, Home Use, Retail, Food Shop, Food & Beverage Shops, Other

- Showroom Location: Egypt, Philippines, Japan

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Warranty of core components: 1 Year

- Core Components: PLC, Engine, Pump

- Condition: New

- Application: Food, Beverage, Commodity, Medical, Chemical

- Driven Type: Electric

- Automatic Grade: Automatic

- Voltage: AC 220V/50Hz

- Packaging Type: Bottles

- Packaging Material: Plastic, Metal, Glass, Wood

- Dimension(L*W*H): 2180*1150*1760mm

- Weight: 400 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Equipment Weight: Full Automatic Servo Capping Machine

- Production Capacity: 30-50 bottles/minute

- Air Source Pressure: 0.6-0.7Mpa

- Bottle Type: According to Customer's products

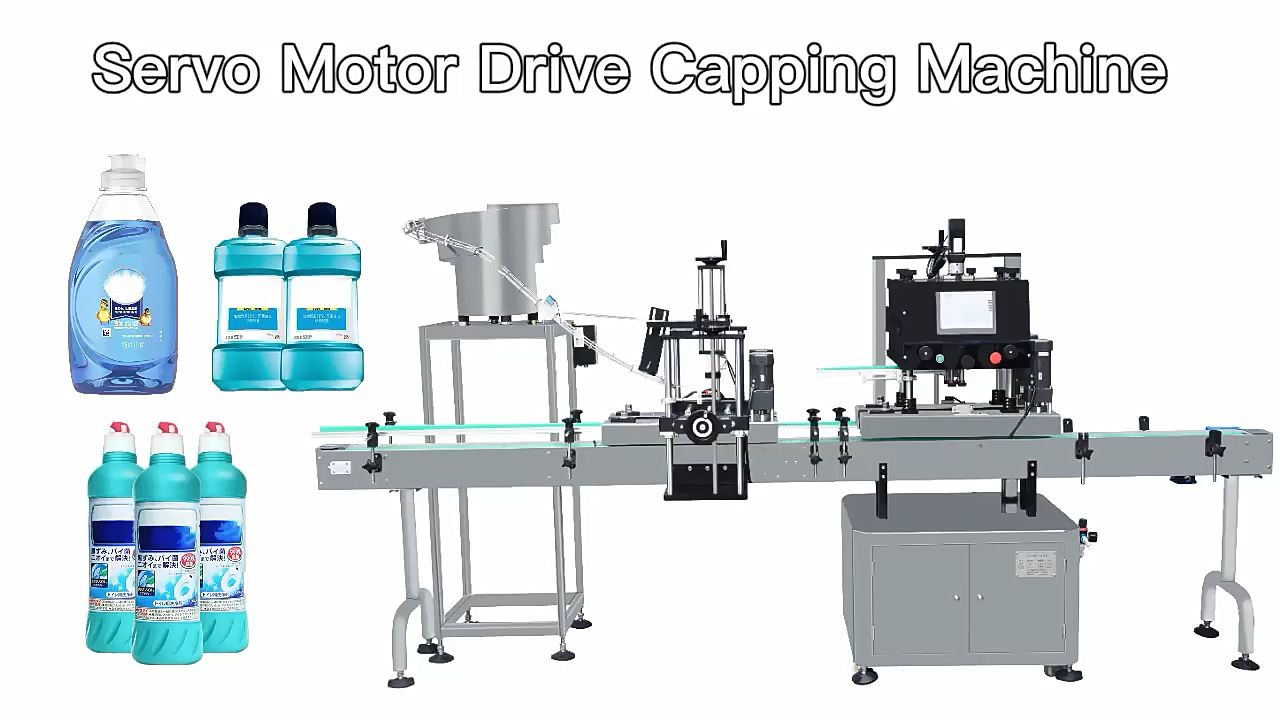

- Keywords: Servo motor drive screw capping Machine

- Cap feeding method: Elevator cap sorter

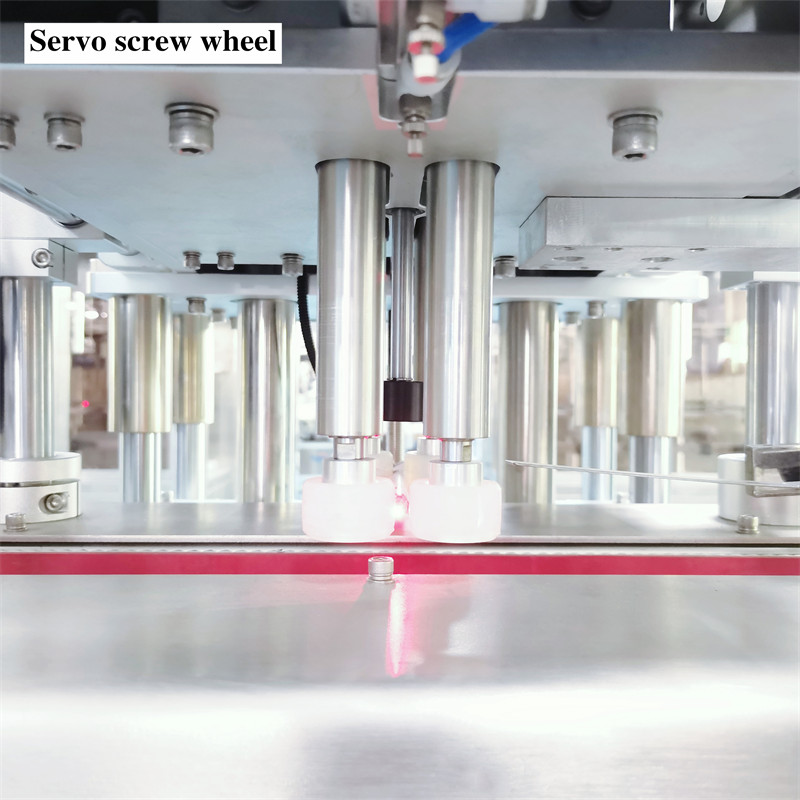

- Capping method: Servo electric screw

- Company advantage: Professtional service, visit factory at any time

- Machine advantage: Factory price, Free parts replacement

- Control system: PLC touch screen

- Marketing Type: Hot Product 2022

More Details

Description:

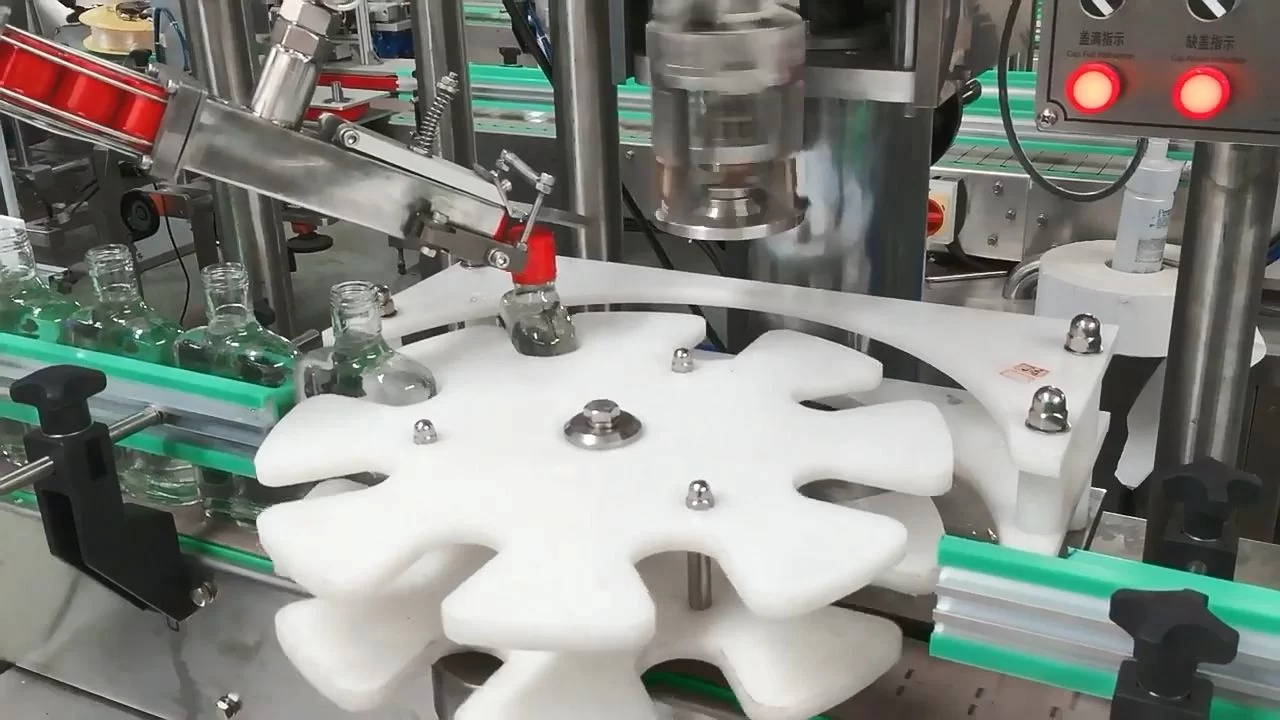

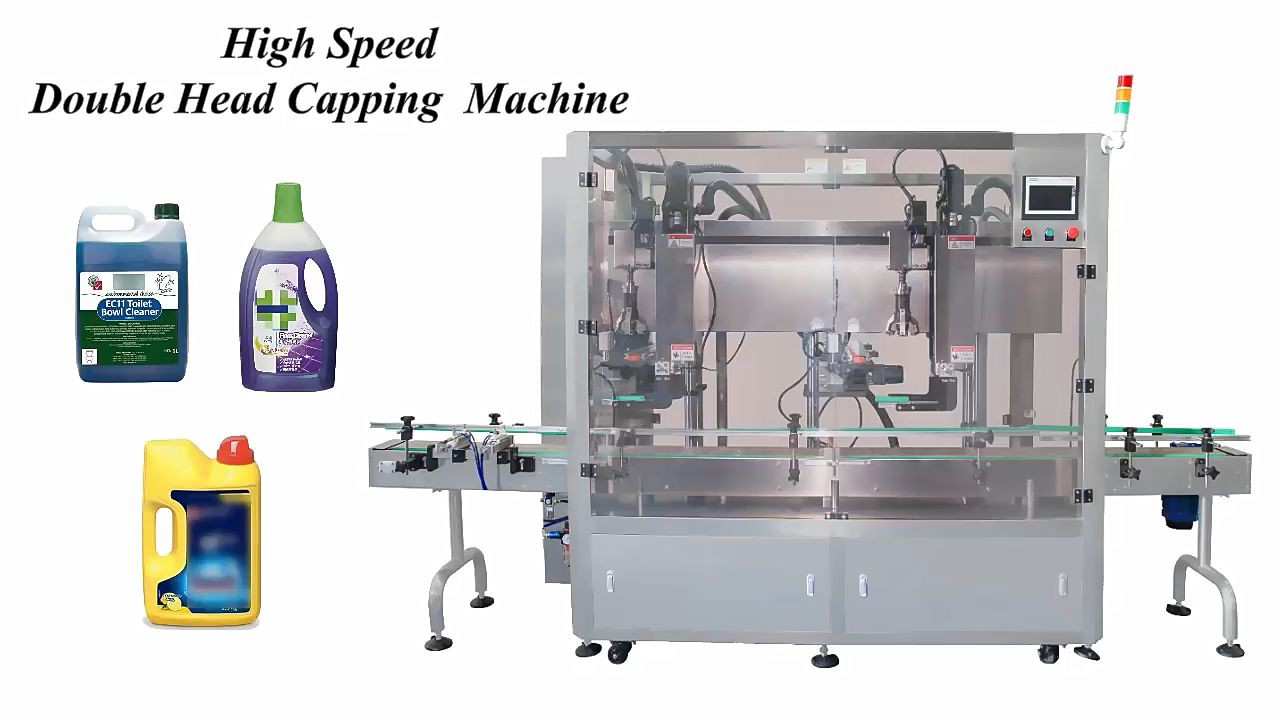

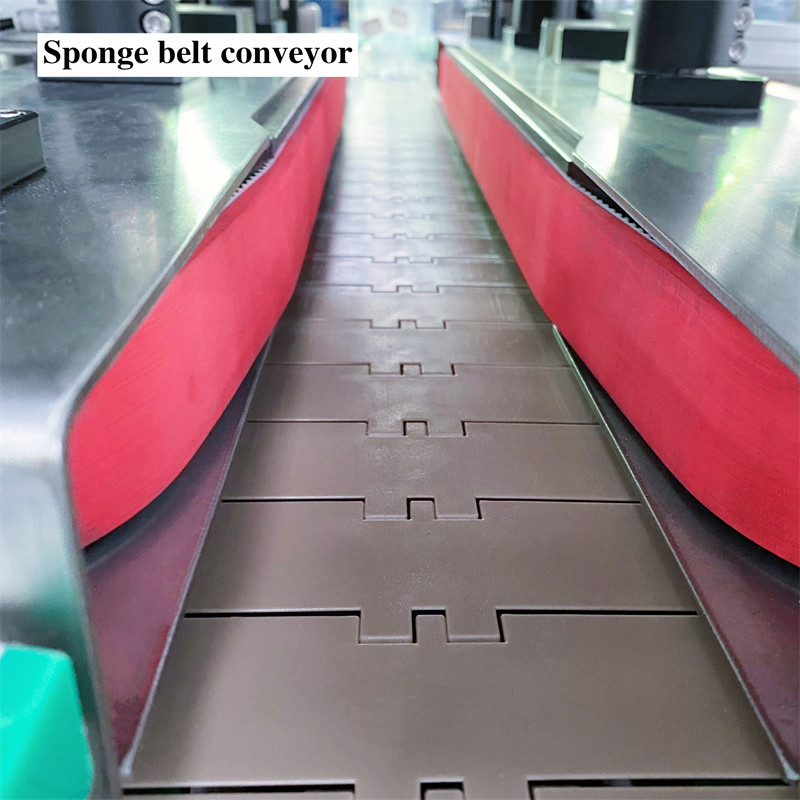

This machine is used for automatic capping for plastic bottles, glass bottles and metal bottles in cosmetic, food, beverage, chemical industry and medicine industry. It can be applied to a variety of bottle types with high production efficiency.

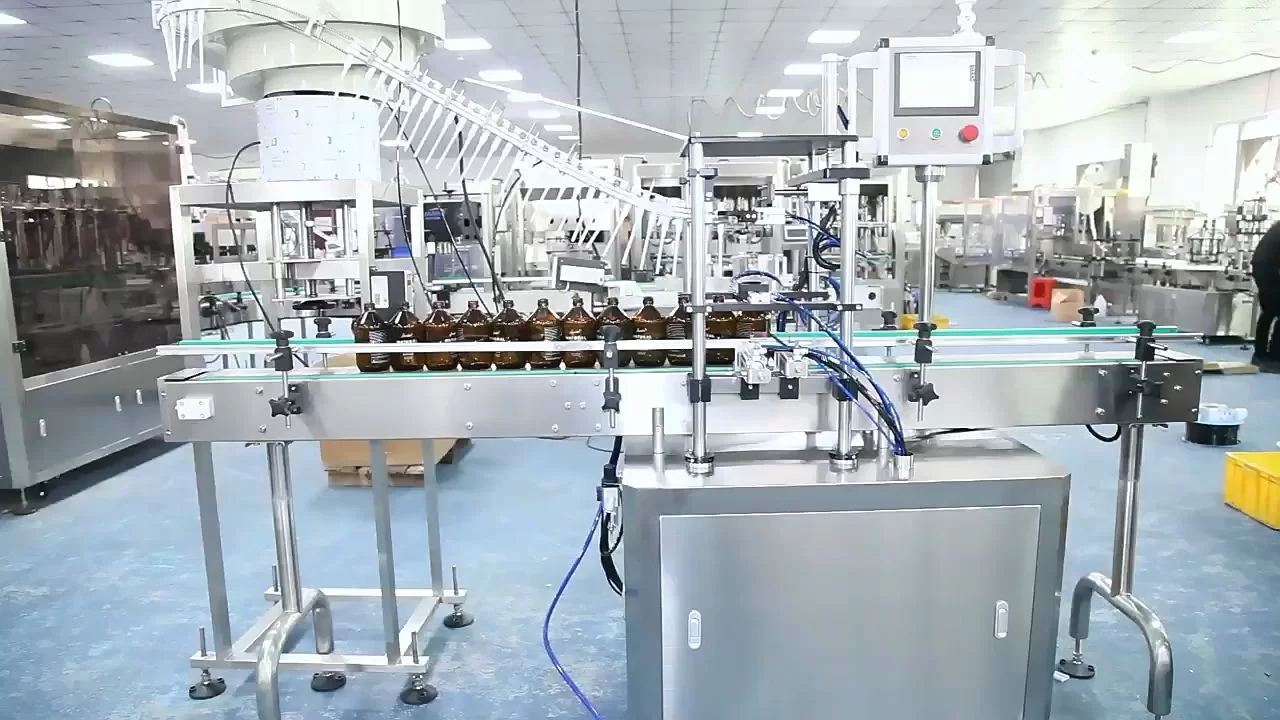

This is a fully automatic capping line, which can help you improve work efficiency and save a lot of production costs. There is no filling machine in this line. Please contact us if you need a filling machine.

| Cap feeding method | Elevator feeding caps |

| Capping form | Servo electric clamp |

| Bottle height | 70-320mm |

| Cap diameter | 20-90mm |

| Bottle diameter | 30-140mm |

| Capping speed | 30-40 bottles/min |

| Capping voltage | 1ph AC 220V 50/60Hz |

| Air pressure | 0.6-0.8MPa |

| Dimension | 2180(L)*1150(W)*1860(H)mm |

| Packing size | 2300(L)*1200(W)*1900(H)mm |

| Machine weight | About 350KG |

This is a plastic bottle screw capping machine designed for capping lotion and ointment bottles. The machine uses a rotating cap feeder to sort and supply caps to the capping station, where they are securely tightened onto the bottle using a screwing mechanism.

The capping machine is equipped with an adjustable torque control system to ensure that the caps are tightened to the desired level of tightness. This helps to prevent over-tightening, which can damage the bottle or cause the product to leak, as well as under-tightening, which can cause the cap to come loose during transportation or storage.

The machine is made of high-quality materials and is designed to be durable and reliable. It is easy to operate and maintain, with a user-friendly interface and simple adjustment mechanisms. The machine is also designed to be flexible, with adjustable settings that allow it to be used with a wide range of bottle sizes and cap types.

Overall, this capper equipment is an essential tool for any manufacturer or packager of lotion and ointment products. It can help to increase production efficiency and accuracy, while also ensuring product quality and safety.