Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Restaurant, Home Use, Retail, Other, Advertising Company

- Showroom Location: Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Brazil, Saudi Arabia, Mexico, Russia, Spain, Thailand, Argentina, South Korea, Kazakhstan, Malaysia, Australia

- Application: Food, Beverage, Commodity, Chemical, Machinery & Hardware, sanitizer

- Packaging Type: Barrel, Bottles, CANS, Other

- Packaging Material: Metal, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 110V 220V 380V

- Place of Origin: Shanghai, China

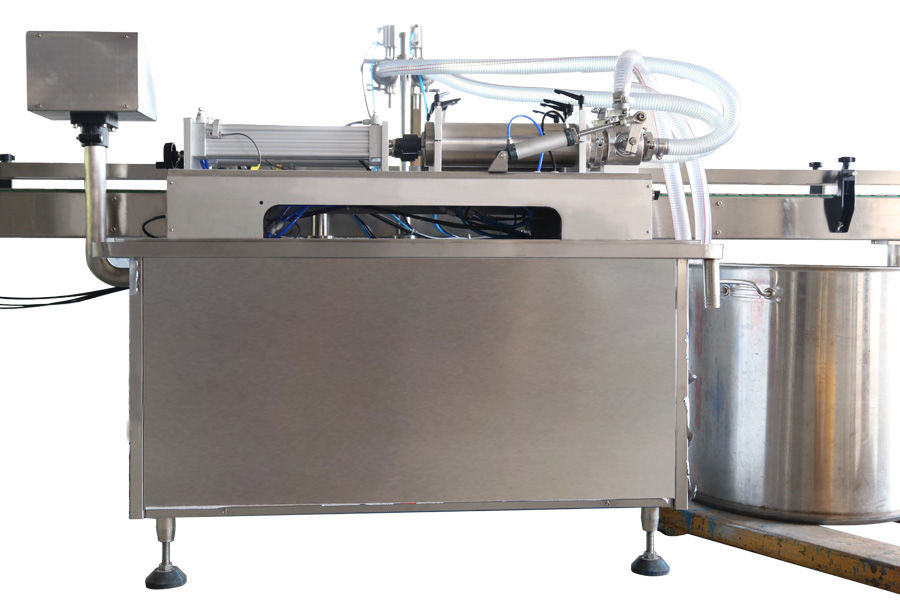

- Dimension(L*W*H): 1800*1000*2000mm

- Weight: 600 KG

- Warranty: 6 Months, Six months free

- Key Selling Points: High Safety Level

- Filling Material: Other, Water, aerosol

- Filling Accuracy: ≥99%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 6 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Machine Name: Body lotion filling machine

- Yield: 1500-4000BPH(Customized)

- Accuracy: ≥99%

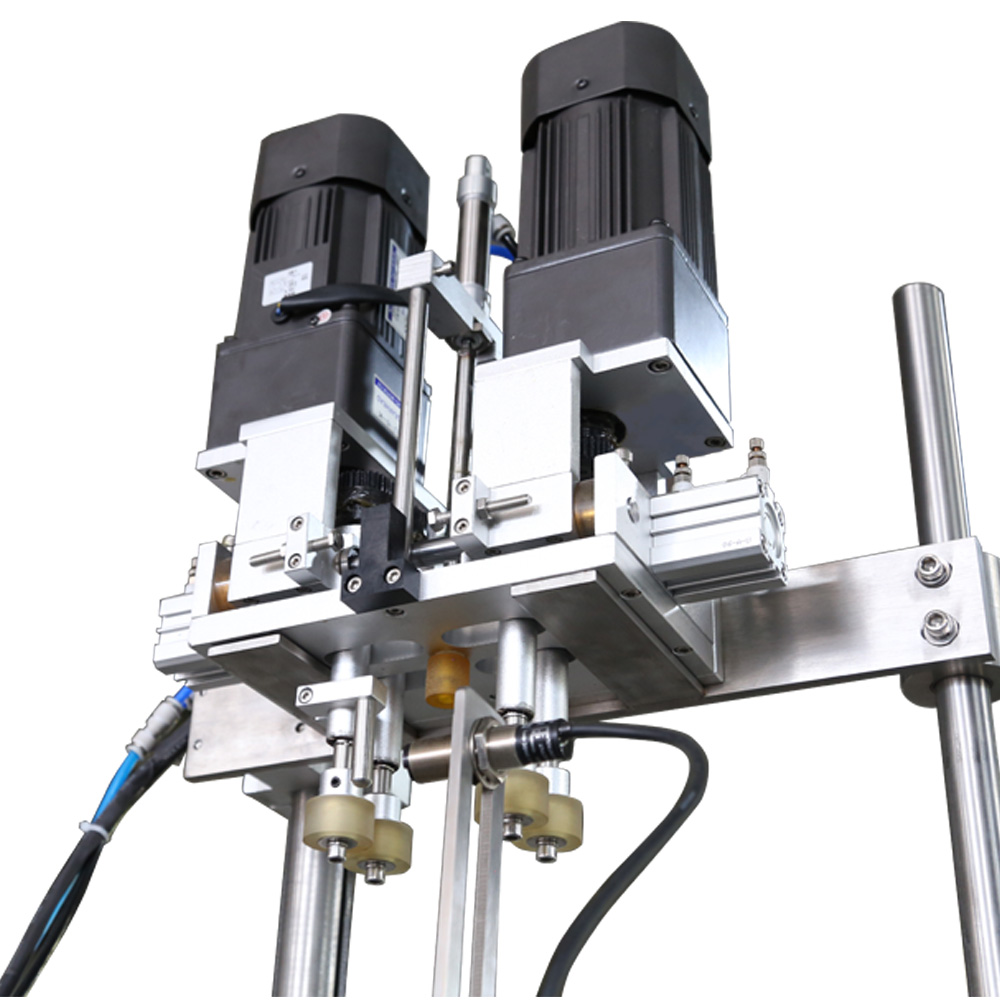

- Driving: Servo motor

- Metal Quality: SS304 and SS316

- Work voltage: 110/220/380V 50/60HZ

- Power: 1-3.5KW

- package: Wooden case

- After-sales Service Provided: Online technical support

More Details

Product description:

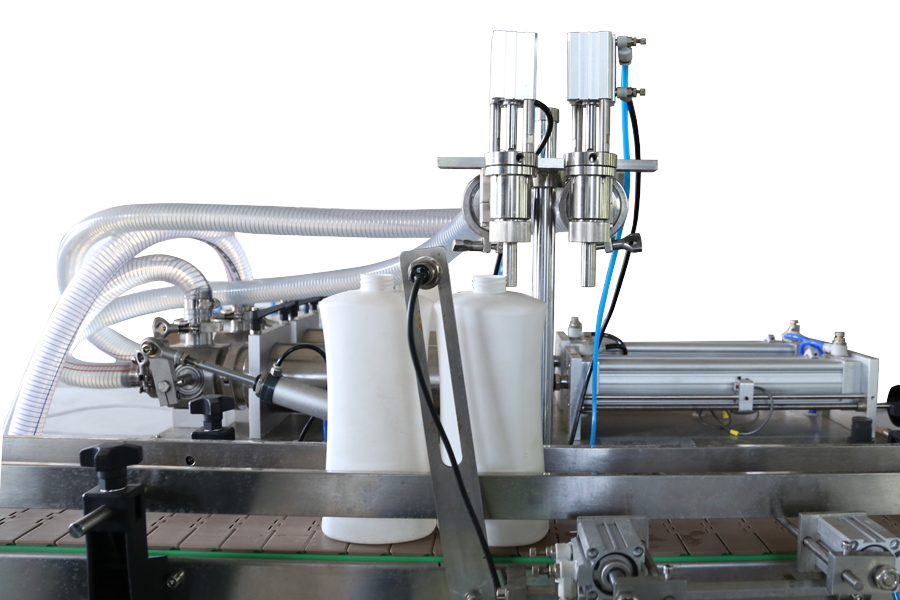

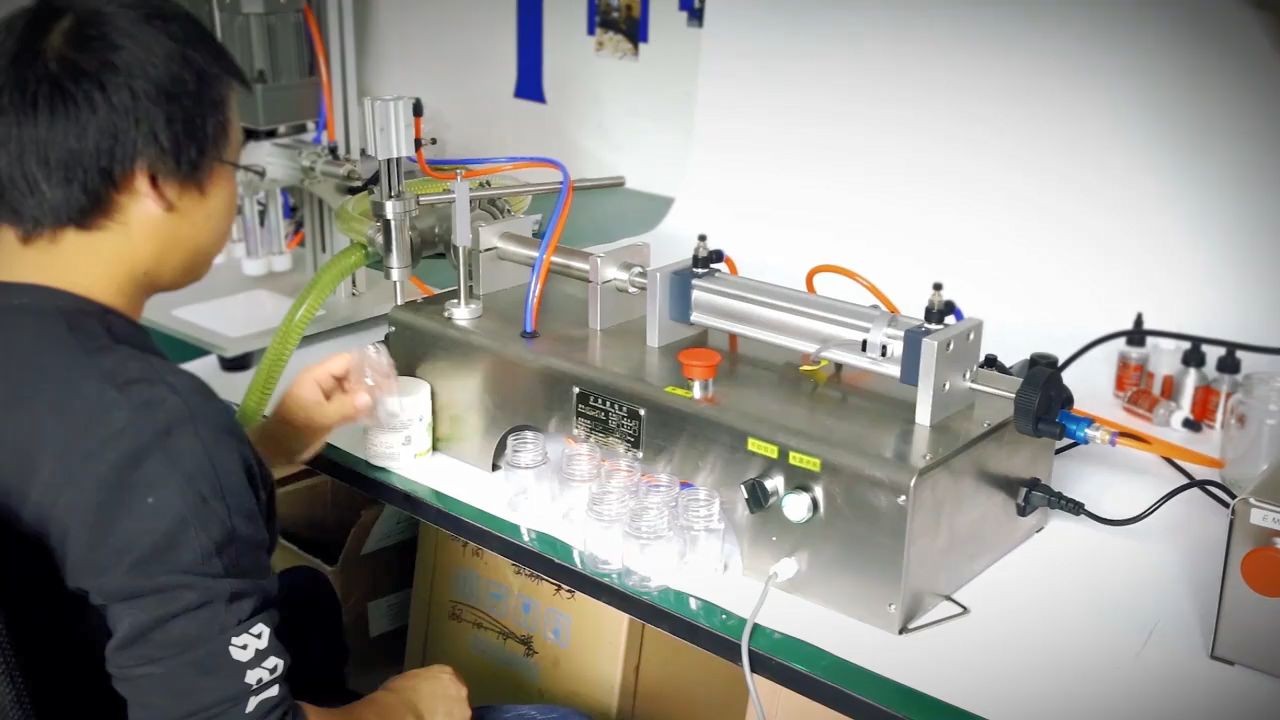

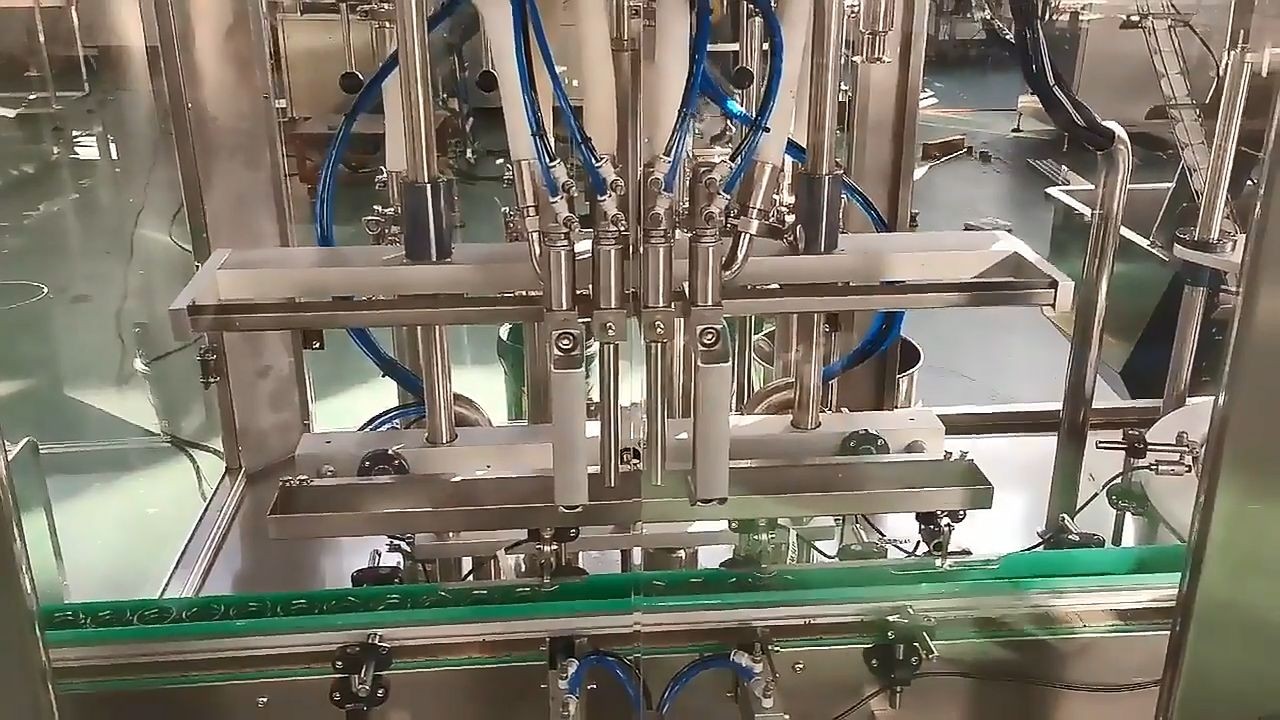

The Smart Filler integrated filling line is rated for 30 bottles per minute, depending on fill volume. Use in-line filling of 10-180ml containers. This machine adopts servo drive, easy to maintain precision and speed, only in the man-machine interface input ideal filling volume and speed, this is the significance of the servo motor. Different from traditional filling line, this machine uses high vibrator to arrange bottle direction , and feed bottle into filling star wheel from high position. It can fill different bottles, we set a scale in the adjustment part, used to record the relationship between different specifications of the bottle and the equipment position. This greatly improves the convenience of the equipment.

For alcohol material , explosion-proof is essential, we prepare separated cabinet for the circut board, in this way, to keep the electric component staying away from the machine unit.

Main technical parameter:

| Product Name | Hand washer/body lotion filling machine |

| Yield | 1500-4000BPH (customized) |

| Filling heads | Customized |

| Filling pump | Piston pump |

| Work voltage | 220/380V 50/60HZ |

| Air presstion | 0.6MPA |

| Accuracy | ≥99% |

| Power | 2.2KW |

| Driving | Servo motor |

| Pump volume | 100-150ml (Customized) |

| United size | 1200*900*2200mm |

| Single machine noise | ≤50dB |

| Weight | 550KG |

| Material | SS304 SS316 |

| HMI | 7.5” Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Speed controller | Variable Speed Controls |

| Detecting system | Vial Detector & Counter |

You may be worried about

1- How can I fill so many formats my bottles with the machine perfectly without complex adjusment?

2- How can I understand your quality? I do not want any kinds bad machine which failed to live up to my investment.

3- How can I know your machine life? It looks always beautiful but only in your room.

4- How can I install such a big long machine by myself? It looks never easy at all.

5- How can I recognize the real difference in chinese market? So many suppliers quoted me every day!!!

6- What should I do if the machine is broken? Who is gonna to help me?

What VKPAK do

Compared with traditional machinery, VKPAK smart filler has characters below which are beneficial to each customer operation experience:

1- With servo driving , operator just edit the filling parameter on HMI to realize all kinds products packing.

2- 150mm width SS304 protection frame which equiped with induction switch is able to stop machine whenever operator open the plexiglass door which is good for human protection.

3- VKPAK's machines are all equiped with scale rules for diffeferent kinds bottle replacing, which is convenient for date recording and save the time in adjusting.

4- All VKPAK's machine are made of SS304 SS316 which avoiding pollution perfectly, protect the quality of customer's product.

5- Machines are delivered as whole which solving the stress of after-sale installation for customer . VKPAK's technicians are standing by all time for on-site service

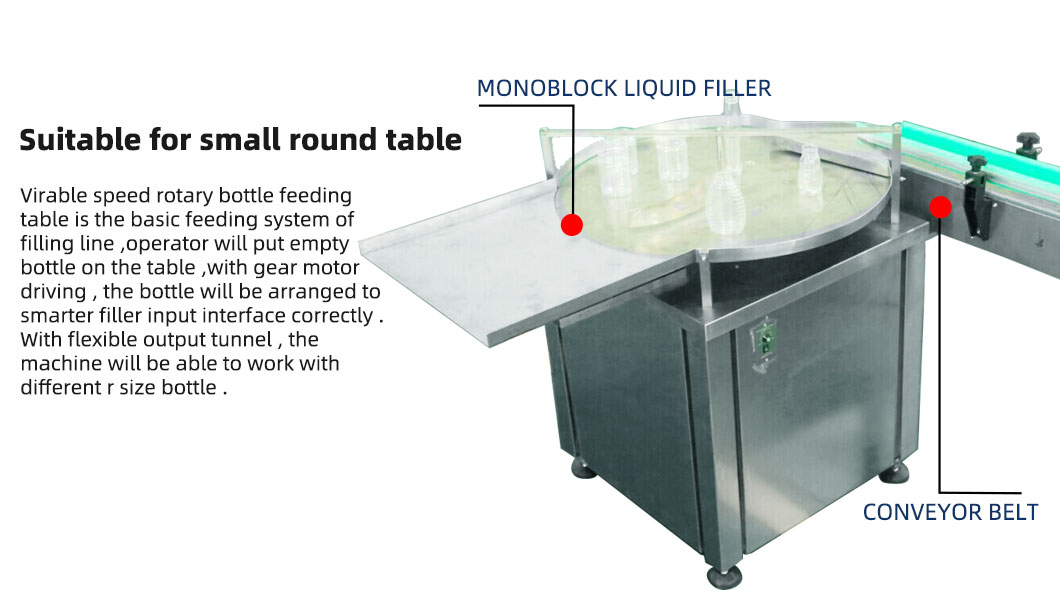

Bottle feeding table

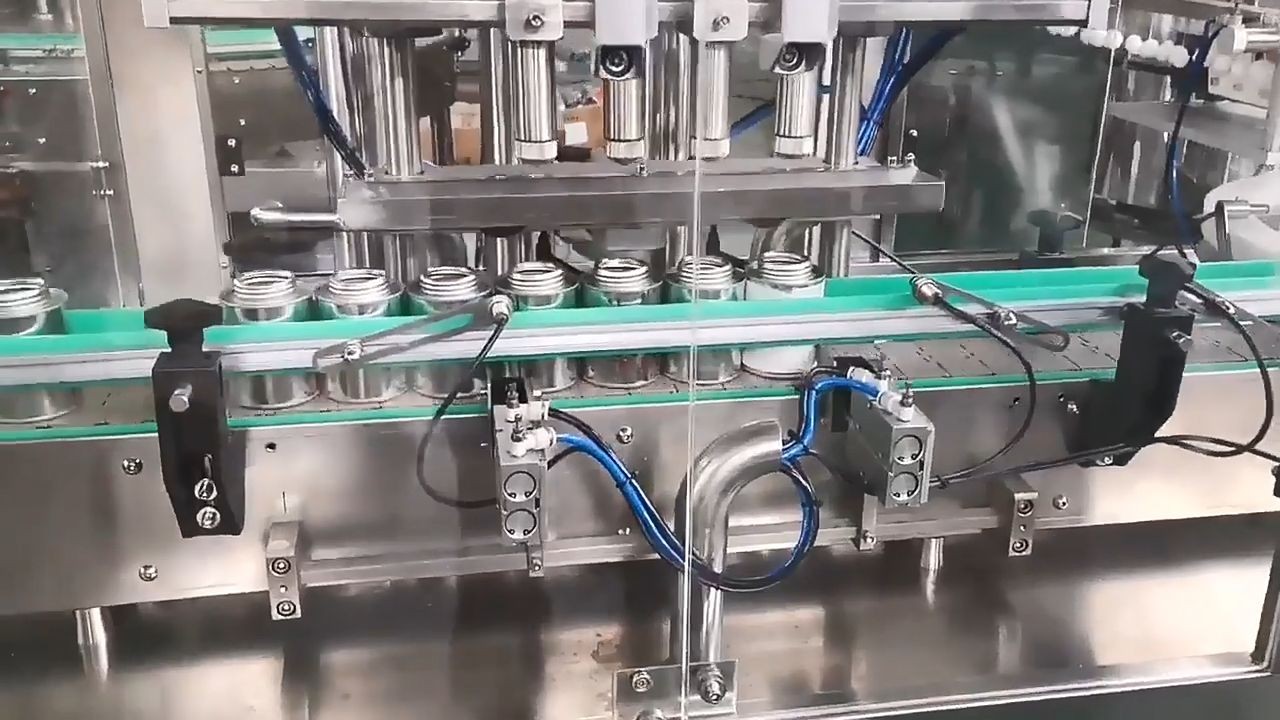

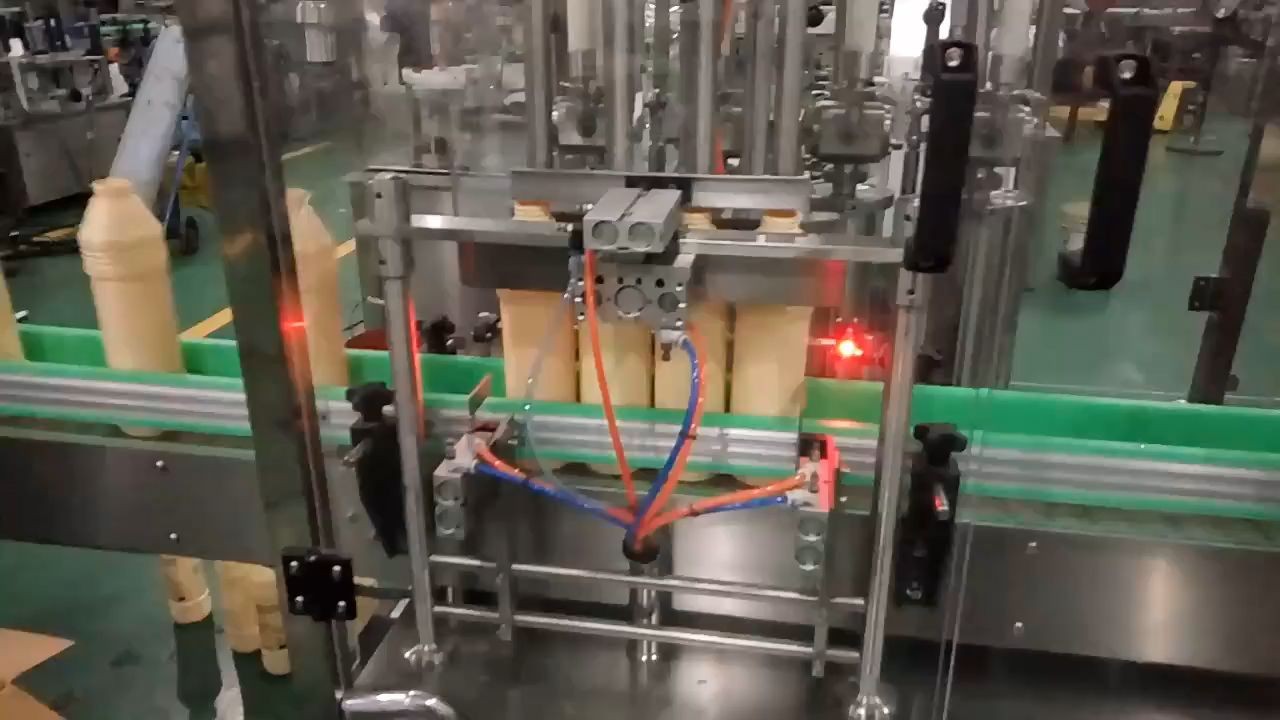

Filling and capping staion