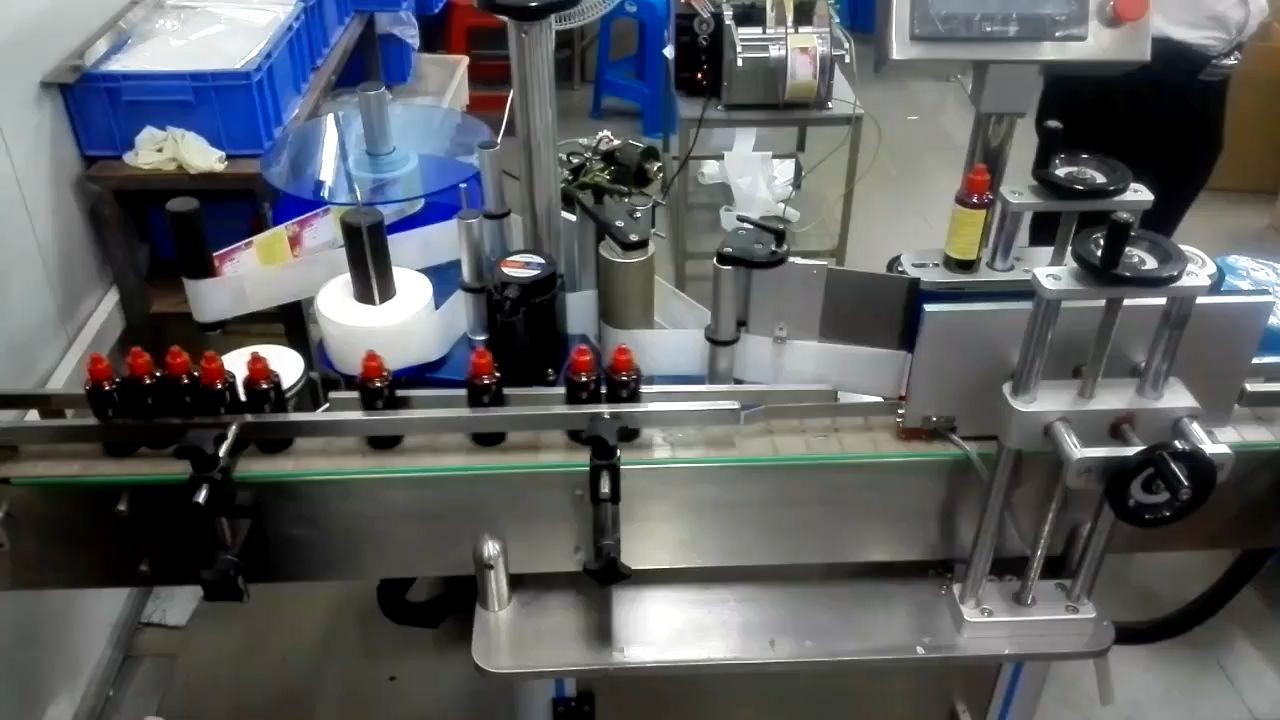

The Desktop Small Round Glass Bottle Sticker Labeling Machine is a specialized device that is designed to apply stickers or labels onto small round glass bottles with precision and accuracy. This machine is commonly used in industries such as cosmetics, pharmaceuticals, and food and beverage, where small glass bottles are frequently used as packaging.

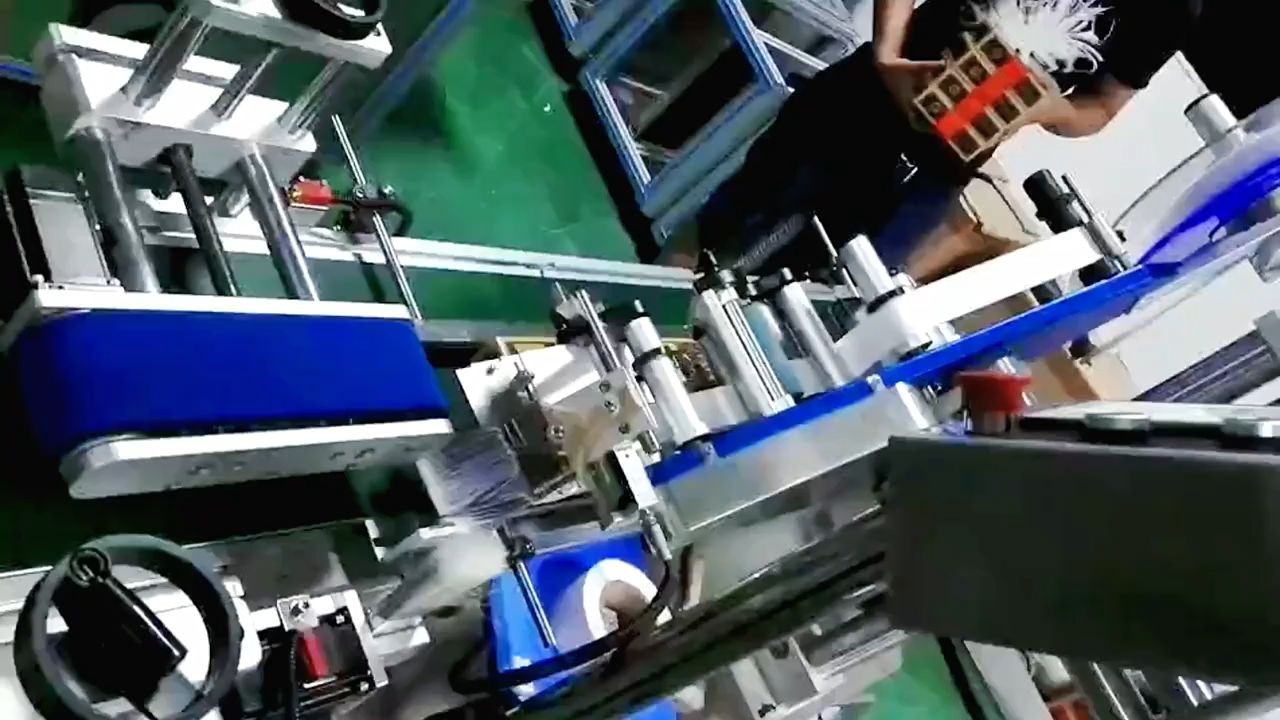

The machine is equipped with an advanced labeling system that can apply labels onto bottles of various sizes and shapes. It uses high-precision sensors to detect the bottle's position and orientation, ensuring that the label is applied in the correct position and with the proper tension.

The labeling process is highly efficient, with the machine capable of labeling up to 40 bottles per minute. This makes it an ideal solution for businesses that require high-volume production runs.

One of the key benefits of the Desktop Small Round Glass Bottle Sticker Labeling Machine is its versatility. It can handle a variety of different bottle sizes and shapes, making it an ideal solution for businesses that produce a range of different products. The machine can be easily adjusted to accommodate different bottle sizes and shapes, ensuring that the labeling process is always accurate and efficient.

Another benefit of the machine is its ease of use. It is designed to be user-friendly, with a simple interface that allows operators to easily set up and run the machine. This minimizes the need for extensive training, making it easy for businesses to integrate the machine into their existing production lines.

The machine is also designed to be durable and reliable, with a sturdy construction that is built to withstand the rigors of heavy-duty production environments. This ensures that the machine operates consistently and reliably, with minimal downtime or maintenance requirements.

Overall, the Desktop Small Round Glass Bottle Sticker Labeling Machine is an efficient, versatile, and reliable solution for businesses that require high-quality labeling for their small round glass bottles. Its advanced features and user-friendly design make it an ideal investment for businesses looking to streamline their production processes and increase their labeling efficiency.

Quick Description

- Type: LABELING MACHINE

- Applicable Industries: Food & Beverage Factory, Farms, Home Use, Retail, Printing Shops, Energy & Mining, Advertising Company

- Showroom Location: Egypt, Philippines

- Condition: New

- Application: Food, Beverage, Commodity, Medical, Chemical

- Packaging Type: Bottles

- Packaging Material: Plastic, Metal, Glass, Wood

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V/50HZ

- Dimension(L*W*H): 1200*930*720mm

- Weight: 100 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life, Essential oil, cosmetics, small bottle labeling machine

- Machinery Capacity: 0-50BPM, About 20-40 bottles/min

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: PLC, Other, Motor, Bearing

- Product name: Small bottle labeling machine, round paste

- Labeling accuracy: ±1.0mm

- Suitable Label Size: 15-140mm(W)*25-300mm(L)

- Suitable Bottle Diameter: About 30-100mm

- Roll Inside Diameter(mm): 75mm

- After-sales Service Provided: Online support, Free part replacement

- Bottle type: Round Glass Pet Bottle

- Company type: Integration of industry and trade

More Details

Introduction:

This automatic labeling machine is suitable for round bottles of different sizes and materials. It is widely used in round and conical bottles in food, cosmetics, electronics, daily necessities, medicine and other industries. Automatic photoelectric tracking and identification of bottles, no labeling without objects. Using well-known brand components, high-quality stainless steel, reliable quality.

Characteristics:

1. High resolution and large-size man-machine interface with PLC control, touch operation, intuitive and easy to use;

2.The power shaft adopts wear-resistant natural soft rubber, and the cylinder pressure roller mechanism improves the labeling accuracy. It is used for round bottle labeling, with high repeated labeling accuracy;

3. Positioning labeling is adopted, which can be positioned and labeled on the product, one label at a time or symmetrically before and after labeling;

4. Multi group labeling parameter memory, which can quickly change the production of products;

5.The production line can be connected according to the needs of customers, or the feeding equipment can be purchased.

| Technical parameters | |

| Applicable product range | φ10-85mm, unlimited height |

| Applicable label range | 10-100mm width, 10-250mm length |

| Labeling speed | 5-40m/minute |

| Filling speed | 20-30 bottles/min |

| Labeling accuracy | ±1% |

| Voltage | 220V/50Hz |

| Power | 1.3KW |

| Conveyor belt width | 90mm wide PVC conveyor belt, speed 5-20m/min |

| Conveyor belt off the ground | 320 mm ± 20 mm adjustable |

| Inner diameter of paper roll | 76mm |

| Outer diameter of paper roll | max.300mm |