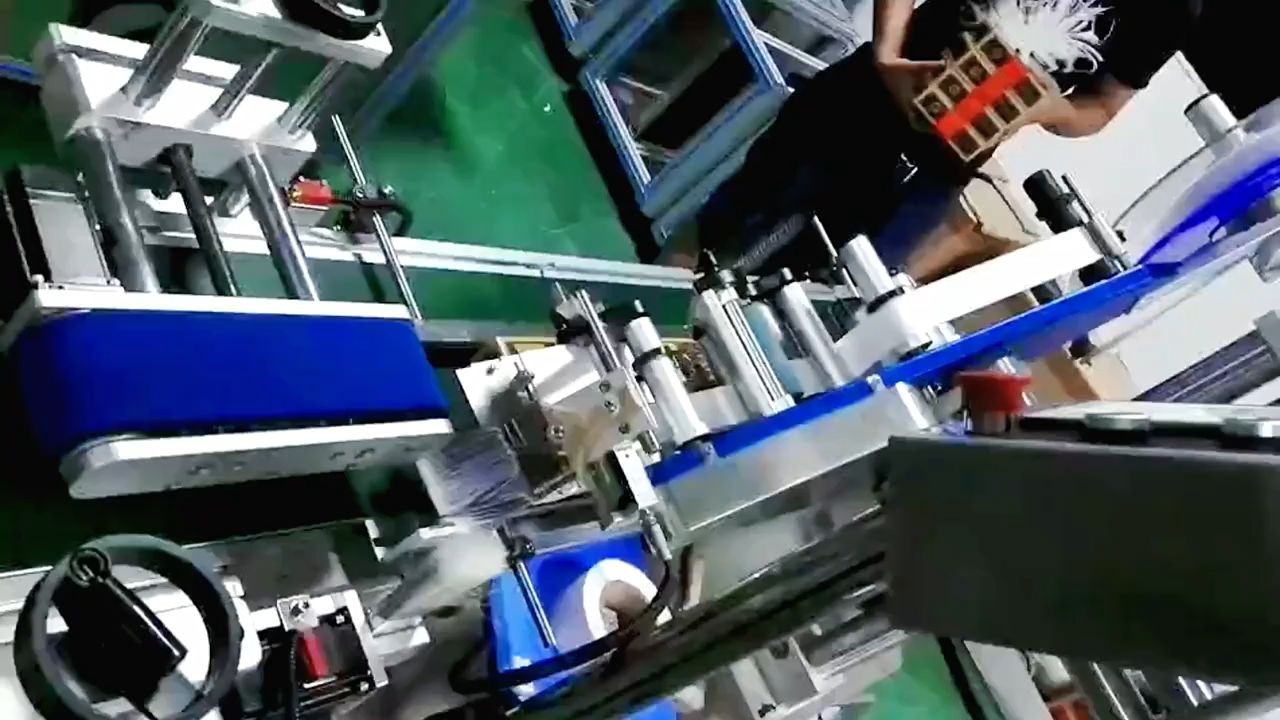

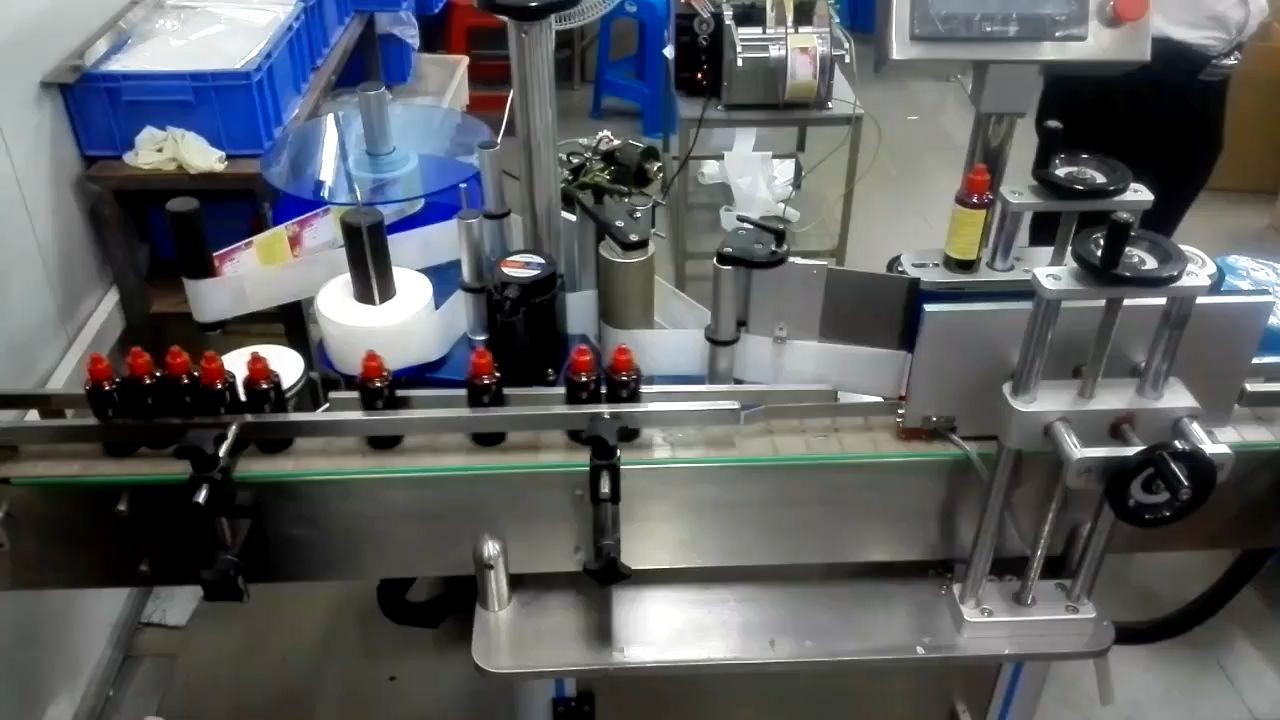

Automatic double sides labelling machine also called front and back labelling machine, double sides labeller, it is application for labelling round, square, flat and unshaped and shaped bottles & containers.

| Labeling Speed | 60-350pcs/min (Depending on label length and bottle thickness) | ||

| Height of Object | 30-350mm | ||

| Thickness of Object | 20-120mm | ||

| Height of Label | 15-140mm | ||

| Length of Label | 25-300mm | ||

| Label Roller Inside Diameter | 76mm | ||

| Label Roller Outside Diameter | 420mm | ||

| Accuracy of Labeling | ±1mm | ||

| Power Supply | 220V 50/60HZ 3.5KW Single-phase | ||

| Gas Consumption of Printer | 5Kg/cm^2 | ||

| Size of Labeling Machine | 2800(L)×1650(W)×1500(H)mm | ||

| Weight of Labeling Machine | 450Kg | ||

The Full Automatic High Speed Wine Bottle Labeling Machine is a state-of-the-art piece of equipment designed to meet the labeling demands of the wine industry. This machine is fully automatic, capable of handling high-speed labeling operations with ease.

One of the most notable features of this machine is its speed. The high-speed labeling process enables the machine to label wine bottles quickly and efficiently. This ensures that production lines can run at optimal speeds, minimizing downtime and maximizing output.

In addition, the machine is designed to handle a wide range of bottle sizes and shapes, making it versatile and adaptable to different labeling needs. This allows for greater flexibility in production, as it eliminates the need for multiple labeling machines to handle different bottle sizes and shapes.

The wine bottle labeling machine is also designed with accuracy in mind. The high-precision label application process ensures that each label is applied with consistency and accuracy, eliminating errors and ensuring a professional finish on every bottle.

The machine's user-friendly interface and simple operation also make it easy for operators to use. The touch screen panel allows for easy adjustments and control, making it simple to set up and operate the machine, even for those with little to no experience.

The machine's construction is also worth noting. It is made from high-quality materials, ensuring durability and reliability in operation. Its low maintenance requirements also help to minimize downtime and reduce maintenance costs.