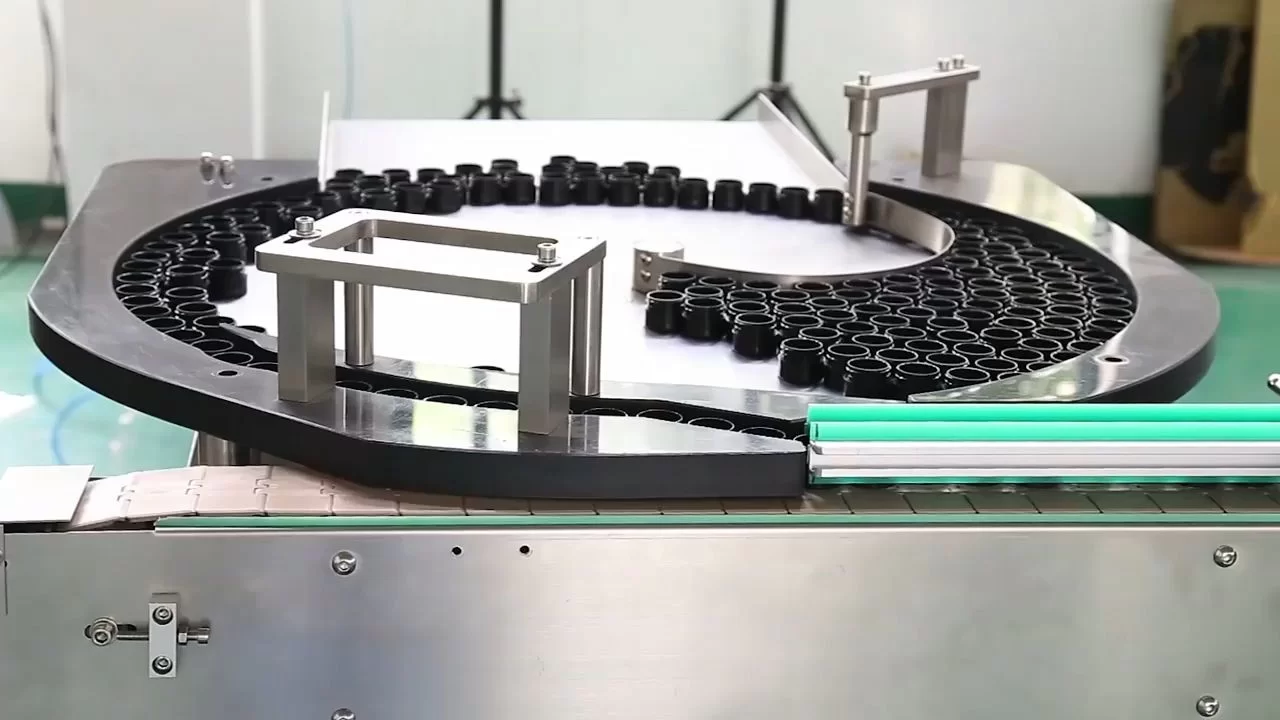

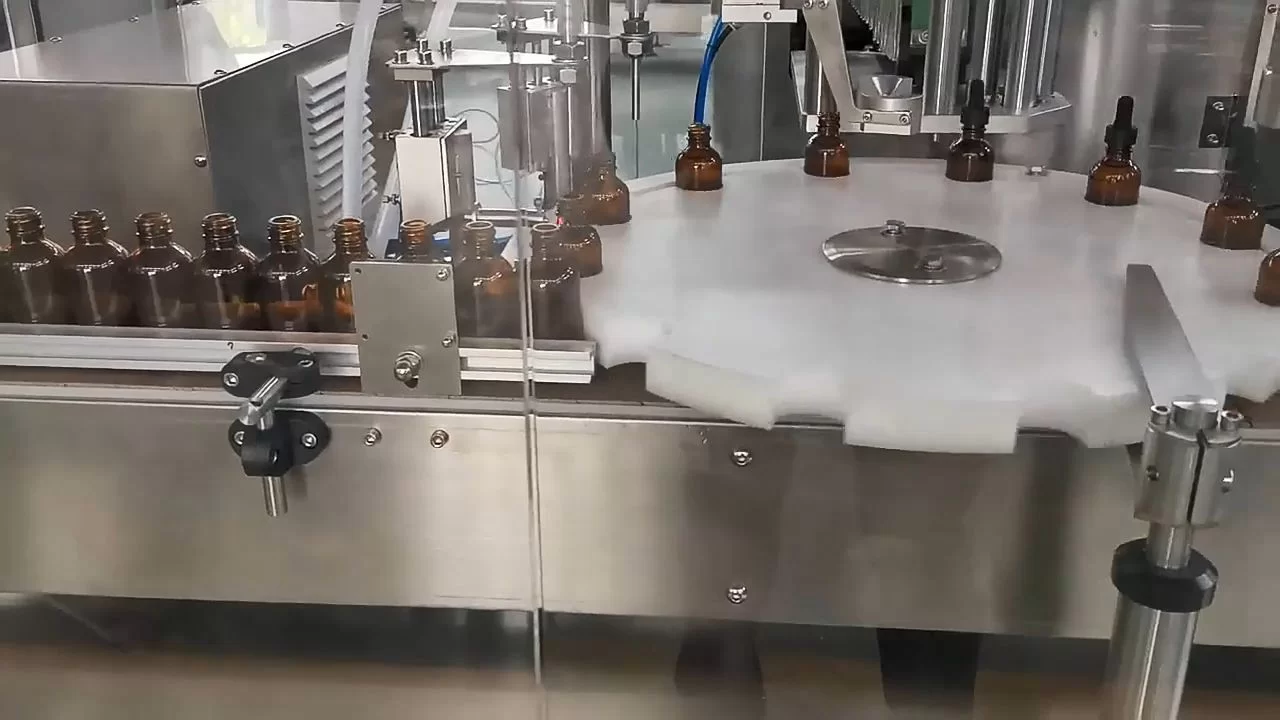

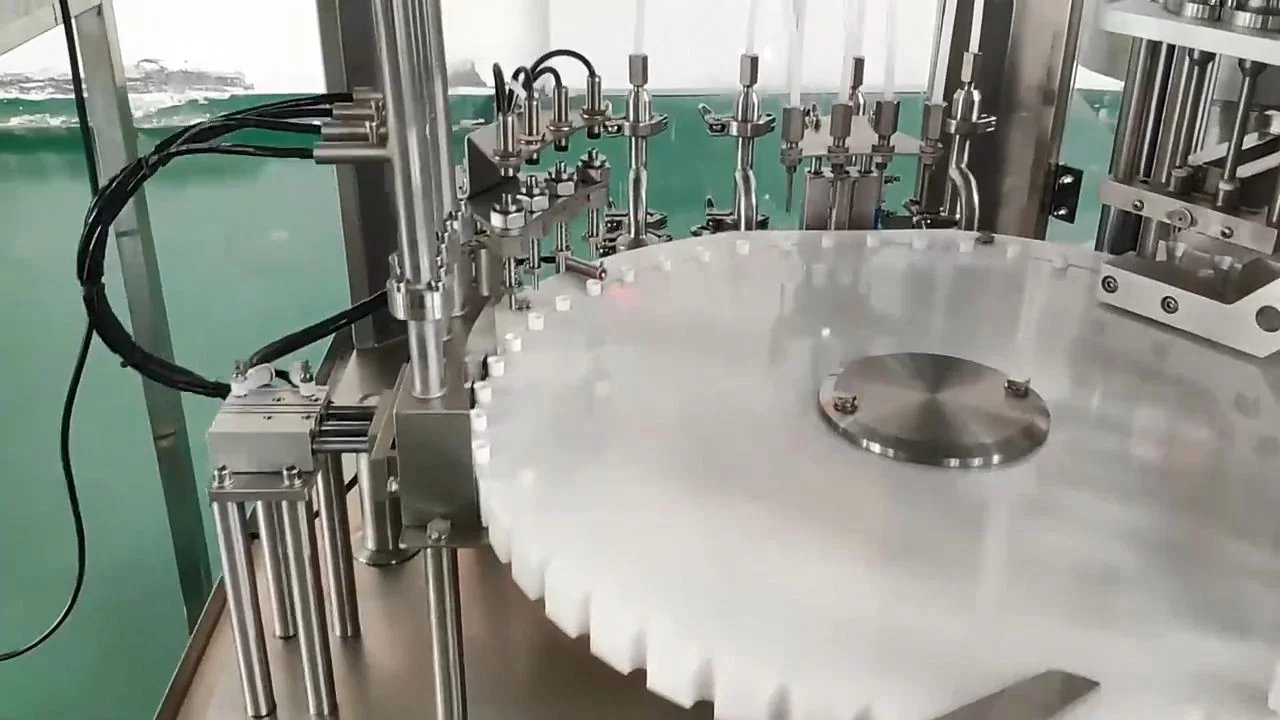

The syrup filling machine adopts piston pump volumetric metering, with high filling accuracy, stable performance, low bottle damage rate and small floor area. It adopts electromagnetic vibration capping and centrifugal capping, and integrates filling and sealing. The sugar filling and capping process can be completed by the whole machine, All parts in contact with drugs are made of 316L stainless steel or PTFE, with the functions of no bottle, no filling,variable frequency speed regulation, etc. This machine is mainly used for filling, pressing and capping of various oral liquid and syrup liquid, and is widely used in food, pharmaceutical, chemical industry and scientific research fields

1. the capacity of the Syrup filling machine is range from 80b/hour to100 bottles per hour

2. the filling volume of the machine is range from 5ml to 200ml

| Yield capacity | 80-100pcs/min | |

| Filling station | 4 | |

| Filling accuracy | ±1% | |

| Filling range | 5ml to 200ml | |

| filling tolerance | ±1% | |

| Capping station | tow | |

| Qualified cap putting | more or equal then 99% | |

| Qualified capping | more or equal then 99% | |

| Speed regulation | by inverter | |

| power supply | 380V 50Hz | |

| Power | 3.5kw | |

| outside dimension | 1410×1170×1850mm | |

A servo motor piston pump 30ml liquid syrup filling capping machine is a sophisticated piece of equipment used for filling and capping bottles containing liquid syrup, such as cough syrups, herbal extracts, and other similar products. The machine uses a servo motor-driven piston pump to accurately measure and dispense the correct amount of syrup into each bottle.

The machine is equipped with a range of features that ensure precise filling and capping. The servo motor provides high accuracy and repeatability, while the piston pump ensures that the correct amount of syrup is dispensed every time. The filling nozzle is designed to minimize foaming and splashing, which can cause inconsistencies in the amount of syrup dispensed.

In addition, the machine can be equipped with a variety of capping heads, including screw caps, snap-on caps, and cork stoppers, allowing it to work with a wide range of bottle types and sizes. The capping process is fully automated, with the machine using sensors and other technologies to ensure that each bottle is capped securely and accurately.

The machine is also equipped with a user-friendly touch screen interface, which allows operators to set and adjust the filling and capping parameters easily. The interface displays important information such as the amount of syrup filled, the number of bottles processed, and any error messages or alerts.

Overall, a servo motor piston pump 30ml liquid syrup filling capping machine is an essential piece of equipment for any company that needs to fill and cap bottles containing liquid syrup quickly and accurately. Its advanced features, including servo motor-driven piston pumps, accurate filling nozzles, and customizable capping heads, make it a versatile and reliable solution for the pharmaceutical, food, and beverage industries.