Quick Description

- Condition: New

- Type: Filling Machine

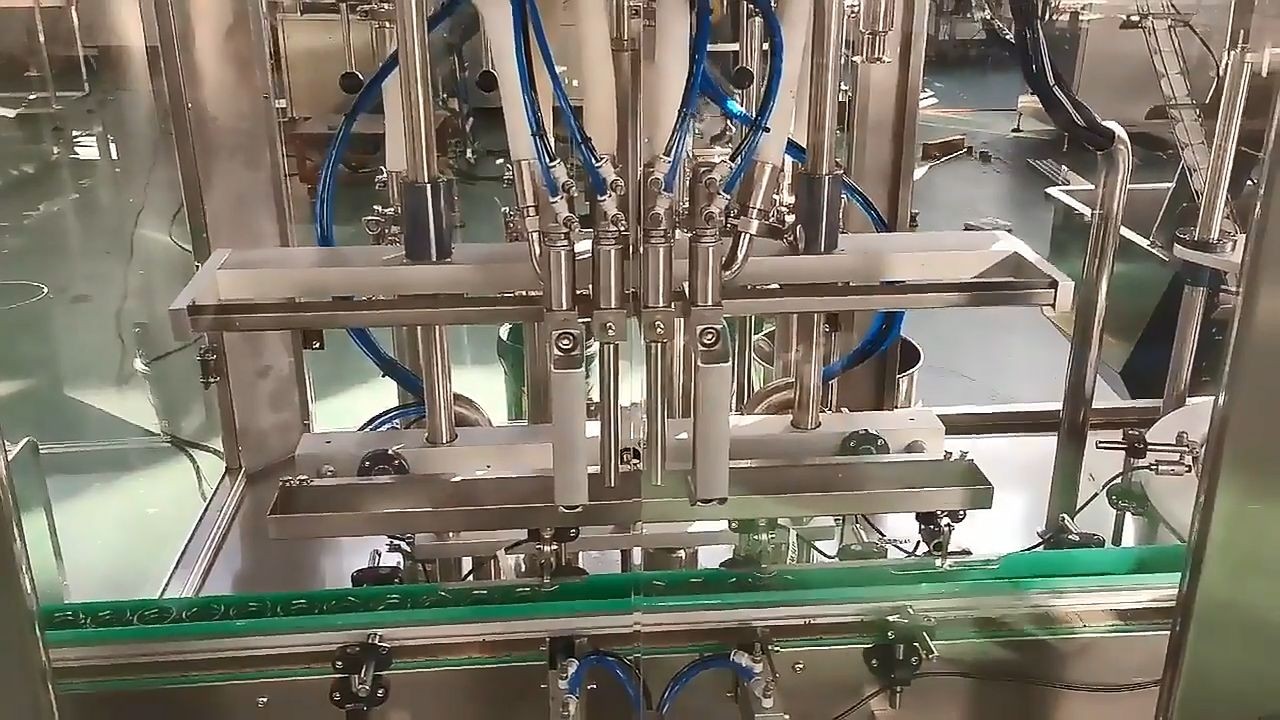

- Machinery Capacity: 4000BPH, 6000BPH, 2000BPH, 1000BPH, customization

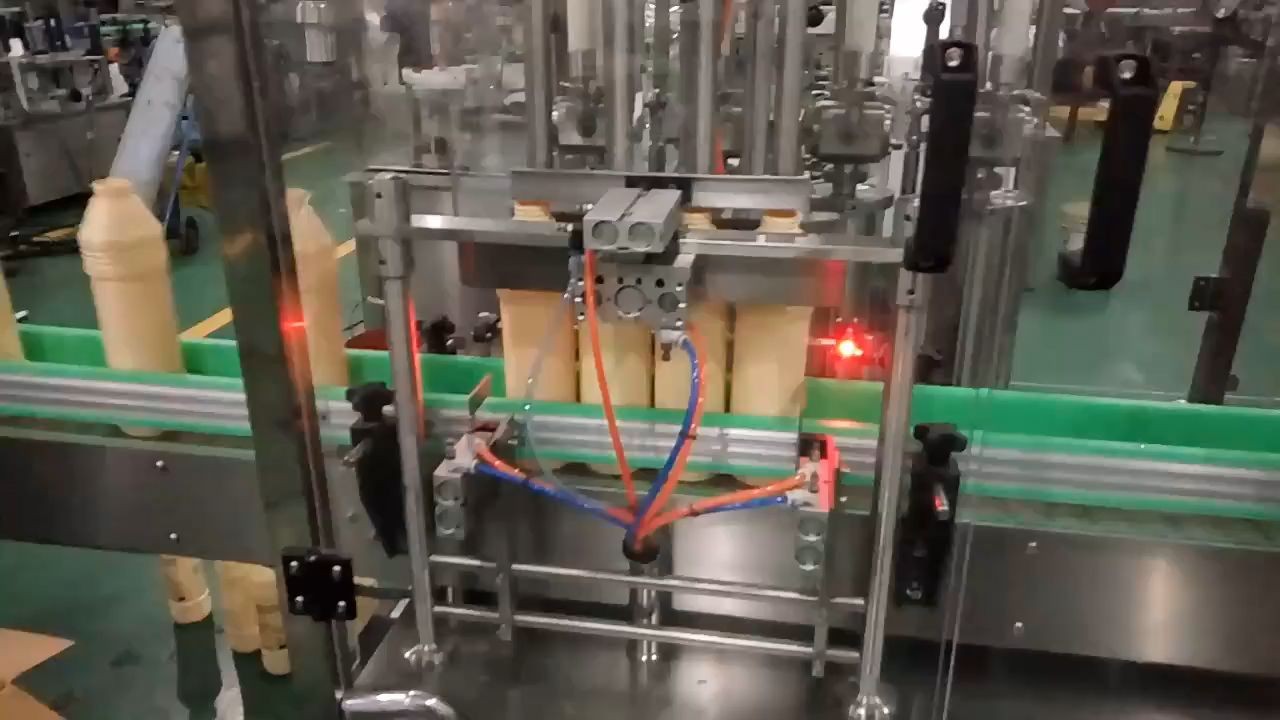

- Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Food factory, daily chemical supplies factory

- Showroom Location: Egypt, Italy, Philippines, Thailand, None

- Application: Food, Beverage, Chemical, Machinery & Hardware, Food factory, daily chemical supplies factory

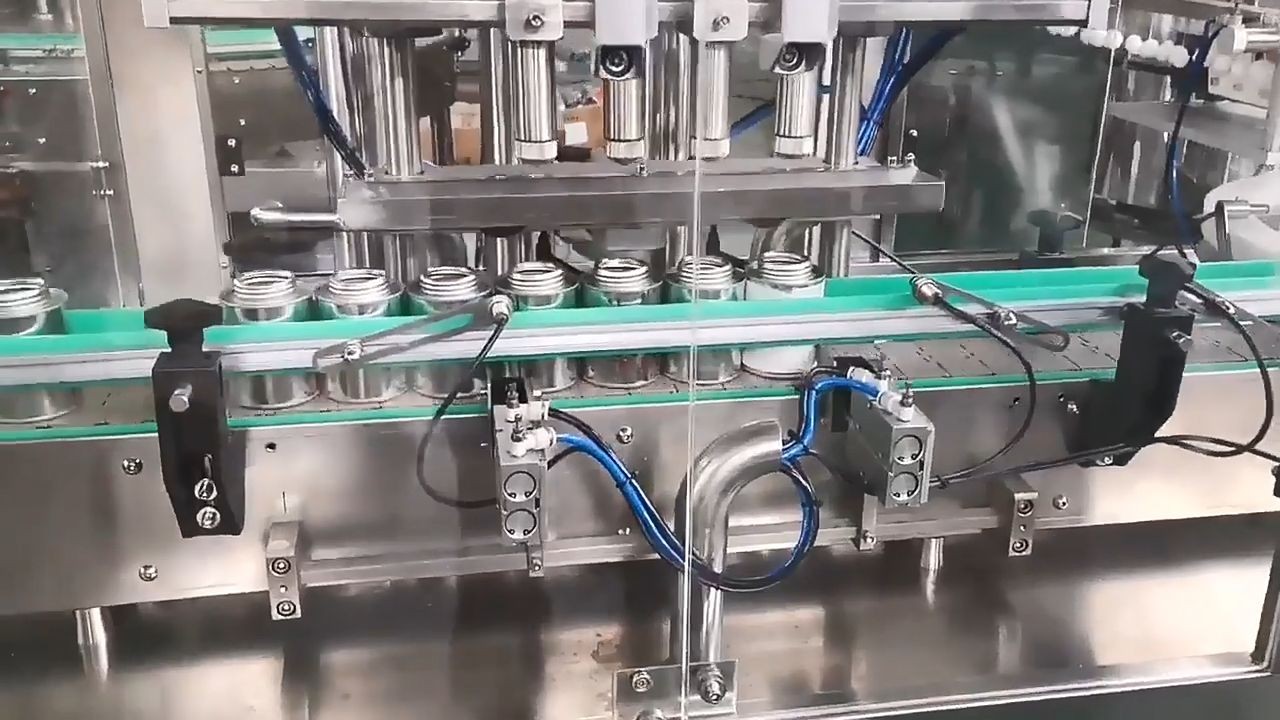

- Packaging Type: CANS, Bottles, Barrel, Stand-up Pouch, Pouch, case

- Packaging Material: Plastic, Metal, Glass

- Automatic Grade: Semi-automatic

- Driven Type: Electric

- Voltage: 220/110V 50/60Hz

- Dimension(L*W*H): depends on design

- Weight: KG

- Warranty: 1-3 Years

- Key Selling Points: Long Service Life,Easy to Operate

- Filling Material: Water, Oil, Powder, Paste Lotion Hair Spray Gel Wax Cosmetic Cream

- Filling Accuracy: <1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1-3 Year

- Core Components: Motor, Pump, PLC, Gear, Gearbox, Engine, standard

- After-sales Service Provided: on line service

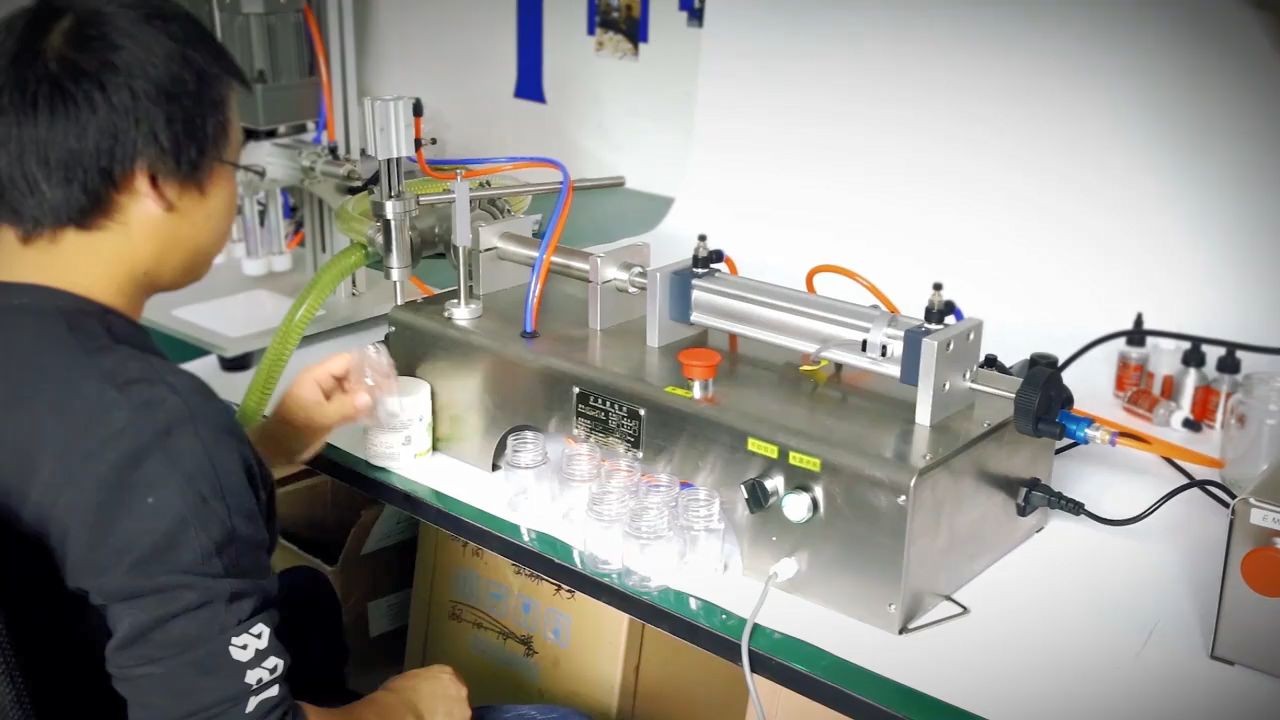

- Product name: cream filing machine semi automatic

- Filling range: Can be customized

- Capping distributor way: Vibration shaking plate( different types need exchange the set)

- Suitable bottles: Depend on design and customer's design

- Cap feeding way: Pneumatic fetch

- Capping way: Can be customized

- Capacity: Can be customized

- Material: 304 SUS

- Program control: Share with filling machine

- Marketing Type: New Product 2020,Hot Product 2019

More Details

| Technical Parameter: | ||

| One Head | Two Head | |

| Powe supply | 220/110V 50/60Hz | |

| Power | 100W | 200W |

| Sir pressure | 0.4-0.6MPa | |

| Filling speed | 5-30 bottles/min | 10-60 bottles/min |

| Filling accuracy | ≤±1% | |

| Filling volumes range | 5-100ml 10-300ml 20-500ml 50-1000ml 500-3000ml 1000-5000ml | |

Description:

Its structure is simpler and more reasonable, accuracy is high, operation is more simpler and more convenient. Suitable for the pharmaceutics, daily chemical, foodstuff, agriculture chemical and special trade, it is the ideal filling equipment for paste, ointment, viscous fluid.

Functions:

This machine is the Semi-automatic Piston Type Vertical Filling Machine.

This machine is reasonable in design, small and exquisite in model, vertical structure, saving the place.

Easy to operate, the pneumatic part adopts the pneumatic components Taiwan AirTac.

Filling valve is controlled by the electromagnetic valve, filling accuracy is higher.

Both filling volume and filling speed can be adjusted at will.

Use the special turnning valve for material effective filling.

The part contacting materials is made of 304 stainless steel.

Material contact parts can be customized SS316.

Also can be customized fully-pneumatic & no power explosion-proof.

Can be bottom seal on the filling nozzle for prevent leaking.

Filling nozzle can be do lift filling.

Filling nozzle diameter can be replaced.

The hopper can be customized double fully-sealed warm type.

The hopper can be customized mixer(with motor) type.

Hopper can be installed liquid level automatic control system.

Double fully-sealed warm type

40 liter hopper wooden box size 47 * 47 * 52cm

Box size 500 and 1000 single paste 122 * 37 * 34cm

Box size 1000 double paste 122 * 50 * 35cm

Wooden box size of vertical filling machine:

Full pneumatic 280 double paste: 90 * 55 * 152cm hopper is buckled on the top

All pneumatic 2000 double fluid: 91 * 73 * 160cm

The semi-automatic paste filling machine is a versatile and efficient equipment that is specifically designed for filling various types of pastes, such as honey, peanut butter, cream, and more, into bottles, cans, and other containers. This machine is ideal for small and medium-sized businesses that require efficient and accurate filling of their products.

The machine is made of high-quality stainless steel material that is durable, easy to clean, and resistant to rust and corrosion. The filling process is simple and user-friendly, with a foot-pedal control that enables the operator to start and stop the filling process. The machine can also be easily adjusted to accommodate different container sizes.

The semi-automatic paste filling machine uses a piston pump that draws the paste from a hopper and fills it into the container. The pump is designed with an adjustable stroke, which enables the operator to control the volume of paste that is dispensed into the container. The filling accuracy is high, ensuring that each container is filled with the same amount of paste.

The machine is also designed with a drip-proof filling nozzle that prevents the paste from dripping or spilling during the filling process. The nozzle can be easily removed for cleaning and maintenance.

Overall, the semi-automatic paste filling machine is an efficient, reliable, and cost-effective solution for filling various types of pastes into containers. It can help businesses increase their productivity and profitability while ensuring high-quality and consistent filling results.