Automatic Essential Oil Bottle Filling Machine is applicable to the pharmaceutical industry in the 2-30 ml bottle of liquid filling and sealing packing process, high precision piston pump (or peristaltic pump) filling, measuring accurate, adjustable, convenient maintenance, easy operation, no bottle no filling, no bottle no plug, not plug cover function.

| Production capacity | 30-40 bottles/minute | |

| Filling nozzle | 2 nozzles | |

| Filling accuracy | ±1% | |

| Press capping nozzles | 1 nozzles | |

| Capping rate | 99% or more (depending on the characteristics of plug appropriate adjustment) | |

| Speed control | frequency control | |

| Bottle size | More than 10 mm | |

| The power supply | 380 V 50 Hz | |

| Power | 2 kw | |

| Air supply | 0.3~04kfg/cm2 | |

| Gas consumption | 10~15m3/h | |

| Overall dimensions | 3000×1300×1700 mm | |

A custom automated bottle essential oil liquid filling capping machine is an advanced packaging equipment designed for efficient, accurate, and reliable filling and capping of essential oil bottles. It is a fully automatic machine that can handle various bottle sizes, shapes, and volumes with minimal changeover time.

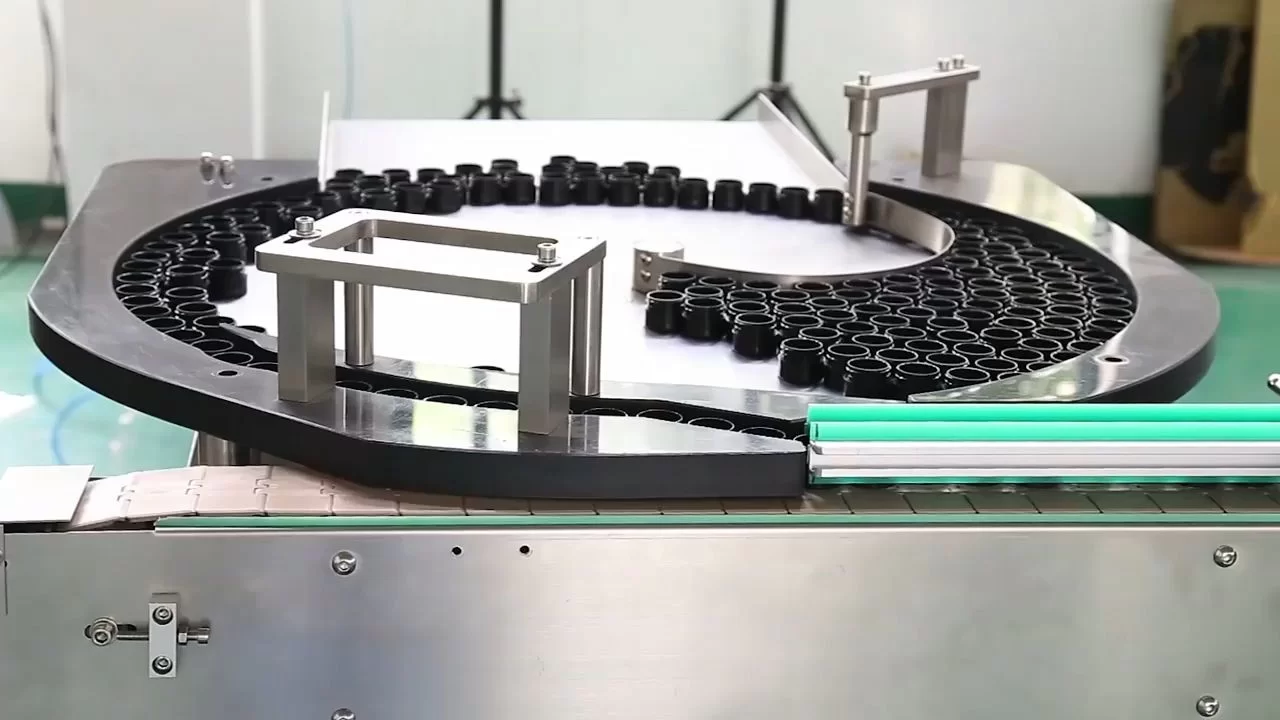

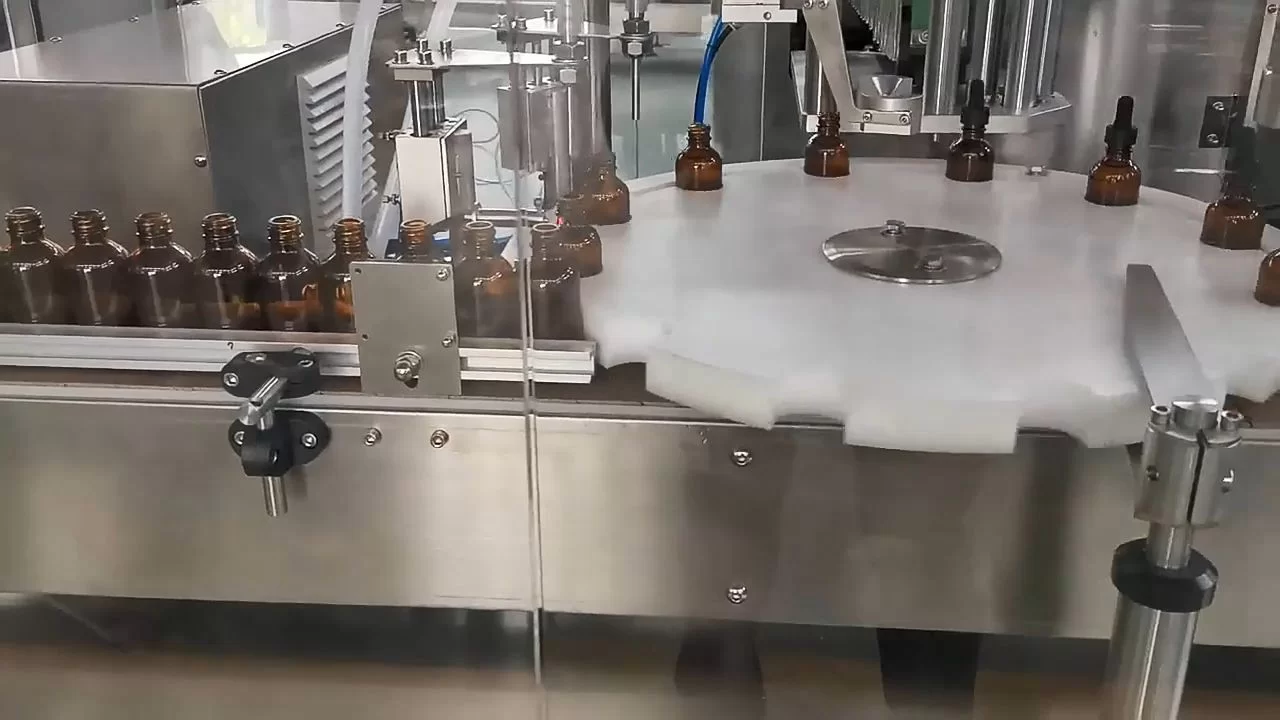

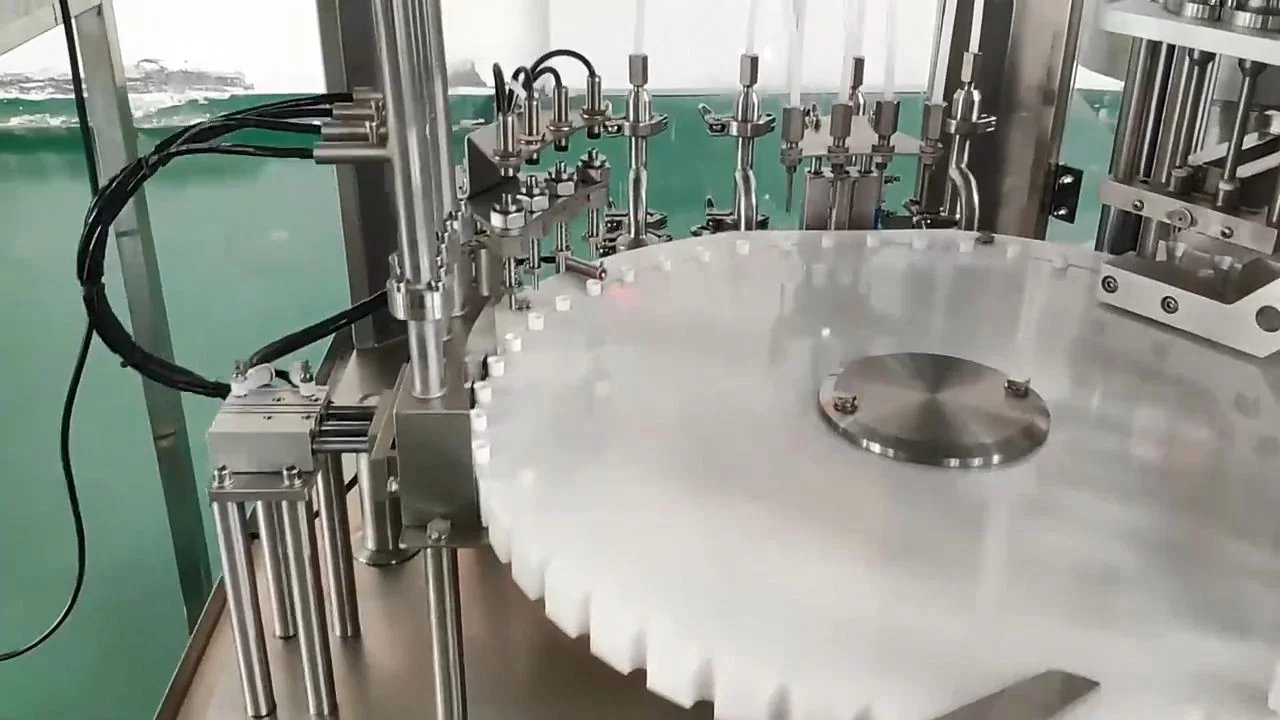

The machine comprises of several components, including a bottle feeding system, a filling system, a capping system, and a control system. The bottle feeding system uses a conveyor belt to transport empty bottles to the filling station, where the filling system precisely dispenses the essential oil into each bottle. The capping system then applies the caps onto the bottles before they are discharged onto another conveyor belt.

The filling system uses advanced technology to ensure accurate filling of the bottles to the desired levels. This technology includes a piston filling mechanism, which allows for precise measurement and control of the essential oil volume. The capping system utilizes a variety of cap handling mechanisms, including screw caps, pump caps, and spray caps, to cater to the different capping requirements of the various essential oil bottle types.

The machine is highly customizable and can be tailored to suit specific filling and capping requirements. For instance, it can be fitted with a labeling system that applies labels onto the bottles after filling and capping. The control system is also customizable, and it allows for the programming of various filling and capping parameters, such as the filling volume, filling speed, and capping torque.

Overall, the custom automated bottle essential oil liquid filling capping machine is an indispensable piece of equipment for any essential oil manufacturer. It ensures that the filling and capping process is fast, accurate, and reliable, thus maximizing production efficiency and minimizing downtime.