Quick Description

- Type: LABELING MACHINE

- Applicable Industries: Hotels, Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Food & Beverage Shops

- Showroom Location: Egypt, Philippines

- Condition: New

- Application: Food, Beverage, Commodity, Medical, Chemical

- Packaging Type: Bottles

- Packaging Material: Plastic, Metal, Glass, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V/50HZ

- Place of Origin: Shanghai, China

- Brand Name: VKPAK

- Dimension(L*W*H): 2000mmx850mmx1500mm

- Weight: 165 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Capacity: 0-50BPM

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing

- Product name: Round Bottle Labeling Machine

- Applicable label length: 20mm ~ 200mm

- Applicable label backing paper width: 20mm ~ 160 (100) mm

- Applicable product size (round bottle): diameter :20~80mm; height: 30~280mm

- Applicable standard roll outer diameter: 300mm; applicable standard roll inner diameter: 76mm;

- Labeling accuracy: ±1.0mm

- Labeling speed: 0 ~ 300pcs / min (depending on the size of the bottle and the label)

- Conveying speed: 5-20m/min

- Bottle type: Round Glass Pet Bottle

- Company type: Integration of industry and trade

More Details

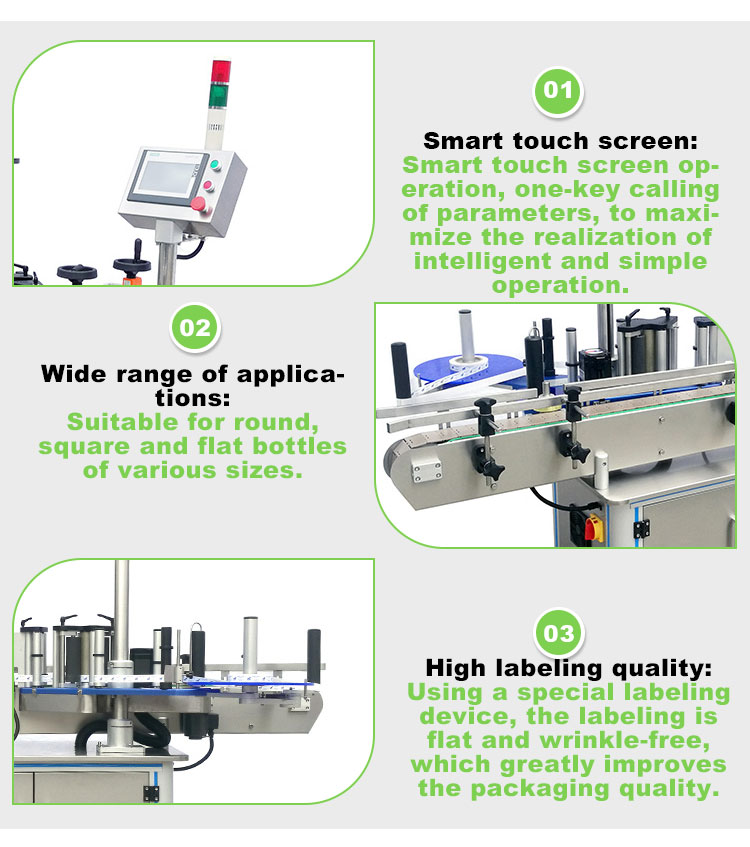

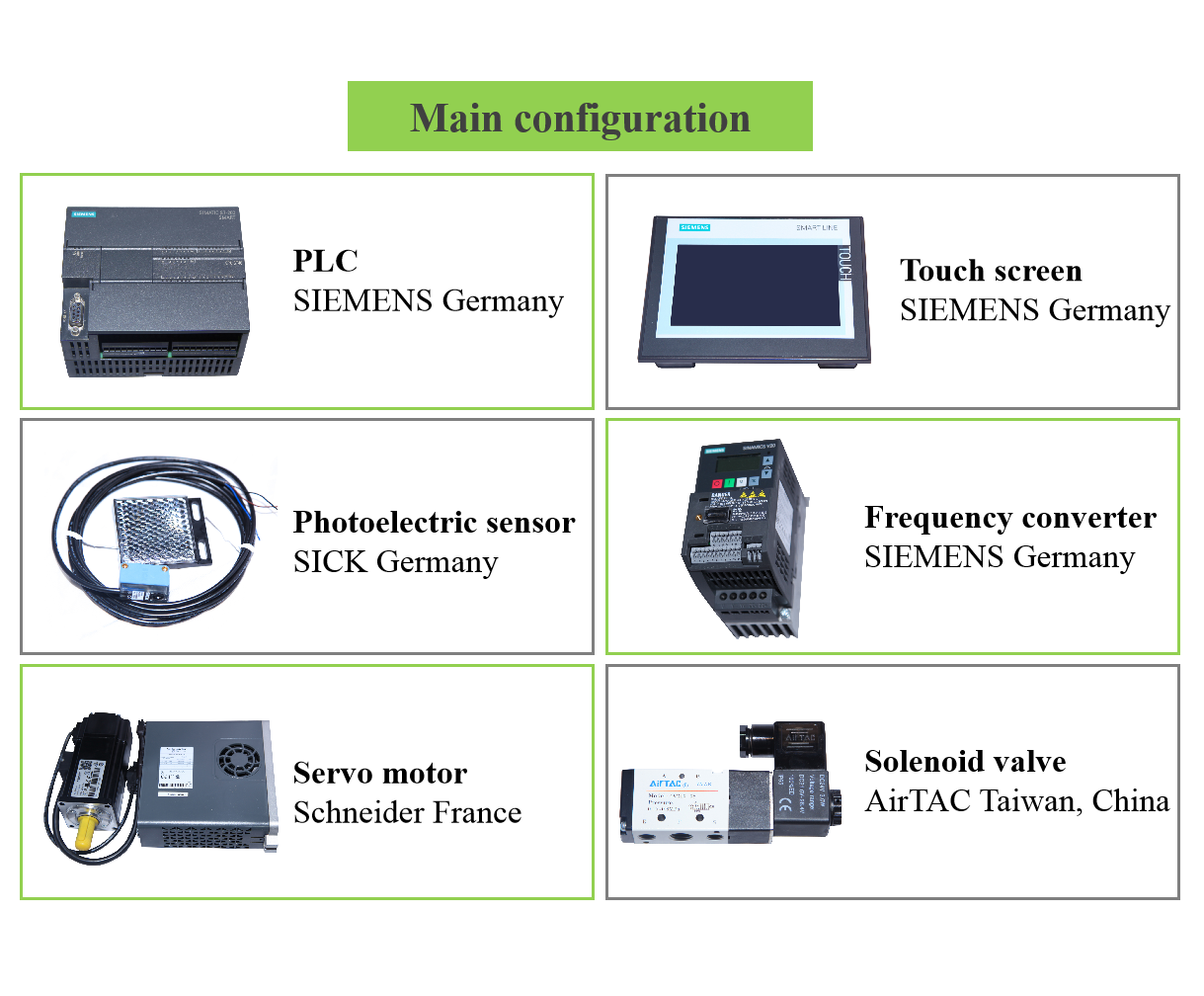

This labeling machine is equipped with computer touch screen which layout very large scale integrated circuit .it is controlled by micro-computer with Chinese character touch screen, realized the man-machine communication .Micro-computer configuration is helpful for all data input by touch screen and also for all-round control the running condition once machine started.

The Main Features:

1. Shift production count: every shift that label count, available unit effective control of production quantity.

2. class yield preset: pre-set need production. When you get to the set value after they stop.

3. Stop automatically once labels used up: it can alarm once all labels used up.

4. Centralized control of speed adjustment motor: Controller can directly control speed of each speed adjustment motor, start and stop.

5. Motion menu with Chinese information cue: different contents show for different interface on touch screen realized motion menu, all round alarm and vividly explained with Chinese or English.

6. Data power-off reserve: Controller can protect the parameter setting and statistical data to avoid data lost if machine was shut down by accident.

7. Indication of malfunction: monitor many fault in labeling procedure, machine will be shut down automatically with alarmed, and red light on once system break down.

| Technical Parameter | |

| Model | Vertical Round Bottle Labeling Machine |

| Suitable label | L: 10-290mm; W: 10-160mm |

| Suitable bottle | Diameter: 20-90mm; H: 20-200mm |

| Suitable label roll | Inner Diameter: 76mm Outer diameter: 280mm |

| Labeling precision | ±1% |

| Labeling speed | 0-300 bottles/min |

| Conveyor moving speed | 5-50 m/min |

| Power | 220V 50Hz 700W |

| Net weight | 165KG |

| Machine size | L2000*W850*H1500mm |

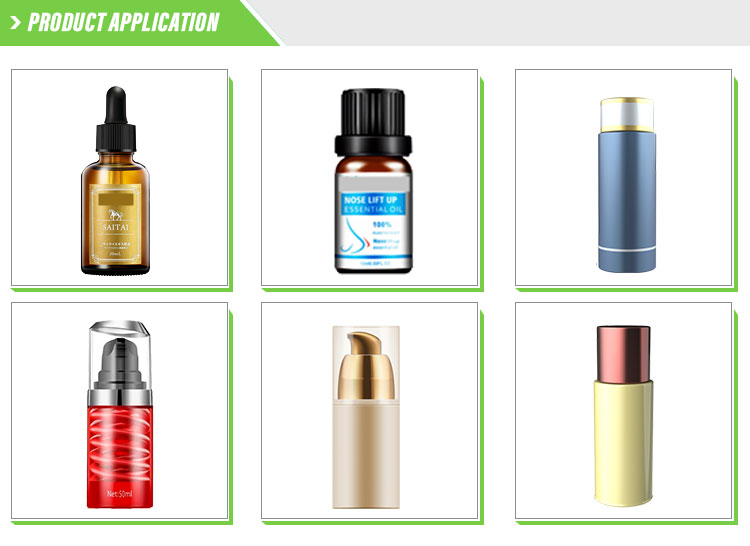

Wide Range of Applictions

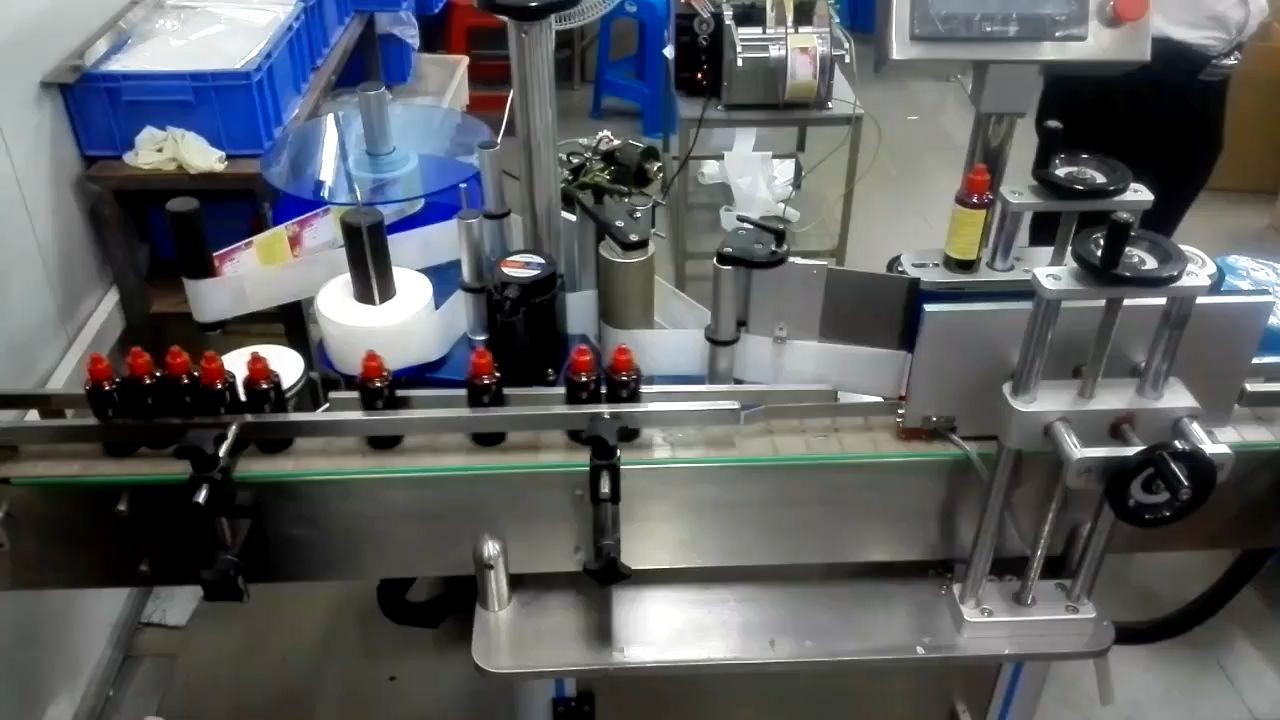

Details Images

FAQ

Q: What industry is your product suitable for?

A: The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A: Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q: What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method