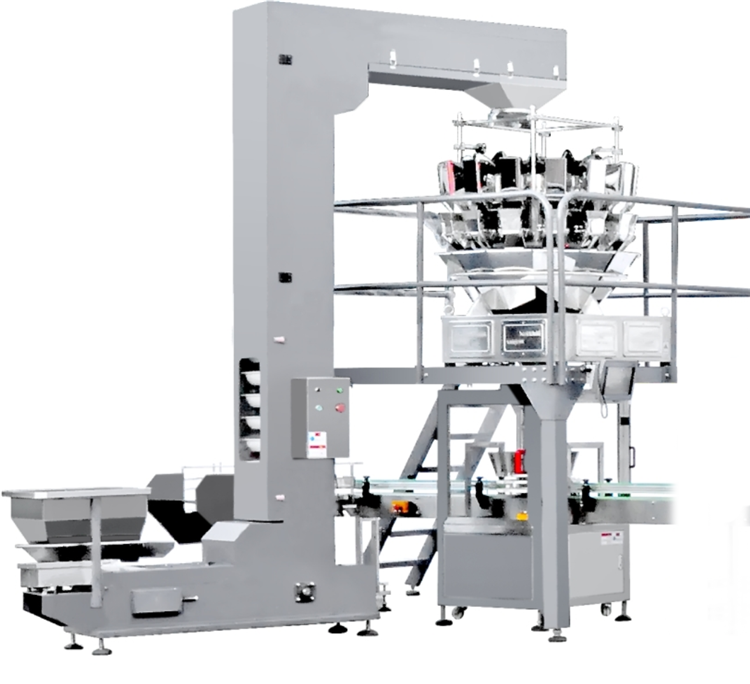

The Granule Coffee Grain Nuts Bottle Weighing Filling Packing Machine is an advanced device that is designed to accurately weigh, fill, and pack granule products such as coffee, grain, nuts, and other small-sized products into bottles. The machine uses advanced technology to ensure that the products are weighed accurately and filled into bottles quickly and efficiently.

The machine is equipped with a high-precision weighing system that ensures that the products are weighed accurately. The weighing system can be calibrated to accommodate different product weights and sizes, making it ideal for businesses that require flexibility in their packaging process.

The filling process is also highly efficient, with the machine capable of filling up to 60 bottles per minute. This makes it an ideal solution for businesses that require high-volume production runs.

One of the key benefits of the Granule Coffee Grain Nuts Bottle Weighing Filling Packing Machine is its versatility. It can handle a variety of different product types and sizes, making it an ideal solution for businesses that produce a range of different products. The machine can be easily adjusted to accommodate different product weights and sizes, ensuring that the packaging process is always accurate and efficient.

Another benefit of the machine is its ease of use. It is designed to be user-friendly, with a simple interface that allows operators to easily set up and run the machine. This minimizes the need for extensive training, making it easy for businesses to integrate the machine into their existing production lines.

The machine is also designed to be durable and reliable, with a sturdy construction that is built to withstand the rigors of heavy-duty production environments. This ensures that the machine operates consistently and reliably, with minimal downtime or maintenance requirements.

Overall, the Granule Coffee Grain Nuts Bottle Weighing Filling Packing Machine is an efficient, versatile, and reliable solution for businesses that require high-quality packaging for their granule products. Its advanced features and user-friendly design make it an ideal investment for businesses looking to streamline their production processes and increase their packaging efficiency.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: custom

- Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Retail, factory

- Showroom Location: None

- Application: Food, Beverage, Commodity, Chemical, Machinery & Hardware, Weighing Candy Granule Coffee Grain Nuts Filling Packing

- Packaging Type: CANS, Bottles, Barrel, Stand-up Pouch, Bags

- Packaging Material: Plastic, Metal, Glass, bottle/can

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Dimension(L*W*H): customized size

- Weight: 500 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Filling Material: Weighing Candy Granule Coffee Grain Nuts

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: standard

- Product name: Weighing Candy Granule Coffee Grain Nuts Filling Packing Machine

- Filling nozzle quantity: 1

- Filling volume: According to customer samples

- Filling capacity: 30BPM

- Air pressure: 0.6-0.8MPa

- Desiccant parcel size: 15-30*40-60mm

- Cap feeding way: Pneumatic feeding

- Cap distributor way: Lift

- Label precision: ±1

More Details

This Automatic Filling Line can be customized to fill various products,such as candy, nuts, plum, jelly, soy, etc.

Equipment Brief Introduction:

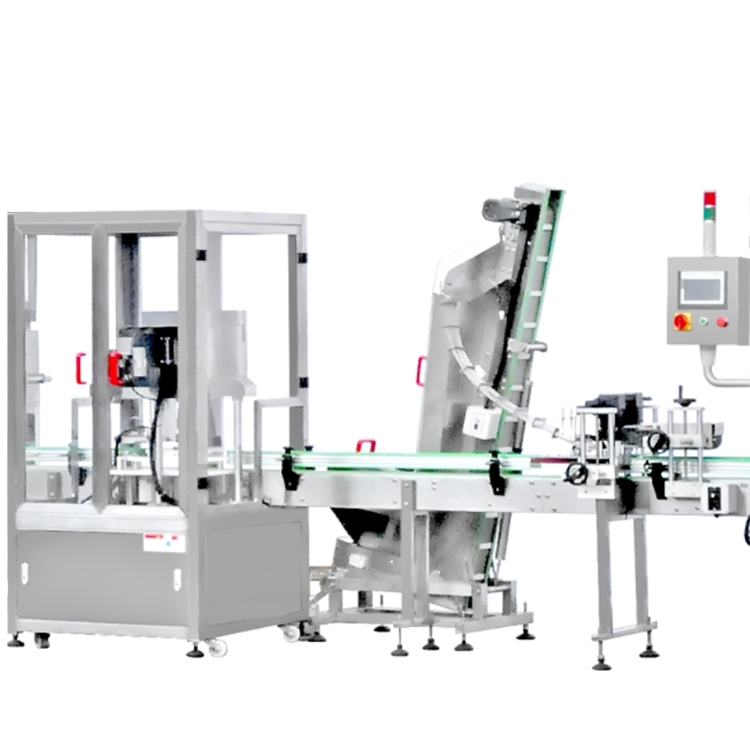

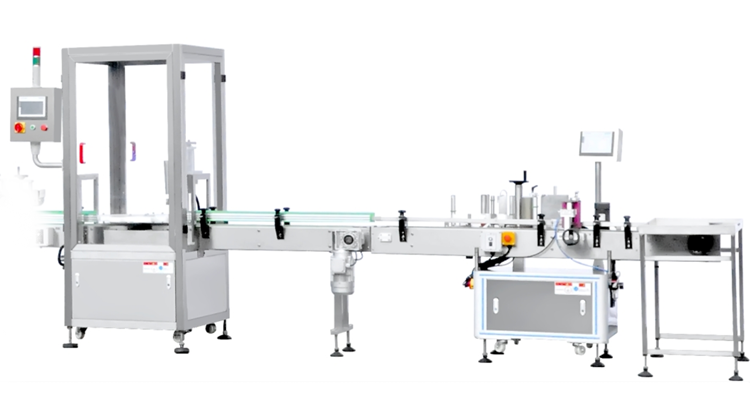

This Production Line Includes A Turn Table, A Capping Machine, A Multiple Weigh Filler, A Chuck Type Filling Machine, A Desiccant Parcel Delivery Machine, A Chuck Type Can Sealing Machine, A Automatic Screw Capping Machine And A Vertical Round Bottle Labeling Machine ;

The Machine Type, Number Of Machines, Speed, Capacity, Size, Etc. Of The Production Line Can Be Customized According To The Customer's Production Needs; We Can Develop A Professional Integrated Filling And Packaging Production Line Plan For The Customer.

| Parameters of Turn Table | |

| Suitable bottles | According to customer samples |

| Turn table diameter | 900mm, H: 750mm |

| Power | 220V, 140W, 50HZ, single phase |

| Parameters of Multiple Weigh Filler | |

| Each time weigh range | 10-1000g |

| Max weigh weight | 6500g |

| Average bag error | 0.2-0.7g |

| Weigh precision | 0.1-1.5g |

| Max weigh speed | 1200BPH (1000g) |

| Tank | Twin row no memory tank, volume: 2500ml |

| Driven | Stepping motor |

| Products preset 99 groups | |

| Multiple weigh quantity | 14 |

| Filling quantity | 1 |

| Parameters of Chuck Type Filling Machine | |

| SFilling nozzle quantit | 1 |

| Suitable bottles | According to customer samples |

| Filling volume | According to customer samples |

| Filling capacity | 30BPM |

| Power | 220V, 1.5KW, 50/60HZ, single phase |

| Air pressure | 0.6-0.8MPa |

| Parameters of Desiccant Parcel Delivery Machine | |

| Desiccant parcel size | 15-30*40-60mm |

| Capacity | 30BPM |

| Power | 220V, 50H |

| Dimension | 650*650*1360mm |

| Machine weight | 100kg |

| Parameters of Chuck Type Can Sealing Machine | |

| Suitable products | According to customer samples |

| Cap feeding way | Pneumatic feeding |

| Can sealing way | Single head claw type sealing |

| Capacity | 30BPM |

| Main motor | 370W |

| Parameters of Automatic Screw Capping Machine | |

| Cap distributor way | Lift |

| Suitable products | According to customer samples |

| Capacity | 30BPM |

| Power | 800W |

| Parameters of Vertical Round Bottle Labeling Machine | |

| Suitable products | According to customer samples |

| Label position | Cycle of the round bottle |

| Label precision | ±1 |

| Capacity | 30BPM |

| Power | 220V, 800W |