A tabletop plastic bottle liquid filling and labeling machine is a device that is used to fill plastic bottles with liquid products and apply labels to the bottles. This type of machine is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where accurate filling and labeling are essential for product safety and quality.

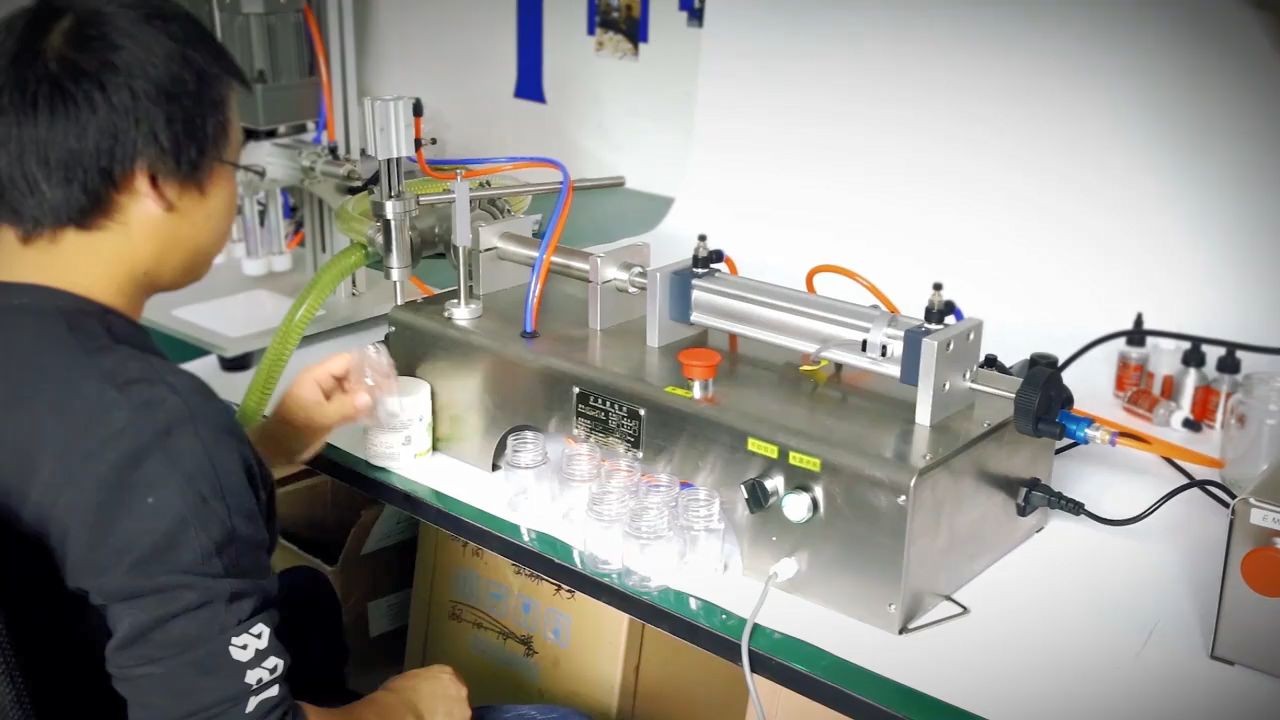

The machine is designed to be compact and portable, making it easy to move around and use in different settings. It is typically placed on a tabletop or workbench and can be operated by a single operator.

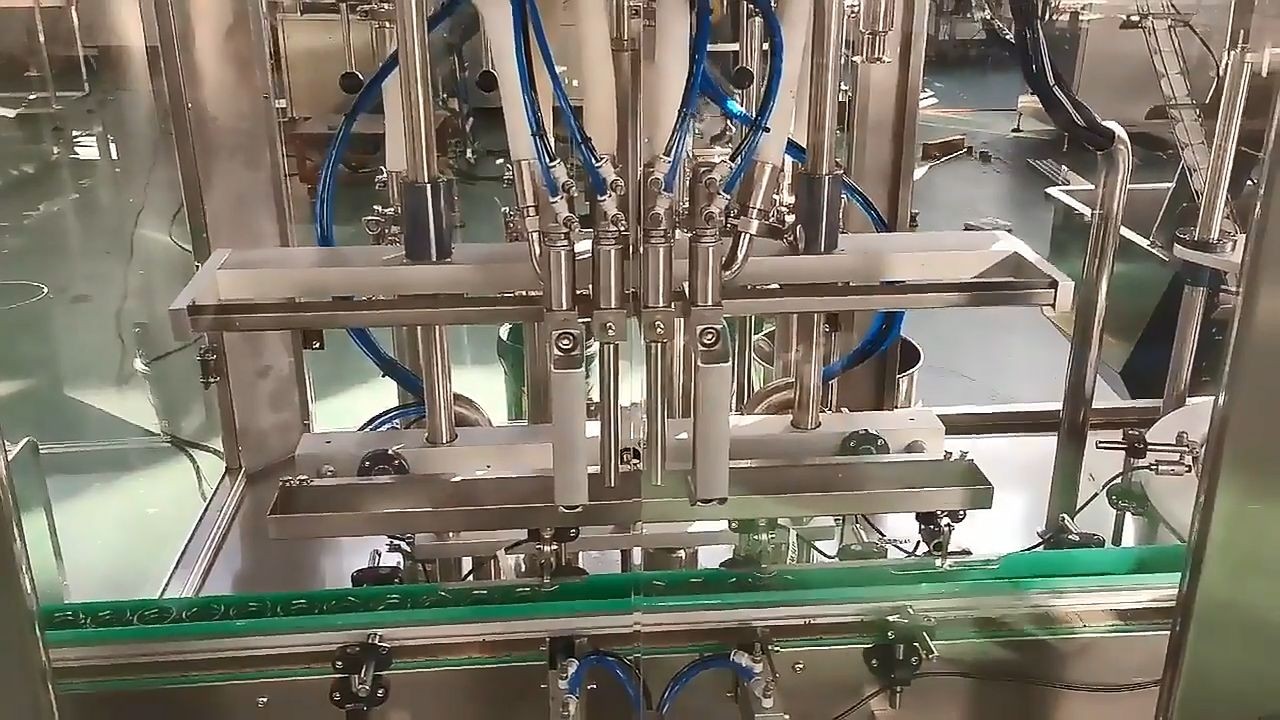

The filling process is automated and is controlled by a computer program. The operator simply places the empty bottles onto the machine's conveyor belt, and the machine fills them with the desired amount of liquid. The machine is capable of filling bottles of different sizes and shapes, and the filling volume can be adjusted to meet the specific requirements of the product.

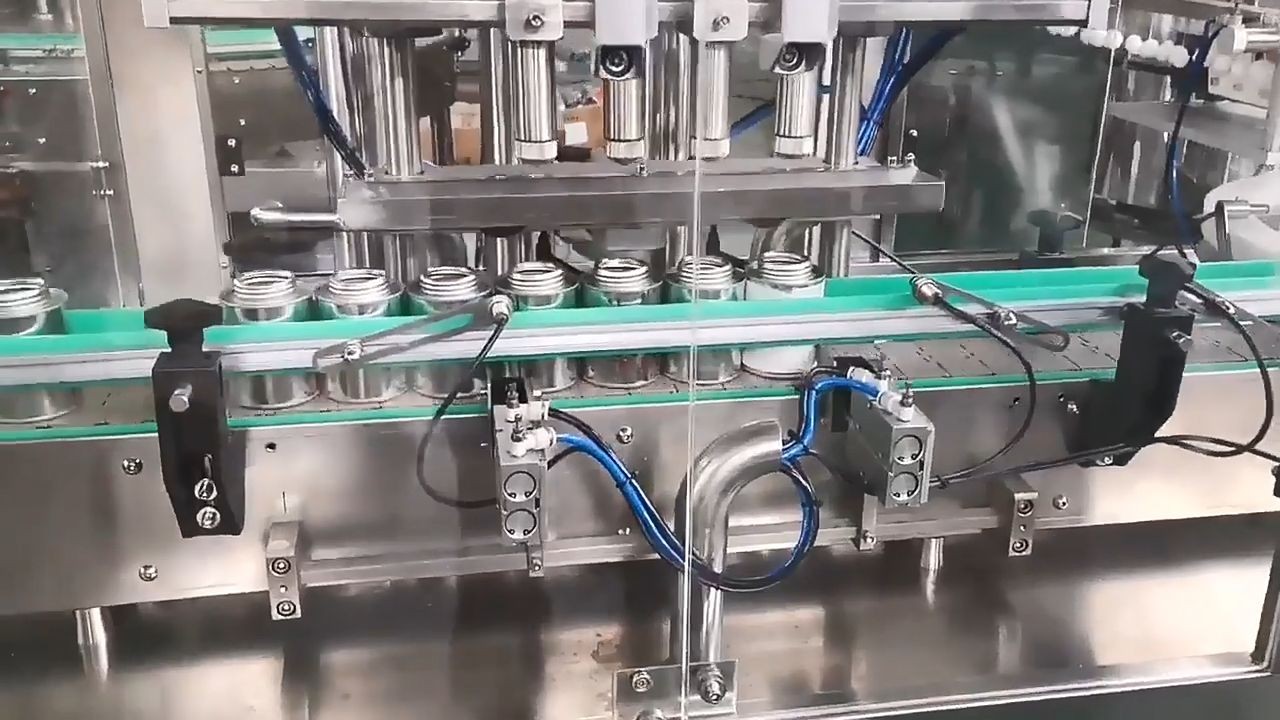

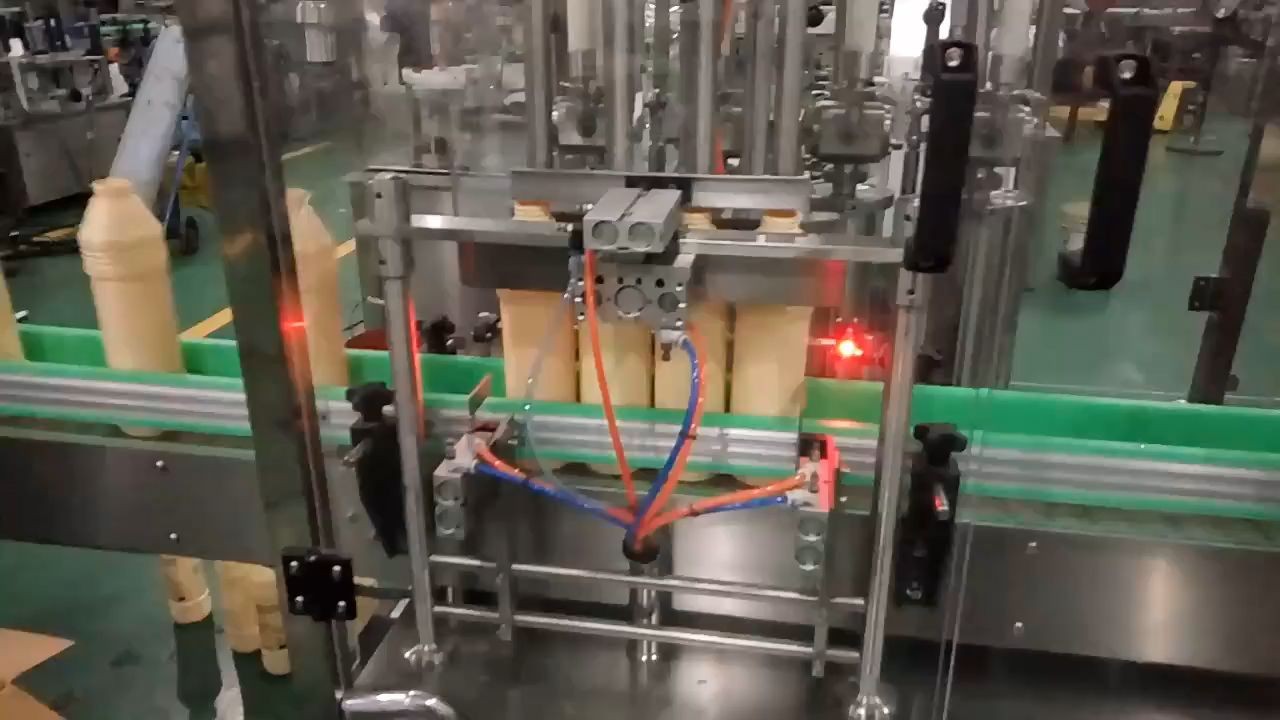

Once the bottles are filled, the labeling process begins. The machine applies adhesive labels onto the bottles, which can include important product information such as the product name, ingredients, and expiration date. The labels are applied accurately and quickly, ensuring that each bottle is properly labeled and ready for distribution.

The tabletop plastic bottle liquid filling and labeling machine offers several advantages over manual filling and labeling. It is faster and more efficient, which means that manufacturers can produce more products in a shorter period of time. It is also more accurate, which reduces the risk of errors and improves the consistency of the product. Additionally, the machine is designed to be easy to clean and maintain, which reduces downtime and extends the lifespan of the equipment.

In conclusion, the tabletop plastic bottle liquid filling and labeling machine is an essential piece of equipment for manufacturers who need to fill plastic bottles with liquid products and apply labels to them. It offers a fast, accurate, and efficient way to produce high-quality products, while also improving productivity and reducing costs.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 500BPH, 2000BPH, 1000BPH

- Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Retail, Food Shop, Printing Shops, Factory Production workshop

- Showroom Location: Egypt, Germany, Philippines

- Application: The function of the production line can be customized

- Packaging Type: Packaging type can be customized according to the filled product.

- Packaging Material: Packaging type can be customized

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Dimension(L*W*H): 2000mm*651mm*1084mm

- Weight: 150 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Filling Material: Liquid, Cosmetic prosucts

- Filling Accuracy: ±1%

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump, PLC

- Product name: Automatic Table Top Bottle Liquid Filling Production Line

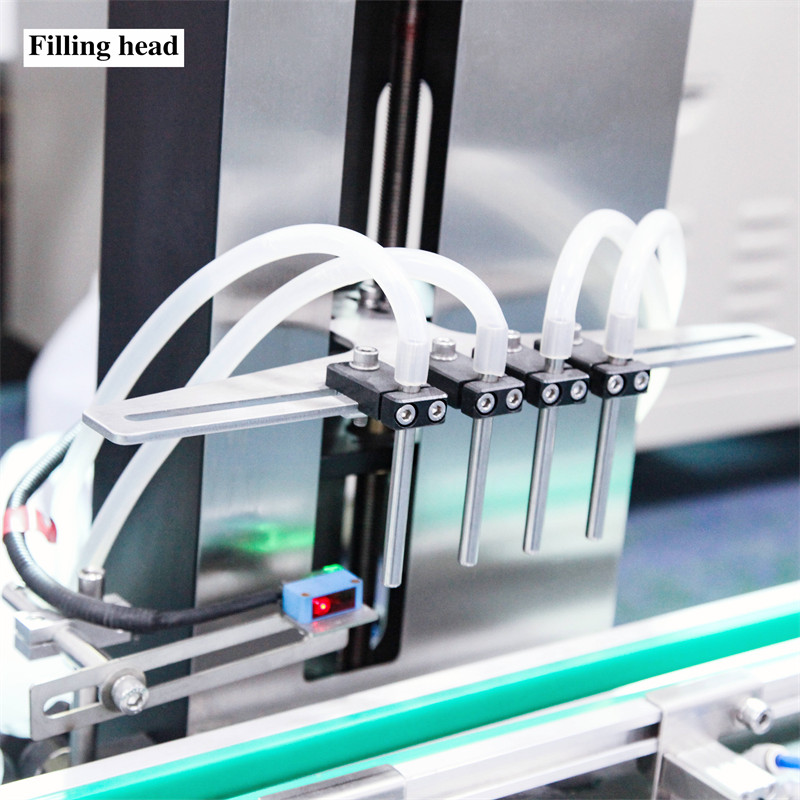

- Filling head: 4, can be customized

- Filling speed: 20-30 bottles/min(50-500ml)

- Capping speed: 20-35 bottles/min

- After-sales Service: 7/24 Video service, online service, spare parts

- Bottle type: The bottle provided by the customer

- Advantage: 20 Years Experiences, factory price

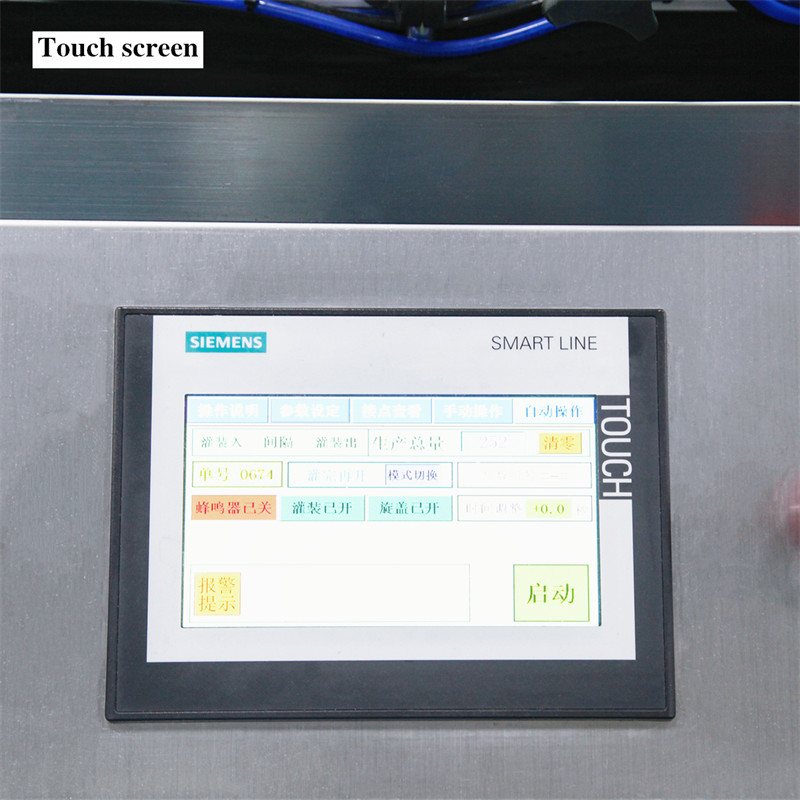

- Control: PLC Touch Screen

- Material: Stainless Steel 304/316

- Marketing Type: Hot Product 2021

More Details

Description:

The whole machine is a linear mechanism, which is driven by magnetic pump and servo motor to achieve high-precision filling dosage. It is easy to operate and can change the bottle type quickly. The biggest feature of this machine is that it covers a small area, is affordable, and is easy to disassemble and clean.

It is used for automatic fillling and capping for bottles in cosmetic, daily chemical, medicine industry, water, beverage. It can be applied to a variety of bottle types with high production efficiency.

| Technical Parameter | |

| Number of filling heads | 4 |

| Filling range | 50-500ml |

| Filling form | Magnetic pump multi-head filling |

| Cap putting form | Put the cover manually or automatically |

| Capping form | Electric screw |

| Working speed | 1200-1800 bottles/hour |

| Apply bottle diameter | Φ10-85mm, unlimited height |

| Apply label range | 10-100mm width, 10-250mm length |

| Labeling speed | 5-40 meter/minute |

| Program control | PLC Touch screen |

| Overall dimension | 2000mm×655mm×1084mm(L×W×H) |