A plastic bottle capping machine is a type of equipment used in the food and beverage industry to seal bottles with caps or lids. The machine works by using automated technology to screw or close the caps onto the bottles, ensuring that the contents are properly sealed and protected from contamination.

The capping process is a critical step in the packaging of food and beverage products. It is important that the caps are tightly secured onto the bottles to prevent any leaks or spillages that can cause damage to the product, the packaging, or the surrounding environment. Additionally, the capping process helps to preserve the freshness and quality of the contents inside the bottle, ensuring that the product remains safe and consumable for a longer period of time.

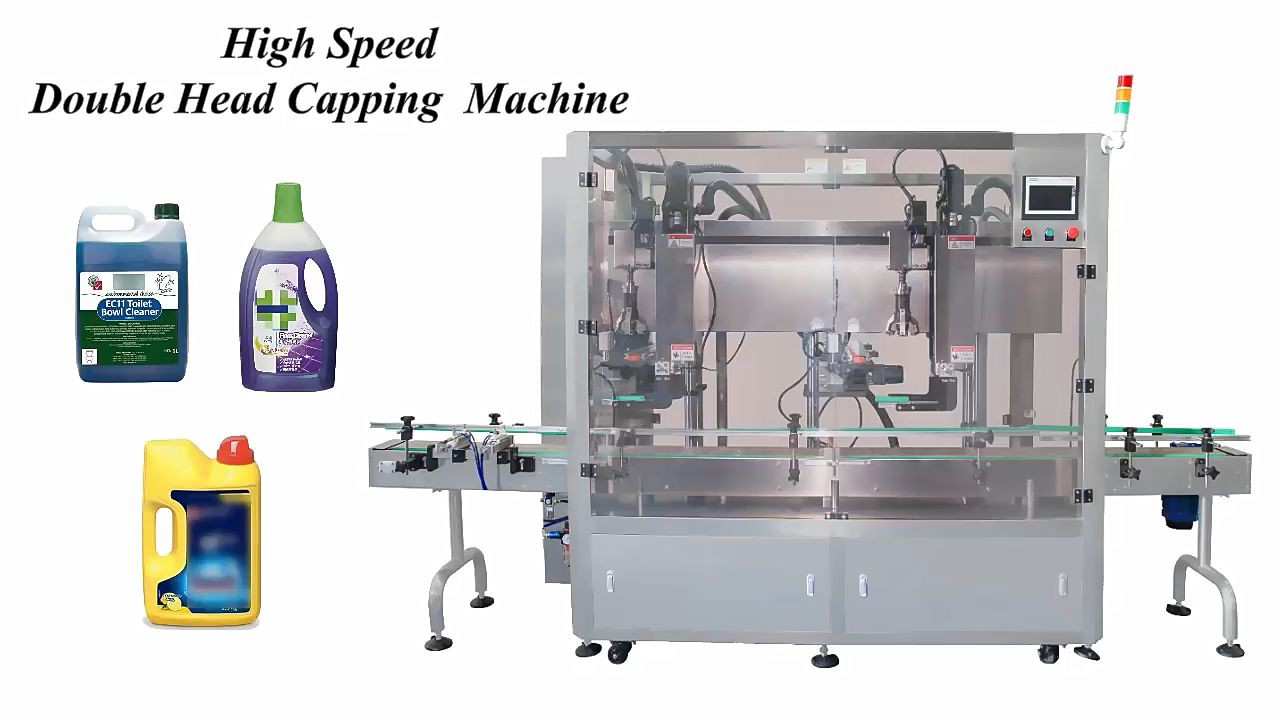

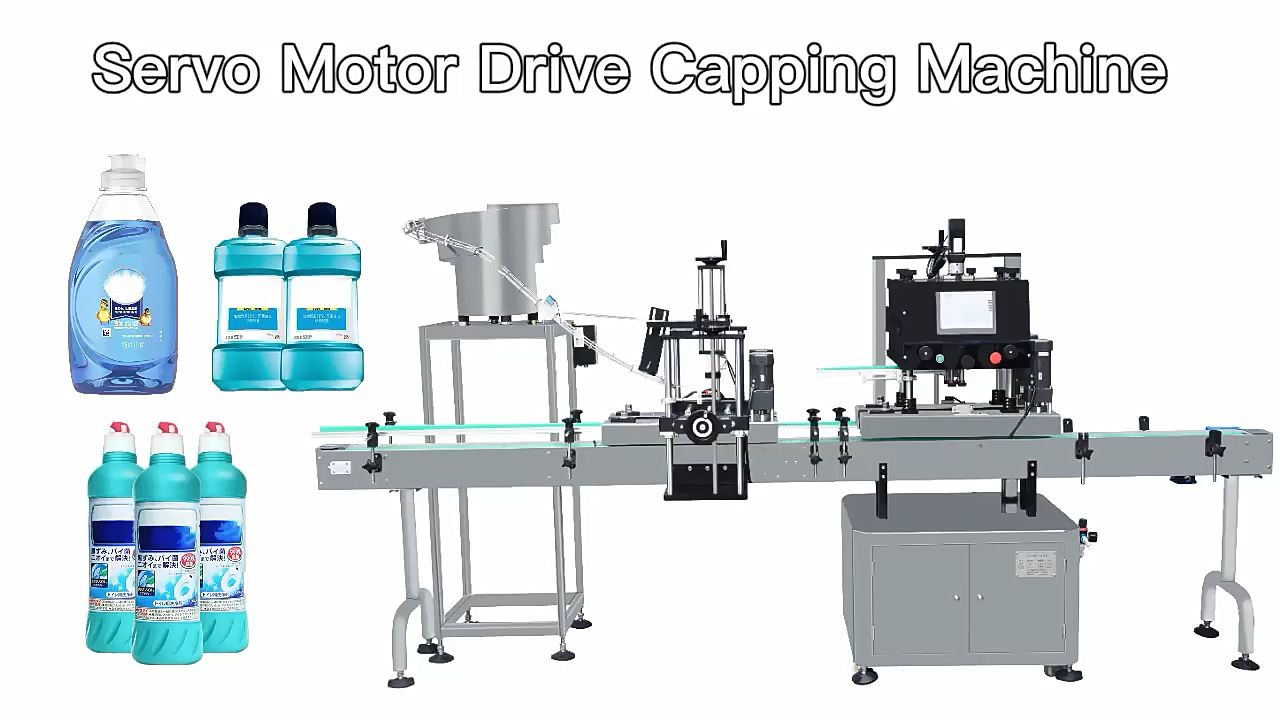

Plastic bottle capping machines come in different shapes and sizes, and they can be customized to meet the specific needs of different manufacturers. Some capping machines are designed to handle a single size and type of cap, while others can handle different sizes and types of caps, making them more versatile and suitable for a wider range of applications.

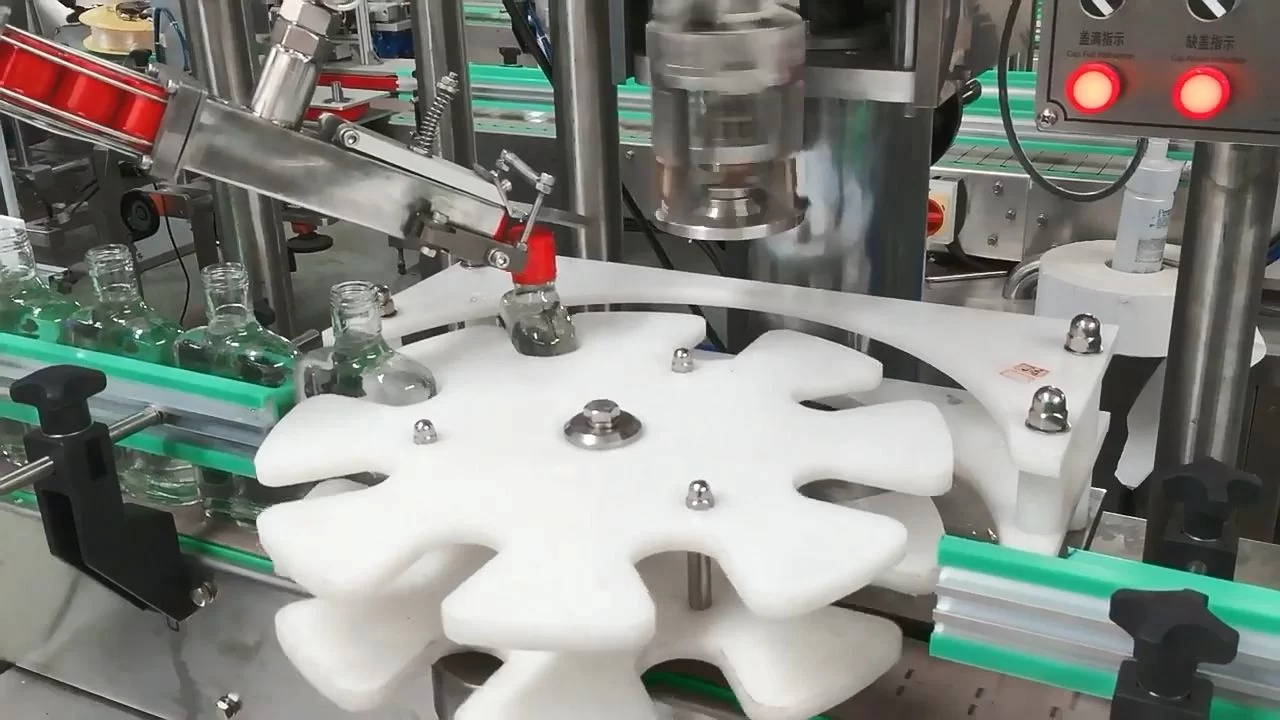

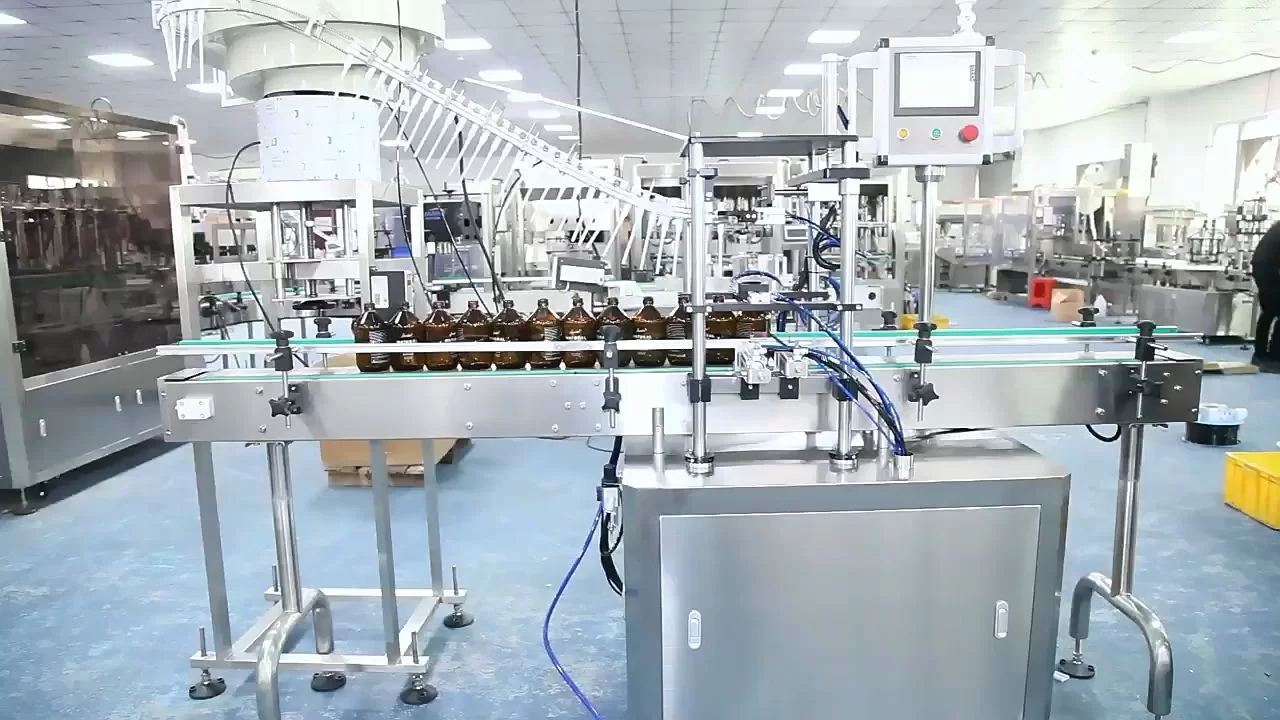

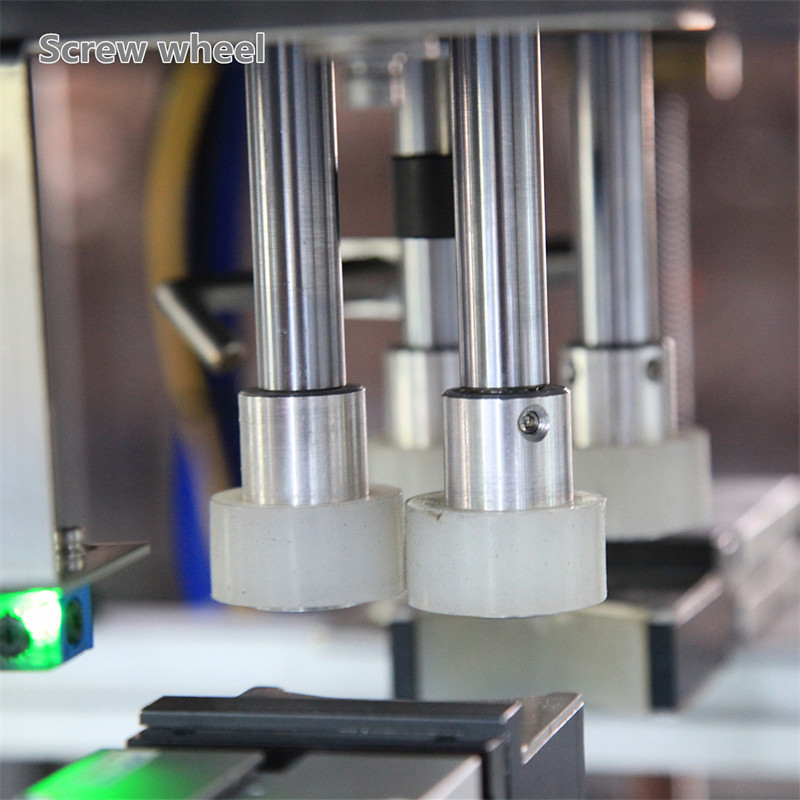

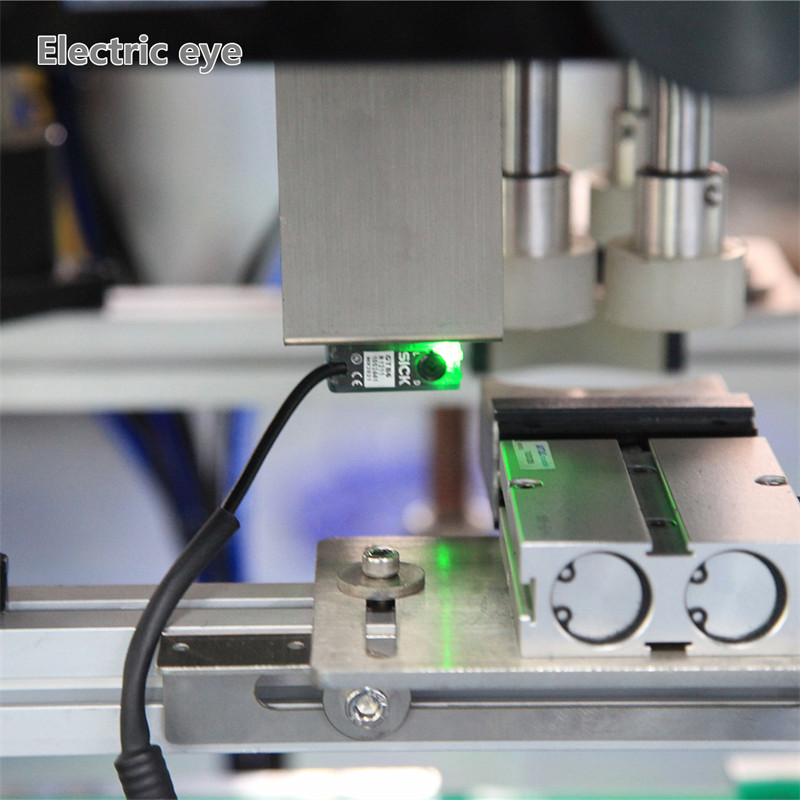

The operation of a plastic bottle capping machine is typically automated, which means that it requires minimal human intervention. The bottles are loaded onto the machine's conveyor belt, which then moves them through the capping process. The machine uses a variety of mechanisms to securely fasten the caps onto the bottles, including screwing, pressing, or snapping. Once the caps are in place, the bottles are discharged from the machine and are ready for further processing or distribution.

In conclusion, plastic bottle capping machines play an important role in the food and beverage industry by ensuring that bottles are properly sealed and protected from contamination. They are designed to be efficient, reliable, and easy to use, making them a valuable investment for manufacturers who are looking to improve the quality and safety of their products.

Quick Description

- Type: Capping Machine

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Egypt, Philippines, South Korea, Japan

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Warranty of core components: 5 years

- Core Components: PLC, Bearing, Motor, Pump

- Condition: New

- Application: Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, Can be customized

- Driven Type: Electric

- Automatic Grade: Automatic

- Voltage: AC220V/50Hz

- Packaging Type: Cartons

- Packaging Material: Plastic, Paper, Metal, Glass, Wood

- Dimension(L*W*H): 2000*800*1550mm

- Weight: 550 KG

- Warranty: 3 years

- Key Selling Points: Automatic, Easy To Operate

- Product Name: Syrup Honey Bottle Plastic Glass Jar Filling And Capping Machine

- After-Sales Service Provided: Automatic Four Wheel Servo Rotor Pneumatic Screw Capping Machine

- Equipment Weight: Full Automatic Servo Capping Machine

- Suitable Bottles: The bottle provided by customers

- Production Capacity: 2500-3000 bottles / hour

- Keywords: Servo Rotor Capping Machine

- Capping Way: Servo Drive Screw Capping

- Advantage: High Efficiency, multifunctional, competitive price

- Function: Capping Regular

- Company Type: Integration Of Industry And Trade

More Details

Description:

This machine is used for automatic capping for plastic bottles and glass bottles in cosmetic, food, beverage, chemical industry and medicine industry. It can be applied to a variety of bottle types with high production efficiency.

| Technical Parameter | |

| Cover method | Vibration plate cover |

| Capping form | Servo electric clamp |

| Bottle height | 70-320mm |

| Cap diameter | 20-90mm |

| Bottle diameter | 30-140mm |

| Capping speed | 30-40 bottles/min |

| Capping voltage | 1ph AC 220V 50/60Hz |

| Air pressure | 0.6-0.8MPa |

| Dimension | 2380(L)*1150(W)*1660(H)mm |

| Packing size | 2400(L)*1200(W)*1800(H)mm |

| Machine weight | About 400KG |