Main features

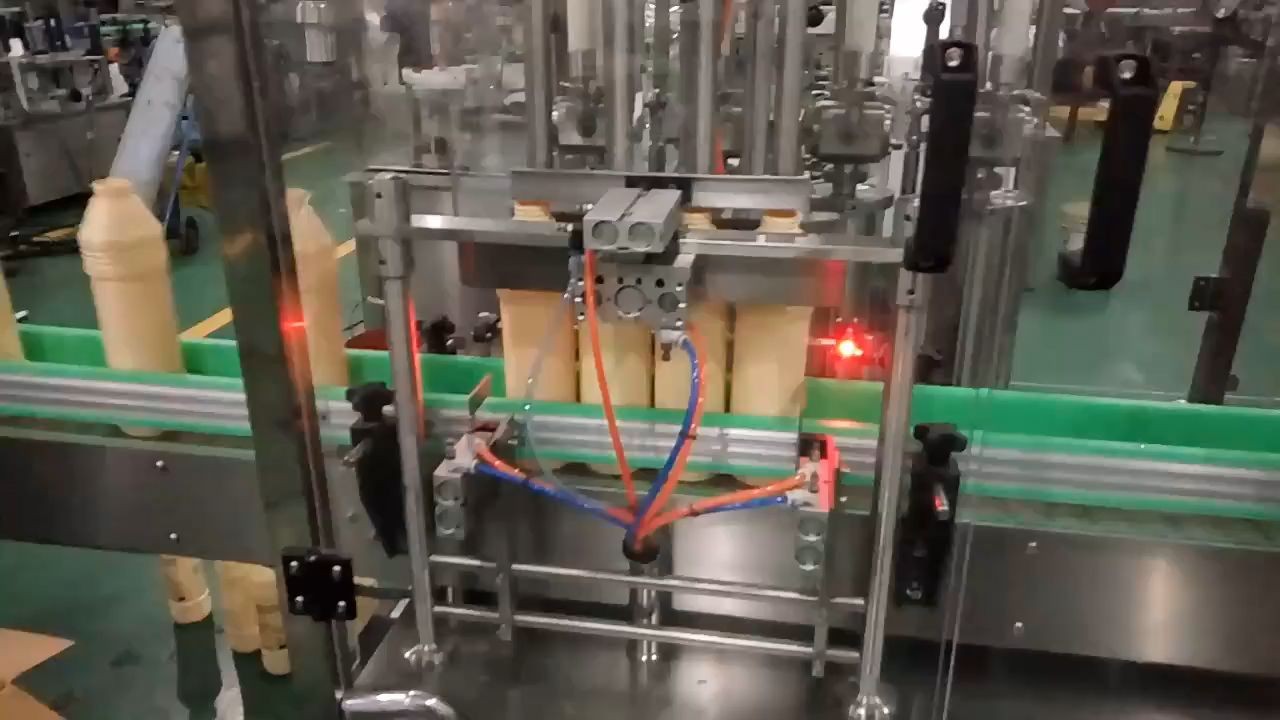

1. High degree of automation, simple operation, stable operation, can effectively save enterprise costs, improve production efficiency.

2. Each stand-alone machine can complete its work independently. It has independent operating system, digital control display and other electrical components to control and adjust various parameters and display settings. It can help enterprises realize standardized production

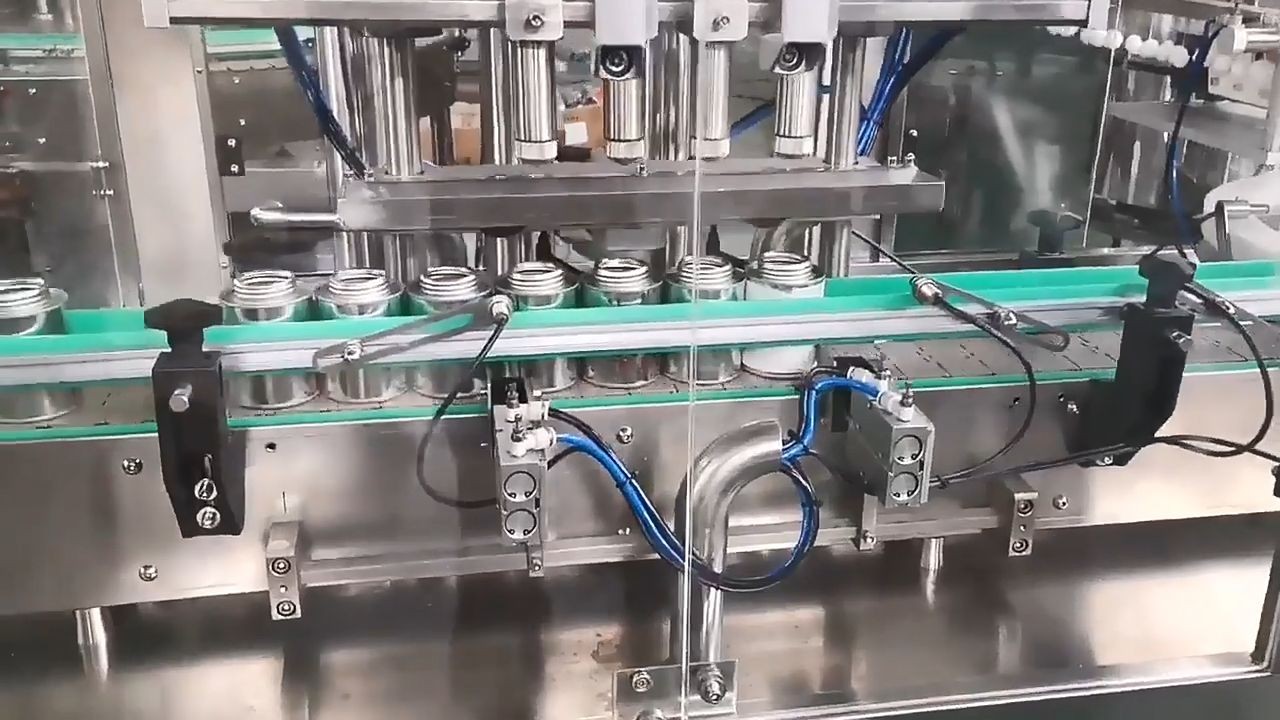

3. The single machine linkage, separation fast, and adjust fast, simple, so that each production process to ensure coordination.

4. Each stand-alone machine can adapt to the packaging of various specifications of bottles with few adjusting parts.

5. The packaging production line adopts the international new process design, in line with GMP standards.

6. The production line runs smoothly, the combination of various functions is convenient, and the maintenance is convenient

| Model | VK-2 | VK-4 | VK-6 | VK-8 | VK-10 | VK-12 | VK-16 |

| Heads | 2 | 4 | 6 | 8 | 10 | 12 | 16 |

| Range(ml) | 100-500,100-1000,1000-5000 | ||||||

| Capacity(bpm)base on 500ml | 12-14 | 24-28 | 36-42 | 48-56 | 60-70 | 70-80 | 80-100 |

| Air Pressure(mpa) | 0.6 | ||||||

| Accuracy(%) | ±0.1-0.3 | ||||||

| Power | 220VAC SINGLE PHASE 1500W | 220VAC SINGLE PHASE 3000W | |||||

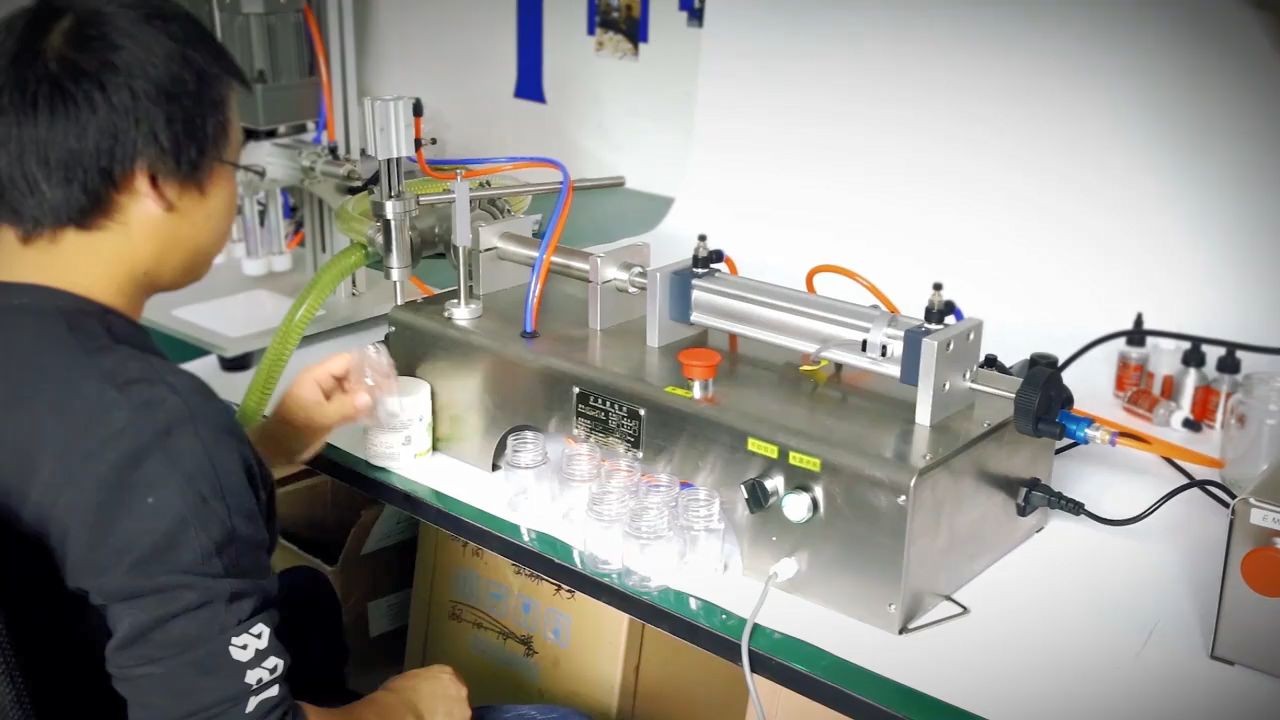

A high viscosity lotion liquid detergent soap filling machine is a specialized industrial equipment designed to automatically fill containers with high viscosity liquids such as lotions, liquid detergents, and soaps. This machine is commonly used in the cosmetics, cleaning, and personal care industries.

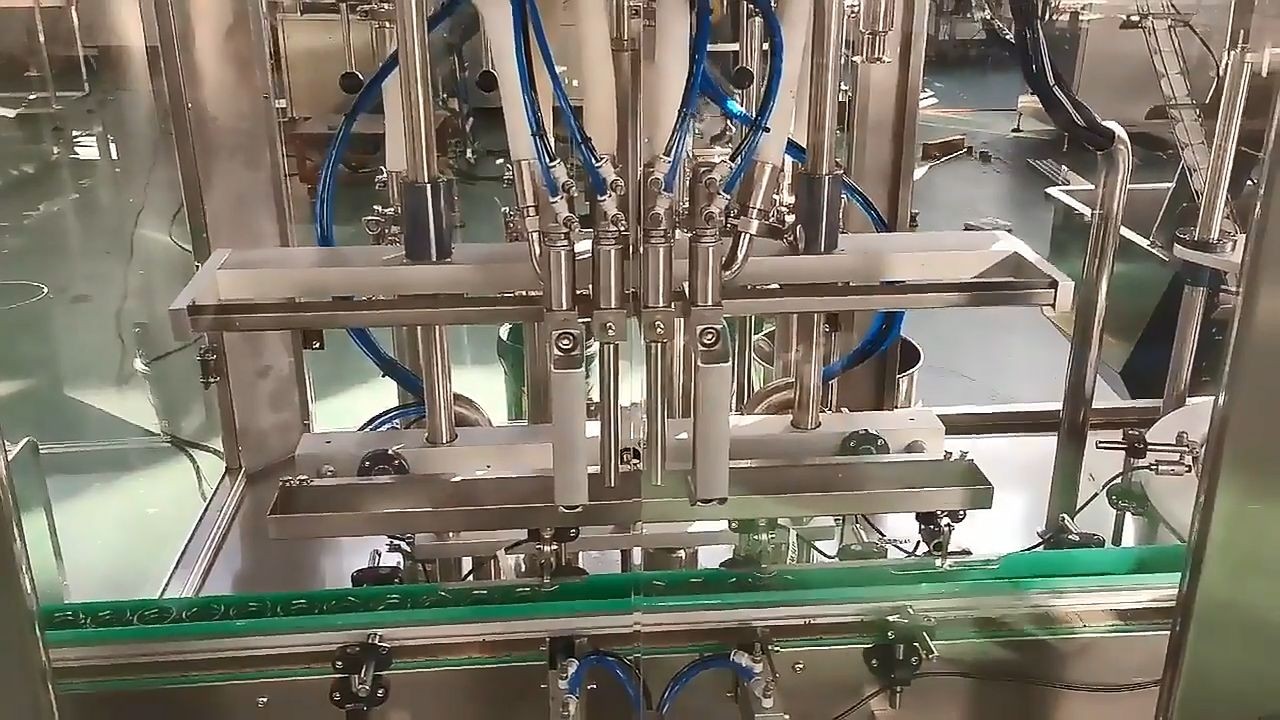

The machine works by placing empty containers onto the conveyor belt, which then moves them through the filling station. The machine uses a positive displacement pump to dispense the high viscosity liquid into the containers at a predetermined volume. This type of pump is particularly useful for filling thick or dense liquids, as it ensures consistent filling volume and minimizes the risk of spillage.

One of the key advantages of the high viscosity lotion liquid detergent soap filling machine is its high speed and accuracy. With the ability to fill multiple containers simultaneously, this machine can achieve a filling speed of up to 60 containers per minute, depending on the viscosity of the liquid. This level of automation significantly increases production efficiency, reduces labor costs, and improves overall product quality.

Another advantage of this machine is its versatility. It can handle a wide range of container sizes and shapes, thanks to its adjustable conveyor and filling head. The machine's flexibility also allows for easy switching between different types of lotions, liquid detergents, and soaps, minimizing downtime and maximizing productivity.

Additionally, the machine is equipped with a user-friendly touch screen interface that makes it easy to control and monitor the filling process. The interface allows operators to adjust the filling volume, conveyor speed, and other settings, ensuring optimal performance and efficiency.

Overall, a high viscosity lotion liquid detergent soap filling machine is an essential piece of equipment for any company that needs to fill large quantities of containers with high viscosity liquids quickly and accurately. Its speed, accuracy, versatility, and ease of use make it an ideal solution for improving production efficiency and quality in the cosmetics, cleaning, and personal care industries.