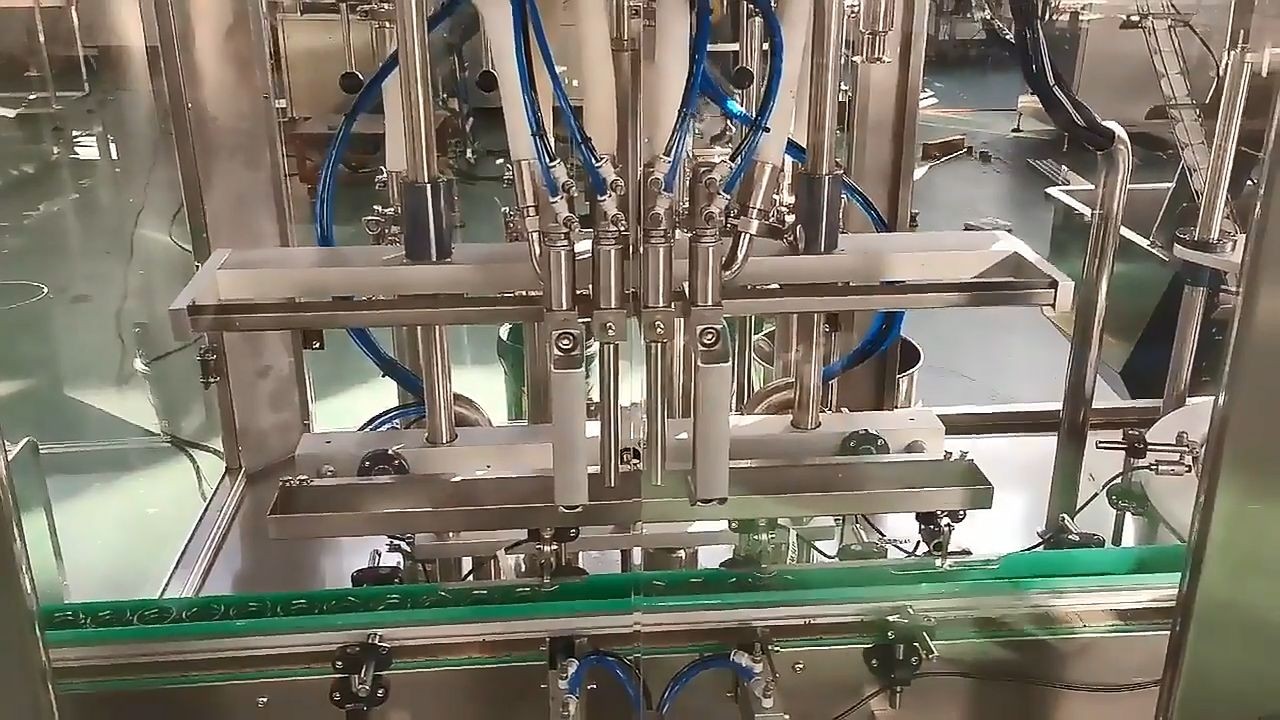

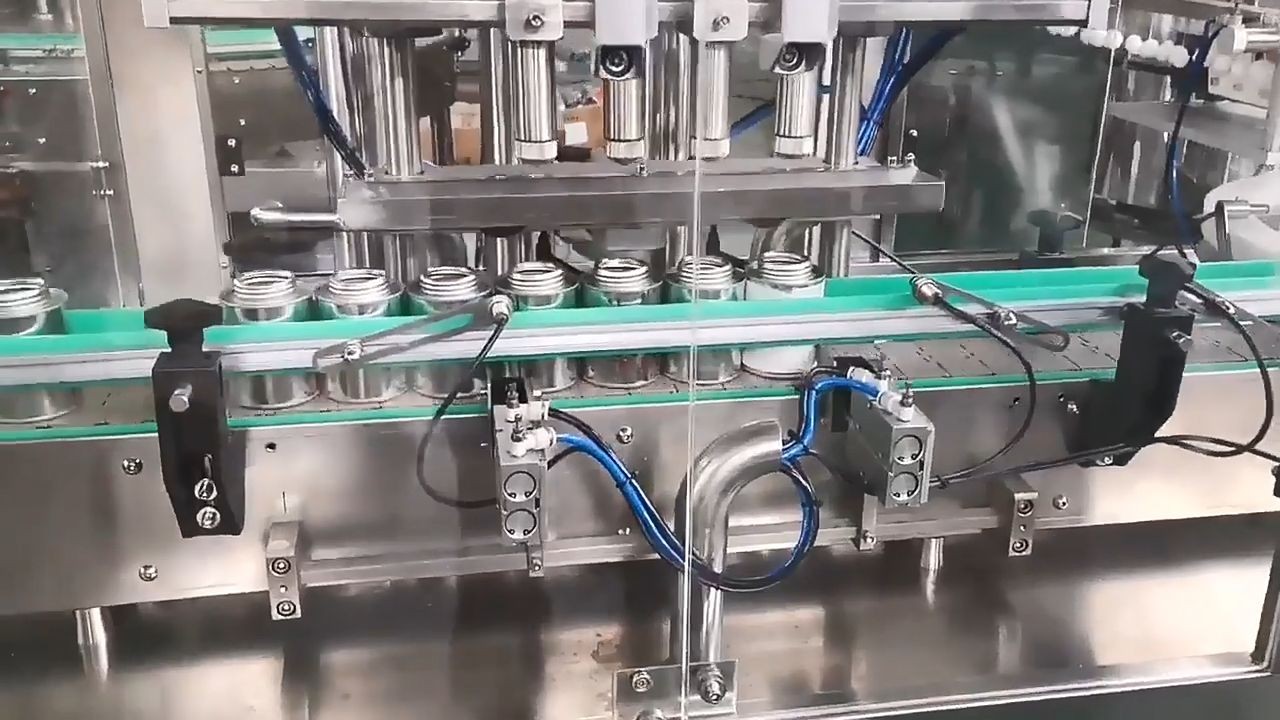

The Customized Automatic Linear Bottles Versatile Filling Capping Machine is a highly efficient and versatile packaging equipment that is designed for use in the food, beverage, pharmaceutical, and cosmetic industries. This filling capping machine is engineered to fill and cap a wide range of bottles, including plastic, glass, and metal bottles, at high speeds with precision and accuracy.

The machine is fully automatic and can be customized to meet specific production requirements. It has a linear design that allows for easy integration into an existing production line, and it is equipped with advanced technology that ensures consistent performance and reliability.

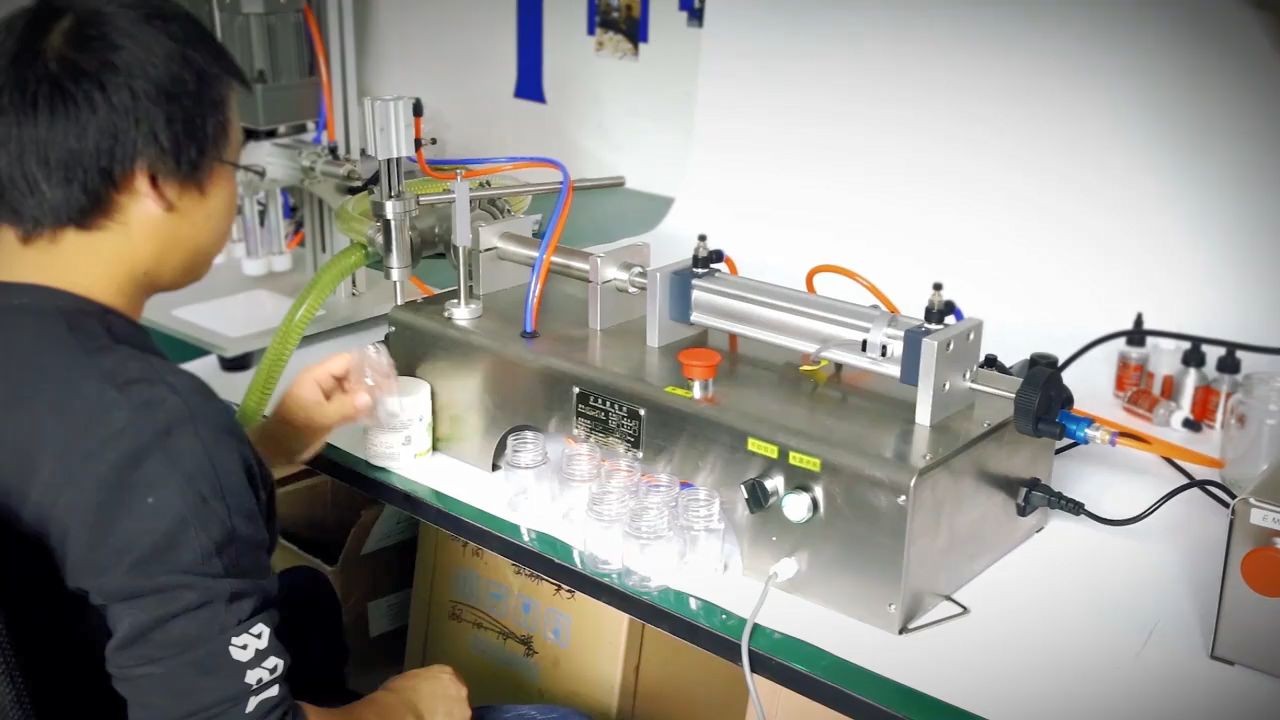

One of the major advantages of the Customized Automatic Linear Bottles Versatile Filling Capping Machine is its versatility. It can handle a wide range of products, including liquid, semi-liquid, and viscous products, as well as powders, granules, and tablets. This makes it an ideal choice for manufacturers who need a flexible packaging solution that can adapt to changing production needs.

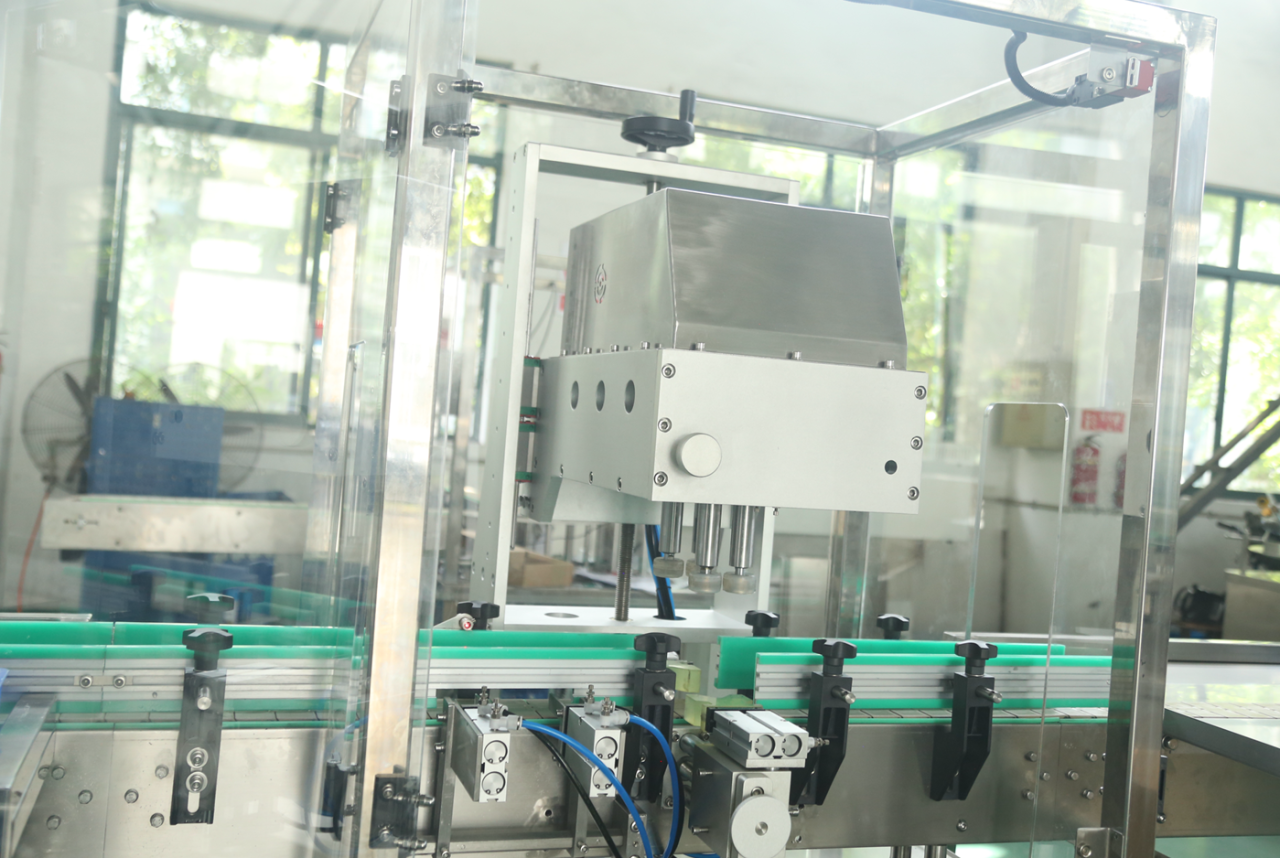

The machine is also designed with user safety in mind. It has a safety interlock system that prevents access to moving parts during operation, and it is equipped with an automatic stop system that shuts down the machine if any abnormality is detected.

In terms of characteristics, the Customized Automatic Linear Bottles Versatile Filling Capping Machine is equipped with a high-precision filling system that ensures accurate filling levels, and a capping system that ensures tight and secure closure of the bottles. It also has a user-friendly interface that allows for easy operation and maintenance.

The Customized Automatic Linear Bottles Versatile Filling Capping Machine is an important product in the packaging equipment industry, and its development has been driven by the need for high-speed and flexible packaging solutions. With its advanced technology and versatility, it is an ideal choice for manufacturers who need a reliable and efficient packaging solution for their products.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Other, Advertising Company

- Showroom Location: Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Brazil, Saudi Arabia, Mexico, Russia, Spain, Thailand, Argentina, South Korea, Kazakhstan, Malaysia, Australia

- Application: Food, Beverage, Commodity, Chemical

- Packaging Type: Barrel, Bottles, CANS, Other

- Packaging Material: Metal, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 110V 220V 380V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2200*900*1800mm

- Weight: 600 KG

- Warranty: 6 Months, Six months free

- Key Selling Points: Multifunctional

- Filling Material: Other, Water, Oil

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 6 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Machine Name: Versatile filling capping machine

- Yield: 1000-8000BPH

- Driving: Servo motor

- Diameter range of applicable cap: 10-35mm

- Metal Quality: SS304 and SS316

- Work voltage: 110/220/380V 50/60HZ

- Power: 1-2KW

- package: Wooden case

- After-sales Service Provided: Online technical support

More Details

Main technical parameter:

| Product Name | Versatile capping machine |

| Yield | 1000-8000BPH (Customized) |

| Diameter range of applicable cap | 10-35mm |

| Work voltage | 110/220/380V 50/60HZ |

| Air pressure | 0.6MPA |

| Power | 2.2KW |

| Driving | Servo motor |

| United size | 2200*900*1800mm |

| Single machine noise | ≤60dB |

| Weight | 600KG |

| Material | SS304 SS316 |

| HMI | 7.5” Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Speed controller | Variable Speed Controls |

| Detecting system | Vial Detector & Counter |

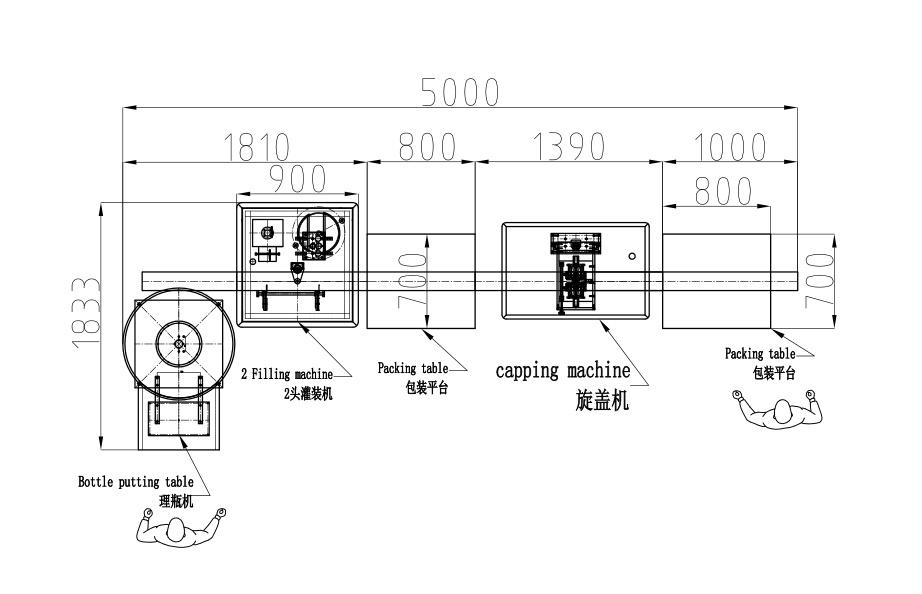

Layout design

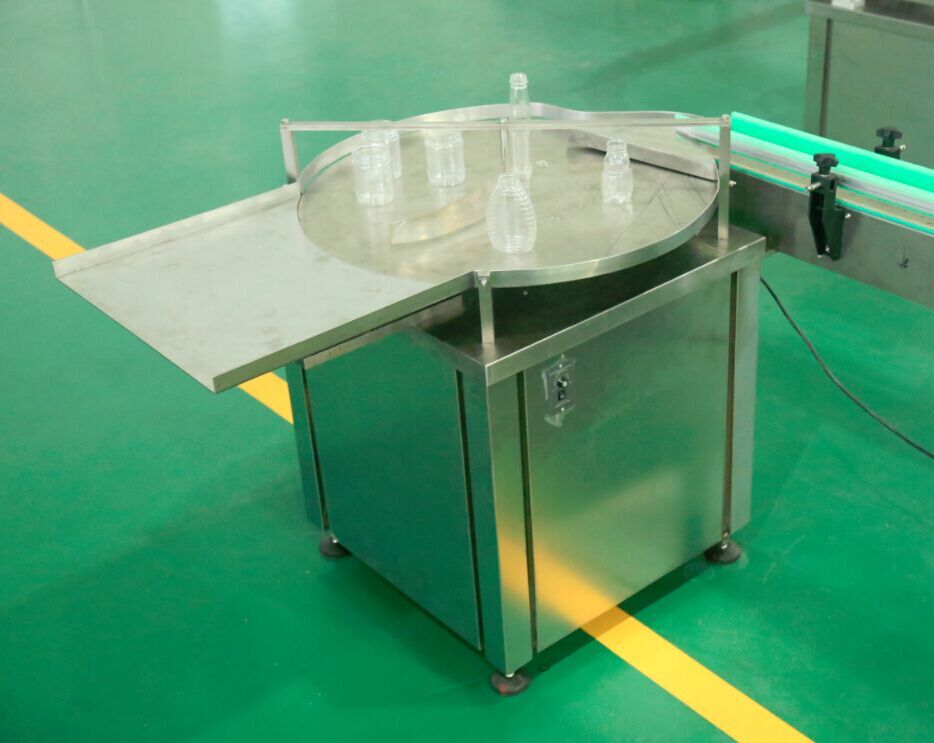

Bottle feeding table

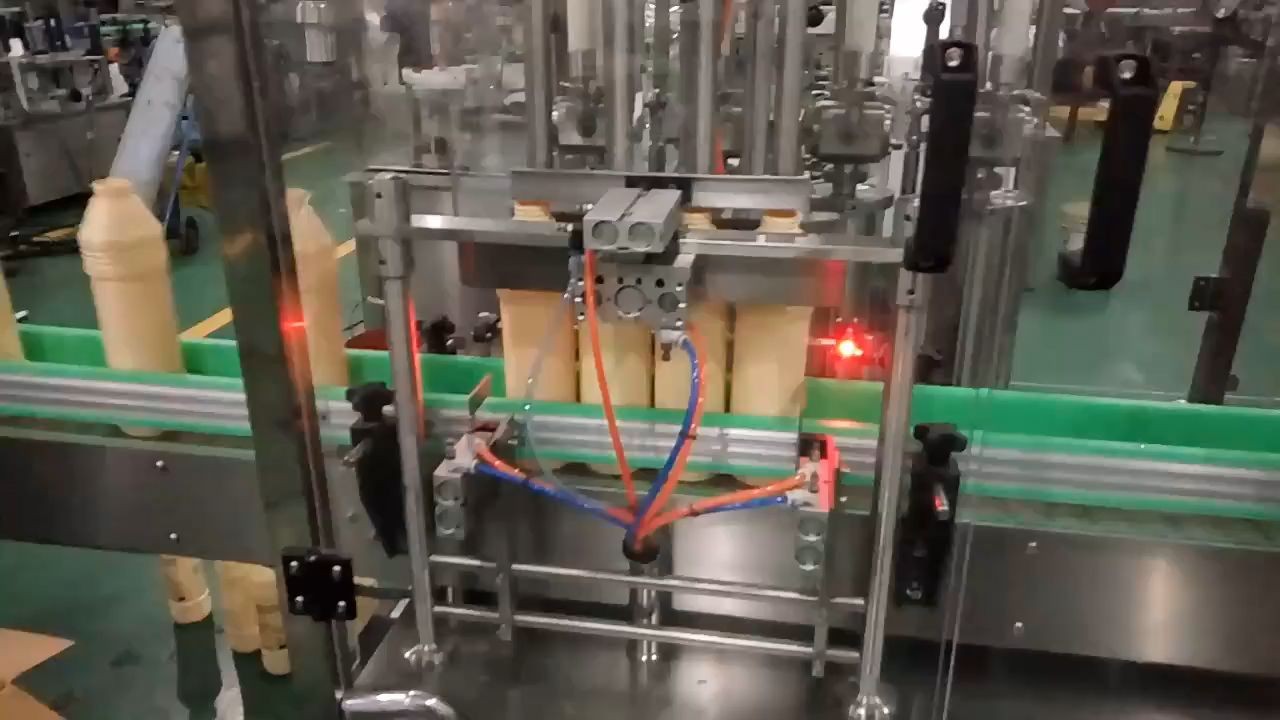

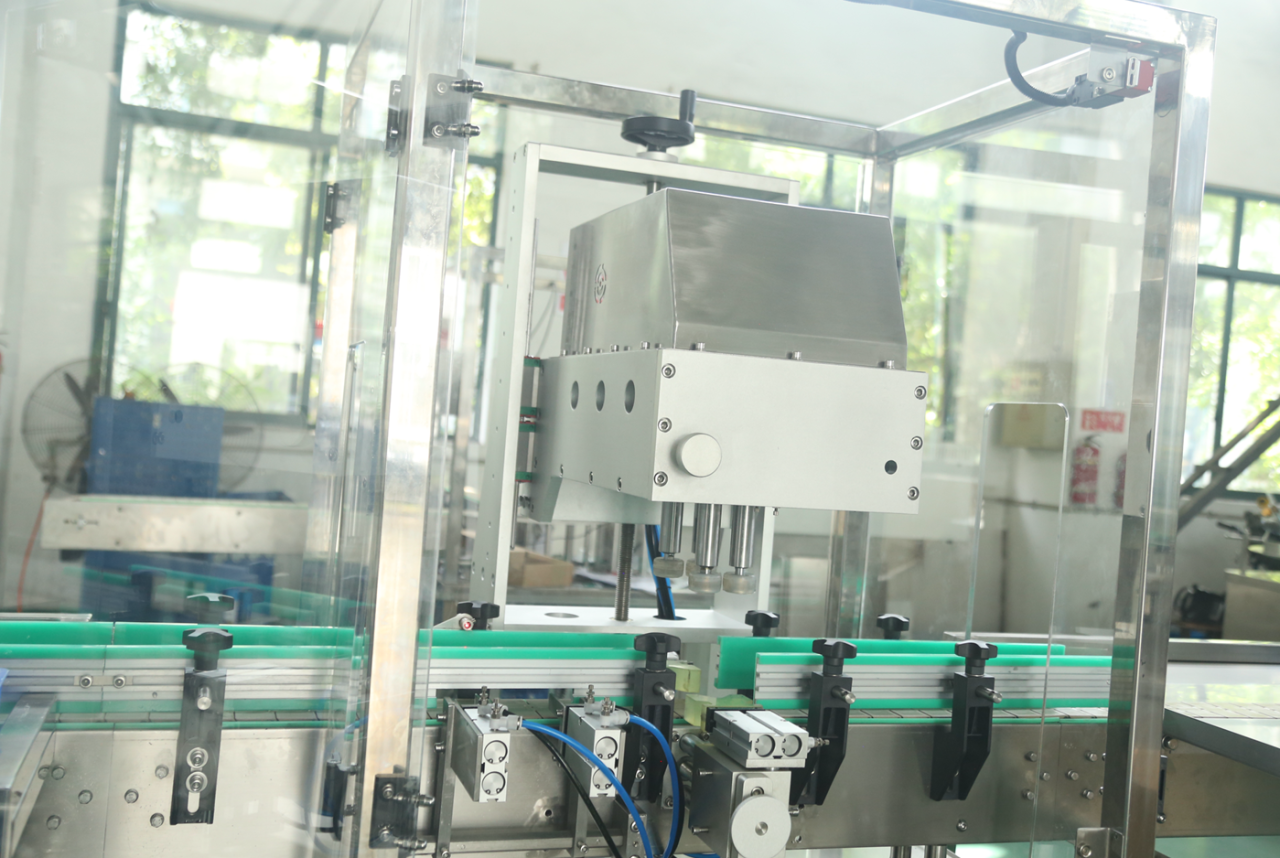

Capping station