Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: United States, None

- Application: APPAREL, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Textiles

- Packaging Type: Bags, Barrel, Bottles, CANS, Capsule, Cartons, case, Pouch, Stand-up Pouch

- Packaging Material: Glass, Metal, Paper, Plastic, Wood

- Automatic Grade: Automatic

- Driven Type: Hydraulic

- Voltage: 380V

- Place of Origin: Shanghai, China

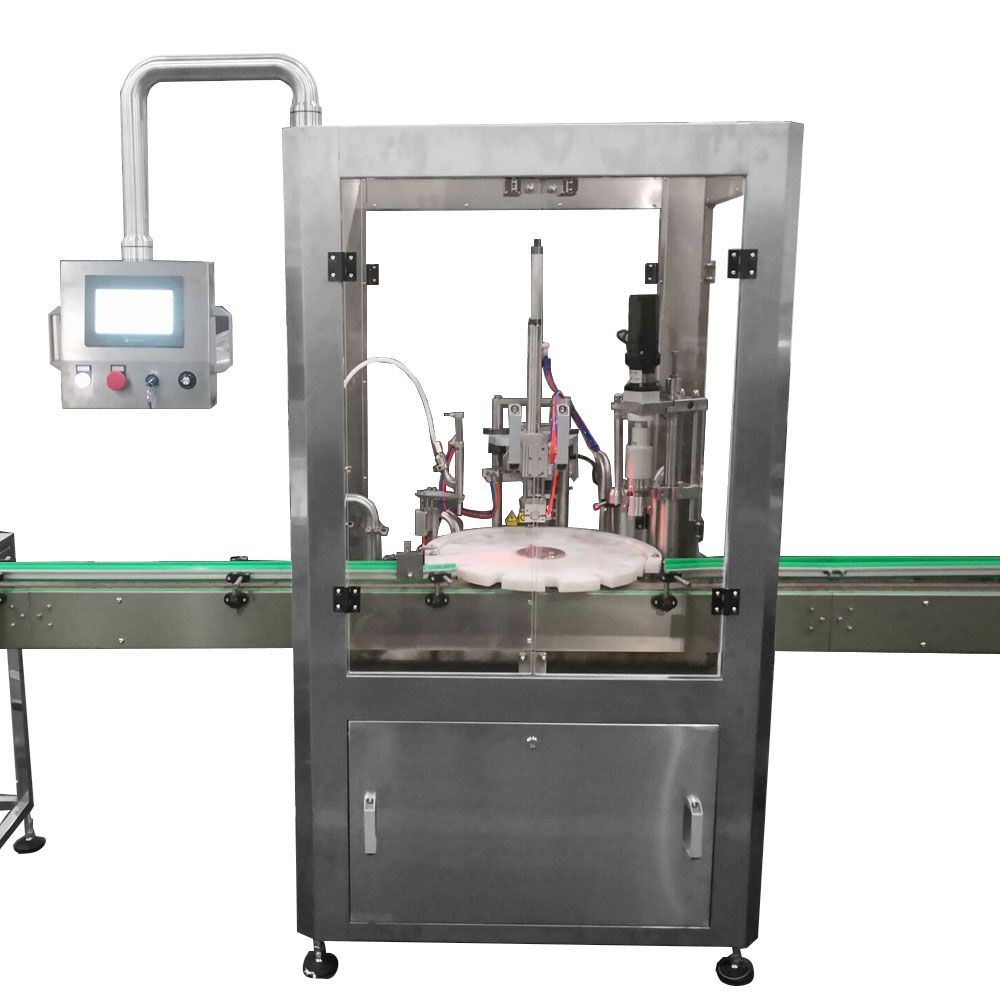

- Dimension(L*W*H): 2400*1500*2300

- Weight: 600kg

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Filling Material: Milk, Water, Oil, Juice, Powder

- Filling Accuracy: 99

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

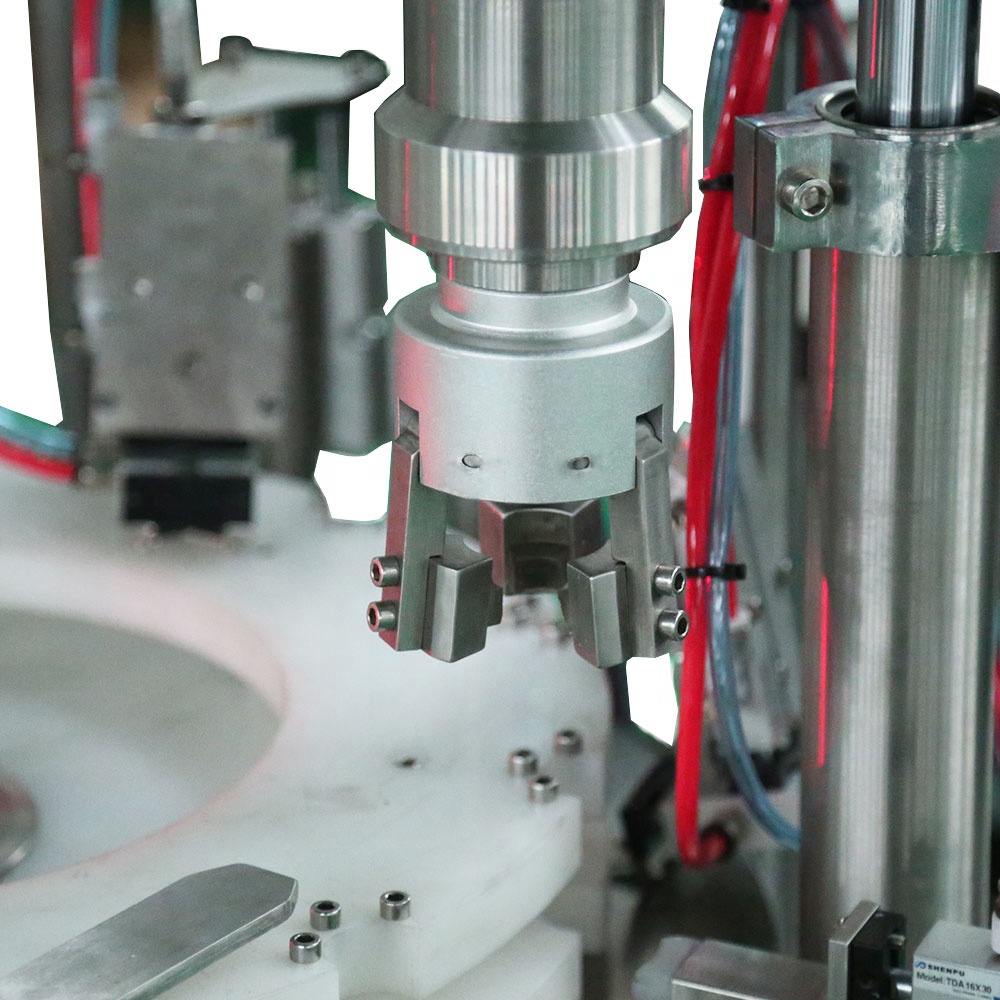

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Product name: windshield washer fluid filling capping machine

- HS Code: 8422303090

- Processing Types: Filling Capping

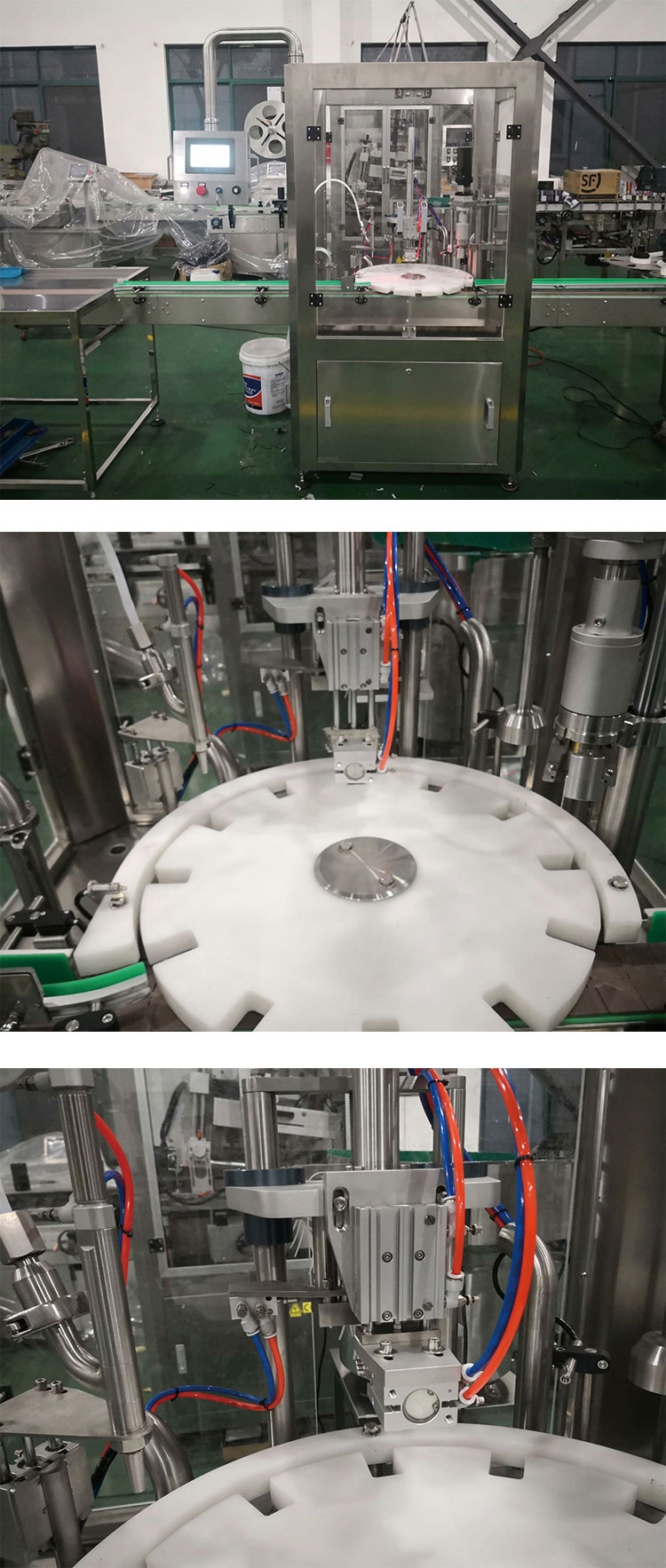

- Function: Rinser Filler Capper

- Usage: Filling Material

- Capacity: 2000-24000bph

- Filling material: Flowing Liquid

- Model: Filling Equipment

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: United States, None

- After-sales Service Provided: Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

- Marketing Type: New Product 2020

- Certification: CE

More Details

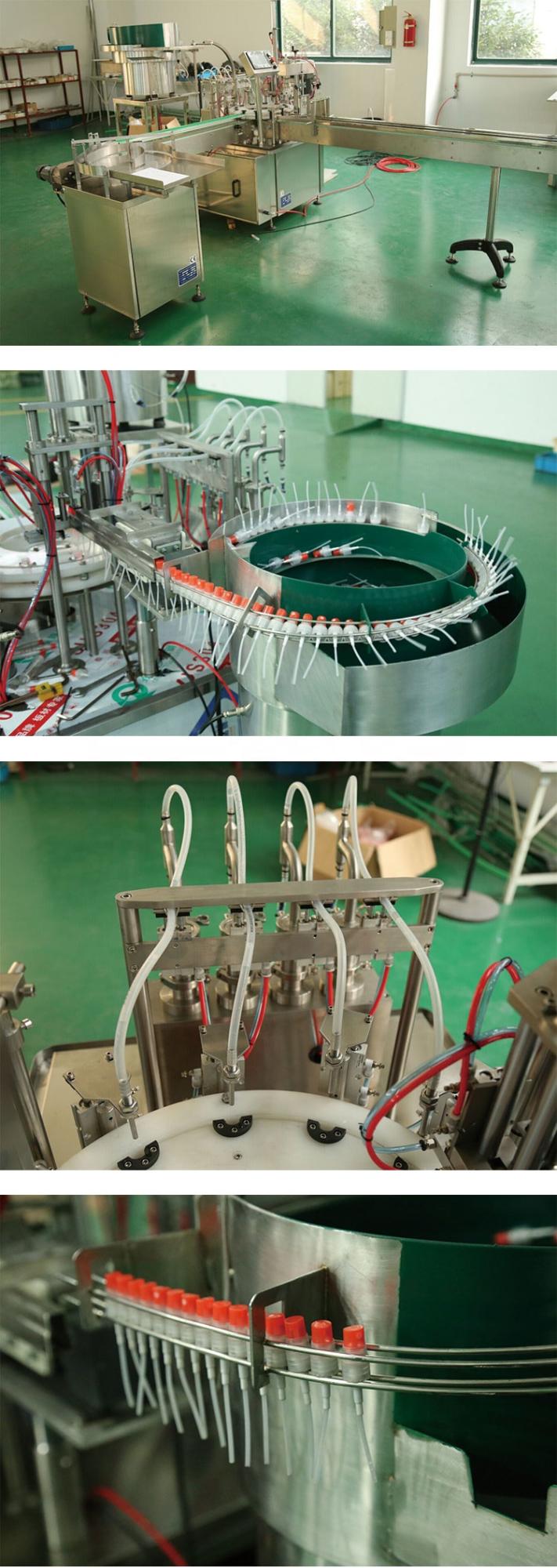

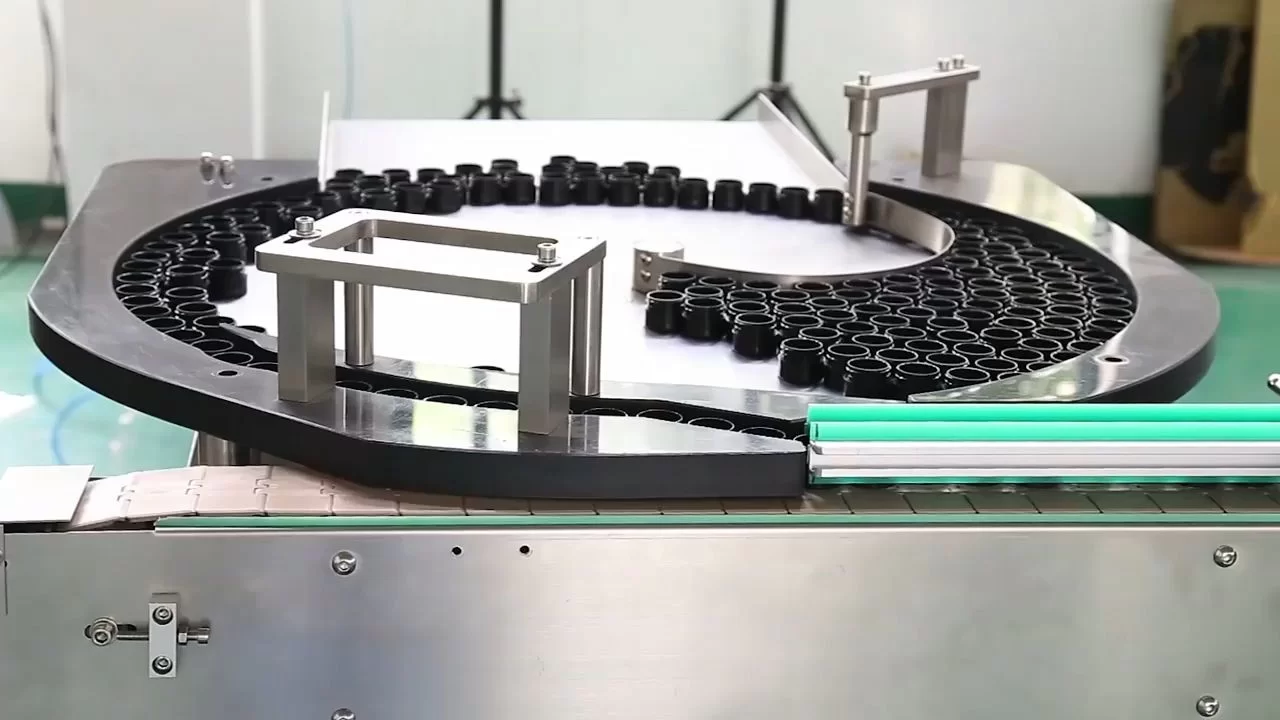

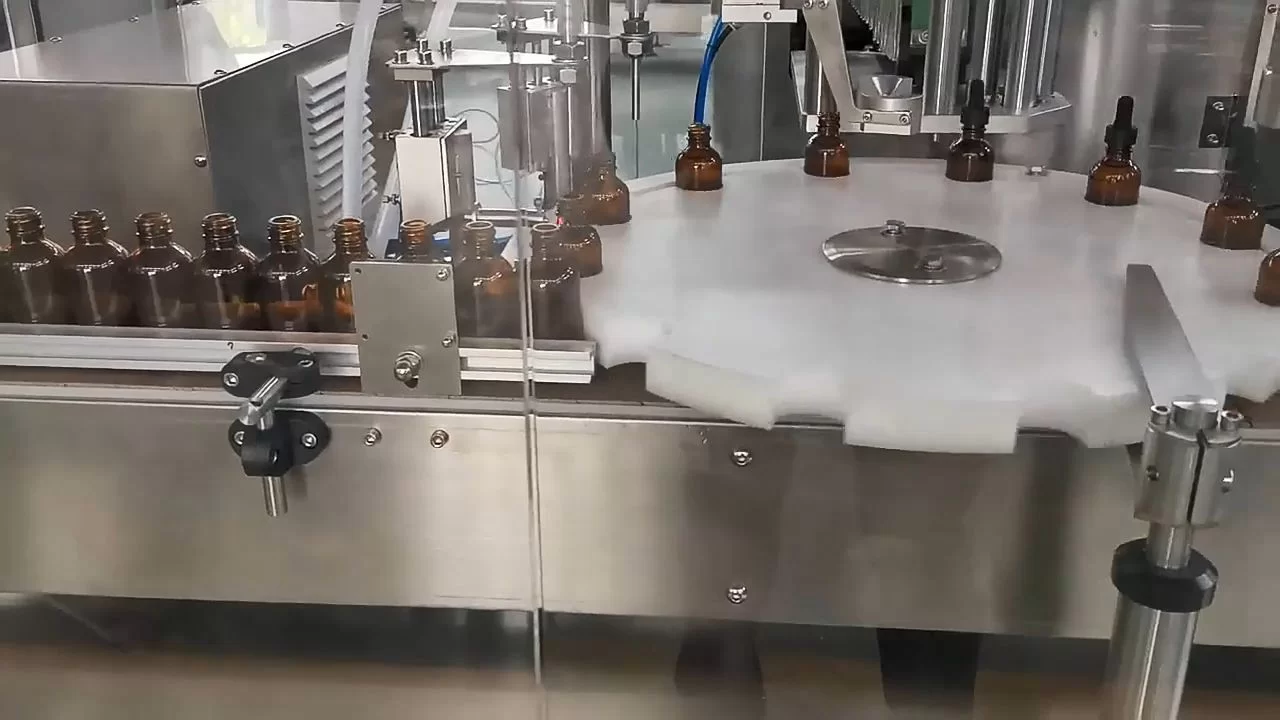

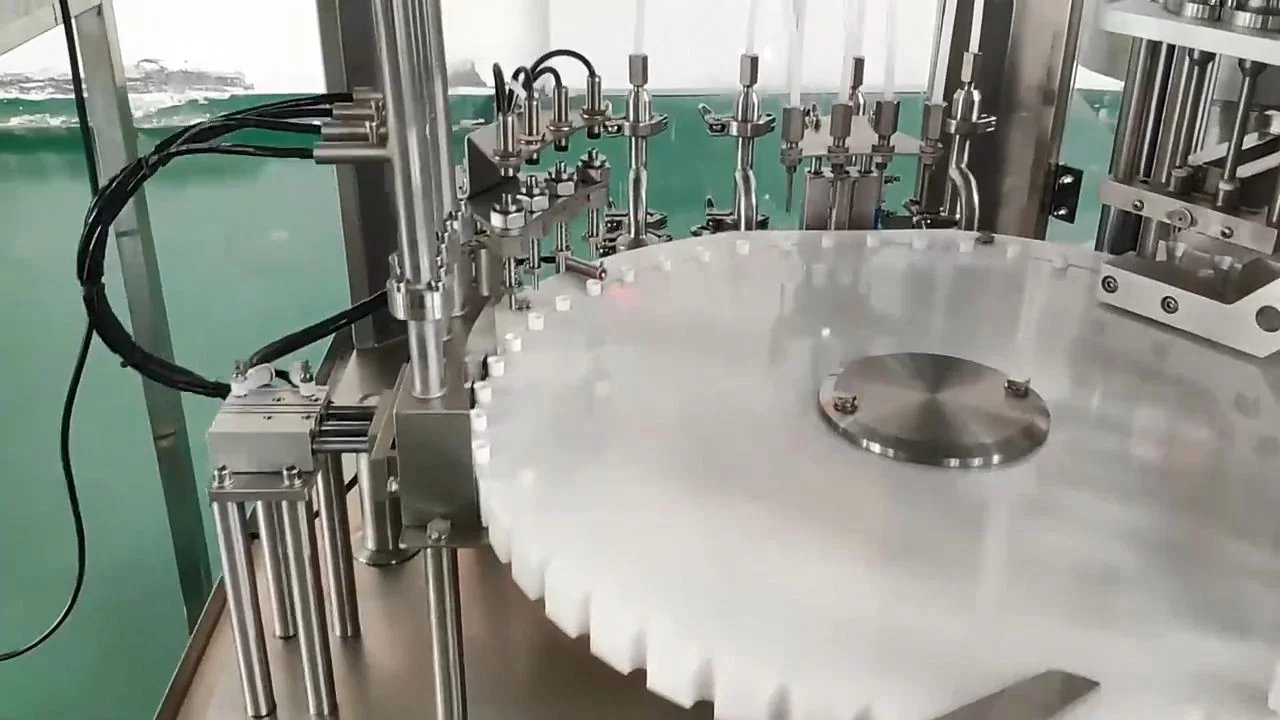

The piston type fluid filling capping machine have the advantages of complete function, compact structure, advanced design and high degree of automation, and equipped with PLC system and touch screen, whose key components are imported from Germany, Taiwan, American assembly. Quality guaranteed.Easy operation,can be applied to bottles of all sizes and shapes by simple adjustment. equipped with servo motor,easy adjustment on touch screen,no need complicated adjustment. At the same time, this filling machine is designed by our company in the reference overseas similar product, and adds some additional function, which makes the product more simple and convenient in operation, adjustment, cleaning and maintenance. No bottle no filling. Equipped with count function. Adopting anti-drip and anti-drawing’s filling head, lifting system to avoid foaming, bottle positioning system and liquid level control system.

Features:

1. Simple structure in rotary type ,easy in installation and maintain

2. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3. High pressure double crank to control the die opening and closing.

4. Running in a high automatic and intelligentize no pollution

5. Apply a linker to connect with bottle unscrambler and labeling machine,to form a whole filling line.

Technical Parameters:

| Technical Parameters: | |||

| Main performance parameters | Main performance parameters | km/h | 6.0/4.0 |

| Filling speed (max. & min.) | bpm | 40-80 | |

| bottle size | ml | 10-1000 | |

| Hydraulic system | Power | V | 220/380 |

| Demension | mm | 2500*1500*1600 | |

| Weight | Kg | 600 | |